LulzBot TK0

Posted by jebba

|

LulzBot TK0 September 29, 2012 04:59PM |

Registered: 13 years ago Posts: 108 |

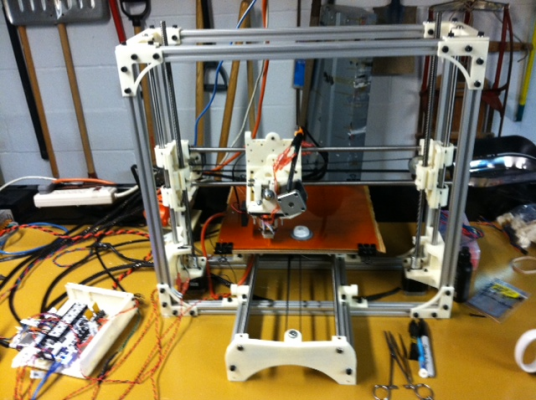

We have released files for a new RepRap design, the LulzBot TK-0. Code, design docs, STLs, photos, etc. are here:

[devel.lulzbot.com]

Some highlights:

* Really is Open Hardware, no catches. GPL and CC-BY-SA licenses. We push the files as soon as they are available.

* 300mm x 300mm x 225mm build volume.

* Reliable 250mm/sec printing speedat 100 microns.

* The printer has been heavily abused to find every possible cause of skips, breakages, etc. and eliminate them. Very robust. Check the Zipper.gcode--this runs on the machine for days to try to physically break it.

* Uses only 3 different bolt SKUs. All extrusions are the same length. Same with rods and belts.

* Easily swappable carriage, plans for many more toolheads.

* Folds for easy shipping.

* [www.thingiverse.com]

What may be of most interest to this forum is the "Design for Excellence" (DfX) review we had done by Vergent Products ( [www.vergentproducts.com] ). See:

[devel.lulzbot.com]

Have fun,

-Jeff Moe (jebba)

Aleph Objects, Inc.

[www.lulzbot.com]

P.S. Also posted to reprap-dev, but that list seems to be getting less action than in the past, so sorry for two posts.

[devel.lulzbot.com]

Some highlights:

* Really is Open Hardware, no catches. GPL and CC-BY-SA licenses. We push the files as soon as they are available.

* 300mm x 300mm x 225mm build volume.

* Reliable 250mm/sec printing speedat 100 microns.

* The printer has been heavily abused to find every possible cause of skips, breakages, etc. and eliminate them. Very robust. Check the Zipper.gcode--this runs on the machine for days to try to physically break it.

* Uses only 3 different bolt SKUs. All extrusions are the same length. Same with rods and belts.

* Easily swappable carriage, plans for many more toolheads.

* Folds for easy shipping.

* [www.thingiverse.com]

What may be of most interest to this forum is the "Design for Excellence" (DfX) review we had done by Vergent Products ( [www.vergentproducts.com] ). See:

[devel.lulzbot.com]

Have fun,

-Jeff Moe (jebba)

Aleph Objects, Inc.

[www.lulzbot.com]

P.S. Also posted to reprap-dev, but that list seems to be getting less action than in the past, so sorry for two posts.

|

Re: LulzBot TK0 September 29, 2012 06:27PM |

Registered: 11 years ago Posts: 95 |

|

Re: LulzBot TK0 September 29, 2012 11:04PM |

Registered: 11 years ago Posts: 374 |

Impressive. You guys definitely look like you're doing reliability testing right.

I think it's very interesting to watch the convergence of many designs on common concepts and approaches (AL extrusion, for example).

You're still using smooth rod mounted parallel to the AL extrusions for your linear motion surface. Did you look at what it would take to remove those and go to using the extrusions for the frame and linear motion combined? If you used seemecnc's cheapskate bearing you could remove the rods and LM bearings from the BOM and add a few acrylic/printed plates and some additional 608 bearings.

I think it's very interesting to watch the convergence of many designs on common concepts and approaches (AL extrusion, for example).

You're still using smooth rod mounted parallel to the AL extrusions for your linear motion surface. Did you look at what it would take to remove those and go to using the extrusions for the frame and linear motion combined? If you used seemecnc's cheapskate bearing you could remove the rods and LM bearings from the BOM and add a few acrylic/printed plates and some additional 608 bearings.

|

Re: LulzBot TK0 September 30, 2012 07:05AM |

Registered: 11 years ago Posts: 6 |

> Did you look at what it would take to remove those [rods] and go to using the extrusions for the frame and linear motion combined?

