|

Which way for retraction? November 25, 2012 01:39PM |

Registered: 12 years ago Posts: 132 |

I've been getting a few prints where moves from the perimeter leave a blob followed by a gap, in Slic3r. I'm guessing this is a retraction issue, but which way should I go with it? The settings are 1.5mm distance, 45mm/s speed, no restart. I can't remember if Z lift was on, if so it would have been .25. It's a direct drive extruder, which can move the filament up and down at that speed, though it can't push it out the nozzle that fast.

|

Re: Which way for retraction? November 25, 2012 05:12PM |

Registered: 11 years ago Posts: 560 |

You are retracting too much, causing the nozzle to pause too long, which blobs the print. Did the print you posted in your other post about the vertical banding have these blobs? Don't think the pic you posted there had these.

When you retract, you are really only relieving pressure in your hot end, not actually pulling material back in at the tip.

My settings for a layer height of .05mm only has a retraction of .25mm, no blobs, no strings.

Edited 1 time(s). Last edit at 11/25/2012 05:13PM by Dirty Steve.

When you retract, you are really only relieving pressure in your hot end, not actually pulling material back in at the tip.

My settings for a layer height of .05mm only has a retraction of .25mm, no blobs, no strings.

Edited 1 time(s). Last edit at 11/25/2012 05:13PM by Dirty Steve.

|

Re: Which way for retraction? November 25, 2012 07:45PM |

Registered: 13 years ago Posts: 1,780 |

Turn off z-lift. This also worsens blobs. Is this PLA? If so, you need to you may need to blow air on your hot end thermal insulator to keep the filament from softening above the heating block. When it gets soft, then retract/restart doesn't work as well. Depending on your hot end, you might also need to provide cooling on the thermal insulator with ABS. Also, 1 mm retract is enough in most cases.

|

Re: Which way for retraction? November 26, 2012 04:45PM |

Registered: 12 years ago Posts: 132 |

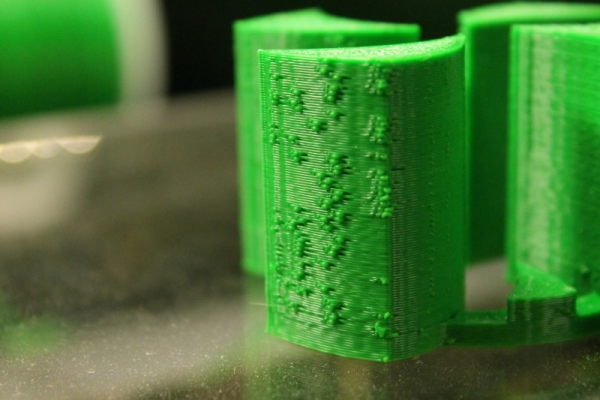

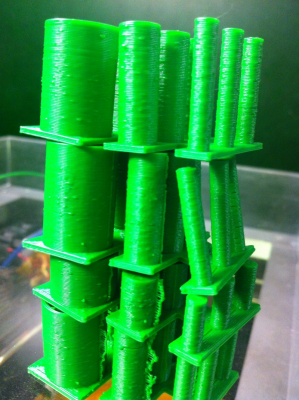

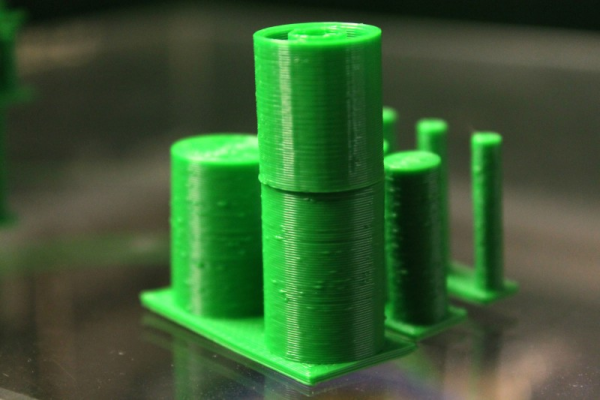

This is with ABS, and Slic3r 097. 097 has some bugs, one of which seems to be that is it randomizing starting points, even though that option is unchecked. That's why there are blobs all around, though if it wasn't randomizing, I expect the resulting seam would still be raised a fair amount. Here are 4 prints with 097. From the bottom the retraction lengths are .1, .25, .5 and 1. The 1mm retraction has eliminated the stringing, but the blobs are unchanged. It wasn't using retraction on the changes between loops, so on the 1mm print I set minimum travel to 0. It retracted a little on the changes for that print, but maybe it didn't have time to retract enough since the move is so small. I don't know if the blobs are the transition between inner loop to perimeter, or the move from perimeter to fill.

