Hello from a newcomer, and opening thoughts.

Posted by xclusive585

|

Hello from a newcomer, and opening thoughts. November 28, 2012 12:26PM |

Registered: 11 years ago Posts: 374 |

Hello, I'm new here and new to Reprap besides the months of planning I've been doing and purchising kits and parts.

I have everything I need to assemble my reprap minus a piece of glass for the heatbed, and some shrinktube or similar. So I have recently moved on to the firmware phase and initial bench testing.

My setup:

Prusa

Ramps 1.4 mega2560 kit (reprapdiscount) with ultimaker click-encoder/SD reader

Marlin firmware

Linux Mint currently limits my baud to 115200, not Marlins 250000 default. (This problem is solvable in certain cases, I haven't got that far yet and am not concerned about this issue yet)

For my inital testing Im using nothing but the Ramps and the click-encoder panel, and the USB connection. Nothing else is wired to the Ramps yet, nothing.

I have setup the firmware for my hardware, compiled and uploaded it, several times. It goes well and seems to work. I can connect to the Ramps from Pronterface at 115,200, of course I get errors about temps as I have nothing wired yet ;-). Everything seems great so far, except for one strange issue. There seems to be a huge amount of noise affecting the ultimaker click encoder and speaker. The encoder works with unreliable results, as well as seems to be changing selections without being touched, and the speaker emits varying high pitched squeels that change coinciding with changes on the LCD.

So I'm thinking one of three things here. Either the Ramps and Firmware is acting up because there is nothing hooked up to it, no motors thermistors, endstops, or heaters. Or the click-encoder panel has a short on it or other issue. Or my firmware has some setting that needs to be changed from the defaults, for this very generic kit I don't think that's likely.

Compiling the firmware for use with the LCD withOUT the click-encoder, seems 100% normal. I have no noise from the speaker, and no weird happenings with the LCD, and no controller to be ghost-controlled. But, I'd really like to use the click-encoder for free-standing operation...

My next step will be to fully assemble the electronics, and tune the pots on the drivers etc. After I do this I will try my firmware again and hope for better results from the panel and hopefully no noise.

Any thoughts or experience with the click-encoder panel, and noise/ strange operation? Am I just jumping the gun here and it may work fine once the electronics are all wired?

-Dave

I have everything I need to assemble my reprap minus a piece of glass for the heatbed, and some shrinktube or similar. So I have recently moved on to the firmware phase and initial bench testing.

My setup:

Prusa

Ramps 1.4 mega2560 kit (reprapdiscount) with ultimaker click-encoder/SD reader

Marlin firmware

Linux Mint currently limits my baud to 115200, not Marlins 250000 default. (This problem is solvable in certain cases, I haven't got that far yet and am not concerned about this issue yet)

For my inital testing Im using nothing but the Ramps and the click-encoder panel, and the USB connection. Nothing else is wired to the Ramps yet, nothing.

I have setup the firmware for my hardware, compiled and uploaded it, several times. It goes well and seems to work. I can connect to the Ramps from Pronterface at 115,200, of course I get errors about temps as I have nothing wired yet ;-). Everything seems great so far, except for one strange issue. There seems to be a huge amount of noise affecting the ultimaker click encoder and speaker. The encoder works with unreliable results, as well as seems to be changing selections without being touched, and the speaker emits varying high pitched squeels that change coinciding with changes on the LCD.

So I'm thinking one of three things here. Either the Ramps and Firmware is acting up because there is nothing hooked up to it, no motors thermistors, endstops, or heaters. Or the click-encoder panel has a short on it or other issue. Or my firmware has some setting that needs to be changed from the defaults, for this very generic kit I don't think that's likely.

Compiling the firmware for use with the LCD withOUT the click-encoder, seems 100% normal. I have no noise from the speaker, and no weird happenings with the LCD, and no controller to be ghost-controlled. But, I'd really like to use the click-encoder for free-standing operation...

My next step will be to fully assemble the electronics, and tune the pots on the drivers etc. After I do this I will try my firmware again and hope for better results from the panel and hopefully no noise.