This is a very cool idea. Dealing with rods is a hassle! Not sure what about this change would need acrylic, but dropping part count is good, and rods can bend, scratch, are tough to buy straight ones, tough to ship without bending, tough to cut through, etc.

This is a very cool idea. Dealing with rods is a hassle! Not sure what about this change would need acrylic, but dropping part count is good, and rods can bend, scratch, are tough to buy straight ones, tough to ship without bending, tough to cut through, etc.

|

Re: LulzBot TK0 September 30, 2012 09:40AM |

Registered: 11 years ago Posts: 11 |

|

Re: LulzBot TK0 September 30, 2012 11:08AM |

Registered: 13 years ago Posts: 108 |

Thank you all! I'm glad the design has met with such enthusiasm.

Many different options were considered for linear motion, and many were tested. Run this file on your bots (danger! It may destroy them!) if you want to see what kind of stress tests the linear motion systems went through:

[devel.lulzbot.com]

Realize that Zipper.gcode *runs for days* beating the hell out of the machine.

Check page 10 of this for some of the notes about linear motion and avoiding skips. This was a MAJOR design consideration to have it *never* skip a step. Folks that run factories expect stuff to work all the time, they won't use a machine they have to babysit. Plus at AO we have 28 printers we run daily, which should be at 40 real-soon-now, so we see any and all types of issues an end user may see:

[devel.lulzbot.com]

Makerslide was looked at as well. We have two ORDBots (one built, one parted out). The ORDBot is a nice little system too. One drawback there is supply chain issues, which we also take into consideration (including making our own dies and such). We'll be getting a much more detailed report about this and other issues. The PDF above is a powerpoint overview of the results so far. The process is ongoing.

Rods will all get Checked for straightness when they are received from the vendor. Also, the system is being designed so it will even work if a rod gets bent. One nice thing to note is all rods are the same length.

We will make the vitamins available, but we have to start sourcing them ourselves in quantity. The BOM is still being worked on. There is only one TK-0 in the world at the moment. We will also sell the printed parts. The BOM lists vendors and MPNs (manufacturer part numbers), so alternate vendors can be found. One design goal is to make sure that the parts we depend on aren't hard to find or obscure:

[devel.lulzbot.com]

Thanks for all the feedback, we welcome more!

-Jeff

Many different options were considered for linear motion, and many were tested. Run this file on your bots (danger! It may destroy them!) if you want to see what kind of stress tests the linear motion systems went through:

[devel.lulzbot.com]

Realize that Zipper.gcode *runs for days* beating the hell out of the machine.

Check page 10 of this for some of the notes about linear motion and avoiding skips. This was a MAJOR design consideration to have it *never* skip a step. Folks that run factories expect stuff to work all the time, they won't use a machine they have to babysit. Plus at AO we have 28 printers we run daily, which should be at 40 real-soon-now, so we see any and all types of issues an end user may see:

[devel.lulzbot.com]

Makerslide was looked at as well. We have two ORDBots (one built, one parted out). The ORDBot is a nice little system too. One drawback there is supply chain issues, which we also take into consideration (including making our own dies and such). We'll be getting a much more detailed report about this and other issues. The PDF above is a powerpoint overview of the results so far. The process is ongoing.

Rods will all get Checked for straightness when they are received from the vendor. Also, the system is being designed so it will even work if a rod gets bent. One nice thing to note is all rods are the same length.

We will make the vitamins available, but we have to start sourcing them ourselves in quantity. The BOM is still being worked on. There is only one TK-0 in the world at the moment. We will also sell the printed parts. The BOM lists vendors and MPNs (manufacturer part numbers), so alternate vendors can be found. One design goal is to make sure that the parts we depend on aren't hard to find or obscure:

[devel.lulzbot.com]

Thanks for all the feedback, we welcome more!

-Jeff

|

Re: LulzBot TK0 September 30, 2012 01:52PM |

Registered: 13 years ago Posts: 7,616 |

Glad you got skipped steps sorted out, jebba.

My good old WolfStrap never skips a step, too. I run it for weeks without homing. To my experience, it's all a matter of a reasonable acceleration setting, reasonable maximum feedrate settings and a firmware (I use Teacup) respecting these.

