Price of child reprap

Posted by David Iscool

|

Price of child reprap September 18, 2008 03:06PM |

|

Re: Price of child reprap September 18, 2008 03:43PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Price of child reprap September 18, 2008 08:17PM |

Registered: 17 years ago Posts: 550 |

|

Re: Price of child reprap September 18, 2008 08:55PM |

Registered: 15 years ago Posts: 62 |

|

Re: Price of child reprap September 18, 2008 09:07PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Price of child reprap September 19, 2008 01:39AM |

Registered: 15 years ago Posts: 37 |

|

Re: Price of child reprap September 20, 2008 01:05PM |

Registered: 16 years ago Posts: 536 |

I bought a set of cast parts from Bits from Bytes, had them shipped to Canada, and then bought all the heavy hardware locally. I hope to start printing some spare parts next week, but don't hold your breath. It could be another four months.

Also, at this point, I think the shipping charges are minor compared to the number of man hours I've put in building. This project is still very much in the experimental realm.

Also, at this point, I think the shipping charges are minor compared to the number of man hours I've put in building. This project is still very much in the experimental realm.

|

Re: Price of child reprap September 20, 2008 06:55PM |

Registered: 15 years ago Posts: 199 |

David Iscool Wrote:

-------------------------------------------------------

> About how much does it cost to clone a reprap?

> including printed and "nonprinted" parts? thanks.

You'll need the electronics, Arduino and cable: $190 plus shipping from RRRF.

A posting from January lists the "Steel Frame Kit Subtotal:

-------------------------------------------------------

> About how much does it cost to clone a reprap?

> including printed and "nonprinted" parts? thanks.

You'll need the electronics, Arduino and cable: $190 plus shipping from RRRF.

A posting from January lists the "Steel Frame Kit Subtotal:

|

Re: Price of child reprap September 20, 2008 09:03PM |

Registered: 15 years ago Posts: 62 |

|

Re: Price of child reprap September 21, 2008 02:29AM |

Registered: 16 years ago Posts: 174 |

|

Re: Price of child reprap September 21, 2008 07:11AM |

Registered: 15 years ago Posts: 199 |

|

Re: Price of child reprap September 21, 2008 08:40AM |

Registered: 15 years ago Posts: 199 |

Of course if you are making only one RepRap you might have to pay a lot more for parts than Ian does when he buys in bulk and puts together kits. If you source as much as possible from McMaster-Carr you will end up paying $384.52 for just the Cartesian Bot parts (no extruder parts). That would add about $300 to my estimates above. :-(

A minor part of the problem is trying to get metric parts in the USA. McMaster's M8 rod is oil-hardening tool steel drill blanks, AND the length is only 914mm (36") each so you have to buy 16 instead of 9 (most of the pieces you need to cut are 500mm). That's $78.08 right there! You can save about $60 by going with zinc plated SAE sizes instead of metric. That would be 5/16" rods, 5/16-24 studs (all-thread), nuts and washers.

A big problem with McMaster is that you have to buy fasteners in bulk. If you want one cap screw you have to buy 100 for $5 or $10. At least you'll have LOTS of spares! The 8mm washers and 8mm nuts (or 5/16") are used in enough quantity that it makes sense to buy a box of 100. For the cap screws and grub screws it makes sense to buy locally someplace where you can buy by the piece. If you have to buy in quantity you can get the longer length of cap screw and cut some down to get the shorter lengths. For example the 3mm cap screws are used in 16mm, 25mm and 30mm lengths.

The moral of this exercise is: Nobody has a clue how much it is going to cost YOU to buy all the machined parts.

A minor part of the problem is trying to get metric parts in the USA. McMaster's M8 rod is oil-hardening tool steel drill blanks, AND the length is only 914mm (36") each so you have to buy 16 instead of 9 (most of the pieces you need to cut are 500mm). That's $78.08 right there! You can save about $60 by going with zinc plated SAE sizes instead of metric. That would be 5/16" rods, 5/16-24 studs (all-thread), nuts and washers.

A big problem with McMaster is that you have to buy fasteners in bulk. If you want one cap screw you have to buy 100 for $5 or $10. At least you'll have LOTS of spares! The 8mm washers and 8mm nuts (or 5/16") are used in enough quantity that it makes sense to buy a box of 100. For the cap screws and grub screws it makes sense to buy locally someplace where you can buy by the piece. If you have to buy in quantity you can get the longer length of cap screw and cut some down to get the shorter lengths. For example the 3mm cap screws are used in 16mm, 25mm and 30mm lengths.

