Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC)

Posted by Idolcrasher

|

Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) December 31, 2012 05:56PM |

Registered: 12 years ago Posts: 539 |

Link To Announcement Page

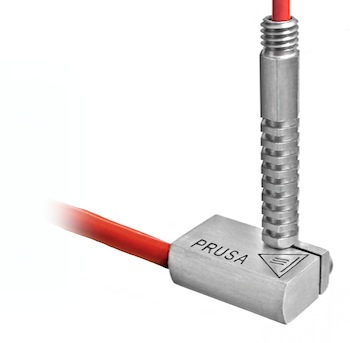

If you have not already, check out the announcement for Josef Prusa's next generation hot-end. It looks to be a nice all-metal construction hot-end. It uses a heater cartridge instead of a heater resistor. It boasts to be a good solution (extra hot) for printing in Nylon, Peek and polycarbonate.

You can catch glimpses of this bad boy in some of Josef's newer YouTube videos, and he made a few tweets about it as well.

It is exciting to, see new hot-end designs emerging. This one looks nice

Your thoughts?

Edited 2 time(s). Last edit at 01/01/2013 10:01AM by Idolcrasher.

FabberForge - Printing Happiness

[www.fabberforge.com]

If you have not already, check out the announcement for Josef Prusa's next generation hot-end. It looks to be a nice all-metal construction hot-end. It uses a heater cartridge instead of a heater resistor. It boasts to be a good solution (extra hot) for printing in Nylon, Peek and polycarbonate.

You can catch glimpses of this bad boy in some of Josef's newer YouTube videos, and he made a few tweets about it as well.

It is exciting to, see new hot-end designs emerging. This one looks nice

Your thoughts?

Edited 2 time(s). Last edit at 01/01/2013 10:01AM by Idolcrasher.

FabberForge - Printing Happiness

[www.fabberforge.com]

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) December 31, 2012 05:59PM |

Registered: 12 years ago Posts: 539 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) December 31, 2012 06:01PM |

Registered: 12 years ago Posts: 539 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) December 31, 2012 07:38PM |

Registered: 13 years ago Posts: 1,918 |

Idolcrasher Wrote:

-------------------------------------------------------

> So if you can print in PEEK... you could print

> yourself a J-Head hot-end for printing PLA... EPIC

>

Did you notice that PEEK is highly crystalline? Expect a lot of warping.

Btw, why do you want to print PEEK, when you have an all metal hotend?

Detlef

-------------------------------------------------------

> So if you can print in PEEK... you could print

> yourself a J-Head hot-end for printing PLA... EPIC

>

Did you notice that PEEK is highly crystalline? Expect a lot of warping.

Btw, why do you want to print PEEK, when you have an all metal hotend?

Detlef

| Excalibur Hotend |

reprapzone.blogspot.de |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) December 31, 2012 08:15PM |

Registered: 12 years ago Posts: 539 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 06:17AM |

Registered: 13 years ago Posts: 7,616 |

Looks excellent, but not like a RepRap design.

- IMHO, heater cartridges are a waste of money. No technical advantage over wire resistors.

- The hotend is no better suited for PEEK than any other all-metal hotend.

- Where's the thermistor? I hope it's not inside the cartridge.

- To mount it, you apparently need another metal part in the extruder for the M6 thread. A generic nut won't suffice.

- IMHO, heater cartridges are a waste of money. No technical advantage over wire resistors.

- The hotend is no better suited for PEEK than any other all-metal hotend.

- Where's the thermistor? I hope it's not inside the cartridge.

- To mount it, you apparently need another metal part in the extruder for the M6 thread. A generic nut won't suffice.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 10:00AM |

Registered: 12 years ago Posts: 539 |

Agree and Disagree,

On Heater Cartridges- Heater cartridges are "perfectly" round allowing for easy/easier install in the heater block. Heater resistors are blobby/wobbly pieces of crap, which never perfectly fit into any circle. This design in particular allows easy exchange of heater cartridge via a screw in the heater block, which is nice. I have lost a few heater blocks to dead heater-resistors which could not be forced out. Heater cartridges can achieve higher temperatures fast; faster than a heater resistor. They also have a theoretical longer life I believe as well (I will have to fact check that) I have been playing with heater cartridges on hand thanks to QU-BD, so from my experience this was a smart move by Prusa.

