J-Head set screw - where is it supposed to be

Posted by tprime

|

J-Head set screw - where is it supposed to be November 26, 2012 07:41AM |

Registered: 11 years ago Posts: 87 |

Hello,

I've recently purchased a J-head MK/IV (alu, not brass) in europe and have trouble with it having a very high resistance - I need too much force

to push out my plastic.

The documentation seems to mention a set-screw that's supposed to hold the PTFE in place? Where's that supposed to be located - I can't

tell from the pictures, nor find it on my J-Head. The only place I seem to have a grub-screw hole is on the resistor side - which I guessed was to make sure the resistor

was in decent contact with the hot end.

Thanks,

So long,

Tyberius Prime

I've recently purchased a J-head MK/IV (alu, not brass) in europe and have trouble with it having a very high resistance - I need too much force

to push out my plastic.

The documentation seems to mention a set-screw that's supposed to hold the PTFE in place? Where's that supposed to be located - I can't

tell from the pictures, nor find it on my J-Head. The only place I seem to have a grub-screw hole is on the resistor side - which I guessed was to make sure the resistor

was in decent contact with the hot end.

Thanks,

So long,

Tyberius Prime

|

Re: J-Head set screw - where is it supposed to be November 26, 2012 08:33AM |

Registered: 12 years ago Posts: 156 |

|

Re: J-Head set screw - where is it supposed to be November 26, 2012 08:47AM |

Registered: 11 years ago Posts: 87 |

So I guess it is missing on mine then.

Stil ldoesn't quite explain why, if I fix the tubing at the top with a washer it requires so much force.

My barrel is 5mm, with a 4.75mm teflon tube - not 6.35/6mm.

Drives me nuts Tried pretty much everything I could find in the forums, I am cooling it, I've cleaned the nozzle,

Tried pretty much everything I could find in the forums, I am cooling it, I've cleaned the nozzle,

it's hot enough, still I can't reliably print faster than 15mm/s

Stil ldoesn't quite explain why, if I fix the tubing at the top with a washer it requires so much force.

My barrel is 5mm, with a 4.75mm teflon tube - not 6.35/6mm.

Drives me nuts

Tried pretty much everything I could find in the forums, I am cooling it, I've cleaned the nozzle,

Tried pretty much everything I could find in the forums, I am cooling it, I've cleaned the nozzle,it's hot enough, still I can't reliably print faster than 15mm/s

|

Re: J-Head set screw - where is it supposed to be November 26, 2012 01:29PM |

Registered: 12 years ago Posts: 124 |

|

Re: J-Head set screw - where is it supposed to be November 26, 2012 06:27PM |

Registered: 11 years ago Posts: 87 |

@Asger: not at all. J-Heads are a tiny bit hard to source in europe - I wouldn't mind it being produced locally, it's an open source design after all.

But: I can't get it to flow properly. I've cleaned it twice, tried assembling in serveral times now. My last idea is to wrap the PTFE liner in teflon tape,

to exclude that it's leaking - it seems to be pushing a tiny bit of material to the outsides of the tube (and then on into the threading...).

There is another guy on ebay giving the seller good ratings on the J-head, commenting he fixed a bit of leaking with teflon tape.

Otherwise, I'm fresh out of ides. I''ve even made a new alu 'top' with a 3.5mm hole to keep the liner in place.

But: I can't get it to flow properly. I've cleaned it twice, tried assembling in serveral times now. My last idea is to wrap the PTFE liner in teflon tape,

to exclude that it's leaking - it seems to be pushing a tiny bit of material to the outsides of the tube (and then on into the threading...).

There is another guy on ebay giving the seller good ratings on the J-head, commenting he fixed a bit of leaking with teflon tape.

Otherwise, I'm fresh out of ides. I''ve even made a new alu 'top' with a 3.5mm hole to keep the liner in place.

|

Re: J-Head set screw - where is it supposed to be November 26, 2012 08:28PM |

Registered: 15 years ago Posts: 537 |

Hello,

In all probabiliy, there are one or two problems.

1. The nozzle orifice length could be too long. This will increase the extrusion pressure.

2. The other issue, that happened primarily with the Mk IV-B and earlier designs, is that it is possible for the PTFE tubing to be constricting at the junction with the brass. This can happen if the hollow set-screw is too tight.

As I have not personally seen this particular clone, I suppose it is possible that there are other possible issues.

Regards,

Brian

Edited 1 time(s). Last edit at 11/26/2012 08:31PM by reifsnyderb.

In all probabiliy, there are one or two problems.

1. The nozzle orifice length could be too long. This will increase the extrusion pressure.

2. The other issue, that happened primarily with the Mk IV-B and earlier designs, is that it is possible for the PTFE tubing to be constricting at the junction with the brass. This can happen if the hollow set-screw is too tight.