The moral of this exercise is: Nobody has a clue how much it is going to cost YOU to buy all the machined parts.

|

Re: Price of child reprap September 22, 2008 11:10PM |

Registered: 15 years ago Posts: 7 |

Since first time I heard about RepRap, I've always asking myself if self-replication/low cost is something that goes hand to hand, or if they are opposing forces. I mean, if instead of targeting an 500 U$S cost (or any other number, for what matters), RR targets for, I don't know, ten times that cost, let's say 5000 U$S, then it would be easier to achieve a higher percentage of self replication by means of better materials/technologies ? Or is the relatively low cost a necessity for achieving high self-replication (low costs means simpler designs and materials)?

|

Re: Price of child reprap September 22, 2008 11:21PM |

Registered: 15 years ago Posts: 62 |

|

Re: Price of child reprap September 23, 2008 05:14AM |

Registered: 16 years ago Posts: 361 |

Quote

I've always asking myself if self-replication/low cost is something that goes hand to hand

Are non-replicating designs any cheaper?

The bulk of the price seems to be in the electronics right now; a cost that must be shared by any other design. These other, non-replicating designs will not be capable of building spare parts for themselves. nor upgrading themselves, and so their 'total cost of ownership' is going to be greater as a result, and their up-front cost doesn't appear to be significantly lower. Cheaper cartesian bots do exist (like the McWire) but they seem to make many compromises, and haven't really taken off.

Where do you see savings?

Quote

I guess having something like a pick and place tool and a soldering iron ttachment would make it possible for the reprap to replicate its own circuits but would be complicated to replicate

Complex replication isn't so much of an issue; its more the non-printable parts which push up the price and the inconvenience.

Designing such a system has a whole host of prerequisites though... head changing, automated height compensation, etc etc, and these in turn require a fair amount of skilled brain power to overcome. When the problem has been solved once, it will become vastly more easy in the future.

Oh, and it might be simpler to cook the circuits yourself, rather than making a hot air soldering head for the darwin.

|

Re: Price of child reprap September 23, 2008 08:55AM |

Admin Registered: 17 years ago Posts: 1,915 |

Ru Wrote:

-------------------------------------------------------

>

> The bulk of the price seems to be in the

> electronics right now; a cost that must be shared

> by any other design.

>

> Where do you see savings?

>

There is no reason whatsoever that the electronics cost as much as they do with Darwin. Looking at the electronic parts, one of the biggest cost items is the stepper-driver boards. While the L297/L298N controller chips are making designing the board easy and give you upwards of two amps capacity per phase in your stepper that two-chip ensemble also costs about $12-13 PER stepper motor from Mouser.

There are historical reasons for this to have happened. When Reprap began we were using the venerable SN75440 chip, which costs well under $2 to do the same job as the L297/L298N ensemble. The only problem with the 754410 was that it can't deliver more than 1.1 amps/phase. At that time it was very difficult to find bipolar stepper motors with enough copper in their windings to keep the current load at or under 1 amp. It is still not that easy, though it can be done cost effectively.

As well, in designing the Arduino/Sanguino the team restricted themselves to DIP chips as well as ATMEGA offerings because they were able, thereby, to access an excellent open-source (this being extremely important to them) firmware compiler. The downside was, however, that the chips that they had to use, as a result, could communicate with the outside world only through RS232 serial and a variety of that which required a small handful of additional components to talk to your PC. Shifting comms over to USB added even more components. All that makes the controller board both more complex and more expensive than it needs to be.

To give you an idea of the potential impact of this it was mentioned a few days ago that a complete set of controller electronics for Darwin costs about $180. The electronics for Tommelise, my variation on Darwin, which uses steppers drawing a bit less than half an amp/phase and a microcontroller with native USB comms rather than add-on bits comes in at around $40.

It wouldn't be a big deal to redesign Darwin's electronics with cost as the driving criteria and get the parts budget down to about what Tommelise does.

Edited 2 time(s). Last edit at 09/23/2008 09:11AM by Forrest Higgs.

-------------------------------------------------------

>

> The bulk of the price seems to be in the

> electronics right now; a cost that must be shared

> by any other design.

>

> Where do you see savings?