My good old WolfStrap never skips a step, too. I run it for weeks without homing. To my experience, it's all a matter of a reasonable acceleration setting, reasonable maximum feedrate settings and a firmware (I use Teacup) respecting these.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: LulzBot TK0 September 30, 2012 02:49PM |

Registered: 13 years ago Posts: 108 |

Traumflug, can you test this Zipper.gcode on your machine? I'd be curious about the results. I haven't checked your Wolfstrap yet. The bed size in the test may be too large though. It runs at 800mm/sec travel in the test. Basically, it can run at 800mm/sec banging back and forth for days. I'm not talking about skips at 40mm/sec, that is no problem. I'm talking no skips at very high speeds.

[devel.lulzbot.com]

Thanks!

-Jeff

(Edited for clarity about 40mm/sec)

Edited 1 time(s). Last edit at 09/30/2012 04:22PM by jebba.

[devel.lulzbot.com]

Thanks!

-Jeff

(Edited for clarity about 40mm/sec)

Edited 1 time(s). Last edit at 09/30/2012 04:22PM by jebba.

|

Re: LulzBot TK0 October 01, 2012 06:12AM |

Registered: 13 years ago Posts: 7,616 |

Quote

It runs at 800mm/sec travel in the test.

My point is, a properly working and calibrated firmware would simply refuse to run the machine at feedrates it can't keep up with and do the movements at a proper speed instead. So all your testing G-code does is searching for firmware/calibration bugs.

I'd happily run this calibration stress test, but my print area is 150 x 180 x 80 mm only. Before you ask: that's more than sufficient for my needs, it's intentionally that small.

And yes, I'm aware calibrating machines other than the steps per mm values isn't exactly popular. RepRappers still have to learn on how to get the best out of their machine.

Now lets cheer your design can actually do these 800 mm/s. That's really fast and undoubtly an advantage.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: LulzBot TK0 October 01, 2012 08:04AM |

Registered: 12 years ago Posts: 216 |

|

Re: LulzBot TK0 October 01, 2012 03:00PM |

Registered: 12 years ago Posts: 1,236 |

jebba Wrote:

-------------------------------------------------------

> Traumflug, can you test this Zipper.gcode on your

> machine? I'd be curious about the results. I

> haven't checked your Wolfstrap yet. The bed size

> in the test may be too large though. It runs at

> 800mm/sec travel in the test. Basically, it can

> run at 800mm/sec banging back and forth for days.

> I'm not talking about skips at 40mm/sec, that is

> no problem. I'm talking no skips at very high

> speeds.

We would need more information to perform a comparative test. The speed actually achieved depends on the acceleration, as well as the max step rate of the system. Unless you actually measure the step rate, relying on what the Gcode says is not sufficient to conclude that a printer runs reliably at 800mm/sec.

-------------------------------------------------------

> Traumflug, can you test this Zipper.gcode on your

> machine? I'd be curious about the results. I

> haven't checked your Wolfstrap yet. The bed size

> in the test may be too large though. It runs at

> 800mm/sec travel in the test. Basically, it can

> run at 800mm/sec banging back and forth for days.

> I'm not talking about skips at 40mm/sec, that is

> no problem. I'm talking no skips at very high

> speeds.

We would need more information to perform a comparative test. The speed actually achieved depends on the acceleration, as well as the max step rate of the system. Unless you actually measure the step rate, relying on what the Gcode says is not sufficient to conclude that a printer runs reliably at 800mm/sec.

|

Re: LulzBot TK0 October 01, 2012 03:16PM |

Registered: 12 years ago Posts: 216 |

|

Re: LulzBot TK0 October 01, 2012 09:17PM |

Registered: 13 years ago Posts: 108 |

|

Re: LulzBot TK0 October 09, 2012 02:20PM |

Registered: 14 years ago Posts: 93 |

Interested in your design, a few questions

1 In your BOM, you have 9567K314 listed as a Mcmaster Carr part for your Z spring. Can't find that part in Mcmaster. Perhaps 9657K314?

2 Why the spring? I would think that with vibration, you might get small bounces in the z axis. I was puzzling why not build it upside down, the platform resting on the nut, the spring holding it in place in backpressure.

3 Interested in more info on your Acme lead screw. Did you use the Mcmaster 93410A916 ?

1 In your BOM, you have 9567K314 listed as a Mcmaster Carr part for your Z spring. Can't find that part in Mcmaster. Perhaps 9657K314?

