MK8 Plated A2 Tool Steel Wear Resistant Nozzle - Causing warping?

Posted by PDBeal

|

MK8 Plated A2 Tool Steel Wear Resistant Nozzle - Causing warping? May 09, 2020 09:03PM |

Registered: 7 years ago Posts: 558 |

Does anyone have any experiences with the MK8 Plated A2 Tool Steel Wear Resistance Nozzle? Good or bad?

I've run into something rather strange and I'm wondering if this nozzle is causing my issues. I've just recently fitted an E3D Titan extruder and the Micro-Swiss All Metal Hotend Kit for Creality Printers. With this upgrade I also bought the MK8 Plated A2 Tool Steel Wear Resistance Nozzle to go with this setup. Since I've fitted all three new items, I'm getting some very strange bed adhesion issues. I've had to make the nozzle closer to the Build-Tak like surface that's on the Ender-5. I've also tried a PEI sheet stuck to another Build-Tak like surface (another one that I ruined trying to clean it once but stuck a PEI sheet over the entire thing).

It seems the plastic does flow, it sticks to the bed at first, but as the print continues the items begin to curl up. It doesn't seem to matter how big or how small these items are. I have not tried adding a brim though, but printing on a raft works for bed adhesion but the parts curl anyway. This has been experienced with Hatchbox PLA, eSun PLA+, eSun PETG, Hatchbox PETG. I didn't seem to have these adhesion or warping issues before I switched to the Mk8 Plated A2 Tool Steel Wear Resistance Nozzle.

On my other printers I use the E3D hardened nozzles printing PLA+ on the same PEI sheets and don't see any of the adhesion or warping issues. I wonder if there is some sort of oil coating or some coating of some kind that's coming off onto the molten plastic and causing the warping issues? I wondered if anyone else had seen anything similar.

I was planning to try the standard nozzle next and see if it solves the issue, but I was hoping to be able to print some of the Proto-pasta Metal filaments in this machine since it has a slightly larger build volume that my other printers. I have used the E3D hardened nozzles on my other printers and they appear to perform just the same as the brass versions with no weird side affects like I'm seeing with the MK8 one.

I've run into something rather strange and I'm wondering if this nozzle is causing my issues. I've just recently fitted an E3D Titan extruder and the Micro-Swiss All Metal Hotend Kit for Creality Printers. With this upgrade I also bought the MK8 Plated A2 Tool Steel Wear Resistance Nozzle to go with this setup. Since I've fitted all three new items, I'm getting some very strange bed adhesion issues. I've had to make the nozzle closer to the Build-Tak like surface that's on the Ender-5. I've also tried a PEI sheet stuck to another Build-Tak like surface (another one that I ruined trying to clean it once but stuck a PEI sheet over the entire thing).

It seems the plastic does flow, it sticks to the bed at first, but as the print continues the items begin to curl up. It doesn't seem to matter how big or how small these items are. I have not tried adding a brim though, but printing on a raft works for bed adhesion but the parts curl anyway. This has been experienced with Hatchbox PLA, eSun PLA+, eSun PETG, Hatchbox PETG. I didn't seem to have these adhesion or warping issues before I switched to the Mk8 Plated A2 Tool Steel Wear Resistance Nozzle.

On my other printers I use the E3D hardened nozzles printing PLA+ on the same PEI sheets and don't see any of the adhesion or warping issues. I wonder if there is some sort of oil coating or some coating of some kind that's coming off onto the molten plastic and causing the warping issues? I wondered if anyone else had seen anything similar.

I was planning to try the standard nozzle next and see if it solves the issue, but I was hoping to be able to print some of the Proto-pasta Metal filaments in this machine since it has a slightly larger build volume that my other printers. I have used the E3D hardened nozzles on my other printers and they appear to perform just the same as the brass versions with no weird side affects like I'm seeing with the MK8 one.

|

Re: MK8 Plated A2 Tool Steel Wear Resistant Nozzle - Causing warping? May 11, 2020 08:45AM |

Registered: 7 years ago Posts: 558 |

So, I’ll comment more for anyone in the future who experiences this.

I’ve replaced the MK8 Plated A2 Tool Steel Wear Resistant Nozzle with the standard nozzle that came with the all metal hot-end kit. I checked the Z offset since I changed nozzles, and then ran the same gcode file.