>

There is no reason whatsoever that the electronics cost as much as they do with Darwin. Looking at the electronic parts, one of the biggest cost items is the stepper-driver boards. While the L297/L298N controller chips are making designing the board easy and give you upwards of two amps capacity per phase in your stepper that two-chip ensemble also costs about $12-13 PER stepper motor from Mouser.

There are historical reasons for this to have happened. When Reprap began we were using the venerable SN75440 chip, which costs well under $2 to do the same job as the L297/L298N ensemble. The only problem with the 754410 was that it can't deliver more than 1.1 amps/phase. At that time it was very difficult to find bipolar stepper motors with enough copper in their windings to keep the current load at or under 1 amp. It is still not that easy, though it can be done cost effectively.

As well, in designing the Arduino/Sanguino the team restricted themselves to DIP chips as well as ATMEGA offerings because they were able, thereby, to access an excellent open-source (this being extremely important to them) firmware compiler. The downside was, however, that the chips that they had to use, as a result, could communicate with the outside world only through RS232 serial and a variety of that which required a small handful of additional components to talk to your PC. Shifting comms over to USB added even more components. All that makes the controller board both more complex and more expensive than it needs to be.

To give you an idea of the potential impact of this it was mentioned a few days ago that a complete set of controller electronics for Darwin costs about $180. The electronics for Tommelise, my variation on Darwin, which uses steppers drawing a bit less than half an amp/phase and a microcontroller with native USB comms rather than add-on bits comes in at around $40.

It wouldn't be a big deal to redesign Darwin's electronics with cost as the driving criteria and get the parts budget down to about what Tommelise does.

Edited 2 time(s). Last edit at 09/23/2008 09:11AM by Forrest Higgs.

|

Re: Price of child reprap September 23, 2008 09:50AM |

Registered: 16 years ago Posts: 361 |

Quote

There is no reason whatsoever that the electronics cost as much as they do with Darwin. Looking at the electronic parts, one of the biggest cost items is the stepper-driver boards

That is very true; I've made quite a few posts elsewhere talking about possibilities for replacing the L297

I guess also that moving to unipolar motors would lend itself to replacing the L298; but I'm not at all certain about the disadvantages involved with unipolar motors vs bipolar ones. I imagine discrete components for the driver boards would not only be cheaper but also easier to source a suitable part and somewhat future-proofed into the bargain. I looked into h-bridge design though, and decided that it is a job best left to a more skilled engineer than I.

I guess also that moving to unipolar motors would lend itself to replacing the L298; but I'm not at all certain about the disadvantages involved with unipolar motors vs bipolar ones. I imagine discrete components for the driver boards would not only be cheaper but also easier to source a suitable part and somewhat future-proofed into the bargain. I looked into h-bridge design though, and decided that it is a job best left to a more skilled engineer than I.The steppers themselves are also none too cheap; I watch with interest your efforts to assemble your own!

Anyway, my original point still stands: the control logic and motors represent a major chunk of the cost of a CNC tool, cost which is shared by repraps and other systems. This leaves the cost of the structural components and materials which for reprap represent perhaps $100-150 dollars? plus a whole load of machine time. That seems pretty damn cheap to me, considering what you're getting out of it in the end.

|

Re: Price of child reprap September 23, 2008 10:10AM |

Admin Registered: 17 years ago Posts: 1,915 |

Ru Wrote:

-------------------------------------------------------

>

> The steppers themselves are also none too cheap; I

> watch with interest your efforts to assemble your

> own!

>

Funny you should mention that. I resolved this morning that I would take a crack at making Tommelise cut the thin sheet steel to do the field offsets for the linear tin can stepper that I've designed.

I bought a little diamond cutting head for about $9 that works with my Dremel. It will be interesting to see how long it takes to cut the steel profiles that I need. I plan on using a 3/8-24 inch threaded rod for a lead screw for now till I figure out how to cut my own lead screws. You can buy that kind of threaded rod in most good hardware stores.

One of the gripes that I have with the Haydon linear stepper motors is that the 3 mm lead screw is far to flimsy for the lengths I'm using. Making my own linear steppers lets me fix that problem as well as controlling the costs.

Now I just have to write a little routine that will generate the profiles that I need to cut.

Edited 2 time(s). Last edit at 09/23/2008 10:19AM by Forrest Higgs.

-------------------------------------------------------

>

> The steppers themselves are also none too cheap; I

> watch with interest your efforts to assemble your

> own!

>

Funny you should mention that. I resolved this morning that I would take a crack at making Tommelise cut the thin sheet steel to do the field offsets for the linear tin can stepper that I've designed.