Achieve High Temperatures- you are right that there are other all metal hot-ends out there can achieve HIGH temps. My eckertech all metal hot-end can hang out at 350 C without breaking a sweat. It also uses a less common nicrome wire setup to heat-up too. It is slower to get to temperature but very stable. I think my ecker tech hot end would have just as much luck printing in peek as the new Prusa design. Eckertech Hot-End

On the Looks - Saying that this does not exactly look like a design we have seen so far sounds about right. It has the core elements they all have. A Nozzel, a heater block, a a heating element and thermistor. I think this is the most elegant hot-end design I have ever seen.

Edited 2 time(s). Last edit at 01/01/2013 06:39PM by Idolcrasher.

On Heater Cartridges- Heater cartridges are "perfectly" round allowing for easy/easier install in the heater block. Heater resistors are blobby/wobbly pieces of crap, which never perfectly fit into any circle. This design in particular allows easy exchange of heater cartridge via a screw in the heater block, which is nice. I have lost a few heater blocks to dead heater-resistors which could not be forced out. Heater cartridges can achieve higher temperatures fast; faster than a heater resistor. They also have a theoretical longer life I believe as well (I will have to fact check that) I have been playing with heater cartridges on hand thanks to QU-BD, so from my experience this was a smart move by Prusa.

Achieve High Temperatures- you are right that there are other all metal hot-ends out there can achieve HIGH temps. My eckertech all metal hot-end can hang out at 350 C without breaking a sweat. It also uses a less common nicrome wire setup to heat-up too. It is slower to get to temperature but very stable. I think my ecker tech hot end would have just as much luck printing in peek as the new Prusa design. Eckertech Hot-End

On the Looks - Saying that this does not exactly look like a design we have seen so far sounds about right. It has the core elements they all have. A Nozzel, a heater block, a a heating element and thermistor. I think this is the most elegant hot-end design I have ever seen.

Edited 2 time(s). Last edit at 01/01/2013 06:39PM by Idolcrasher.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 01:19PM |

Registered: 12 years ago Posts: 34 |

The only thing that confuses me and appears to be new (to me) is the ALL stainless steel design. No one has done that that I am aware of. Everyone uses some copper/brass/bronze/aluminum near the nozzle. The basic design structure certainly isn't new, though - although it does look nice. Is there a reason to not use a more conductive metal at the tip near the nozzle that no one has caught onto, yet?

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 02:37PM |

Registered: 12 years ago Posts: 539 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 06:32PM |

Registered: 12 years ago Posts: 34 |

I'm a machinist and I know stainless certainly isn't easier to machine than copper, bronze, aluminum, or brass. You can use cheaper tooling for those metals and maintain decent speed of machining. Stainless you can get away with using some cheap tooling, but it will dramatically slow down production, so you lose money in the machining time...and that is usually more expensive than tooling. "Food grade" would be another silly requirement, because all of those metals can also be food grade. I doubt it's efficiency having such a poor conductor next to the tip.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 06:40PM |

Registered: 11 years ago Posts: 939 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 11:22PM |

Registered: 12 years ago Posts: 34 |

It doesn't appear to be one piece to me...it has a slit cut out of the heating block that I assume allows you to tighten the upper portion into the heating block. Also, a fan would do little good for stainless steel. It is a great insulator, but there is a reason they don't make very many heatsinks out of stainless steel. I would guess that it's tapered at the nozzle point some internally, but I'd imagine the portion for the filament that isn't supposed to be melting is diametrically consistent.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 01, 2013 11:31PM |

Registered: 11 years ago Posts: 939 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 04:03AM |

Admin Registered: 11 years ago Posts: 1,063 |

Polygonhell: if machined with a bit of care those interfaces between sections should be unoticable, to the human hand,

Prusa's new hotend should by all rights work quite well with abs an pla possbly wth no fan dependng on how much of a wall thickness there is , the only problem have is how t's advertised, not one image has been seen of the alumnum mountng plate that comes with it,

Prusa's new hotend should by all rights work quite well with abs an pla possbly wth no fan dependng on how much of a wall thickness there is , the only problem have is how t's advertised, not one image has been seen of the alumnum mountng plate that comes with it,

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 04:32AM |

Registered: 12 years ago Posts: 38 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 06:21AM |

Registered: 12 years ago Posts: 539 |

eMakers hot-end (I have several of them) is great but... It is 3 pieces, requires the use of a small bit of PTFE in the stainless steel collar, uses heater resistors, is not popularly used, has no wiki page, and no one out side of eMaker(aka RepRapPro) uses it.

