Color mixing

Posted by lilbuh

|

Color mixing October 10, 2012 07:18AM |

Registered: 11 years ago Posts: 6 |

hey there,

im quite surprized that theres very little reaction/informations about Pia Taubert's color mixing extruder/hotend

[blog.reprap.org]

i d like to know more about it i m currently planning to build a repstrap and i d like to make sure that i ll be able to upgrade my design later on or even build it right now and try to 'beta' test it

could anyone point me to a blog or other source of infos ?

thanks

im quite surprized that theres very little reaction/informations about Pia Taubert's color mixing extruder/hotend

[blog.reprap.org]

i d like to know more about it i m currently planning to build a repstrap and i d like to make sure that i ll be able to upgrade my design later on or even build it right now and try to 'beta' test it

could anyone point me to a blog or other source of infos ?

thanks

|

Re: Color mixing October 11, 2012 08:00AM |

Registered: 11 years ago Posts: 305 |

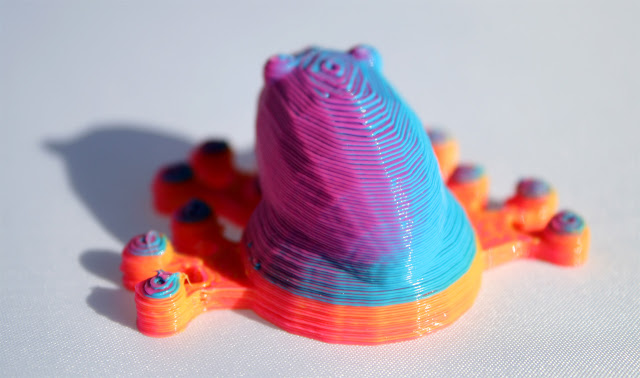

Maybe that should indeed be surprising. Here for instance they show 3d printing colors, but that cannot do gradients.Quote

im quite surprized that theres very little reaction/informations about Pia Taubert's color mixing extruder/hotend

So perhaps she should show off her work a little. I guess the thing that is stopping her at this point is that the software doesn't support colors well enough?

|

Re: Color mixing October 11, 2012 10:15AM |

Registered: 11 years ago Posts: 6 |

|

Re: Color mixing October 11, 2012 07:35PM |

Registered: 12 years ago Posts: 1,236 |

It's a bit chicken and egg. Without the tools, it is difficult to do color models, but the tools are not updated because no one wants color

I would love OpenSCAD to support color via AMF, it already supports color in preview, but not rendering. AMF is very similar to STL, there are some patches to generate AMF but need some work. If only I had more time...

Generally it would be useful for tools to support AMF for mulltiple materials as a starting point. Then I just need to figure out to attach my new dual extruder to my printer.

I would love OpenSCAD to support color via AMF, it already supports color in preview, but not rendering. AMF is very similar to STL, there are some patches to generate AMF but need some work. If only I had more time...

Generally it would be useful for tools to support AMF for mulltiple materials as a starting point. Then I just need to figure out to attach my new dual extruder to my printer.

|

Re: Color mixing October 11, 2012 09:16PM |

Registered: 11 years ago Posts: 72 |

|

Re: Color mixing October 12, 2012 04:13AM |

Registered: 12 years ago Posts: 1,236 |

PomeroyB Wrote:

-------------------------------------------------------

> I thought that Stratasys had a patent on mixing

> colors in the extruder head, and that was why it

> hasn't been done a lot.

You're right, [www.google.com] I guess we have to wait til 2030.

That patent applies in the US, I don't now about ROW. Practically speaking, if you build one for personal use, they are unlikely to come after you. People who sell infringing hardware may be at risk.

-------------------------------------------------------

> I thought that Stratasys had a patent on mixing

> colors in the extruder head, and that was why it

> hasn't been done a lot.

You're right, [www.google.com] I guess we have to wait til 2030.