I bought a little diamond cutting head for about $9 that works with my Dremel. It will be interesting to see how long it takes to cut the steel profiles that I need. I plan on using a 3/8-24 inch threaded rod for a lead screw for now till I figure out how to cut my own lead screws. You can buy that kind of threaded rod in most good hardware stores.

One of the gripes that I have with the Haydon linear stepper motors is that the 3 mm lead screw is far to flimsy for the lengths I'm using. Making my own linear steppers lets me fix that problem as well as controlling the costs.

Now I just have to write a little routine that will generate the profiles that I need to cut.

Edited 2 time(s). Last edit at 09/23/2008 10:19AM by Forrest Higgs.

|

Re: Price of child reprap September 23, 2008 12:16PM |

Admin Registered: 17 years ago Posts: 7,879 |

Ru Wrote:

Root 2 times less torque for the same power.

Edited 1 time(s). Last edit at 09/23/2008 12:17PM by nophead.

[www.hydraraptor.blogspot.com]

Quote

I'm not at all certain about the disadvantages involved with unipolar motors vs bipolar ones.

Root 2 times less torque for the same power.

Edited 1 time(s). Last edit at 09/23/2008 12:17PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Price of child reprap September 23, 2008 12:21PM |

Admin Registered: 17 years ago Posts: 1,915 |

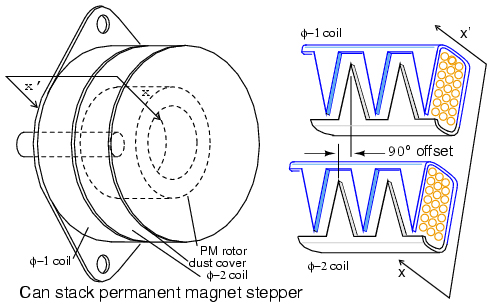

I'm planning on cutting the field offsets template in something like this shape.

I'm not quite sure why tin can stepper designers make the inner offsets pointy and the outer ones square, but I'm going to stick with conventional wisdom till I have something at least sort of working.

I discovered a little while ago that I can make lead screws by simply buying a cheap thread die cutter and running it down a rod.

Now I've got to figure out how to draw wire. I can build a foundry that will let me melt recycled aluminum tin cans and lawn furniture into ingots easily enough. Once I've built my little EDM machine I could be able to cut dies to draw the wire from the ingots. Lordy!

A later reflection.... You know. I just actually looked at that template and realised that it could be easily done with a compass and ruler. That's probably why they made the inner offsets pointy. Tin can steppers have been around since I was a child back in the 1950's. I remember having one to play with for a project then.

Edited 3 time(s). Last edit at 09/23/2008 01:49PM by Forrest Higgs.

I'm not quite sure why tin can stepper designers make the inner offsets pointy and the outer ones square, but I'm going to stick with conventional wisdom till I have something at least sort of working.

I discovered a little while ago that I can make lead screws by simply buying a cheap thread die cutter and running it down a rod.

Now I've got to figure out how to draw wire. I can build a foundry that will let me melt recycled aluminum tin cans and lawn furniture into ingots easily enough. Once I've built my little EDM machine I could be able to cut dies to draw the wire from the ingots. Lordy!

A later reflection.... You know. I just actually looked at that template and realised that it could be easily done with a compass and ruler. That's probably why they made the inner offsets pointy. Tin can steppers have been around since I was a child back in the 1950's. I remember having one to play with for a project then.

Edited 3 time(s). Last edit at 09/23/2008 01:49PM by Forrest Higgs.

|

Re: Price of child reprap September 23, 2008 12:32PM |

Admin Registered: 17 years ago Posts: 1,915 |

nophead Wrote:

-------------------------------------------------------

>

> Root 2 times less torque for the same power.

>

Um... You're the expert and I'm an idiot in these things by comparison, but isn't it

unipolar torque = bipolar torque/(2^0.5)

what with the square root of two being something 1.414? I'm probably just not understanding how you're expressing it.

-------------------------------------------------------

>

> Root 2 times less torque for the same power.

>

Um... You're the expert and I'm an idiot in these things by comparison, but isn't it

unipolar torque = bipolar torque/(2^0.5)

what with the square root of two being something 1.414? I'm probably just not understanding how you're expressing it.

|

Anonymous User

Re: Price of child reprap September 23, 2008 01:54PM |

|

Re: Price of child reprap September 23, 2008 01:59PM |

Registered: 16 years ago Posts: 447 |

|

Re: Price of child reprap September 23, 2008 03:28PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes unipolar torque is less than bipolar torque by the factor sqrt(2) is what I intended my sentence to mean but Steve's is a clearer way of saying the same thing.

