Wrong Object Height

Posted by 13asilis

|

Wrong Object Height November 25, 2012 05:07PM |

Registered: 12 years ago Posts: 43 |

Hi guys,

I have a really weird problem with my Z-object height ...

After a Marlin firmware update (actually after losing my firmware settings and setting it all up again), my Z object height is completely off...

I'm using M8 screws with 1/16 microstepping and direct drive and have the z-steps set to 2560 steps/mm in the firmware! When I ask the z-axis to move it moves the exact demanded length!

But when I try to print an object, the object height is completely off!

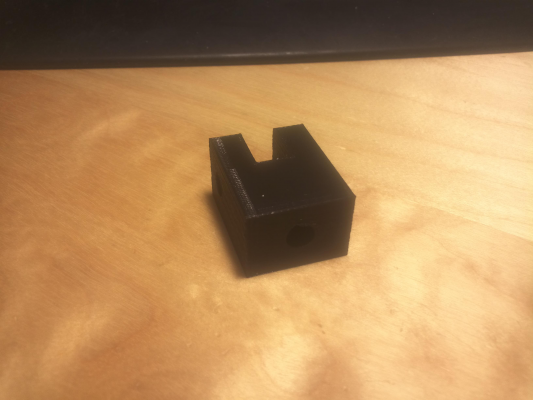

In the attached image you can see 3 gears:

Middle: older print which was printed correctly (~11mm height)

Right: new print with 2560 steps/mm -> resulting height is about 8.7mm!

Left: adjusted z-steps (about 3200 steps/mm) -> resulting height is about 13.3mm

The layer height is set to 0.2mm with a 0.35 nozzle!

Using newest Marlin, Slic3r 0.8.4 and LCD panel with SD card! (Prusa i2)

Any ideas?

Oh and another minor problem which is kind of annoying:

My printer doesn't finish the last few moves! in the attached picture you can see that a few lines from the last layer are missing, it just stopped before finishing all the moves!

Again, anyone having the same problem or even a solution for it?

Regards,

Basilis

I have a really weird problem with my Z-object height ...

After a Marlin firmware update (actually after losing my firmware settings and setting it all up again), my Z object height is completely off...

I'm using M8 screws with 1/16 microstepping and direct drive and have the z-steps set to 2560 steps/mm in the firmware! When I ask the z-axis to move it moves the exact demanded length!

But when I try to print an object, the object height is completely off!

In the attached image you can see 3 gears:

Middle: older print which was printed correctly (~11mm height)

Right: new print with 2560 steps/mm -> resulting height is about 8.7mm!

Left: adjusted z-steps (about 3200 steps/mm) -> resulting height is about 13.3mm

The layer height is set to 0.2mm with a 0.35 nozzle!

Using newest Marlin, Slic3r 0.8.4 and LCD panel with SD card! (Prusa i2)

Any ideas?

Oh and another minor problem which is kind of annoying:

My printer doesn't finish the last few moves! in the attached picture you can see that a few lines from the last layer are missing, it just stopped before finishing all the moves!

Again, anyone having the same problem or even a solution for it?

Regards,

Basilis

|

Re: Wrong Object Height November 26, 2012 02:04PM |

Registered: 11 years ago Posts: 42 |

|

Re: Wrong Object Height November 26, 2012 05:57PM |

Registered: 12 years ago Posts: 43 |

Thanks a lot for the reply, I did check it and it moves the demanded length per layer (at 0,2mm layer height always 0.2mm!)

I got a tip from a friend of mine today, he told me that I should check if the Z-axis was always turned on in the firmware - because turning it off may result to it slipping downwards while moving fast! I'll give that a try and report back!

EDIT: OK I've checked and the "disable z-axis when not in use" is false .. so I suppose it's turned on at all times ...

I really need some help guys, I have absolutely no clue what to do :_(

Edited 1 time(s). Last edit at 11/26/2012 06:14PM by 13asilis.

I got a tip from a friend of mine today, he told me that I should check if the Z-axis was always turned on in the firmware - because turning it off may result to it slipping downwards while moving fast! I'll give that a try and report back!