That patent applies in the US, I don't now about ROW. Practically speaking, if you build one for personal use, they are unlikely to come after you. People who sell infringing hardware may be at risk.

|

Re: Color mixing October 12, 2012 06:15AM |

Registered: 13 years ago Posts: 818 |

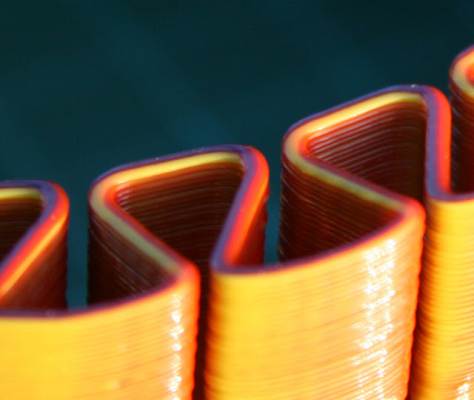

I hope to do a lot more on my 3-way colour blending extruder, but the next step would be Gcode and firmware changes to dynamically support mixing.

The proof of concept worked, so hopefully it can be moved on now.

If anyone wants to make one and try to help move this forwards, let me know.

[richrap.blogspot.com]

The proof of concept worked, so hopefully it can be moved on now.

If anyone wants to make one and try to help move this forwards, let me know.

[richrap.blogspot.com]

|

Re: Color mixing October 12, 2012 02:07PM |

Registered: 11 years ago Posts: 6 |

|

Re: Color mixing October 12, 2012 02:09PM |

Registered: 15 years ago Posts: 123 |

That's a cool extruder you have RIchRap but it doesn't seem like it is actually mixing the colors the same way Pia Taubert's is.

I would be interested to know what sort of spatial resolution the Pia Taubert mixer has in terms of rapid color changes. Can we now print multiple materials out of one nozzle or would that require extensive purging at every material change?

I would be interested to know what sort of spatial resolution the Pia Taubert mixer has in terms of rapid color changes. Can we now print multiple materials out of one nozzle or would that require extensive purging at every material change?

|

Re: Color mixing October 12, 2012 02:14PM |

Registered: 13 years ago Posts: 818 |

If you read my blog post about it, I decided not to try to remove the toothpaste effect. But it is very hard to get good mixing - Adrian Bowyer and Myles Corbett spent quite some time working on passive systems until using a motor to stir the molten filament.

Also take a look and read the final report Here

[richrap.blogspot.com]

Also take a look and read the final report Here

[richrap.blogspot.com]

|

Re: Color mixing October 12, 2012 03:32PM |

Registered: 11 years ago Posts: 939 |

I think one of the bigger issues, outside the mixing is how much filament you need to flush for a clean color change, and how frequently it is likely to be required. Even if each layer only used 2 colors, a 100 layer object would have to flush ~200 times.

Has anyone done any research on reducing the size of the meltzone, or some other way to make flushing more efficient?

AFAICS there are two potentially practical ways to deal with multicolor printing, either mix pre-colored filaments, or apply mixed color to a neutrally colored filament as it's deposited, if the latter could be done at the very end of the extrusion process I think it's the better approach, having said that I don't really have any insight on how to go about it, so it's somewhat useless speculation.

Has anyone done any research on reducing the size of the meltzone, or some other way to make flushing more efficient?

AFAICS there are two potentially practical ways to deal with multicolor printing, either mix pre-colored filaments, or apply mixed color to a neutrally colored filament as it's deposited, if the latter could be done at the very end of the extrusion process I think it's the better approach, having said that I don't really have any insight on how to go about it, so it's somewhat useless speculation.

|

Re: Color mixing October 12, 2012 04:15PM |

Registered: 13 years ago Posts: 818 |

You just need to do the flushing inside the objects infill so you don't waste much, and can have clean colour changes on the perimeter.