Any thoughts or experience with the click-encoder panel, and noise/ strange operation? Am I just jumping the gun here and it may work fine once the electronics are all wired?

-Dave

|

Re: Hello from a newcomer, and opening thoughts. November 28, 2012 01:24PM |

Registered: 12 years ago Posts: 1,611 |

Marlin generally disables itself if no hot end thermistor is attached. You may get unexpected results because of this, even with the encoder. Try hooking up a thermistor to the RAMPS board, then retest. Also, when attaching things to the board, put one thing on at a time, and test it, rather than all at once. And do not plug in/unplug motors or stepper drivers if the board is powered up. And make sure the stepper drivers are delivering only 1A to the motors before plugging them in! [reprap.org] (RepRapDiscount driver boards are exact copies of the Pololu board)

|

Re: Hello from a newcomer, and opening thoughts. November 29, 2012 08:24PM |

Registered: 11 years ago Posts: 374 |

So the noise from the buzzer and malfunctioning encoder, was simply an oversight on my part, I missed a couple changes in my pins.h. Once I made the changes in the firmware and uploaded it again it was smooth sailing.

Bench tested everything tonight, and the motors are doing fine at well under 1A, so far so good. I guess now it's just time to build this thing. :-D

I'm sure I'll update when I'm done, and I know when I get into printing with it I will have many questions.

-Dave

Bench tested everything tonight, and the motors are doing fine at well under 1A, so far so good. I guess now it's just time to build this thing. :-D

I'm sure I'll update when I'm done, and I know when I get into printing with it I will have many questions.

-Dave

|

Re: Hello from a newcomer, and opening thoughts. January 05, 2013 02:38AM |

Registered: 11 years ago Posts: 374 |

OK.

I've built the thing, and I've now had over a week of printing and many prints.

On my second day I got a .1mm yoda bust off, looked mint. Any parts with round edges come out mint. My sizes are close enough to perfect to keep me happy. All in all, this thing went together almost too nicely.

I do .25mm slices typically. Using slic3r/pronterface on a prusa lm8uu. Marlin firmware, Ramps 1.4.

Now, here's the issues I cannot seem to get past:

1.) oozing and retraction..... GRRRRR. What gives.

I have a J-head with .35mm tip, and I'm pushing 3mm PLA. Wade's/Greg's. Everything I've learned and read around the community tells me 1mm retraction should be more than enough with this hotend. 1mm is NOT enough. With 1mm retraction the head will never leave the surface cleanly. At about 1.5mm retraction the head leaves edges cleanly with only a few very fine hairs left here and there, sounds good right? Wrong. Even at 1.5 mm retraction, filament starts oozing out before the head returns to the work surface, leaving filament all over the place, but only as the head returns, not as it leaves. Even by the end of a non print travel across the infill from one edge to another, PLA will start extruding onto the infill.

Even 2mm retraction only gives me about 1 second until filament has started to protrude from the tip again. Ive played with temps from my absolute minimum before the extruder struggles and strips the filament (165c) up to my max where the PLA starts to become liquid (190c), no joy. <-This is an example of what it looks like at 1mm retraction, not enough retraction to even allow the tip to leave an edge cleanly.

There is always a huge amount of backpressure in my hotend, I definitely think this contributes to the problem. (There is a nipple on this hotend, are the tips without nipples that much better at not keeping pressure built up?)

Ideas?

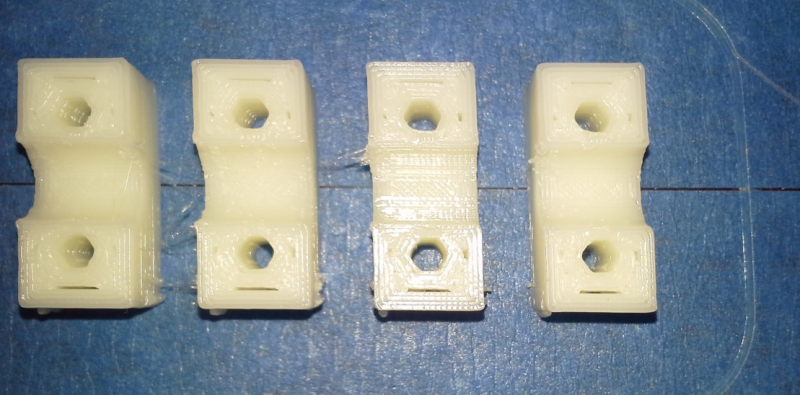

2.) Square corners... Another WTH I cannot figure out.