The Prusa Nozzel, is two pieces, has no PTFE component at all, uses heater cartridges (it's a plus trust me), will be popular and used on many different types of builds.

The Prusa Nozzel, is two pieces, has no PTFE component at all, uses heater cartridges (it's a plus trust me), will be popular and used on many different types of builds.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 10:33AM |

Registered: 12 years ago Posts: 38 |

I hardly think popularity is a measure of how good something is. But I disgress. I believe you can find detailed documentation of the hot end in their google docs. I believe Dr. Bowyer who co-owns Reprappro is a firm believer of open-source.

The PTFE for the collar is just part of the bowden setup. I don't think that adds any complexity to the design.

I've never use heater cartridges but I'm sure they are pretty good and high powered. But then why ruin that advantage by using stainless steel? It's not going to efficiently conduct the heat as well as brass or aluminium.

Have to say that render is very nice.

The PTFE for the collar is just part of the bowden setup. I don't think that adds any complexity to the design.

I've never use heater cartridges but I'm sure they are pretty good and high powered. But then why ruin that advantage by using stainless steel? It's not going to efficiently conduct the heat as well as brass or aluminium.

Have to say that render is very nice.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 11:23AM |

Registered: 12 years ago Posts: 539 |

PTFE in Steel Part of RRP HOTEND: There is a 5mm PTFE sleeve which is inserterted into the stainless steel tube, which is in the middle of the extruder (not part of the Bowden setup)

RRP Hot end build instructions

It adds complexity, and adds some limitation to max temp.

Popularity Matters in a Niche Hobby Like This: Popularity, while not necessarily a measure of how "good" the hot-end is; it does directly effect the number of carriages and extruders are designed to handle the hot-end.

For example, I think I know of two carriages and two extruders (3 if you count a mod) specifically made for the RepRapPro Hot-end.

While there are J-Head extruders and carriages all over thingiverse.

Popularity also effects how easy it is to is to buy one; the more popular the hot-end the cheaper you will find it too. The eMaker shop is about the only place you can find parts for a RRP extruder; even then, they are only available some of the time.

A popularized, "Prusa-Branded" hot-end, that is easier to use and assemble will mean more available extruder and carriage designs, more places to buy it cheap, and a more common frame of reference for RepRap hobbyists in general. That's what the hype is

Edited 5 time(s). Last edit at 01/02/2013 07:20PM by Idolcrasher.

RRP Hot end build instructions

It adds complexity, and adds some limitation to max temp.

Popularity Matters in a Niche Hobby Like This: Popularity, while not necessarily a measure of how "good" the hot-end is; it does directly effect the number of carriages and extruders are designed to handle the hot-end.

For example, I think I know of two carriages and two extruders (3 if you count a mod) specifically made for the RepRapPro Hot-end.

While there are J-Head extruders and carriages all over thingiverse.

Popularity also effects how easy it is to is to buy one; the more popular the hot-end the cheaper you will find it too. The eMaker shop is about the only place you can find parts for a RRP extruder; even then, they are only available some of the time.

A popularized, "Prusa-Branded" hot-end, that is easier to use and assemble will mean more available extruder and carriage designs, more places to buy it cheap, and a more common frame of reference for RepRap hobbyists in general. That's what the hype is

Edited 5 time(s). Last edit at 01/02/2013 07:20PM by Idolcrasher.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 04:56PM |

Registered: 13 years ago Posts: 486 |

I tried all steel including the nozzle and felt the poor conductivity at the tip was limiting the speed that the hotend could be run. It was a pretty unscientific test though and there are a lot of things that can impact the nozzle performance like the length of the small hole which can be tricky to control with hand machining

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 05:18PM |

Registered: 11 years ago Posts: 142 |

Pazu Wrote:

-------------------------------------------------------

> I hardly think popularity is a measure of how good

> something is.

This is new to me. I want to learn more from you. Because I think the same.

For example: I don t understand why facebook is popular. I was programming professional websites for companies as Zuckerberg was 12 years old. The success is not the website, but the stupid idea. I must confess, there are more stupid people than anything else on the planet.

BUT talking about machines, I can t follow you. A machine does work good or not. The popularity is really a scale in this case.

Just my 2 $ > <

<

-------------------------------------------------------

> I hardly think popularity is a measure of how good

> something is.