[richrap.blogspot.com]

[richrap.blogspot.com]

|

Re: Color mixing October 12, 2012 04:56PM |

Registered: 11 years ago Posts: 939 |

|

Re: Color mixing October 12, 2012 05:05PM |

Registered: 11 years ago Posts: 335 |

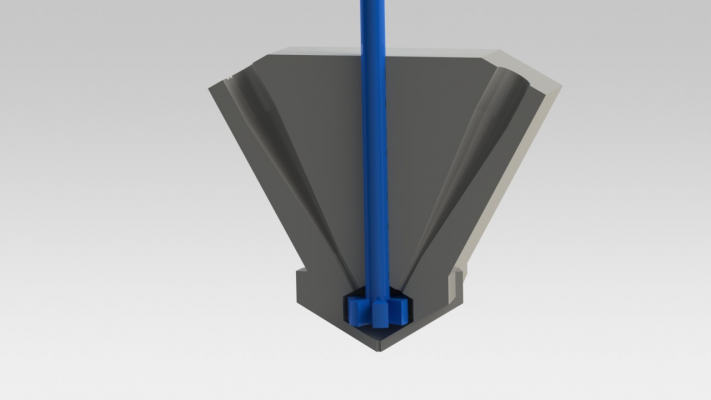

I've been thinking about how to effectively perform colour mixing for a while now. From what I gather, the two most important measures of a mixing extruder's performance are the level of mixing (toothpaste effect) and how fast the mix can change (fade time).

After reading Corbett's report on color mixing, it is pretty clear that passive mixing is not a viable solution and an active system must be used.

I can only think of one way to reduce fade time, and that is to have the "mix zone" be as small as possible. I came up with a design that essentially involves two or more standard extruders feeding into a very small chamber where they are mixed.

Because the filaments are independently melted ahead of time and remain separated, fade time is no longer linked to the length of the melt zone.

The volume of the mixing chamber is only a few cubic millimetres so fades should be fairly quick.

Unfortunately, I won't be able to build this until after Christmas but I think the idea is good.

After reading Corbett's report on color mixing, it is pretty clear that passive mixing is not a viable solution and an active system must be used.

I can only think of one way to reduce fade time, and that is to have the "mix zone" be as small as possible. I came up with a design that essentially involves two or more standard extruders feeding into a very small chamber where they are mixed.

Because the filaments are independently melted ahead of time and remain separated, fade time is no longer linked to the length of the melt zone.

The volume of the mixing chamber is only a few cubic millimetres so fades should be fairly quick.

Unfortunately, I won't be able to build this until after Christmas but I think the idea is good.

|

Re: Color mixing October 13, 2012 05:16AM |

Registered: 11 years ago Posts: 72 |

|

Re: Color mixing October 14, 2012 11:51AM |

Admin Registered: 15 years ago Posts: 1,470 |

bobc Wrote:

-------------------------------------------------------

> You're right,

> [www.google.com] I

> guess we have to wait til 2030.

>

> That patent applies in the US, I don't now about

> ROW. Practically speaking, if you build one for

> personal use, they are unlikely to come after you.

> People who sell infringing hardware may be at

> risk.

That patent is extremely specific and so does not apply to the way we would be using a filament mixer. For starters, it specifies using filament in the 1.3mm to 2.5mm range, so could be sidestepped by using 3mm filament. Also, it specifies using the mixer in a heated chamber, something that we do not do and is already patented elsewhere.

"and further comprising a housing that defines an interior region, wherein at least a portion of the interior region is configured to be maintained at one or more elevated temperatures."

-------------------------------------------------------

> You're right,

> [www.google.com] I

> guess we have to wait til 2030.

>

> That patent applies in the US, I don't now about

> ROW. Practically speaking, if you build one for

> personal use, they are unlikely to come after you.

> People who sell infringing hardware may be at

> risk.

That patent is extremely specific and so does not apply to the way we would be using a filament mixer. For starters, it specifies using filament in the 1.3mm to 2.5mm range, so could be sidestepped by using 3mm filament. Also, it specifies using the mixer in a heated chamber, something that we do not do and is already patented elsewhere.

"and further comprising a housing that defines an interior region, wherein at least a portion of the interior region is configured to be maintained at one or more elevated temperatures."