2 Why the spring? I would think that with vibration, you might get small bounces in the z axis. I was puzzling why not build it upside down, the platform resting on the nut, the spring holding it in place in backpressure.

3 Interested in more info on your Acme lead screw. Did you use the Mcmaster 93410A916 ?

|

Re: LulzBot TK0 October 09, 2012 08:07PM |

Registered: 11 years ago Posts: 44 |

|

Re: LulzBot TK0 October 13, 2012 05:13PM |

Registered: 13 years ago Posts: 108 |

Idaholion Wrote:

-------------------------------------------------------

> Interested in your design, a few questions

> 1 In your BOM, you have 9567K314 listed as a

> Mcmaster Carr part for your Z spring. Can't find

> that part in Mcmaster. Perhaps 9657K314?

Correct, the numbers got transposed.

> 2 Why the spring? I would think that with

> vibration, you might get small bounces in the z

> axis. I was puzzling why not build it upside

> down, the platform resting on the nut, the spring

> holding it in place in backpressure.

This part is being totally redone and won't have that spring.

> 3 Interested in more info on your Acme lead

> screw. Did you use the Mcmaster 93410A916 ?

I think that one is too short. We're looking for another vendor too because, as awesome as McMaster is, it is pretty expensive there.

Zimtower Wrote:

-------------------------------------------------------

> I assume that when vitamins are being sold in the

> shop, it's safe to start building TK-0?

It will be under continual flux. When it is formally finished, the files will land at [download.lulzbot.com]

The files in [devel.lulzbot.com] are development files.

Have fun,

-Jeff

-------------------------------------------------------

> Interested in your design, a few questions

> 1 In your BOM, you have 9567K314 listed as a

> Mcmaster Carr part for your Z spring. Can't find

> that part in Mcmaster. Perhaps 9657K314?

Correct, the numbers got transposed.

> 2 Why the spring? I would think that with

> vibration, you might get small bounces in the z

> axis. I was puzzling why not build it upside

> down, the platform resting on the nut, the spring

> holding it in place in backpressure.

This part is being totally redone and won't have that spring.

> 3 Interested in more info on your Acme lead

> screw. Did you use the Mcmaster 93410A916 ?

I think that one is too short. We're looking for another vendor too because, as awesome as McMaster is, it is pretty expensive there.

Zimtower Wrote:

-------------------------------------------------------

> I assume that when vitamins are being sold in the

> shop, it's safe to start building TK-0?

It will be under continual flux. When it is formally finished, the files will land at [download.lulzbot.com]

The files in [devel.lulzbot.com] are development files.

Have fun,

-Jeff

|

Re: LulzBot TK0 October 16, 2012 01:19AM |

Registered: 11 years ago Posts: 15 |

It looks like a very nice design, so I'm thinking of printing parts for one shortly.

I have a couple of questions though.

How many of the brass threaded inserts are needed, and where do they go?

If I can't obtain any, I'll have to try modifying the files for plain M3 nuts and bolts.

Also the BOM specifies 20x20mm extrusions for the frame and M5x14 bolts, but as the brackets are 4mm thick, that leaves 10mm to stick into the extrusion, which doesn't seem possible.

Also it would be nice if the OpenSCAD files allowed for use of plain 8mm threaded rod and nuts for the Z axis.

TIA

I have a couple of questions though.

How many of the brass threaded inserts are needed, and where do they go?

If I can't obtain any, I'll have to try modifying the files for plain M3 nuts and bolts.

Also the BOM specifies 20x20mm extrusions for the frame and M5x14 bolts, but as the brackets are 4mm thick, that leaves 10mm to stick into the extrusion, which doesn't seem possible.

Also it would be nice if the OpenSCAD files allowed for use of plain 8mm threaded rod and nuts for the Z axis.

TIA

|

Re: LulzBot TK0 November 28, 2012 01:39AM |

I like everything about this except the price of the current model, which I assume the new model might match. $1,750 is twice as much as a Printrbot. This does have a larger build volume, but I just don't see the ROI unless you are going to build the whole thing for me and I can just plug it in and print five minutes after it arrives.

What would I pay for this kit? Perhaps $1,300 at most, considering that I have to assemble it myself. That's what a larger build volume, easier assembly, decent print head clearance (so I can develop my own, which would need to be large), and fast accurate printing are worth to me.