This is new to me. I want to learn more from you. Because I think the same.

For example: I don t understand why facebook is popular. I was programming professional websites for companies as Zuckerberg was 12 years old. The success is not the website, but the stupid idea. I must confess, there are more stupid people than anything else on the planet.

BUT talking about machines, I can t follow you. A machine does work good or not. The popularity is really a scale in this case.

Just my 2 $ >

<

<

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 09:13PM |

Registered: 12 years ago Posts: 38 |

Funny, I have the original emaker huxley and the hot end does not have a ptfe inserted. I dunno why they decided to change that cos IMHO, that they had an excellent design that is extremely robust.

I once had a failed print that stopped for unknown reasons and the hot end was frozen at 230C for 8hours leaving the ABS completely charred. All I had to do was to restart up the machine and manually turn the extruder and it cleared.

I meant to say that putting popularity into an arguement of how good a hot end is does not add to the merit. It may have a huge market or tons of carriage that goes with it but that is really beside the arguement.

Guess I'm not the type to follow the norm.

Edited 1 time(s). Last edit at 01/02/2013 09:17PM by Pazu.

I once had a failed print that stopped for unknown reasons and the hot end was frozen at 230C for 8hours leaving the ABS completely charred. All I had to do was to restart up the machine and manually turn the extruder and it cleared.

I meant to say that putting popularity into an arguement of how good a hot end is does not add to the merit. It may have a huge market or tons of carriage that goes with it but that is really beside the arguement.

Guess I'm not the type to follow the norm.

Edited 1 time(s). Last edit at 01/02/2013 09:17PM by Pazu.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 02, 2013 09:33PM |

Registered: 12 years ago Posts: 539 |

Lol,

I suppose I want the norm to be a more robust model. I wish the norm was the RRP style hot-end or similar, but instead popularity made peek-construction hot-ends the norm.

I am hopeful that a new "popular" all-metal hot-end helps others to see the light and accept the grace of an all metal design

I suppose I want the norm to be a more robust model. I wish the norm was the RRP style hot-end or similar, but instead popularity made peek-construction hot-ends the norm.

I am hopeful that a new "popular" all-metal hot-end helps others to see the light and accept the grace of an all metal design

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 12:21AM |

Registered: 11 years ago Posts: 143 |

I've used both wire resistors, and these ceramic heaters that are coming out of China.

The wire resistors are far less efficient, and the mosfets cannot supply enough power to heat them anywhere close to the temperatures that the ceramic heaters can get to. The mosfets can heat a ceramic heater to twice the heat a resistor can get to, without breaking a sweat. I had a thermistor fall out of a jhead nozzle (cheap chinese knock off), that was using one of these ceramic heaters but with a thermistor held in only by a thin strip of Kapton tape. As my nozzle was melting into a blob of melted peek, I managed to put the thermistor back into the block and the themperature in pronterface read 350 plus. I touched the heatsink for the mosfet with my finger, and it was still cool. When the blob all cooled down and the smoke had cleared, I salvaged the heater, used it to re-melt the peek enough to squish the nozzle back tothether with what was left of the peek, re drilled the peek, wired it together with spring wire, like a kids braces, sealed it with high temperature sealant, sealed in the thermistor this time, and two months, and many prints later, I'm still using it today to print without problems. (See photo). SO, my point is that these ceramic heaters are vastly superior to heat resistors.

Traumflug Wrote:

-------------------------------------------------------

> Looks excellent, but not like a RepRap design.

>

> - IMHO, heater cartridges are a waste of money. No

> technical advantage over wire resistors.

>

> - The hotend is no better suited for PEEK than any

> other all-metal hotend.

>

> - Where's the thermistor? I hope it's not inside

> the cartridge.

>

> - To mount it, you apparently need another metal

> part in the extruder for the M6 thread. A generic

> nut won't suffice.