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Color mixing October 15, 2012 10:58AM |

Registered: 12 years ago Posts: 1,236 |

You have to be very careful how you read the patent claims; they are very carefully written. To infringe the patent, it is not necessary to infringe on all the claims, only a subset.

The central claim is Claim 1, which is an independent claim. Even if you do not infringe Claim 6 or 8, I am fairly sure this method would infringe Claim 1, which is a pretty broad claim.

Much as I would like to see this patent invalidated, I would not like to go to court on it.

The central claim is Claim 1, which is an independent claim. Even if you do not infringe Claim 6 or 8, I am fairly sure this method would infringe Claim 1, which is a pretty broad claim.

Much as I would like to see this patent invalidated, I would not like to go to court on it.

|

Re: Color mixing October 16, 2012 02:23PM |

Registered: 14 years ago Posts: 172 |

Also, it's only a patent application - it hasn't actually been granted. Anyone know of prior art?

[haveblue.org]

[haveblue.org]

|

Re: Color mixing October 16, 2012 03:54PM |

Registered: 15 years ago Posts: 123 |

richrap Wrote:

-------------------------------------------------------

> If you read my blog post about it, I decided not

> to try to remove the toothpaste effect. But it is

> very hard to get good mixing - Adrian Bowyer and

> Myles Corbett spent quite some time working on

> passive systems until using a motor to stir the

> molten filament.

Yes I understand the problems and the reasoning. My point is, if we are going for MIXING the colors, then it seems having a motor is the way to go. Your way, while interesting, is not MIXING but (essentially) just depositing the colors really close together.

We must ask ourselves then, what is the point of mixing? And I think the conclusion would be something like, to get a more complete range of colors. Spatial resolution perhaps isn't the point, thus you would still want to have two nozzles, maybe both of them are mixers, to facilitate rapid color changes. But you are still limited to two different colors per flat layer, or barring that, lots of purges which means really slow prints.

If that crazy micro-mixer nozzle ends up being possible, maybe that's the way to go but honestly I can't see it being easily built, especially with those tapered holes requiring custom drill bits or something... Maybe it can be made in several pieces? Good luck to prevent leakage.

-------------------------------------------------------

> If you read my blog post about it, I decided not

> to try to remove the toothpaste effect. But it is

> very hard to get good mixing - Adrian Bowyer and

> Myles Corbett spent quite some time working on

> passive systems until using a motor to stir the

> molten filament.

Yes I understand the problems and the reasoning. My point is, if we are going for MIXING the colors, then it seems having a motor is the way to go. Your way, while interesting, is not MIXING but (essentially) just depositing the colors really close together.

We must ask ourselves then, what is the point of mixing? And I think the conclusion would be something like, to get a more complete range of colors. Spatial resolution perhaps isn't the point, thus you would still want to have two nozzles, maybe both of them are mixers, to facilitate rapid color changes. But you are still limited to two different colors per flat layer, or barring that, lots of purges which means really slow prints.

If that crazy micro-mixer nozzle ends up being possible, maybe that's the way to go but honestly I can't see it being easily built, especially with those tapered holes requiring custom drill bits or something... Maybe it can be made in several pieces? Good luck to prevent leakage.

|

Re: Color mixing October 22, 2012 05:58AM |

Registered: 13 years ago Posts: 228 |

|

Re: Color mixing October 22, 2012 04:17PM |

Registered: 11 years ago Posts: 6 |

Nice to hear that sound ! Was planning to fork slic3r for it

Now we have to decide how implement this in gcode since it will need parameters for 5 colors steppers CYMK and W if we want full color range and probably add a "purge" command or use it as infill if possible: if there is infill in that layer and a color change use as infill else purge it somewhere

Now we have to decide how implement this in gcode since it will need parameters for 5 colors steppers CYMK and W if we want full color range and probably add a "purge" command or use it as infill if possible: if there is infill in that layer and a color change use as infill else purge it somewhere

|

Re: Color mixing October 22, 2012 04:32PM |

Registered: 13 years ago Posts: 818 |

You need 7 feeds really, Clear and support material - if going from one nozzle - maybe two nozzles with 4 feeds would be easier to implement - then a mechanical switch method would be preferable instead of having 7 or 8 extruder motors.