As I have not personally seen this particular clone, I suppose it is possible that there are other possible issues.

Regards,

Brian

Edited 1 time(s). Last edit at 11/26/2012 08:31PM by reifsnyderb.

|

Re: J-Head set screw - where is it supposed to be November 27, 2012 03:22AM |

Registered: 11 years ago Posts: 87 |

Thank for chiming in Brian - I appreciate all the work you put in designing these!

2. I believe I can exclude. The PTFE liner flushes with the top of the PEEK (no set screw) without forcing it, then there's basically just a plate above it holding it

in place. If I take it out, by itself, it slides nicely along the filament.

I've also tried adding a tamper with a pencil sharpener, which should give it room to expand if it needs to.

Hm. Perhaps the ID of the liner is to small - large enough when cold, but constricting when it get's hotter?

I gotta measure this tonight!

So long,

Tyberius Prime

2. I believe I can exclude. The PTFE liner flushes with the top of the PEEK (no set screw) without forcing it, then there's basically just a plate above it holding it

in place. If I take it out, by itself, it slides nicely along the filament.

I've also tried adding a tamper with a pencil sharpener, which should give it room to expand if it needs to.

Hm. Perhaps the ID of the liner is to small - large enough when cold, but constricting when it get's hotter?

I gotta measure this tonight!

So long,

Tyberius Prime

|

Re: J-Head set screw - where is it supposed to be November 27, 2012 03:27AM |

Registered: 12 years ago Posts: 124 |

tprime Wrote:

-------------------------------------------------------

> @Asger: not at all. J-Heads are a tiny bit hard to

> source in europe - I wouldn't mind it being

> produced locally, it's an open source design after

> all.

> But: I can't get it to flow properly. I've cleaned

> it twice, tried assembling in serveral times now.

> My last idea is to wrap the PTFE liner in teflon

> tape,

> to exclude that it's leaking - it seems to be

> pushing a tiny bit of material to the outsides of

> the tube (and then on into the threading...).

>

> There is another guy on ebay giving the seller

> good ratings on the J-head, commenting he fixed a

> bit of leaking with teflon tape.

>

> Otherwise, I'm fresh out of ides. I''ve even made

> a new alu 'top' with a 3.5mm hole to keep the

> liner in place.

I have to call BS on "J-Heads are a tiny bit hard to source in europe"

firstly, reifsnyderb charges 3.75$ for international shipping and the actual hotend is 54,99$

I too live in Europe, and have yet to see a source offering the hotend and shipping cheaper

-------------------------------------------------------

> @Asger: not at all. J-Heads are a tiny bit hard to

> source in europe - I wouldn't mind it being

> produced locally, it's an open source design after

> all.

> But: I can't get it to flow properly. I've cleaned

> it twice, tried assembling in serveral times now.

> My last idea is to wrap the PTFE liner in teflon

> tape,

> to exclude that it's leaking - it seems to be

> pushing a tiny bit of material to the outsides of

> the tube (and then on into the threading...).

>

> There is another guy on ebay giving the seller

> good ratings on the J-head, commenting he fixed a

> bit of leaking with teflon tape.

>

> Otherwise, I'm fresh out of ides. I''ve even made

> a new alu 'top' with a 3.5mm hole to keep the

> liner in place.

I have to call BS on "J-Heads are a tiny bit hard to source in europe"

firstly, reifsnyderb charges 3.75$ for international shipping and the actual hotend is 54,99$

I too live in Europe, and have yet to see a source offering the hotend and shipping cheaper

|

Re: J-Head set screw - where is it supposed to be November 27, 2012 06:20AM |

Registered: 11 years ago Posts: 87 |

> I have to call BS on "J-Heads are a tiny bit

> hard to source in europe"

> firstly, reifsnyderb charges 3.75$ for

> international shipping and the actual hotend is

> 54,99$

>

> I too live in Europe, and have yet to see a source

> offering the hotend and shipping cheaper

Depends on how you define 'tiny bit hard'.

Dealing with customs (+19% price increase here) and waiting 4 weeks (or longer if you're in the unlucky 5%), plus the risk of an uninsured international package with USPS 'International first class' is a tiny bit hard to me.

Though admittedly not difficult.

I have a t-shirt seller that claims that shipping method has a 2% loss rate for them, right on their website. Earlier on it said 'they ship them with oxen

52.55 EUR from Denmark, here in 2 days was an a competitive offer. Negligible cheaper (about 1 EUR), but much faster.

Plus, it offered both 3mm and 1.75mm in one hot-end, simply by adding another liner.

Though of course if I factor in how not-well it is working...

> hard to source in europe"

> firstly, reifsnyderb charges 3.75$ for

> international shipping and the actual hotend is

> 54,99$

>

> I too live in Europe, and have yet to see a source

> offering the hotend and shipping cheaper

Depends on how you define 'tiny bit hard'.