The wire resistors are far less efficient, and the mosfets cannot supply enough power to heat them anywhere close to the temperatures that the ceramic heaters can get to. The mosfets can heat a ceramic heater to twice the heat a resistor can get to, without breaking a sweat. I had a thermistor fall out of a jhead nozzle (cheap chinese knock off), that was using one of these ceramic heaters but with a thermistor held in only by a thin strip of Kapton tape. As my nozzle was melting into a blob of melted peek, I managed to put the thermistor back into the block and the themperature in pronterface read 350 plus. I touched the heatsink for the mosfet with my finger, and it was still cool. When the blob all cooled down and the smoke had cleared, I salvaged the heater, used it to re-melt the peek enough to squish the nozzle back tothether with what was left of the peek, re drilled the peek, wired it together with spring wire, like a kids braces, sealed it with high temperature sealant, sealed in the thermistor this time, and two months, and many prints later, I'm still using it today to print without problems. (See photo). SO, my point is that these ceramic heaters are vastly superior to heat resistors.

Traumflug Wrote:

-------------------------------------------------------

> Looks excellent, but not like a RepRap design.

>

> - IMHO, heater cartridges are a waste of money. No

> technical advantage over wire resistors.

>

> - The hotend is no better suited for PEEK than any

> other all-metal hotend.

>

> - Where's the thermistor? I hope it's not inside

> the cartridge.

>

> - To mount it, you apparently need another metal

> part in the extruder for the M6 thread. A generic

> nut won't suffice.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 05:40AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

The wire resistors are far less efficient

All resistors are 100% efficient. They convert electrical energy to heat, nothing else.

[www.hydraraptor.blogspot.com]

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 05:57AM |

Registered: 11 years ago Posts: 143 |

nophead Wrote:

-------------------------------------------------------

> The wire resistors are far less efficient

>

> All resistors are 100% efficient. They convert

> electrical energy to heat, nothing else.

That's not true.

Not at all.

The role of a resistor is to resist the flow of electrons, and the heat some produce is a byproduct.

Resistors can convert electricity to heat and/or light.

An efficient resistor produces no heat and no light, it simply resists the flow of electricity.

Much research has been done in this area since the days of Edison, to make resistors more efficient.

Have you heard of super conductors? The goal there is to control the flow of electrons without generating heat, which is wasted energy.

These ceramic heaters have one purpose, and that is to generate heat, not resist the flow of electrons and so to that end, they are very efficient.

Resistors produce heat as a byproduct, and poorly constructed resistors produce more heat than well constructed ones.

An good engineer would tell you that a circuit constructed with efficient resistors will consume less power than the same circuit constructed with inefficient resistors.

Edited 1 time(s). Last edit at 01/03/2013 06:02AM by Tekwizard.

-------------------------------------------------------

> The wire resistors are far less efficient

>

> All resistors are 100% efficient. They convert

> electrical energy to heat, nothing else.

That's not true.

Not at all.

The role of a resistor is to resist the flow of electrons, and the heat some produce is a byproduct.

Resistors can convert electricity to heat and/or light.

An efficient resistor produces no heat and no light, it simply resists the flow of electricity.

Much research has been done in this area since the days of Edison, to make resistors more efficient.

Have you heard of super conductors? The goal there is to control the flow of electrons without generating heat, which is wasted energy.

These ceramic heaters have one purpose, and that is to generate heat, not resist the flow of electrons and so to that end, they are very efficient.

Resistors produce heat as a byproduct, and poorly constructed resistors produce more heat than well constructed ones.

An good engineer would tell you that a circuit constructed with efficient resistors will consume less power than the same circuit constructed with inefficient resistors.

Edited 1 time(s). Last edit at 01/03/2013 06:02AM by Tekwizard.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 06:27AM |

Admin Registered: 17 years ago Posts: 7,879 |

Sorry but you don't understand the principal of conservation of energy. All the electrical power going into the resistor V * I is converted to heat (unless you get it so hot it lights up or explodes, in which case you get some sound and light).

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 07:47AM |

Registered: 12 years ago Posts: 1,236 |

Tekwizard Wrote:

-------------------------------------------------------

> That's not true.

> Not at all.

> The role of a resistor is to resist the flow of

> electrons, and the heat some produce is a

> byproduct.

>

> Resistors can convert electricity to heat and/or

> light.

> An efficient resistor produces no heat and no

> light, it simply resists the flow of electricity.

> Much research has been done in this area since the

> days of Edison, to make resistors more efficient.

>

> Have you heard of super conductors? The goal there

> is to control the flow of electrons without

> generating heat, which is wasted energy.

> These ceramic heaters have one purpose, and that

> is to generate heat, not resist the flow of

> electrons and so to that end, they are very

> efficient.

>

> Resistors produce heat as a byproduct, and poorly

> constructed resistors produce more heat than well

> constructed ones.