If Alessandro (Sound) is interested in getting Mixing extruders working well with Slic3r, then let's try to solve some more of the mechanical issues and get a few more prototypes of mixing extruders in the world of RepRap - We could lead the field here and it's going to be really important soon as mixing both colours and material types is going to open up a whole load of new uses for home 3D printing!

We still need good Firmware support even when we have a good mechanical solution...

Slic3r is already starting to support the new AMF format, so it's way ahead in terms of more complicated models, with colours and different materials in the same file.

[richrap.blogspot.com]

If Alessandro (Sound) is interested in getting Mixing extruders working well with Slic3r, then let's try to solve some more of the mechanical issues and get a few more prototypes of mixing extruders in the world of RepRap - We could lead the field here and it's going to be really important soon as mixing both colours and material types is going to open up a whole load of new uses for home 3D printing!

We still need good Firmware support even when we have a good mechanical solution...

Slic3r is already starting to support the new AMF format, so it's way ahead in terms of more complicated models, with colours and different materials in the same file.

[richrap.blogspot.com]

|

Re: Color mixing October 22, 2012 05:22PM |

Registered: 11 years ago Posts: 6 |

|

Re: Color mixing October 23, 2012 10:52PM |

Registered: 11 years ago Posts: 11 |

Hey guys,

I'm new so excuse me if its been suggested before. Perhaps a permanent Thermochromatic dye could be mixed into the ABS plastic that is designed to change colours permanently when the extruder gets hotter or colder. This way there wouldnt need to be multiple strands mixed together to create a colour, the code would simply change the tempurature of the extruder as needed.

Thoughts?

And if this idea is genius you better not steal it!! haha

I'm new so excuse me if its been suggested before. Perhaps a permanent Thermochromatic dye could be mixed into the ABS plastic that is designed to change colours permanently when the extruder gets hotter or colder. This way there wouldnt need to be multiple strands mixed together to create a colour, the code would simply change the tempurature of the extruder as needed.

Thoughts?

And if this idea is genius you better not steal it!! haha

|

Re: Color mixing October 24, 2012 02:18AM |

Registered: 11 years ago Posts: 6 |

Wasn t aware of that possibility but my first thougth was : how about fast color change ? E.g. The dye turns red when hot blue when colder if we need to get from red to blue it will need some time and we ll have a rainbow while cooling to the right temp wich will require a purge and very precise temp control

Good idea tho

Good idea tho

|

Re: Color mixing October 24, 2012 05:25AM |

Registered: 11 years ago Posts: 11 |

|

Re: Color mixing October 24, 2012 05:56AM |

Registered: 11 years ago Posts: 335 |

|

Re: Color mixing October 24, 2012 06:39AM |

Registered: 11 years ago Posts: 11 |

|

Re: Color mixing October 25, 2012 04:11PM |

Registered: 11 years ago Posts: 335 |

I was just thinking and I realized that with a color mixing extruder it is possible that plastic will sit in the melt zone without being extruded for many hours.

Will ABS degrade if it is left at 230c+ for an extended period of time? In the worse case the plastic could sit for days at an elevated temperature or through several heat/cool cycles.

Will ABS degrade if it is left at 230c+ for an extended period of time? In the worse case the plastic could sit for days at an elevated temperature or through several heat/cool cycles.

|

Re: Color mixing June 16, 2013 11:06PM |

I'm working on a design ATM based loosely on the budaschnozzle. I have the mixing extruder design done, but I'm still trying to figure out how to terminate the bowden drive tubes. Only problem with it is that it will need some machine tools to make due to the tolerances required. I have the tools, but no printer as yet (working on that - one on order from Reprappro), and I've been off my feet for the past month with a back injury.

Sorry, only registered users may post in this forum.