Dealing with customs (+19% price increase here) and waiting 4 weeks (or longer if you're in the unlucky 5%), plus the risk of an uninsured international package with USPS 'International first class' is a tiny bit hard to me.

Though admittedly not difficult.

I have a t-shirt seller that claims that shipping method has a 2% loss rate for them, right on their website. Earlier on it said 'they ship them with oxen

52.55 EUR from Denmark, here in 2 days was an a competitive offer. Negligible cheaper (about 1 EUR), but much faster.

Plus, it offered both 3mm and 1.75mm in one hot-end, simply by adding another liner.

Though of course if I factor in how not-well it is working...

|

Re: J-Head set screw - where is it supposed to be November 27, 2012 06:54AM |

Registered: 12 years ago Posts: 124 |

tprime Wrote:

-------------------------------------------------------

> > I have to call BS on "J-Heads are a tiny bit

> > hard to source in europe"

> > firstly, reifsnyderb charges 3.75$ for

> > international shipping and the actual hotend is

> > 54,99$

> >

> > I too live in Europe, and have yet to see a

> source

> > offering the hotend and shipping cheaper

>

> Depends on how you define 'tiny bit hard'.

> Dealing with customs (+19% price increase here)

> and waiting 4 weeks (or longer if you're in the

> unlucky 5%), plus the risk of an uninsured

> international package with USPS 'International

> first class' is a tiny bit hard to me.

> Though admittedly not difficult.

> I have a t-shirt seller that claims that shipping

> method has a 2% loss rate for them, right on their

> website. Earlier on it said 'they ship them with

> oxen

>

> 52.55 EUR from Denmark, here in 2 days was an a

> competitive offer. Negligible cheaper (about 1

> EUR), but much faster.

> Plus, it offered both 3mm and 1.75mm in one

> hot-end, simply by adding another liner.

>

>

>

> Though of course if I factor in how not-well it is

> working...

Sounds like you are in Germany? I am in Denmark 25% here plus various other evil fees, granted the lead time is longer, but having purchased 4 j-heads now from hotends.com I've never paid a cent of tax on any of the shipments, neither has any of my reprap-ing friends. Maybe it's the fact that it's shipped like a letter and not a parcel (securely packaged in bobblewrap) not much that can break inside even if dropped.

Who did you purchase from in Denmark, thy3d? captain-slow? reprap.me?

-------------------------------------------------------

> > I have to call BS on "J-Heads are a tiny bit

> > hard to source in europe"

> > firstly, reifsnyderb charges 3.75$ for

> > international shipping and the actual hotend is

> > 54,99$

> >

> > I too live in Europe, and have yet to see a

> source

> > offering the hotend and shipping cheaper

>

> Depends on how you define 'tiny bit hard'.

> Dealing with customs (+19% price increase here)

> and waiting 4 weeks (or longer if you're in the

> unlucky 5%), plus the risk of an uninsured

> international package with USPS 'International

> first class' is a tiny bit hard to me.

> Though admittedly not difficult.

> I have a t-shirt seller that claims that shipping

> method has a 2% loss rate for them, right on their

> website. Earlier on it said 'they ship them with

> oxen

>

> 52.55 EUR from Denmark, here in 2 days was an a

> competitive offer. Negligible cheaper (about 1

> EUR), but much faster.

> Plus, it offered both 3mm and 1.75mm in one

> hot-end, simply by adding another liner.

>

>

>

> Though of course if I factor in how not-well it is

> working...

Sounds like you are in Germany? I am in Denmark 25% here plus various other evil fees, granted the lead time is longer, but having purchased 4 j-heads now from hotends.com I've never paid a cent of tax on any of the shipments, neither has any of my reprap-ing friends. Maybe it's the fact that it's shipped like a letter and not a parcel (securely packaged in bobblewrap) not much that can break inside even if dropped.

Who did you purchase from in Denmark, thy3d? captain-slow? reprap.me?

|

Re: J-Head set screw - where is it supposed to be November 27, 2012 07:13AM |

Registered: 11 years ago Posts: 87 |

Yeah Germany. The local customs work out to a 50/50 chance in the long run for me.

(And my old V5 hotend broke, and I wanted to get back into printing and prevent the issue at the same time,

hence the emphasis on prompt delivery. Well, that went well... )

I bought it from the later shop you mentioned.

(And my old V5 hotend broke, and I wanted to get back into printing and prevent the issue at the same time,

hence the emphasis on prompt delivery. Well, that went well... )

I bought it from the later shop you mentioned.

|

Re: J-Head set screw - where is it supposed to be November 27, 2012 11:36AM |

Registered: 15 years ago Posts: 537 |

Hello,

A Mk IV-B without a setscrew to hold the PEEK in place? The Mk I had the liner held in place by the extruder (No hollow set-screw.) and the major improvement, of the Mk II, was to add the set-screw. Without the set screw, a gap can form in between the liner and brass. This could also cause problems.

