support structures

Posted by rogerw

|

support structures October 15, 2012 06:33PM |

Registered: 11 years ago Posts: 229 |

hello i am wanting to buy a 3d printer. the shapes i need to bring have a horz surface (a vert tube bending 90 degrees into a horz tube for 15mm or so). i believe i will need to add some additional plastice to support this :

1, do i have to manually add a support structure to my part (in solidworks) or

2. does the CAM software (rapsnapper or skeinforge, etc) know that the bit is horz and adds it automatically (have lloked at these programs and the option seem to not mention bridge, etc).

3. i think the support structure plastice is different so that it can be broken away easiey - how / who specifies this

thanks

roger.

1, do i have to manually add a support structure to my part (in solidworks) or

2. does the CAM software (rapsnapper or skeinforge, etc) know that the bit is horz and adds it automatically (have lloked at these programs and the option seem to not mention bridge, etc).

3. i think the support structure plastice is different so that it can be broken away easiey - how / who specifies this

thanks

roger.

|

Re: support structures October 16, 2012 08:00PM |

Registered: 13 years ago Posts: 1,797 |

|

Re: support structures October 16, 2012 08:46PM |

Registered: 11 years ago Posts: 229 |

hello james,

i have since found out on another forum that the slicer programs slic3r and skeinforge have a support option.

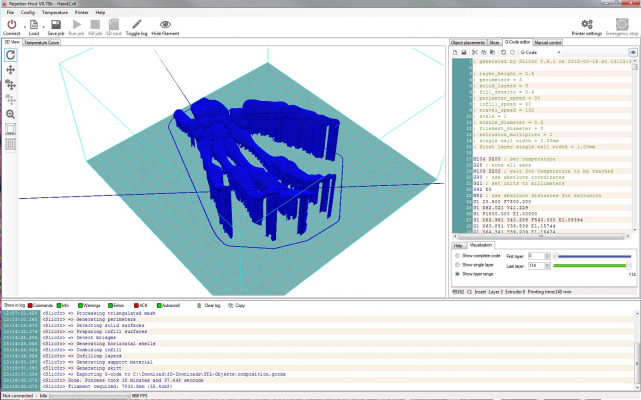

and also can use repitier to look at the suuport when added - see picture.

have ordered my 3d printer and will be 2 weeks to get it.

it uses pla plastic - do u know how/if you can glue parts of pla together?

thanks for reply

ta roger

i have since found out on another forum that the slicer programs slic3r and skeinforge have a support option.

and also can use repitier to look at the suuport when added - see picture.

have ordered my 3d printer and will be 2 weeks to get it.

it uses pla plastic - do u know how/if you can glue parts of pla together?

thanks for reply

ta roger

|

Re: support structures October 16, 2012 10:58PM |

Registered: 11 years ago Posts: 939 |

How accurate does the part have to be?

FWIW I find Kisslicer has the best support of the slicers I've used.

The problem with support in PLA is it can be a pig to remove, though you're picture looks like it wouldn't be too bad.

With ABS for the most part I find suport just peels off, with PLA I find I have to use a razor blade, and it can only really be cleanly removed where is'd accessible.

FWIW I find Kisslicer has the best support of the slicers I've used.

The problem with support in PLA is it can be a pig to remove, though you're picture looks like it wouldn't be too bad.

With ABS for the most part I find suport just peels off, with PLA I find I have to use a razor blade, and it can only really be cleanly removed where is'd accessible.

|

Re: support structures October 16, 2012 11:53PM |

Registered: 11 years ago Posts: 229 |

polygonhell,

the inside of the tube can be a bit rough as it is a fluid running thru it but the outside will have to

be pretty good as it rotates inside another part - see attached

thanks for the info regarding Kissslicer - what difference is between them all, is it just ease of use or do they generate different g codes

roger

the inside of the tube can be a bit rough as it is a fluid running thru it but the outside will have to

be pretty good as it rotates inside another part - see attached

thanks for the info regarding Kissslicer - what difference is between them all, is it just ease of use or do they generate different g codes

roger

|

Re: support structures October 17, 2012 12:04AM |

Registered: 11 years ago Posts: 939 |

Slic3r, Skeinforge and Kisslicer as far as I can see all use different algorithms for the actual slicing, so they result in different GCode.

Slic3r and Kisslicer are on the simple to use end of the spectrum, Skeinforge isn't really all that much more complicated, but it's really just a plugin host, it's not clear as a new user which plugins should be enabled, and the defaults are often just insane for historic reasons.

I haven't tried Slic3r support recently, it didn't work well im 0.72 the last version I think is usable.

Slic3r and Kisslicer are on the simple to use end of the spectrum, Skeinforge isn't really all that much more complicated, but it's really just a plugin host, it's not clear as a new user which plugins should be enabled, and the defaults are often just insane for historic reasons.

I haven't tried Slic3r support recently, it didn't work well im 0.72 the last version I think is usable.

|

Re: support structures October 17, 2012 02:38AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I've tested support with Repetier+Slic3r recently (could be Slicer version 0.91), what worked with some 'glitches' in the viewer (not in the produced G-code) - but this was not for FDM-printing, so no experiences with printing quality.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: support structures October 17, 2012 04:32AM |

Registered: 11 years ago Posts: 172 |

|

Re: support structures October 17, 2012 05:12AM |

Registered: 11 years ago Posts: 229 |

|

Re: support structures October 18, 2012 03:35PM |

Registered: 15 years ago Posts: 123 |

I have used KISSlicer's support to great effect. Here is an example: [kisslicer.com]

I used ABS so I can attest to the support being easy to remove, especially when you decrease its flow rate to 70%.

I used ABS so I can attest to the support being easy to remove, especially when you decrease its flow rate to 70%.

|

Re: support structures October 18, 2012 05:56PM |

Registered: 12 years ago Posts: 182 |

Sorry, only registered users may post in this forum.