Darwin will easily work at torques less than 70% of the motor rating and the motors are 8 wire, so unipolar drive will definitely work. In fact I think Ian Adkins uses it. It does have the disadvantage of wasting power in the form of heat in the motor so if you are using motor mounts with a low melting point it may matter.

Unipolar electronics are more efficient than bipolar of course.

[www.hydraraptor.blogspot.com]

Darwin will easily work at torques less than 70% of the motor rating and the motors are 8 wire, so unipolar drive will definitely work. In fact I think Ian Adkins uses it. It does have the disadvantage of wasting power in the form of heat in the motor so if you are using motor mounts with a low melting point it may matter.

Unipolar electronics are more efficient than bipolar of course.

[www.hydraraptor.blogspot.com]

|

Re: Price of child reprap September 23, 2008 04:45PM |

Registered: 16 years ago Posts: 184 |

Forrest Higgs Wrote:

-------------------------------------------------------

> Now I've got to figure out how to draw wire. I

> can build a foundry that will let me melt recycled

> aluminum tin cans and lawn furniture into ingots

> easily enough. Once I've built my little EDM

> machine I could be able to cut dies to draw the

> wire from the ingots. Lordy!

Forrest - I built a foundry and do melt aluminum. Don't bother with the cans as all you will get is "DROSS" about 5% of the can will be melted metal and the rest will oxidize away and is not worth the effort. Melting lawn furniture and such solid item works fine. I do that all the time. I do sand casting and sometimes I even get what I designed in the first pass. The nice part of this is that all it takes is charcoal and a hairdryer to melt the metal.

Here is a link to the book on the foundry. Dead simple to make and works great.

[www.lindsaybks.com]

Bob Teeter

Bob Teeter

"What Box?"

-------------------------------------------------------

> Now I've got to figure out how to draw wire. I

> can build a foundry that will let me melt recycled

> aluminum tin cans and lawn furniture into ingots

> easily enough. Once I've built my little EDM

> machine I could be able to cut dies to draw the

> wire from the ingots. Lordy!

Forrest - I built a foundry and do melt aluminum. Don't bother with the cans as all you will get is "DROSS" about 5% of the can will be melted metal and the rest will oxidize away and is not worth the effort. Melting lawn furniture and such solid item works fine. I do that all the time. I do sand casting and sometimes I even get what I designed in the first pass. The nice part of this is that all it takes is charcoal and a hairdryer to melt the metal.

Here is a link to the book on the foundry. Dead simple to make and works great.

[www.lindsaybks.com]

Bob Teeter

Bob Teeter

"What Box?"

|

Re: Price of child reprap September 26, 2008 06:10AM |

Admin Registered: 17 years ago Posts: 7,879 |

A nice calculator for stepper power and torque, etc.

[www.linengineering.com]

[www.hydraraptor.blogspot.com]

[www.linengineering.com]

[www.hydraraptor.blogspot.com]

|

Re: Price of child reprap September 26, 2008 07:30AM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Price of child reprap September 29, 2008 05:21AM |

Registered: 16 years ago Posts: 361 |

|

"Interesting" units and their application September 29, 2008 09:59AM |

Registered: 15 years ago Posts: 251 |

Ru Wrote:

-------------------------------------------------------

> Ooh, thats a dead useful page. Well found.

>

> I'd never even heard of the measurement of 'slug

> feet' before.

Slug-feet my be an archaic measure, but it's quite useful for quantifying sliminess -- applicable to lawyers, hedge-fund managers, and politicians. ;-)

For such applications, the prefixes mega, giga or larger may be required.

-- Larry

-------------------------------------------------------

> Ooh, thats a dead useful page. Well found.

>

> I'd never even heard of the measurement of 'slug

> feet' before.

Slug-feet my be an archaic measure, but it's quite useful for quantifying sliminess -- applicable to lawyers, hedge-fund managers, and politicians. ;-)

For such applications, the prefixes mega, giga or larger may be required.

-- Larry

|

Re: Price of child reprap September 29, 2008 11:29AM |

Admin Registered: 17 years ago Posts: 1,915 |

Sorry, only registered users may post in this forum.

<

<