If the ID, of the liner is too small, you may be able to enlarge it with a drill bit.

Regards,

Brian

tprime Wrote:

-------------------------------------------------------

> Thank for chiming in Brian - I appreciate all the

> work you put in designing these!

>

> 2. I believe I can exclude. The PTFE liner flushes

> with the top of the PEEK (no set screw) without

> forcing it, then there's basically just a plate

> above it holding it

> in place. If I take it out, by itself, it slides

> nicely along the filament.

> I've also tried adding a tamper with a pencil

> sharpener, which should give it room to expand if

> it needs to.

>

> Hm. Perhaps the ID of the liner is to small -

> large enough when cold, but constricting when it

> get's hotter?

> I gotta measure this tonight!

>

> So long,

> Tyberius Prime

A Mk IV-B without a setscrew to hold the PEEK in place? The Mk I had the liner held in place by the extruder (No hollow set-screw.) and the major improvement, of the Mk II, was to add the set-screw. Without the set screw, a gap can form in between the liner and brass. This could also cause problems.

If the ID, of the liner is too small, you may be able to enlarge it with a drill bit.

Regards,

Brian

tprime Wrote:

-------------------------------------------------------

> Thank for chiming in Brian - I appreciate all the

> work you put in designing these!

>

> 2. I believe I can exclude. The PTFE liner flushes

> with the top of the PEEK (no set screw) without

> forcing it, then there's basically just a plate

> above it holding it

> in place. If I take it out, by itself, it slides

> nicely along the filament.

> I've also tried adding a tamper with a pencil

> sharpener, which should give it room to expand if

> it needs to.

>

> Hm. Perhaps the ID of the liner is to small -

> large enough when cold, but constricting when it

> get's hotter?

> I gotta measure this tonight!

>

> So long,

> Tyberius Prime

|

Re: J-Head set screw - where is it supposed to be November 27, 2012 11:54AM |

Registered: 11 years ago Posts: 87 |

Yes indeed, it was sold as a MK IV (no  , and even listed a hollow set-screw.

, and even listed a hollow set-screw.

Unfortunately, I didn't catch on to that right away, since none of the pictures on the wiki show the top of the J-head.

I presume it's a combination of this thing not having the ridge for the line to sit on (the 'melt chamber') nor a set screw.

I keep it in place with a small aluminum plate, but that's a way worse solution than the set screw.

Thanks for all your input!

, and even listed a hollow set-screw.

, and even listed a hollow set-screw.Unfortunately, I didn't catch on to that right away, since none of the pictures on the wiki show the top of the J-head.

I presume it's a combination of this thing not having the ridge for the line to sit on (the 'melt chamber') nor a set screw.

I keep it in place with a small aluminum plate, but that's a way worse solution than the set screw.

Thanks for all your input!

|

Re: J-Head set screw - where is it supposed to be December 03, 2012 06:27AM |

Registered: 13 years ago Posts: 818 |

Hello tprime,

I bought two of these from 'RepRap me' (via eBay) and tried them at the weekend, had a similar experience to you.

I have used tens of J-heads (as far as I know all of them were made and came from Brian, via a number of UK re-sellers) and had no issues at all with any of them even after 9 months of every-day printing.

This model of the j-head design from 'RepRap me' does not have the PTFE liner set-screw fitted. The loose double barrel liners seem to work, but something is making the force required to extrude really massive even when it's clamped at the top of the nozzle with a plate, resulting in a very poor flow and extremely low speed of operation. (and a stalling and over worked Extruder motor).

They both leak (a lot) even with PTFE sealing tape they still leak after only 40+ mins of operation.

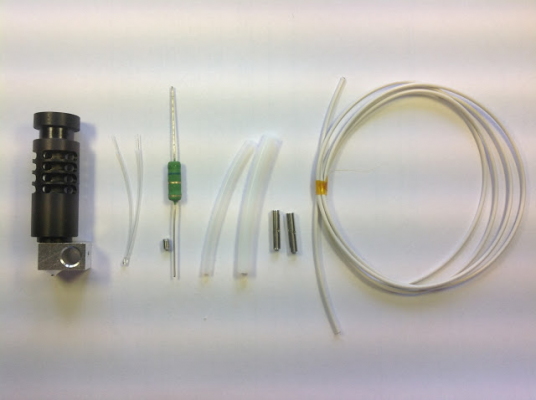

Original 'RepRap me' j-head design -

If this is your only experience of a J-head, it's not typical, I can't use this design as it stands, I'll see if 'RepRap me' has any ideas to make it work, but I doubt it.