Round edges come out great, points come out pointy, but try to do a square and those corners get ugly. And Im not talking about issues from z-lift, this happens on corners that are laid down while printing the perimeter of a layer. See look at the corners and how the filament bows out at the corners, almost as if the extruder is not slowing down enough for the turn (or almost as if there's too much back pressure for it to slow down...) You can see this on the left of pic "number2" as well.

Ideas?

3) Slic3r's toolpath... WTH

I love the software, skeinforge is dated and even as someone who is comfortable in a bash shell, it looks scary to me as a newcomer to 3d printing. ;-)

I really do like slicer. that said, why must it constantly drag my hotend over parts of the layer it has already printed, I mean seriously? I understand the shortest distance between two points is a straight line, but maybe theres a better two points to be travelling from/to.

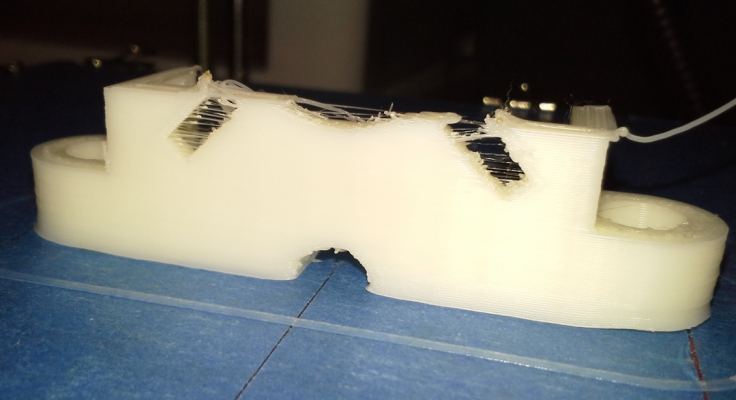

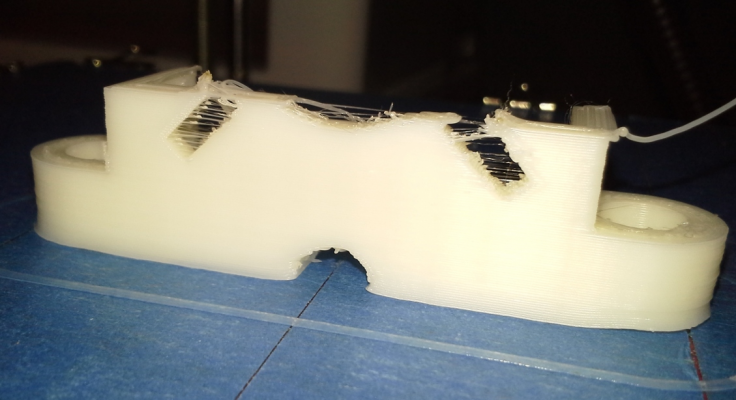

Here's why it's been a huge problem for me, the tip of the hotend drags on the layer it's just printed, as if the layer is somehow higher than the bottom of the hotend. This confuses me, as I would think the pla would shrink a little as it cools, not expand. So when I have two separate parts, or a gap in a single part, man does that tip whack the part hard. Really hard. Enough where it will cause my motor (and I'd argue anyone's motor) to skip steps. The first run of was ruined by this happening, the tip was whacking every edge as it travelled around and after a little while of that I of course ran into skipped steps. The second time through I sat there and cringed as it whacked away but luckily didn't miss any steps on that run. The same thing happened to this single part , due to the gaps in the part. You can see how the point over the motor screw slot is lifted, that happened from repeated hitting of the head against it, which ultimately after lifting it little by little ended in a 1/2" skip of my Y, ruining the print.