I would also recommend asking the board manufacturer about adding a BUNCH more channels. I would like to do some research into designing a print head that can do arbitrary colors. There are two ways to do this and they both require more channels than a single-filament head. The fine resolution, high accuracy, and apparent clearance given to the print head are all reasons why I like this design better than some of the others.

What would I pay for this kit? Perhaps $1,300 at most, considering that I have to assemble it myself. That's what a larger build volume, easier assembly, decent print head clearance (so I can develop my own, which would need to be large), and fast accurate printing are worth to me.

I would also recommend asking the board manufacturer about adding a BUNCH more channels. I would like to do some research into designing a print head that can do arbitrary colors. There are two ways to do this and they both require more channels than a single-filament head. The fine resolution, high accuracy, and apparent clearance given to the print head are all reasons why I like this design better than some of the others.

|

Re: LulzBot TK0 November 28, 2012 08:58AM |

Registered: 12 years ago Posts: 156 |

Huns Wrote:

-------------------------------------------------------

> but I just don't see the ROI unless you are going

> to build the whole thing for me and I can just

> plug it in and print five minutes after it

> arrives.

As the LulzBot page states (twice), AO-100 does come "preassembled and calibrated".

(TK0 is in dev and not available as a kit or a preassembled product)

But what's nifty about open source is this - you can download the files, find someone to print them for you, source the rest of the vitamins and build one yourself, saving some of the money.

Edited 1 time(s). Last edit at 11/28/2012 09:01AM by orcinus.

-------------------------------------------------------

> but I just don't see the ROI unless you are going

> to build the whole thing for me and I can just

> plug it in and print five minutes after it

> arrives.

As the LulzBot page states (twice), AO-100 does come "preassembled and calibrated".

(TK0 is in dev and not available as a kit or a preassembled product)

But what's nifty about open source is this - you can download the files, find someone to print them for you, source the rest of the vitamins and build one yourself, saving some of the money.

Edited 1 time(s). Last edit at 11/28/2012 09:01AM by orcinus.

|

Re: LulzBot TK0 December 02, 2012 05:37PM |

Registered: 13 years ago Posts: 108 |

The goal of the TK-0 is to eventually make it *less* expensive than the AO-100/AO-101 series, but we're not there yet. It does take half as much time to assemble, so that is a big plus in terms of my build cost.

I have been doing some experiments with dual color recently too (on AO-100):

[devel.lulzbot.com]

[devel.lulzbot.com]

I have been doing some experiments with dual color recently too (on AO-100):

[devel.lulzbot.com]

[devel.lulzbot.com]

|

Re: LulzBot TK0 December 02, 2012 06:52PM |

Registered: 12 years ago Posts: 93 |

|

Re: LulzBot TK0 February 10, 2013 01:52AM |

Registered: 11 years ago Posts: 13 |

I can't wait to get a TK0 and give it a try!

I'd like to know a couple of things though. Does it have dual-head capabilities? If yes, will there be a kit for that sold? Also, will there be other heads (like the CNC) being sold or only the extruder one ? (from [www.youtube.com] )

Finally, I saw in your BOM some "to be sorted out" items concerning an LCD, and I couldn't see one in any of the videos/photos on your website. Can you confirm whether or not the TK0 will have an LCD screen and standalone print capabilities?

Thanks.

I'd like to know a couple of things though. Does it have dual-head capabilities? If yes, will there be a kit for that sold? Also, will there be other heads (like the CNC) being sold or only the extruder one ? (from [www.youtube.com] )

Finally, I saw in your BOM some "to be sorted out" items concerning an LCD, and I couldn't see one in any of the videos/photos on your website. Can you confirm whether or not the TK0 will have an LCD screen and standalone print capabilities?

Thanks.

|

Re: LulzBot TK0 February 16, 2013 04:36PM |

Registered: 13 years ago Posts: 108 |

@ foshon: we went to Misumi LM10UU linear bearings for a bit, but found them really noisy. The pillow block bushings in 10mm size are quite huge. In the end, we have settled on something in the middle: the self-lubricating Igus bushings, the same as on the AO-100/AO-101, but in an LM10UU form factor.