I can add a few images I had over the weekend of the failures for both nozzles, if anyone is interested.

I have just contacted the seller on eBay and explained the problems, and also my testing results. It looks like they are aware of at least some issues, as an alternative design is also now up on eBay - anyone seen this design before? does it work?

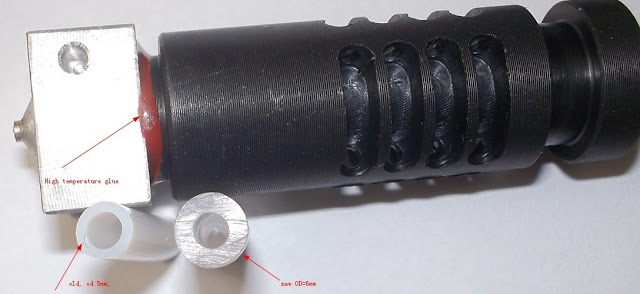

'Alternative design?' -

The alternative design is using high temperature glue around the nozzle and aluminium head, not something I would expect to see, so I guess the sealing issues may still not yet be resolved. This design also claims to have both 1.75mm and 3mm filament options so I guess as it's using a set-screw they must now have to use two different liners and not one inside the other? - If not I'm not sure how else it's going to work?

I will let you know how they respond to my questions about this alternative J-head design, and if I get a satisfactory conclusion.

Rich.

[richrap.blogspot.com]

I bought two of these from 'RepRap me' (via eBay) and tried them at the weekend, had a similar experience to you.

I have used tens of J-heads (as far as I know all of them were made and came from Brian, via a number of UK re-sellers) and had no issues at all with any of them even after 9 months of every-day printing.

This model of the j-head design from 'RepRap me' does not have the PTFE liner set-screw fitted. The loose double barrel liners seem to work, but something is making the force required to extrude really massive even when it's clamped at the top of the nozzle with a plate, resulting in a very poor flow and extremely low speed of operation. (and a stalling and over worked Extruder motor).

They both leak (a lot) even with PTFE sealing tape they still leak after only 40+ mins of operation.

Original 'RepRap me' j-head design -

If this is your only experience of a J-head, it's not typical, I can't use this design as it stands, I'll see if 'RepRap me' has any ideas to make it work, but I doubt it.

I can add a few images I had over the weekend of the failures for both nozzles, if anyone is interested.

I have just contacted the seller on eBay and explained the problems, and also my testing results. It looks like they are aware of at least some issues, as an alternative design is also now up on eBay - anyone seen this design before? does it work?

'Alternative design?' -

The alternative design is using high temperature glue around the nozzle and aluminium head, not something I would expect to see, so I guess the sealing issues may still not yet be resolved. This design also claims to have both 1.75mm and 3mm filament options so I guess as it's using a set-screw they must now have to use two different liners and not one inside the other? - If not I'm not sure how else it's going to work?

I will let you know how they respond to my questions about this alternative J-head design, and if I get a satisfactory conclusion.

Rich.

[richrap.blogspot.com]

|

Re: J-Head set screw - where is it supposed to be December 03, 2012 06:53AM |

Registered: 11 years ago Posts: 87 |

@Rich: Reprap.me has offered to replace the j-head for one with the set screw, presumably because the ebay auction claimed it had one and I pointed this out under the danish 'right of complaint' law.

I'm still not certain what's actually wrong with the first one if you clamp the teflon liner externally.

Perhaps it's cut too short for that.

The PTFE liner on the alternative design looks awfully short as well.

We'll see if it has a 'melt chamber'/ridge for the liner to sit.

The thermal glue has me worried - I don't think that you can dismantle and reassemble this thing in

case of jam.

I'll report back once the replacement is here.

I'm still not certain what's actually wrong with the first one if you clamp the teflon liner externally.

Perhaps it's cut too short for that.

The PTFE liner on the alternative design looks awfully short as well.

We'll see if it has a 'melt chamber'/ridge for the liner to sit.

The thermal glue has me worried - I don't think that you can dismantle and reassemble this thing in

case of jam.

I'll report back once the replacement is here.

|

Re: J-Head set screw - where is it supposed to be December 03, 2012 07:15AM |

Registered: 12 years ago Posts: 156 |

There's article on jheadnozzle blog about some design from ebay, looking similar to your's. It points out so there's also problem with heater block design.

Quote

jheadnozzle

There are 3 major problems with it, however. The first is that the interior is based upon the original design and does not have a melt chamber section. So, the liner goes all the way to the tip. Another issue is that the nozzle orifice is supposed to be 0.50mm; however, it is closer to 0.53mm in diameter. The final issue is that the nozzle orifice length is a whopping 3mm long. I would bet that the extrusion pressure is pretty high.

|

Re: J-Head set screw - where is it supposed to be December 03, 2012 08:52AM |

Registered: 13 years ago Posts: 818 |

@tprime - Thanks for the update. 'RepRap me' has refused to refund or replace them for me, stating the 14 day period has expired, this is true, but these devices simply do not work as implied by the good name they are using to promote (J-head). They are certainly not like any j-head I have ever used.