The odd thing is that if I print a single column, those blobs become tiny gaps. The only difference should be that there are no other columns to move to. From the other picture we can see that those artifacts from moves between objects are accounted for and eliminated by retraction.

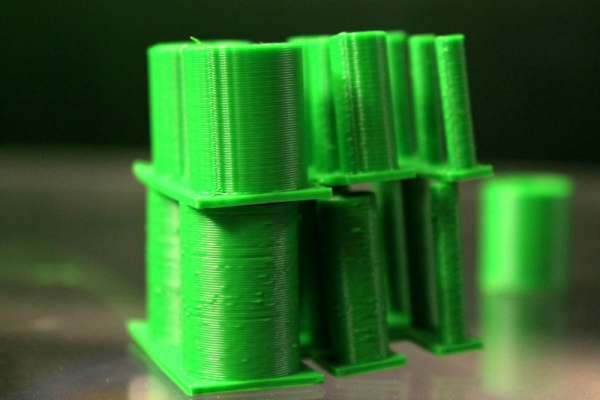

The next picture is Slic3r on the bottom, KISSlicer on the top. KS has made the seam,which is fairly smooth. There is a slight gap from the thread curving in the transition between loop and perimeter.

I still need to run this print in Slic3r 096 or 093 and see if it will run it without randomizing starting points. It would be nice to use that feature to eliminate the seam, but it is useless if it just creates blobs everywhere. I would rather sand down a seam than the entire circumference.

The odd thing is that if I print a single column, those blobs become tiny gaps. The only difference should be that there are no other columns to move to. From the other picture we can see that those artifacts from moves between objects are accounted for and eliminated by retraction.

The next picture is Slic3r on the bottom, KISSlicer on the top. KS has made the seam,which is fairly smooth. There is a slight gap from the thread curving in the transition between loop and perimeter.

I still need to run this print in Slic3r 096 or 093 and see if it will run it without randomizing starting points. It would be nice to use that feature to eliminate the seam, but it is useless if it just creates blobs everywhere. I would rather sand down a seam than the entire circumference.

|

Re: Which way for retraction? November 26, 2012 04:54PM |

Registered: 13 years ago Posts: 1,797 |

increase perimeters, decrease flow rate, and increase retraction to say 6.5, and restart to 0.25. but it looks to me your flow needs to be less, because the defects shown are normally on inside perimeter, outside perimeter is done last, and if flow is where it should be defect should not show on outside of part, if perimeters are set to 2 or greater. set extruder multiplier to say .95 and go from there.

|

Re: Which way for retraction? November 26, 2012 05:10PM |

Registered: 11 years ago Posts: 482 |

|

Re: Which way for retraction? November 26, 2012 06:01PM |

Registered: 12 years ago Posts: 132 |

The flow rate is correct. I have an Extrusion Multiplier of .89, and when I print a single wall with a .42 thread width, I get a .40-.42 wall. I had been getting a little gapping in top solid layers, so I reduced the nozzle diameter to .33 to get the threads closer together. Would that have any effect in the outer perimeter?

Simba, how fast do you think travel would need to go to be as effective as retraction? I could crank it up to 300, but I would be concerned with overshoot. I have had noticeable artifacts from overshoot printing at 150, but maybe it won't be a factor on travel moves, if the nozzle has time to bounce back before extrusion.

Simba, how fast do you think travel would need to go to be as effective as retraction? I could crank it up to 300, but I would be concerned with overshoot. I have had noticeable artifacts from overshoot printing at 150, but maybe it won't be a factor on travel moves, if the nozzle has time to bounce back before extrusion.

|

Re: Which way for retraction? November 26, 2012 07:07PM |

Registered: 13 years ago Posts: 1,780 |

I've found that it's almost impossible to completely get rid of blobs. You can try decreasing the hot end temperature a little. At high temperature, the viscosity of ABS is lower and it tends to form more blobs during the restart. But if you lower the T too much, you'll get more pressure build up in the nozzle which results in ooze even with retract. So, I think there's an optimal temperature where you can minimize both blob and ooze.

|

Re: Which way for retraction? November 27, 2012 03:16AM |

Registered: 13 years ago Posts: 1,797 |

IanJohnson :yes it will effect perimeter. you adjusted for nozzle width of 0.33, try 0.34. also note that flow rate changes based on calculated width and height of filament in slic3r, so with 0.34 you will need to again calibrate flow rate if it is not now dead on.....

also use at least 2 perimeters.

Edited 1 time(s). Last edit at 11/27/2012 03:17AM by jamesdanielv.

also use at least 2 perimeters.

Edited 1 time(s). Last edit at 11/27/2012 03:17AM by jamesdanielv.

Sorry, only registered users may post in this forum.