EDIT: OK I've checked and the "disable z-axis when not in use" is false .. so I suppose it's turned on at all times ...

I really need some help guys, I have absolutely no clue what to do :_(

Edited 1 time(s). Last edit at 11/26/2012 06:14PM by 13asilis.

|

Re: Wrong Object Height November 27, 2012 09:04AM |

Registered: 13 years ago Posts: 7,616 |

Are you sure the Z axis can achieve the feedrates commanded in the G-code? With 1/16 microstepping and a 16 MHz controller, maximum feedrate can be as low as 100 mm/minute (1.7 mm/s) on this axis.

When commanding an axis to go faster than it can, it'll move parts of the acceleration and parts of the deceleration ramp, only, missing some of the steps in between.

And a note: for testing movements it isn't neccessary to put filament in.

When commanding an axis to go faster than it can, it'll move parts of the acceleration and parts of the deceleration ramp, only, missing some of the steps in between.

And a note: for testing movements it isn't neccessary to put filament in.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Wrong Object Height November 27, 2012 11:35AM |

Registered: 11 years ago Posts: 42 |

Make sure the z-rods are not slipping compared to the stepper motor. I had that problem on one side only so it was obvious after a little while, because the whole x axis carriage started to tip. But if both are slipping, then you might not notice. I am using plastic tube as my z axis couples, so I added zip ties and oiled the threaded rod.

|

Re: Wrong Object Height November 28, 2012 02:23PM |

Registered: 12 years ago Posts: 43 |

Hi guys thanks a lot for the help!

I've managed to resolve the problem by decreasing the ZJERK from 0.4 to 0, now the object height is spot on!

I've noticed a different problem now:

I can't really classify it, if you look at the picture you can see some weird traces left behind the printed circle ... it seems to me that when changing direction the extrusion is a bit irregular, is that related to the XYJERK maybe? the XYJERK is currently at 10...

I've managed to resolve the problem by decreasing the ZJERK from 0.4 to 0, now the object height is spot on!

I've noticed a different problem now:

I can't really classify it, if you look at the picture you can see some weird traces left behind the printed circle ... it seems to me that when changing direction the extrusion is a bit irregular, is that related to the XYJERK maybe? the XYJERK is currently at 10...

|

Re: Wrong Object Height November 28, 2012 03:31PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Wrong Object Height November 28, 2012 04:17PM |

Registered: 12 years ago Posts: 43 |

|

Re: Wrong Object Height November 28, 2012 05:14PM |

Registered: 11 years ago Posts: 42 |

|

Re: Wrong Object Height November 28, 2012 06:09PM |

Registered: 13 years ago Posts: 1,780 |

It's definitely from vibrations when the x or y axis stops. Remember that to make a 90 turn at the corners, one of the axes has to stop and the other one starts. When the vibration occurs along the axis that stopped and it results in the wavy walls that look like damped oscillation. If you slow down the print, the vibration frequency would change and if you slow down enough, it should eventually go away. You can also reduce it by decreasing the x and y acceleration or the xy jerk in the fw.

|

Re: Wrong Object Height December 05, 2012 04:14AM |

Registered: 12 years ago Posts: 43 |

Hi guys, thanks a lot for the help!

I've managed to get rid of the weird oscillating traces of edges by turning the acceleration way down .. to about 500! (on the X and Y axis) ...

After turning the XY-Jerk down as well, I have the feeling that too much material is being put onto the edges, leaving weird pimples that stick out in the edge-area! I've turned the Jerk up to 30 by now but maybe I do have to go up again with the acceleration?

I've managed to get rid of the weird oscillating traces of edges by turning the acceleration way down .. to about 500! (on the X and Y axis) ...

After turning the XY-Jerk down as well, I have the feeling that too much material is being put onto the edges, leaving weird pimples that stick out in the edge-area! I've turned the Jerk up to 30 by now but maybe I do have to go up again with the acceleration?

Sorry, only registered users may post in this forum.