Newbie / junkstrap

Posted by throbscottle

|

Newbie / junkstrap February 15, 2022 12:26PM |

Registered: 2 years ago Posts: 4 |

Hi

First post here, I wonder if someone can help me avoid some pitfalls.

Intending to make a junkstrap machine with a view to creating one of the nice delta type designs with it.

I have:

Very low budget (under £100)

Some dexxan type steel racking - will weld if I use it

Reclaimed materials:

Steel sheet, acrylic sheet, bits of aluminium

A variety of wood - can cut reasonably accurate. Some ply, not much.

An awful lot of steel rods of various sizes mainly taken from scrap inkjet printers, + belts and a few other bits

Electronic parts (mostly re-claimed) and tools

Press drill

Table and cross-cut saws

A lot of hand tools

"woodpecker" type CNC engraver I haven't had the chance to do more than test so far so I'm only one step ahead there

I'm making some additional powered workshop tools when I have the space, which will help.

So the budget will mostly go on motors, extruder, bed heater and whatever electronics parts I don't have and boards I either can't build or haven't got time to build

So, the question breaks down into, of my junk collection, what materials should I choose, and which of the existing designs would be a good one to base it on? With the context of: I want to be able to use the printer to make more than just another printer!

What is likely to completely banjax a design like this, make me wish I'd never started, and cause generalised doom?

What aspects do I not need to be so concerned about?

Is it possible for DC motors to have any place in a 3D printer? I ask because I have a lot of them from old inkjet printers.

Ok fingers crossed I don't get laughed at

Thanks in advance...

First post here, I wonder if someone can help me avoid some pitfalls.

Intending to make a junkstrap machine with a view to creating one of the nice delta type designs with it.

I have:

Very low budget (under £100)

Some dexxan type steel racking - will weld if I use it

Reclaimed materials:

Steel sheet, acrylic sheet, bits of aluminium

A variety of wood - can cut reasonably accurate. Some ply, not much.

An awful lot of steel rods of various sizes mainly taken from scrap inkjet printers, + belts and a few other bits

Electronic parts (mostly re-claimed) and tools

Press drill

Table and cross-cut saws

A lot of hand tools

"woodpecker" type CNC engraver I haven't had the chance to do more than test so far so I'm only one step ahead there

I'm making some additional powered workshop tools when I have the space, which will help.

So the budget will mostly go on motors, extruder, bed heater and whatever electronics parts I don't have and boards I either can't build or haven't got time to build

So, the question breaks down into, of my junk collection, what materials should I choose, and which of the existing designs would be a good one to base it on? With the context of: I want to be able to use the printer to make more than just another printer!

What is likely to completely banjax a design like this, make me wish I'd never started, and cause generalised doom?

What aspects do I not need to be so concerned about?

Is it possible for DC motors to have any place in a 3D printer? I ask because I have a lot of them from old inkjet printers.

Ok fingers crossed I don't get laughed at

Thanks in advance...

|

Re: Newbie / junkstrap February 20, 2022 12:27AM |

Registered: 7 years ago Posts: 321 |

I suspect a lot of those motors will actually be stepper motors. Although probably a bit small for 3d printers.

You could maybe have enough Dexian for a CoreXY frame. If not, at least a base frame.

Will help to kill vibration if nothing else.

I've had people come up to me and the only thing they haven't recycled is the usb cable to plug it in with.

If you want to pre-order a pretty nice, inexpensive control board, the BTT skr mini e3 v3 can be preordered.

Pretty good for about 40 American, a bit more UK. Not due to ship until April/May.

You wouldn't pay much less for an Arduino, Ramps and nice drivers.

Even if you printer doesn't come together, would still do pretty well as a laser engraver or CNC controller.

Edited 1 time(s). Last edit at 02/20/2022 12:28AM by DragonFire.

You could maybe have enough Dexian for a CoreXY frame. If not, at least a base frame.

Will help to kill vibration if nothing else.

I've had people come up to me and the only thing they haven't recycled is the usb cable to plug it in with.

If you want to pre-order a pretty nice, inexpensive control board, the BTT skr mini e3 v3 can be preordered.

Pretty good for about 40 American, a bit more UK. Not due to ship until April/May.

You wouldn't pay much less for an Arduino, Ramps and nice drivers.

Even if you printer doesn't come together, would still do pretty well as a laser engraver or CNC controller.

Edited 1 time(s). Last edit at 02/20/2022 12:28AM by DragonFire.

|

Re: Newbie / junkstrap February 20, 2022 03:48AM |

Registered: 7 years ago Posts: 321 |

If that seems a lot to spend on one item - it is.