> An good engineer would tell you that a circuit

> constructed with efficient resistors will consume

> less power than the same circuit constructed with

> inefficient resistors.

>

LOL, I thought I'd heard it all... so sorry, but that is all nonsense. Now, I can forgive people for not understanding the basics, we all have to start somewhere, but you can't just invent your theories! Your theory is not even self consistent.

The equations V = IR and P = VI are actually quite simple to understand, it is really worth taking the time to study them.

Any conductor has a resistance. The heat generated can be calculated by P= V^2 / R. This formulation shows that the power dissipated by a conductor as heat increases with applied voltage, and decreases with resistance.

A perfect insulator has an infinite resistance, and therefore the heat generated is zero. A cartridge heater has a low resistance, and therefore generates more heat. The difference in performance is entirely due to resistance, nothing to do with "efficiency".

Ohms law does not apply to superconductors, they operate in a particular quantum state, where the flow of electrons does not cause heating.

-------------------------------------------------------

> That's not true.

> Not at all.

> The role of a resistor is to resist the flow of

> electrons, and the heat some produce is a

> byproduct.

>

> Resistors can convert electricity to heat and/or

> light.

> An efficient resistor produces no heat and no

> light, it simply resists the flow of electricity.

> Much research has been done in this area since the

> days of Edison, to make resistors more efficient.

>

> Have you heard of super conductors? The goal there

> is to control the flow of electrons without

> generating heat, which is wasted energy.

> These ceramic heaters have one purpose, and that

> is to generate heat, not resist the flow of

> electrons and so to that end, they are very

> efficient.

>

> Resistors produce heat as a byproduct, and poorly

> constructed resistors produce more heat than well

> constructed ones.

> An good engineer would tell you that a circuit

> constructed with efficient resistors will consume

> less power than the same circuit constructed with

> inefficient resistors.

>

LOL, I thought I'd heard it all... so sorry, but that is all nonsense. Now, I can forgive people for not understanding the basics, we all have to start somewhere, but you can't just invent your theories! Your theory is not even self consistent.

The equations V = IR and P = VI are actually quite simple to understand, it is really worth taking the time to study them.

Any conductor has a resistance. The heat generated can be calculated by P= V^2 / R. This formulation shows that the power dissipated by a conductor as heat increases with applied voltage, and decreases with resistance.

A perfect insulator has an infinite resistance, and therefore the heat generated is zero. A cartridge heater has a low resistance, and therefore generates more heat. The difference in performance is entirely due to resistance, nothing to do with "efficiency".

Ohms law does not apply to superconductors, they operate in a particular quantum state, where the flow of electrons does not cause heating.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 12:54PM |

Registered: 11 years ago Posts: 334 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 04:31PM |

Registered: 11 years ago Posts: 143 |

Keep laughing out loud Bob. Flat earthers dazzled others with equations and "proof" that the world was the center of all things, and that the world was flat for century's, before they were shown otherwise.

The ohm's laws that you "present" here only govern basic resistance of conductors, and do not apply to efficient resistors. Poor conductors are not the only types of resistors available, and efficient resistors have charactaristics to which the power formula's derived from jules laws do not apply exactly. As I've said, the only "purpose" of a resistor is to resist the flow of electrons. They are not intended to generate heat or light, and any formula that maps out the inefficiency of the technology used to resist that flow is not - basic law, it is only a description of what happens in that particular method. A semi- conductor can control the flow of electrons in a circuit without generating a fraction of the heat a conductor with a high resistance will, and can be used in similar instances to make a circuit more efficient. A 100 watt light bulb produces a fraction of the heat that a 100 watt wire wound resistor does given the same voltage applied, and the newer light bulbs generate so little heat that you can touch them with your hand.

In your statement, you suggest that the "basics" will settle whether or not there can be an efficient resistor vs. an inefficient one because it governs the laws regarding passing electrons through a conductor. Then, you go on to say that "Ohms law does not apply to superconductors". How convenient.

I would be interested if you could demonstrate that a hot end that uses a 5 ohm 5 watt carbon film resistor as a heater, is able to heat the nozzle to operating temperatures using the same amount of electricity as a 5 ohm 5 watt wire wound resistor. If not, can your formula's explain why not? How about you Nophead? Have you been able to make a hot end with a carbon film resistor work as well as a wire wound resistor with the same values? Practice vs. theory always wins out, because it is reality.