Yes, let's discuss z-lift, and how it's really not an option on my machine until I get better lm8uus and technically from a machine standpoint if you arent using an acme thread setup it's a horrible idea IMHO. In my case, my cheap lm8uus bind at random, sometimes so bad they can hold the entire x axis up and allow my nuts to ride out of the bottom (my other axis' bearings bind too but the motors are strong enough to power through it, gravity is not (I have to watch my z everytime it homes and often tap a side if it's bearings bind)), if my z bearings bound up before my z dropped back down to print, I would have a pretty ugly print. So z-lift while it probably would solve this problem, I cannot even try yet until better bearings, and even then the threaded rod/nut setup is not ideal... Any other ideas to keep this collision between my hotend and parts from happening without using z-lift?

If I can get over these hurdles my machine will be in pretty decent shape, I just don't wanna spend a fortune to get it there.

Any help is appreciated and sorry for the long winded ramblings but I'm trying to explain everything as clearly as possible.

-Dave

Edited 2 time(s). Last edit at 01/05/2013 03:21AM by xclusive585.

I've built the thing, and I've now had over a week of printing and many prints.

On my second day I got a .1mm yoda bust off, looked mint. Any parts with round edges come out mint. My sizes are close enough to perfect to keep me happy. All in all, this thing went together almost too nicely.

I do .25mm slices typically. Using slic3r/pronterface on a prusa lm8uu. Marlin firmware, Ramps 1.4.

Now, here's the issues I cannot seem to get past:

1.) oozing and retraction..... GRRRRR. What gives.

I have a J-head with .35mm tip, and I'm pushing 3mm PLA. Wade's/Greg's. Everything I've learned and read around the community tells me 1mm retraction should be more than enough with this hotend. 1mm is NOT enough. With 1mm retraction the head will never leave the surface cleanly. At about 1.5mm retraction the head leaves edges cleanly with only a few very fine hairs left here and there, sounds good right? Wrong. Even at 1.5 mm retraction, filament starts oozing out before the head returns to the work surface, leaving filament all over the place, but only as the head returns, not as it leaves. Even by the end of a non print travel across the infill from one edge to another, PLA will start extruding onto the infill.

Even 2mm retraction only gives me about 1 second until filament has started to protrude from the tip again. Ive played with temps from my absolute minimum before the extruder struggles and strips the filament (165c) up to my max where the PLA starts to become liquid (190c), no joy. <-This is an example of what it looks like at 1mm retraction, not enough retraction to even allow the tip to leave an edge cleanly.

There is always a huge amount of backpressure in my hotend, I definitely think this contributes to the problem. (There is a nipple on this hotend, are the tips without nipples that much better at not keeping pressure built up?)

Ideas?

2.) Square corners... Another WTH I cannot figure out.

Round edges come out great, points come out pointy, but try to do a square and those corners get ugly. And Im not talking about issues from z-lift, this happens on corners that are laid down while printing the perimeter of a layer. See look at the corners and how the filament bows out at the corners, almost as if the extruder is not slowing down enough for the turn (or almost as if there's too much back pressure for it to slow down...) You can see this on the left of pic "number2" as well.

Ideas?

3) Slic3r's toolpath... WTH

I love the software, skeinforge is dated and even as someone who is comfortable in a bash shell, it looks scary to me as a newcomer to 3d printing. ;-)

I really do like slicer. that said, why must it constantly drag my hotend over parts of the layer it has already printed, I mean seriously? I understand the shortest distance between two points is a straight line, but maybe theres a better two points to be travelling from/to.

Here's why it's been a huge problem for me, the tip of the hotend drags on the layer it's just printed, as if the layer is somehow higher than the bottom of the hotend. This confuses me, as I would think the pla would shrink a little as it cools, not expand. So when I have two separate parts, or a gap in a single part, man does that tip whack the part hard. Really hard. Enough where it will cause my motor (and I'd argue anyone's motor) to skip steps. The first run of was ruined by this happening, the tip was whacking every edge as it travelled around and after a little while of that I of course ran into skipped steps. The second time through I sat there and cringed as it whacked away but luckily didn't miss any steps on that run. The same thing happened to this single part , due to the gaps in the part. You can see how the point over the motor screw slot is lifted, that happened from repeated hitting of the head against it, which ultimately after lifting it little by little ended in a 1/2" skip of my Y, ruining the print.