I sent another two messages via eBay, pointing out the statement that a hollow set screw is in the description, but not fitted or even designed into the product. I have asked them to reconsider. If I still do not get any success I'll take it further.

I't a shame, I have bought things in the past from them, and didn't expect such poor service when there is a clear problem with a product they have shipped out to many people.

I'll let you know how this pans out.

@miso - Thanks for the article link. This at least explains why the extrusion force is so extremely high. This hot-end is basically useless in it's design, I can't imagine anyone being able to print with it, or wanting to wait while it slowly extrudes and eventually leaks.

I have just placed an order directly with Brian at Hotends.com, for three nozzles of his newer MK V-BV design, I have total faith in Brian, so I'm sure this will get me back on track for my new machine prototypes.

For the record the reasons I was tempted to try them out were - Aluminium nozzle (light-weight) and 1.75mm filament option (these two combinations have been hard to get over here in the UK)

Very disappointed with 'RepRap.me' - This one is not over yet.

Rich.

[richrap.blogspot.com]

I sent another two messages via eBay, pointing out the statement that a hollow set screw is in the description, but not fitted or even designed into the product. I have asked them to reconsider. If I still do not get any success I'll take it further.

I't a shame, I have bought things in the past from them, and didn't expect such poor service when there is a clear problem with a product they have shipped out to many people.

I'll let you know how this pans out.

@miso - Thanks for the article link. This at least explains why the extrusion force is so extremely high. This hot-end is basically useless in it's design, I can't imagine anyone being able to print with it, or wanting to wait while it slowly extrudes and eventually leaks.

I have just placed an order directly with Brian at Hotends.com, for three nozzles of his newer MK V-BV design, I have total faith in Brian, so I'm sure this will get me back on track for my new machine prototypes.

For the record the reasons I was tempted to try them out were - Aluminium nozzle (light-weight) and 1.75mm filament option (these two combinations have been hard to get over here in the UK)

Very disappointed with 'RepRap.me' - This one is not over yet.

Rich.

[richrap.blogspot.com]

|

Re: J-Head set screw - where is it supposed to be December 03, 2012 09:25AM |

Registered: 11 years ago Posts: 87 |

@Rich: Sorry to hear that you're having trouble returning them. He hasn't much choice under EU consumer protection laws though.

Magic words seem to be 'right of complaint', 'not as advertised' and (and fixing a time limit).

The extrusion hole being too long might be the issue - can't measure mine any more . I guess it could be salvageable by increasing

. I guess it could be salvageable by increasing

the drill depth on the other side. I also presume the extreme force necessary influences the leaking.

I'm going to spend some time experimenting with the 'organ pipe hotend' while waiting for my replacement - and

if that one doesn't work out either, I'll bite the bullet on importing from the US.

Magic words seem to be 'right of complaint', 'not as advertised' and (and fixing a time limit).

The extrusion hole being too long might be the issue - can't measure mine any more

. I guess it could be salvageable by increasing

. I guess it could be salvageable by increasingthe drill depth on the other side. I also presume the extreme force necessary influences the leaking.

I'm going to spend some time experimenting with the 'organ pipe hotend' while waiting for my replacement - and

if that one doesn't work out either, I'll bite the bullet on importing from the US.

|

Re: J-Head set screw - where is it supposed to be December 03, 2012 10:03AM |

Registered: 13 years ago Posts: 818 |

@tprime - After two further messages I had a message back from 'RepRap.me' offering a refund if I return them, which I will do tomorrow. I will update this when I get my refund or if I get any other issues.

The high pressure required for this design makes it impossible for practical use. I was running a geared NEMA17 stepper at 1.3A and with 1.75mm filament, it would skip steps at speeds above about 15mm/sec (Extremely slow). and then leak.

If you plan to run a direct drive stepper extruder, NEMA14 motor or 3mm filament, you basically have no chance at sensible extrusion speed with this design.

And this is going to be why the hot-end leaks, even at low speeds.

People will try to increase the temperature to overcome the pressure problem, but this just makes the problem worse and the plastic more runny, it will just leak faster.

A 'normal' MK-IV J-Head can extrude at +80mm/sec with a 0.4 or 0.5mm nozzle, 3mm filament and a Nema17 stepper set to under 1A without any problems at all.

Well, lessons learnt here, I hope I do get my refund...