I am well familiar with the formula's you've quoted guys, but thinking inside the box like that is only for engineers - the cartographers of of open minded thinkers paths.

Jon

> LOL, I thought I'd heard it all... so sorry, but

> that is all nonsense. Now, I can forgive people

> for not understanding the basics, we all have to

> start somewhere, but you can't just invent your

> theories! Your theory is not even self

> consistent.

>

> The equations V = IR and P = VI are actually quite

> simple to understand, it is really worth taking

> the time to study them.

>

> Any conductor has a resistance. The heat generated

> can be calculated by P= V^2 / R. This formulation

> shows that the power dissipated by a conductor as

> heat increases with applied voltage, and decreases

> with resistance.

>

> A perfect insulator has an infinite resistance,

> and therefore the heat generated is zero. A

> cartridge heater has a low resistance, and

> therefore generates more heat. The difference in

> performance is entirely due to resistance, nothing

> to do with "efficiency".

>

> Ohms law does not apply to superconductors, they

> operate in a particular quantum state, where the

> flow of electrons does not cause heating.

The ohm's laws that you "present" here only govern basic resistance of conductors, and do not apply to efficient resistors. Poor conductors are not the only types of resistors available, and efficient resistors have charactaristics to which the power formula's derived from jules laws do not apply exactly. As I've said, the only "purpose" of a resistor is to resist the flow of electrons. They are not intended to generate heat or light, and any formula that maps out the inefficiency of the technology used to resist that flow is not - basic law, it is only a description of what happens in that particular method. A semi- conductor can control the flow of electrons in a circuit without generating a fraction of the heat a conductor with a high resistance will, and can be used in similar instances to make a circuit more efficient. A 100 watt light bulb produces a fraction of the heat that a 100 watt wire wound resistor does given the same voltage applied, and the newer light bulbs generate so little heat that you can touch them with your hand.

In your statement, you suggest that the "basics" will settle whether or not there can be an efficient resistor vs. an inefficient one because it governs the laws regarding passing electrons through a conductor. Then, you go on to say that "Ohms law does not apply to superconductors". How convenient.

I would be interested if you could demonstrate that a hot end that uses a 5 ohm 5 watt carbon film resistor as a heater, is able to heat the nozzle to operating temperatures using the same amount of electricity as a 5 ohm 5 watt wire wound resistor. If not, can your formula's explain why not? How about you Nophead? Have you been able to make a hot end with a carbon film resistor work as well as a wire wound resistor with the same values? Practice vs. theory always wins out, because it is reality.

I am well familiar with the formula's you've quoted guys, but thinking inside the box like that is only for engineers - the cartographers of of open minded thinkers paths.

Jon

> LOL, I thought I'd heard it all... so sorry, but

> that is all nonsense. Now, I can forgive people

> for not understanding the basics, we all have to

> start somewhere, but you can't just invent your

> theories! Your theory is not even self

> consistent.

>

> The equations V = IR and P = VI are actually quite

> simple to understand, it is really worth taking

> the time to study them.

>

> Any conductor has a resistance. The heat generated

> can be calculated by P= V^2 / R. This formulation

> shows that the power dissipated by a conductor as

> heat increases with applied voltage, and decreases

> with resistance.

>

> A perfect insulator has an infinite resistance,

> and therefore the heat generated is zero. A

> cartridge heater has a low resistance, and

> therefore generates more heat. The difference in

> performance is entirely due to resistance, nothing

> to do with "efficiency".

>

> Ohms law does not apply to superconductors, they

> operate in a particular quantum state, where the

> flow of electrons does not cause heating.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 03, 2013 04:53PM |

Registered: 11 years ago Posts: 939 |

If you have one of the 12V 40W cartridges and are comparing that, then they have lower resistance and draw more power than the typical resistors used in reprap hotends.

I'd also assume that more regular shape gives them a more consistent contact area, and since air is a good insulator that probably helps.

I really don't think we have to discard things like the conservation of energy to explain your observation.

And for the sorts of devices, temperatures, voltages and current that we're talking about Ohms law is more than adequate.

I'd also assume that more regular shape gives them a more consistent contact area, and since air is a good insulator that probably helps.

I really don't think we have to discard things like the conservation of energy to explain your observation.

And for the sorts of devices, temperatures, voltages and current that we're talking about Ohms law is more than adequate.

Sorry, only registered users may post in this forum.