Yes, let's discuss z-lift, and how it's really not an option on my machine until I get better lm8uus and technically from a machine standpoint if you arent using an acme thread setup it's a horrible idea IMHO. In my case, my cheap lm8uus bind at random, sometimes so bad they can hold the entire x axis up and allow my nuts to ride out of the bottom (my other axis' bearings bind too but the motors are strong enough to power through it, gravity is not (I have to watch my z everytime it homes and often tap a side if it's bearings bind)), if my z bearings bound up before my z dropped back down to print, I would have a pretty ugly print. So z-lift while it probably would solve this problem, I cannot even try yet until better bearings, and even then the threaded rod/nut setup is not ideal... Any other ideas to keep this collision between my hotend and parts from happening without using z-lift?

If I can get over these hurdles my machine will be in pretty decent shape, I just don't wanna spend a fortune to get it there.

Any help is appreciated and sorry for the long winded ramblings but I'm trying to explain everything as clearly as possible.

-Dave

Edited 2 time(s). Last edit at 01/05/2013 03:21AM by xclusive585.

|

Re: Hello from a newcomer, and opening thoughts. January 05, 2013 09:38AM |

Registered: 12 years ago Posts: 539 |

|

Re: Hello from a newcomer, and opening thoughts. January 05, 2013 02:13PM |

Registered: 11 years ago Posts: 374 |

Idolcrasher Wrote:

-------------------------------------------------------

> Start with slic3r 9.1 until something newer than

> 9.7 comes out. There are some nasty bugs in

> Slic3r 9.2 - 9.7

Just spent some time reading up on your comments and others on github.

I see that my corner pimples may be an issue of my slic3r version, which you somehow knew I'm using 9.7 by looking at my print ;-)

However, I see no one else seems to be complaining of their nozzle hitting edges of parts hard as it travels around between parts and islands of the same part... So how is it that I'm the only one unlucky enough to have slic3r's toolpath whacking edges hard. Is there something I should be considering here like is it possible I'm extruding too much? (all calibrations point to my extrusion being pretty optimal)

-------------------------------------------------------

> Start with slic3r 9.1 until something newer than

> 9.7 comes out. There are some nasty bugs in

> Slic3r 9.2 - 9.7

Just spent some time reading up on your comments and others on github.

I see that my corner pimples may be an issue of my slic3r version, which you somehow knew I'm using 9.7 by looking at my print ;-)

However, I see no one else seems to be complaining of their nozzle hitting edges of parts hard as it travels around between parts and islands of the same part... So how is it that I'm the only one unlucky enough to have slic3r's toolpath whacking edges hard. Is there something I should be considering here like is it possible I'm extruding too much? (all calibrations point to my extrusion being pretty optimal)

|

Re: Hello from a newcomer, and opening thoughts. January 05, 2013 11:00PM |

Registered: 11 years ago Posts: 40 |

|

Re: Hello from a newcomer, and opening thoughts. January 05, 2013 11:30PM |

Registered: 11 years ago Posts: 374 |

Airtripper Wrote:

-------------------------------------------------------

> I think your fine printing ambitions is probably

> better suited using 1.75mm filament. You're trying

> to manipulate a large amount of melted plastic to

> control a tiny output.

>

> See if increasing the layer height makes a

> difference.

I will give it a shot, why not. But with a .35mm tip, is .25 layer height not the optimal layer height?

So I tried the part from again (same picture as taking a new one makes no sense as it looked the same and did the same thing). This time I placed it at a 45 degree angle. My thought was since the infill runs in relation to the build surface, maybe the hotend travel would too, and I could avoid the nasty collisions with the tips of the diagonal motor bolt holes. I was wrong. The tip travels still ran exactly the same in relation to the part, and as soon as I got towards the top of the bottom set of motor mount holes, I had exactly the same issue, the tip cought the thin end of the top layer right over the diagonal slots and BANG. Another print ruined because slicer wants to do all perimeters and then go back and fill, why the hell can't [slic3r] complete each island before moving on to the next, so that it doesnt have to bang into the perimeter to pass over it to fill. Why why why. I'm getting horribly frustrated at this point.