Everyone else beware of these hot-ends - if they are coming out of China (or anywhere else) without any real-world testing before shipping an unproved design, this is what you get, along with a lot of people in the supply chain also very unhappy.

Happy extruding everyone.

Rich.

[richrap.blogspot.com]

The high pressure required for this design makes it impossible for practical use. I was running a geared NEMA17 stepper at 1.3A and with 1.75mm filament, it would skip steps at speeds above about 15mm/sec (Extremely slow). and then leak.

If you plan to run a direct drive stepper extruder, NEMA14 motor or 3mm filament, you basically have no chance at sensible extrusion speed with this design.

And this is going to be why the hot-end leaks, even at low speeds.

People will try to increase the temperature to overcome the pressure problem, but this just makes the problem worse and the plastic more runny, it will just leak faster.

A 'normal' MK-IV J-Head can extrude at +80mm/sec with a 0.4 or 0.5mm nozzle, 3mm filament and a Nema17 stepper set to under 1A without any problems at all.

Well, lessons learnt here, I hope I do get my refund...

Everyone else beware of these hot-ends - if they are coming out of China (or anywhere else) without any real-world testing before shipping an unproved design, this is what you get, along with a lot of people in the supply chain also very unhappy.

Happy extruding everyone.

Rich.

[richrap.blogspot.com]

|

Re: J-Head set screw - where is it supposed to be December 03, 2012 12:19PM |

Registered: 12 years ago Posts: 124 |

richrap Wrote:

-------------------------------------------------------

> @tprime - After two further messages I had a

> message back from 'RepRap.me' offering a refund if

> I return them, which I will do tomorrow. I will

> update this when I get my refund or if I get any

> other issues.

>

> The high pressure required for this design makes

> it impossible for practical use. I was running a

> geared NEMA17 stepper at 1.3A and with 1.75mm

> filament, it would skip steps at speeds above

> about 15mm/sec (Extremely slow). and then leak.

>

> If you plan to run a direct drive stepper

> extruder, NEMA14 motor or 3mm filament, you

> basically have no chance at sensible extrusion

> speed with this design.

>

> And this is going to be why the hot-end leaks,

> even at low speeds.

>

> People will try to increase the temperature to

> overcome the pressure problem, but this just makes

> the problem worse and the plastic more runny, it

> will just leak faster.

>

>

> A 'normal' MK-IV J-Head can extrude at +80mm/sec

> with a 0.4 or 0.5mm nozzle, 3mm filament and a

> Nema17 stepper set to under 1A without any

> problems at all.

>

> Well, lessons learnt here, I hope I do get my

> refund...

>

> Everyone else beware of these hot-ends - if they

> are coming out of China (or anywhere else) without

> any real-world testing before shipping an unproved

> design, this is what you get, along with a lot of

> people in the supply chain also very unhappy.

>

> Happy extruding everyone.

>

> Rich.

[forums.reprap.org]

[groups.google.com]

maybe it's time to give reprap.me bad reviews on the wiki?

-------------------------------------------------------

> @tprime - After two further messages I had a

> message back from 'RepRap.me' offering a refund if

> I return them, which I will do tomorrow. I will

> update this when I get my refund or if I get any

> other issues.

>

> The high pressure required for this design makes

> it impossible for practical use. I was running a

> geared NEMA17 stepper at 1.3A and with 1.75mm

> filament, it would skip steps at speeds above

> about 15mm/sec (Extremely slow). and then leak.

>

> If you plan to run a direct drive stepper

> extruder, NEMA14 motor or 3mm filament, you

> basically have no chance at sensible extrusion

> speed with this design.

>

> And this is going to be why the hot-end leaks,

> even at low speeds.

>

> People will try to increase the temperature to

> overcome the pressure problem, but this just makes

> the problem worse and the plastic more runny, it

> will just leak faster.

>

>

> A 'normal' MK-IV J-Head can extrude at +80mm/sec

> with a 0.4 or 0.5mm nozzle, 3mm filament and a

> Nema17 stepper set to under 1A without any

> problems at all.

>

> Well, lessons learnt here, I hope I do get my

> refund...

>

> Everyone else beware of these hot-ends - if they

> are coming out of China (or anywhere else) without

> any real-world testing before shipping an unproved

> design, this is what you get, along with a lot of

> people in the supply chain also very unhappy.

>

> Happy extruding everyone.

>

> Rich.

[forums.reprap.org]

[groups.google.com]

maybe it's time to give reprap.me bad reviews on the wiki?

|

Re: J-Head set screw - where is it supposed to be December 11, 2012 06:23PM |

Registered: 11 years ago Posts: 87 |

My replacement arrived. It now has a set screw, it does not show the red thermal glue seen in some photos - and it still requires way too much force to extrude.

As for the 1.75 conversion, apperantly there is no second set screw, but simply a longer piece of inner tubing. I don't quite see how that's supposed to work.