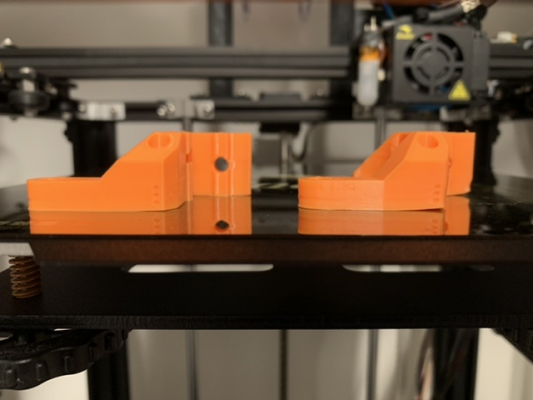

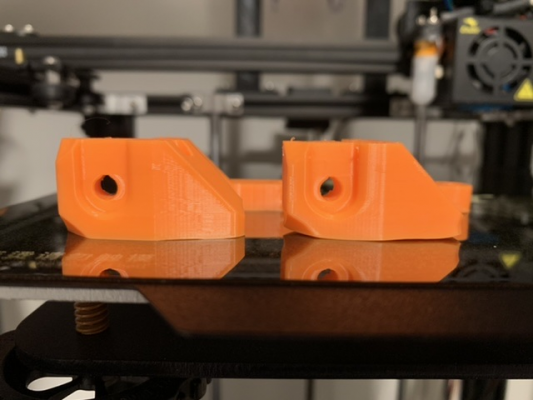

Same material, same temperatures, same machine, same gcode, same bed surface, different nozzles and ended up with different results. The part on the left is the new one with the standard nozzle. The part on the right is the same part but printed with the MK8 Plated A2 Tool Steel Wear Resistant Nozzle.

Whatever they’re using to coat the nozzle and make it wear resistant is definitely having an affect on the plastic sticking to the PEI surface and/or Build-Tak like surface that’s shipped with the Creality machines.

I post this for anyone that runs into this in the future. I suspect this may be true with other coated nozzles.

Edited 1 time(s). Last edit at 05/11/2020 08:48AM by PDBeal.

I’ve replaced the MK8 Plated A2 Tool Steel Wear Resistant Nozzle with the standard nozzle that came with the all metal hot-end kit. I checked the Z offset since I changed nozzles, and then ran the same gcode file.

Same material, same temperatures, same machine, same gcode, same bed surface, different nozzles and ended up with different results. The part on the left is the new one with the standard nozzle. The part on the right is the same part but printed with the MK8 Plated A2 Tool Steel Wear Resistant Nozzle.

Whatever they’re using to coat the nozzle and make it wear resistant is definitely having an affect on the plastic sticking to the PEI surface and/or Build-Tak like surface that’s shipped with the Creality machines.

I post this for anyone that runs into this in the future. I suspect this may be true with other coated nozzles.

Edited 1 time(s). Last edit at 05/11/2020 08:48AM by PDBeal.

|

Re: MK8 Plated A2 Tool Steel Wear Resistant Nozzle - Causing warping? May 11, 2020 09:10AM |

Registered: 11 years ago Posts: 5,780 |

Steel is a poor thermal conductor compared to the brass that's typically used. It might help to bump the hot end temperature up a bit when using a steel nozzle. It might also help to print a little slower.

The biggest problem appears to be prints not sticking to the bed. Try cleaning the bed thoroughly, bump up the bed temperature, slow down the first layer print speed. Is the bed flat? Is it level?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The biggest problem appears to be prints not sticking to the bed. Try cleaning the bed thoroughly, bump up the bed temperature, slow down the first layer print speed. Is the bed flat? Is it level?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: MK8 Plated A2 Tool Steel Wear Resistant Nozzle - Causing warping? May 11, 2020 09:39AM |

Registered: 7 years ago Posts: 558 |

The prints have no issues sticking to the bed, the problem is they are not staying stuck to the bed through the course of the print when using the wear resistant nozzle. First layer is always slow compared to the rest. It's warping which I've never had PLA or PLA+ warp until I started using this wear resistant nozzle.

|

Re: MK8 Plated A2 Tool Steel Wear Resistant Nozzle - Causing warping? May 11, 2020 10:29AM |

Registered: 11 years ago Posts: 5,780 |

Quote

PDBeal

The prints have no issues sticking to the bed, the problem is they are not staying stuck to the bed through the course of the print when using the wear resistant nozzle.

If the print is lifting anytime during the print, it is not sticking to the bed.

The print isn't warping- it's coming off the bed. When it lifts up, the layers get squashed extra thin in the areas where the print has let go of the bed. It looks like warping, but it's not, really. Warping would be if the print stuck to the bed throughout the print and when you removed it from the bed, the shape changed.

OK, you normally print the first layer slower than the others. But you're having a problem with the print letting go when you use that steel nozzle. So try reducing the speed (even more) in order to get that first layer to stick throughout the print.

Edited 1 time(s). Last edit at 05/11/2020 10:36AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: MK8 Plated A2 Tool Steel Wear Resistant Nozzle - Causing warping? May 11, 2020 11:37AM |

Registered: 7 years ago Posts: 558 |

Quote

the_digital_dentist

OK, you normally print the first layer slower than the others. But you're having a problem with the print letting go when you use that steel nozzle. So try reducing the speed (even more) in order to get that first layer to stick throughout the print.

My speeds are only at 80mm/s maximum with external walls at 40mm/s. My first layer is always static at 10mm/s. I found it wasn’t worth trying to go fast on the first 2 layers.

The problem is only with the MK8 Plated A2 Tool Steel Wear Resistant Nozzle. The standard nozzle with the Micro-Swiss kit works just fine. I have seen a few things posted on the wear resistant steel nozzle that people have said they have to run it 10-15C hotter than normal. They’re all talking about nozzle clogging though, which I didn’t run into. I didn’t try to run hotter as I’ve never had to do that with my E3D NozzleX nozzles on my other machines, but might be something to test in a few more trials.

Sorry, only registered users may post in this forum.