How do other people pull off this print without this issue???

Edited 2 time(s). Last edit at 01/05/2013 11:36PM by xclusive585.

-------------------------------------------------------

> I think your fine printing ambitions is probably

> better suited using 1.75mm filament. You're trying

> to manipulate a large amount of melted plastic to

> control a tiny output.

>

> See if increasing the layer height makes a

> difference.

I will give it a shot, why not. But with a .35mm tip, is .25 layer height not the optimal layer height?

So I tried the part from again (same picture as taking a new one makes no sense as it looked the same and did the same thing). This time I placed it at a 45 degree angle. My thought was since the infill runs in relation to the build surface, maybe the hotend travel would too, and I could avoid the nasty collisions with the tips of the diagonal motor bolt holes. I was wrong. The tip travels still ran exactly the same in relation to the part, and as soon as I got towards the top of the bottom set of motor mount holes, I had exactly the same issue, the tip cought the thin end of the top layer right over the diagonal slots and BANG. Another print ruined because slicer wants to do all perimeters and then go back and fill, why the hell can't [slic3r] complete each island before moving on to the next, so that it doesnt have to bang into the perimeter to pass over it to fill. Why why why. I'm getting horribly frustrated at this point.

How do other people pull off this print without this issue???

Edited 2 time(s). Last edit at 01/05/2013 11:36PM by xclusive585.

|

Re: Hello from a newcomer, and opening thoughts. January 06, 2013 08:32AM |

Registered: 11 years ago Posts: 40 |

The nozzle temperature may not be high enough, causing the filament to be stretched across the surface. The filament will pull at the edges as it cools, overhangs being most vulnerable causing them to curl up.

You can see around the base of your print where the edges have lifted, if you can keep the base flat on on the bed, the rest of the print should finish without a hitch.

Increasing the nozzle temperature might do the trick. Also, making sure the feed rate and flow rate is properly calibrated. I've extruded PLA with temperatures as high as 220 degrees to cure really bad warping and edge curls with some filament types.

You can see around the base of your print where the edges have lifted, if you can keep the base flat on on the bed, the rest of the print should finish without a hitch.

Increasing the nozzle temperature might do the trick. Also, making sure the feed rate and flow rate is properly calibrated. I've extruded PLA with temperatures as high as 220 degrees to cure really bad warping and edge curls with some filament types.

|

Re: Hello from a newcomer, and opening thoughts. January 06, 2013 05:14PM |

Registered: 11 years ago Posts: 76 |

"nozzle hitting edges of parts hard as it travels around between parts and islands of the same part... "

I used to have this issue as well but don't seem to suffer now, the two things I changed in the interim (I know I should have only changed one then I'd know what really caused the problem!) were:

Cooling : I have two fans blowing on the print from North and South and I slightly reduced bed temperature - my feeling is that the PLA now cools faster so doesn't get tugged into peaks by the moving head which then causes problems the next time the head comes around.

Width : I started with Slic3r calculating the filament width/height ratio automatically (which gave me a 0.58 mm width on my 0.4 mm head and 0.21 mm layer height); I've now changed Slic3r to force the layer height ratio to give me a 0.4 mm width.

I'd be interested to know if either of these work for you.

I used to have this issue as well but don't seem to suffer now, the two things I changed in the interim (I know I should have only changed one then I'd know what really caused the problem!) were:

Cooling : I have two fans blowing on the print from North and South and I slightly reduced bed temperature - my feeling is that the PLA now cools faster so doesn't get tugged into peaks by the moving head which then causes problems the next time the head comes around.

Width : I started with Slic3r calculating the filament width/height ratio automatically (which gave me a 0.58 mm width on my 0.4 mm head and 0.21 mm layer height); I've now changed Slic3r to force the layer height ratio to give me a 0.4 mm width.

I'd be interested to know if either of these work for you.

Sorry, only registered users may post in this forum.