As for the 1.75 conversion, apperantly there is no second set screw, but simply a longer piece of inner tubing. I don't quite see how that's supposed to work.

|

Re: J-Head set screw - where is it supposed to be December 18, 2012 08:00AM |

Registered: 13 years ago Posts: 818 |

Hi tprime - An update from me on this -

I had my full refund from Peter at reprap.me (snipermand on eBay).

Peter is aware of the issues and is discussing these with his supplier. I have also made Peter aware that only adding the set screw does not resolve most of the fundamental issues with this hot-end design, the main problem is still the extremely long internal nozzle length of around 3mm - it should be more like 0.5mm for any level of sensible extrusion speed being driven by most normal extruders.

Let us know how well the replacement works for you, If the nozzle hole is still very long you will be very speed limited and may still get leaks if you push it too hard.

Hot-ends are not all about speed, I'm very happy to see a slower speed hot-end that has less ooze and die swell. But general purpose hot-ends need to be able to print reasonably fast at this stage in the game.

My official J-head MK V-BV order also arrived from Brian at www.hotends.com - these are fantastic, slightly shorter and lighter than all the previous versions I have used to-date, very well made and clean machining all over.

The nipple end is also gone, this is another good move and should generally give less problems when printing.

I'm using a cartridge heater and thermocouple, gets up to temperature in about 18 seconds. (Remember to run M303 to calibrate your new hot-end PID settings everyone).

I now have the 0.4mm MK V-BV nozzle (1.75mm filament) currently fitted into a Rostock, printing VERY fast, so as soon as I get that settled in I'll post a few pictures.

I have a 0.35mm version (1.75mm) I'm going to use for an upgrade in the Tantilus. And finally a 0.5mm version for a new machine.

Printing over Christmas should give them a very good test, but already I'm impressed with it's performance in Rostock (bowden configuration)

With metal pulleys, good belts and a strong frame, most DIY 3D printers are now good enough to get excellent results by many people, the hot-end, extruder and filament drive mechanism are still (in my opinion) the most critical part of most 3D printers, make sure you choose well and if in doubt ask others how well they perform for what you want to do with them.

When you get something that seems to work well, you can start to compare alternatives, don't assume what you have is the best it can be. I would hope anyone developing hot-ends does some real research and at least benchmarks against some designs the community feel to be working well before releasing them for sale.

Rich.

[richrap.blogspot.com]

I had my full refund from Peter at reprap.me (snipermand on eBay).

Peter is aware of the issues and is discussing these with his supplier. I have also made Peter aware that only adding the set screw does not resolve most of the fundamental issues with this hot-end design, the main problem is still the extremely long internal nozzle length of around 3mm - it should be more like 0.5mm for any level of sensible extrusion speed being driven by most normal extruders.

Let us know how well the replacement works for you, If the nozzle hole is still very long you will be very speed limited and may still get leaks if you push it too hard.

Hot-ends are not all about speed, I'm very happy to see a slower speed hot-end that has less ooze and die swell. But general purpose hot-ends need to be able to print reasonably fast at this stage in the game.

My official J-head MK V-BV order also arrived from Brian at www.hotends.com - these are fantastic, slightly shorter and lighter than all the previous versions I have used to-date, very well made and clean machining all over.

The nipple end is also gone, this is another good move and should generally give less problems when printing.

I'm using a cartridge heater and thermocouple, gets up to temperature in about 18 seconds. (Remember to run M303 to calibrate your new hot-end PID settings everyone).

I now have the 0.4mm MK V-BV nozzle (1.75mm filament) currently fitted into a Rostock, printing VERY fast, so as soon as I get that settled in I'll post a few pictures.

I have a 0.35mm version (1.75mm) I'm going to use for an upgrade in the Tantilus. And finally a 0.5mm version for a new machine.

Printing over Christmas should give them a very good test, but already I'm impressed with it's performance in Rostock (bowden configuration)

With metal pulleys, good belts and a strong frame, most DIY 3D printers are now good enough to get excellent results by many people, the hot-end, extruder and filament drive mechanism are still (in my opinion) the most critical part of most 3D printers, make sure you choose well and if in doubt ask others how well they perform for what you want to do with them.

When you get something that seems to work well, you can start to compare alternatives, don't assume what you have is the best it can be. I would hope anyone developing hot-ends does some real research and at least benchmarks against some designs the community feel to be working well before releasing them for sale.

Rich.

[richrap.blogspot.com]

|

Re: J-Head set screw - where is it supposed to be December 18, 2012 09:31AM |

Registered: 11 years ago Posts: 87 |

|

Re: J-Head set screw - where is it supposed to be December 30, 2012 06:09PM |

Registered: 11 years ago Posts: 87 |

Sorry, only registered users may post in this forum.