Alternatively, what you could look at doing is buying 2nd hand non-working or working. Ebay has a bit of a glut currently,

Maybe about the same money or less.

That would let you get your hands on something, and using Dexian to reframe a Prusa i3 or derivative is not unknown.

Less ambitious, more doable that way.

Alternatively, what you could look at doing is buying 2nd hand non-working or working. Ebay has a bit of a glut currently,

Maybe about the same money or less.

That would let you get your hands on something, and using Dexian to reframe a Prusa i3 or derivative is not unknown.

Less ambitious, more doable that way.

|

Re: Newbie / junkstrap February 20, 2022 03:51AM |

Registered: 7 years ago Posts: 321 |

Only smooth rod delta design I'm aware of is the Rostock.

[reprap.org]

Here's why I'm not recommended you go delta - I've spent 6 years trying to get one to print accurately.

Thanks to a Raspberry Pi 3 and Klipper firmware, I can do that now.

A pi zero 2 W will do the trick, but that's not an easy setup to achieve at one go.

And yeah, you need the Linux host (Pi) as well as the control board. Not necessarily a Pi but they're easier than modding a smart phone and less power hungry than a desktop PC or laptop even.

Edited 2 time(s). Last edit at 02/20/2022 03:55AM by DragonFire.

[reprap.org]

Here's why I'm not recommended you go delta - I've spent 6 years trying to get one to print accurately.

Thanks to a Raspberry Pi 3 and Klipper firmware, I can do that now.

A pi zero 2 W will do the trick, but that's not an easy setup to achieve at one go.

And yeah, you need the Linux host (Pi) as well as the control board. Not necessarily a Pi but they're easier than modding a smart phone and less power hungry than a desktop PC or laptop even.

Edited 2 time(s). Last edit at 02/20/2022 03:55AM by DragonFire.

|

Re: Newbie / junkstrap February 20, 2022 08:33AM |

Registered: 2 years ago Posts: 4 |

Thanks for the tips, DragonFire. That will go a long way towards getting started.

I hadn't seen the core-xy - mesmerising video! So that's looks a nice way to start. I'm pretty sure those old parallel drawing boards it refers to used steel cables wrapped around spools, also same method was used in radio dials - so I'll likely take the fishing line approach anyway. Box frame should be easy enough to make, I've plenty of racking!

I'll have to study the various controllers more. That SKR mini looks nice. No need to pre-order though, it's out already!

FYI - regular inkjet printers haven't used steppers for many (20, maybe) years now. They use DC motors with optical feedback.

Can't do anything till after house move, will post updates

I hadn't seen the core-xy - mesmerising video! So that's looks a nice way to start. I'm pretty sure those old parallel drawing boards it refers to used steel cables wrapped around spools, also same method was used in radio dials - so I'll likely take the fishing line approach anyway. Box frame should be easy enough to make, I've plenty of racking!

I'll have to study the various controllers more. That SKR mini looks nice. No need to pre-order though, it's out already!

FYI - regular inkjet printers haven't used steppers for many (20, maybe) years now. They use DC motors with optical feedback.

Can't do anything till after house move, will post updates

|

Re: Newbie / junkstrap February 20, 2022 10:00AM |

Registered: 11 years ago Posts: 5,780 |

I've played a bit with cable drive for a corexy mechanism and I can't recommend it. Doing it right is too difficult, and even if you do it right, maintenance is a nightmare.

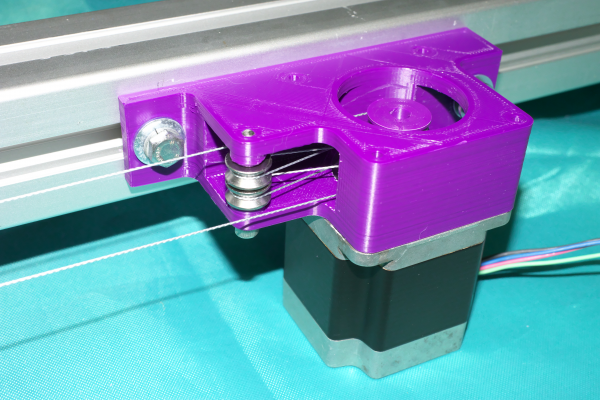

Doing it right requires motor mounts similar to this:

Installing the cables is a good introduction to what maintenance will be like. Cables require multiple turns on the drive and steering pulleys to get sufficient friction to drive the mechanism without slipping, and they flop around loosely, so getting a cable threaded around all those pulleys and then keeping tension on it so it doesn't slip off the pulleys while you try to loop the cable through the other pulleys is a multiperson job or requires development of some clever tools specific to the task. Any maintenance that requires relieving tension of a cable will require you to invite all your friends over again to retension the cable. I used 90 lb (?) dyneema fishing line and found it quite stretchy, especially compared to a 6 mm glass core GT2 belt. Most knots don't like to stay tied in dyneema line, so you'd better study some fishing knot tutorials to learn how to tie off the cables so the knots won't slip. The dyneema line cut my printed ABS drive pulleys apart after a few hours of operation. You'd better plan on using metal drive pulleys. I used some cheap ball-bearing cable pulleys and found them noisy, and the bearings didn't last. Use better pulleys than I did.

