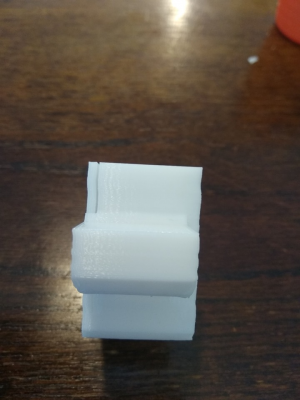

My print is so wavy

Posted by Keshan

My print is so wavy August 30, 2019 08:47PM |

Registered: 6 years ago Posts: 11 |

Just finish a print and it's just so wavy

I put back my sbase 1.3 on my D-bot with external TMC2208 on XYZ and DRV8825 for E

the current I set to 480mA for XY and 780mA for Z, after this print I increase the current on XY to 700mA but the wavy is still there.

I enabled linear advance with K value at 0.1

JUNCTION_DEVIATION_MM 0.022 or should I use Jerk?

enabled S_CURVE_ACCELERATION

Other parameters that I think might have an impact on print quality?

#define DEFAULT_MAX_FEEDRATE { 500, 500, 100, 50 }

#define DEFAULT_MAX_ACCELERATION { 2000, 2000, 100, 2000 }

#define DEFAULT_ACCELERATION 2000

#define DEFAULT_RETRACT_ACCELERATION 3000

#define DEFAULT_TRAVEL_ACCELERATION 2000

I am not sure where I should start to debug the problem, could it be the slicing software? or belt tension?

input is really appreciated, thanks.

Edited 1 time(s). Last edit at 08/30/2019 08:49PM by Keshan.

I put back my sbase 1.3 on my D-bot with external TMC2208 on XYZ and DRV8825 for E

the current I set to 480mA for XY and 780mA for Z, after this print I increase the current on XY to 700mA but the wavy is still there.

I enabled linear advance with K value at 0.1

JUNCTION_DEVIATION_MM 0.022 or should I use Jerk?

enabled S_CURVE_ACCELERATION

Other parameters that I think might have an impact on print quality?

#define DEFAULT_MAX_FEEDRATE { 500, 500, 100, 50 }

#define DEFAULT_MAX_ACCELERATION { 2000, 2000, 100, 2000 }

#define DEFAULT_ACCELERATION 2000

#define DEFAULT_RETRACT_ACCELERATION 3000

#define DEFAULT_TRAVEL_ACCELERATION 2000

I am not sure where I should start to debug the problem, could it be the slicing software? or belt tension?

input is really appreciated, thanks.

Edited 1 time(s). Last edit at 08/30/2019 08:49PM by Keshan.

Re: My print is so wavy September 02, 2019 12:40AM |

Registered: 4 years ago Posts: 2 |

Re: My print is so wavy September 02, 2019 04:57AM |

Registered: 4 years ago Posts: 9 |

Also check the grub screws on pulleys are good as well as bearing of idlers.

[github.com] - #BearUpgrade

[github.com] - #BearUpgrade

Re: My print is so wavy September 06, 2019 07:14AM |

Registered: 8 years ago Posts: 413 |

Think we need some more clues.

What way up and directions for the printed part. I assume its wavy in the Z axis, is the error in both x and Y or just one direction.

Often its hardware related and particularly the z axis constraints. So look for off centre leadscrews, over constrained lead screws (the guid rods are the guides not the lead screws), dodgy bearings etc.

What way up and directions for the printed part. I assume its wavy in the Z axis, is the error in both x and Y or just one direction.

Often its hardware related and particularly the z axis constraints. So look for off centre leadscrews, over constrained lead screws (the guid rods are the guides not the lead screws), dodgy bearings etc.

Re: My print is so wavy September 06, 2019 09:08AM |

Registered: 6 years ago Posts: 1,863 |

Quote

MCcarman

Think we need some more clues.

What way up and directions for the printed part. I assume its wavy in the Z axis, is the error in both x and Y or just one direction.

Often its hardware related and particularly the z axis constraints. So look for off centre leadscrews, over constrained lead screws (the guid rods are the guides not the lead screws), dodgy bearings etc.

I concur, though it is difficult to say for sure with a single image on such a dark background. Including more images plus an image of the STL model to see what the original looks like would help.

On my 3D Printer I wrapped the end of the lead-screw with electrician tape and then carefully press it into the coupler to assure a perfect circular path for the lead-screws,

leaving all fasteners loose and adjusted the Z axis up to tightening the top bolts and down to tighten the bottom bolts, all the time making sure the lead-screws were not binding.

Then finally the wavy lines on all my models were gone, However I still has infill overlap that was causing artifacting and finally adjusted the slicers infill overlap parameters to correct.

Finally setting up junction deviation and s curve acceleration came up with prints that are nearly perfect in every way. For my Hictop 3DP11/12 Cartesian Prusa i3 compatible - 3D Printers.

#define JUNCTION_DEVIATION_MM 0.06

#define S_CURVE_ACCELERATION

The latter also allowed me a higher rate of print speed without shacking this Hictop 3DP11/12 Cartesian Prusa i3 compatible - 3D Printer apart.

Edited 1 time(s). Last edit at 09/06/2019 09:11AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Sorry, only registered users may post in this forum.