@kakaroto: We don't have a dual head designed for it. The toolhead setup can be swapped out by taking out just one bolt though. We may have one at some point, but not right now. We do have a Dremel head mount drawn up, but it is in sketchup and untested:

[devel.lulzbot.com]

[devel.lulzbot.com]

We did do one that had an LCD that we got from another vendor. We were dissatisfied with the soldering work, so we are not going to include it. One could be added easily enough though. It is using a standard RAMBo board, so anything that works with that (or RAMPS?) should work just fine.

Also, we are working on this independently of Tracy (straitjacket on thingiverse), so he's doing his work and we're doing ours. I also notice his new files are released are now -NC, which may be a license conflict with the previous files. I have emailed them to clarify.

@kakaroto: We don't have a dual head designed for it. The toolhead setup can be swapped out by taking out just one bolt though. We may have one at some point, but not right now. We do have a Dremel head mount drawn up, but it is in sketchup and untested:

[devel.lulzbot.com]

[devel.lulzbot.com]

We did do one that had an LCD that we got from another vendor. We were dissatisfied with the soldering work, so we are not going to include it. One could be added easily enough though. It is using a standard RAMBo board, so anything that works with that (or RAMPS?) should work just fine.

Also, we are working on this independently of Tracy (straitjacket on thingiverse), so he's doing his work and we're doing ours. I also notice his new files are released are now -NC, which may be a license conflict with the previous files. I have emailed them to clarify.

|

Re: LulzBot TK0 February 16, 2013 05:32PM |

Registered: 11 years ago Posts: 13 |

Ok, thanks for the reply. I forget that I can modify it if I want :p

It would be nice to have a dual extruder sold or at least the stl for printing the new head adpater. I guess it's details for the post-release though.

I thought Tracy was the one designing the TK0 for you. Do you have an idea of how different your version is from his ?

Thanks.

It would be nice to have a dual extruder sold or at least the stl for printing the new head adpater. I guess it's details for the post-release though.

I thought Tracy was the one designing the TK0 for you. Do you have an idea of how different your version is from his ?

Thanks.

|

Re: LulzBot TK0 February 16, 2013 07:26PM |

Registered: 12 years ago Posts: 53 |

|

Re: LulzBot TK0 February 27, 2013 10:56AM |

Registered: 11 years ago Posts: 5 |

The design doc for the TK0 is well done. Wonderful commitment to open hardware and software.

How long until the TK0 is available?

How long would it take for the AO11 to print the plastic parts for the TK0? I am debating whether to: 1) go ahead and purchase the AO11 now and print parts for the TK0 and source/assemble the TK0 parts and donate the AO11 to our high school robotics club or 2) wait for the TK0 and then print parts for the high schoolers to source/assemble a TK0 or AO11 as a summer engineering project. Thoughts?

How long until the TK0 is available?

How long would it take for the AO11 to print the plastic parts for the TK0? I am debating whether to: 1) go ahead and purchase the AO11 now and print parts for the TK0 and source/assemble the TK0 parts and donate the AO11 to our high school robotics club or 2) wait for the TK0 and then print parts for the high schoolers to source/assemble a TK0 or AO11 as a summer engineering project. Thoughts?

|

Re: LulzBot TK0 February 27, 2013 11:38AM |

Registered: 12 years ago Posts: 108 |

I built my TK-0 from the pictures and BOM on the Lulzbot site and printed my own parts. I did buy the Budaschnozzle 1.2, of course. I used the LM10UU bearings, but the printer is in my shop so if it gets too loud I can go to another room.

I have a QU-BD 300x300mm bed heater and second power supply to power it. I am using a Rumba board with Marlin and Pronterface, and I bought an SSR to power the bed heater, so the Rumba won't burn out trying to pump out 20 amps at 12 volts.The Rumba can only handle 11 amps from what I have read.

Roy

I have a QU-BD 300x300mm bed heater and second power supply to power it. I am using a Rumba board with Marlin and Pronterface, and I bought an SSR to power the bed heater, so the Rumba won't burn out trying to pump out 20 amps at 12 volts.The Rumba can only handle 11 amps from what I have read.

Roy

|

Re: LulzBot TK0 February 28, 2013 02:13PM |

Registered: 11 years ago Posts: 5 |

|

Re: LulzBot TK0 February 28, 2013 02:23PM |

Registered: 12 years ago Posts: 108 |

|

Re: LulzBot TK0 March 01, 2013 01:10AM |

Registered: 11 years ago Posts: 5 |

Sorry, only registered users may post in this forum.