Here's some video.

My adventures in cable drive are documented here.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Doing it right requires motor mounts similar to this:

Installing the cables is a good introduction to what maintenance will be like. Cables require multiple turns on the drive and steering pulleys to get sufficient friction to drive the mechanism without slipping, and they flop around loosely, so getting a cable threaded around all those pulleys and then keeping tension on it so it doesn't slip off the pulleys while you try to loop the cable through the other pulleys is a multiperson job or requires development of some clever tools specific to the task. Any maintenance that requires relieving tension of a cable will require you to invite all your friends over again to retension the cable. I used 90 lb (?) dyneema fishing line and found it quite stretchy, especially compared to a 6 mm glass core GT2 belt. Most knots don't like to stay tied in dyneema line, so you'd better study some fishing knot tutorials to learn how to tie off the cables so the knots won't slip. The dyneema line cut my printed ABS drive pulleys apart after a few hours of operation. You'd better plan on using metal drive pulleys. I used some cheap ball-bearing cable pulleys and found them noisy, and the bearings didn't last. Use better pulleys than I did.

Here's some video.

My adventures in cable drive are documented here.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Newbie / junkstrap February 20, 2022 11:41AM |

Registered: 7 years ago Posts: 321 |

|

Re: Newbie / junkstrap February 20, 2022 11:56AM |

Registered: 7 years ago Posts: 321 |

|

Re: Newbie / junkstrap February 20, 2022 04:02PM |

Registered: 11 years ago Posts: 5,780 |

Not really. There's no magic and it isn't rocket science. When you tighten the first belt, leave it a little looser than you ultimately want it to be. It will pull the X and Y axes out of square. When you tighten the second belt, the first belt will also get tighter (that's why you left it a little loose). Tighten the second belt until the X and Y axes are square again. If the tension feels adequate, you're done. If not, pull the second belt a little tighter, then go back and tighten the first belt a little more. The end goal is not to match belt tensions but to get the X and Y axes square. The absolute tension isn't critical, and with most of the no name belts people use, there's no spec for the optimal tension. Just get them tight enough that they don't flop around without being so tight they bend your pulley axles or motor mounts. You can verify squareness either using a carpenter's or machinist's square to check the axes or you can print a large rectangle and measure the diagonals. If the diagonals match, the axes are square.

The thing that is crucial is positioning the pulleys so that the belts run parallel to the guide rails. If not, belt tension will vary with extruder carriage position, prints will be distorted, especially if they are printed near the ends of the axes or corners of the bed.

When you are looking at corexy designs to copy, or a kit to buy, look carefully at the belt paths. If you see belts that are not parallel to guide rails or clothespin spring tensioners, choose a different design. In a properly executed corexy mechanism the belt tension will not change enough to require a spring to take up slack.

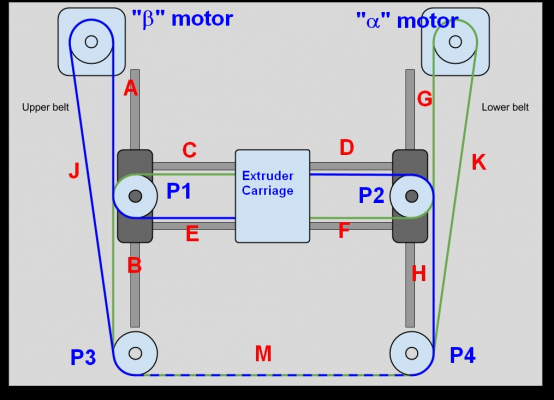

Here is the often posted corexy belt diagram- keep segments labeled A-H parallel to the guide rails and you can do whatever you want with the rest:

That diagram shows a stacked belt, minimum pulley count arrangement. The same rules apply to any belt driven linear positioning mechanism- working segments must be parallel to guide rails (exactly the same as lead screws).

More on corexy layout here.

Edited 4 time(s). Last edit at 02/20/2022 04:19PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The thing that is crucial is positioning the pulleys so that the belts run parallel to the guide rails. If not, belt tension will vary with extruder carriage position, prints will be distorted, especially if they are printed near the ends of the axes or corners of the bed.

When you are looking at corexy designs to copy, or a kit to buy, look carefully at the belt paths. If you see belts that are not parallel to guide rails or clothespin spring tensioners, choose a different design. In a properly executed corexy mechanism the belt tension will not change enough to require a spring to take up slack.

Here is the often posted corexy belt diagram- keep segments labeled A-H parallel to the guide rails and you can do whatever you want with the rest:

That diagram shows a stacked belt, minimum pulley count arrangement. The same rules apply to any belt driven linear positioning mechanism- working segments must be parallel to guide rails (exactly the same as lead screws).

More on corexy layout here.

Edited 4 time(s). Last edit at 02/20/2022 04:19PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Newbie / junkstrap February 21, 2022 06:00PM |

Registered: 2 years ago Posts: 4 |

Hmm, ok. So is getting core x-y set up right likely to be too complicated? It's attractive to me because of it's elegance. My first thought looking at that photo was "why does it need those extra pulleys?" My second thought was "if they were on the other side they could balance out the lateral load on the motor spindle". But hey, I don't know anything yet!

Maybe I should just use belts.

Am I better looking at a design that shift one of the axis motors around? I've got one of you saying core-xy is a nightmare and one saying it's straightforward-ish!

Maybe I should just use belts.

Am I better looking at a design that shift one of the axis motors around? I've got one of you saying core-xy is a nightmare and one saying it's straightforward-ish!

|

Re: Newbie / junkstrap February 22, 2022 11:00PM |

Registered: 11 years ago Posts: 5,780 |

The motor mount for the cable driven machine use the extra pulleys to steer the cable over the drive pulley and prevent the cable from winding over itself. It also provides a fixed position for the cable to wind/unwind from the drive pulley so you can keep the cable parallel to the guide rails (just like drive belts and screws). There are limits to how and where you can position the steering pulleys and still have clearance for both ends of the cable to come out from the motor mount where you need them to.

It's probably easiest to build a more common machine that moves the bed in the Y axis, as long as you aren't trying to get to large a print volume. Corexy is better than bed flingers for medium to large size printers, but works fine for small machines, too. If you want simplicity, forget about cable drive.

Corexy isn't particularly difficult. The problem is sorting through the bad designs and misinformation.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It's probably easiest to build a more common machine that moves the bed in the Y axis, as long as you aren't trying to get to large a print volume. Corexy is better than bed flingers for medium to large size printers, but works fine for small machines, too. If you want simplicity, forget about cable drive.

Corexy isn't particularly difficult. The problem is sorting through the bad designs and misinformation.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Newbie / junkstrap February 23, 2022 02:41AM |

Registered: 3 years ago Posts: 92 |

Step 1. Buy Ender 3

Step 2. Convert to direct extrusion (very easy, and gives much better print quality)

Step 3. Print parts for custom printer

Step 4. Cannibalize Ender 3 for parts to complete custom printer

I was a big fan of the SKR Mini when it cost $30, but it looks like the going price now is $50. Unless you really need any of the TMC2209 features like sensorless homing, I'd go with the Ender 3 stock board to get the power supply, motors, extruder, hotend, fans (surprisingly expensive), LCD (also surprisingly expensive), heat bed, and other stuff as well. But it also depends on what your goals are with the custom printer. If you need a larger bed, or want to use a different style of extruder or hotend, or larger/better quality fans, and don't need the LCD, then you might be better off buying individual parts as needed. Old ATX power supplies are good for these kind of projects. A bit bulky, but gets the job done.

Step 2. Convert to direct extrusion (very easy, and gives much better print quality)

Step 3. Print parts for custom printer

Step 4. Cannibalize Ender 3 for parts to complete custom printer

I was a big fan of the SKR Mini when it cost $30, but it looks like the going price now is $50. Unless you really need any of the TMC2209 features like sensorless homing, I'd go with the Ender 3 stock board to get the power supply, motors, extruder, hotend, fans (surprisingly expensive), LCD (also surprisingly expensive), heat bed, and other stuff as well. But it also depends on what your goals are with the custom printer. If you need a larger bed, or want to use a different style of extruder or hotend, or larger/better quality fans, and don't need the LCD, then you might be better off buying individual parts as needed. Old ATX power supplies are good for these kind of projects. A bit bulky, but gets the job done.

|

Re: Newbie / junkstrap February 23, 2022 04:35PM |

Registered: 7 years ago Posts: 321 |

|

Re: Newbie / junkstrap February 23, 2022 05:03PM |

Registered: 2 years ago Posts: 4 |

Sorry, only registered users may post in this forum.