Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC)

Posted by Idolcrasher

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 10:01AM |

Admin Registered: 17 years ago Posts: 7,879 |

40W is dangerous in most hot ends and should not be used unless the hot end can withstand about 600C, or there is thermal fuse. Safety regs require things to be safe under any single fault condition, such as a shorted MOSFET.

I don't understand why it needs to heat up quickly. 24W takes less than two of minutes, which is nothing compared to the bed and the total build time. Also you need to wait for everything to expand or the first layer height is inconsistent.

I did see a more suitable cartridge heater for sale in Australia. It was lower power and smaller but way too expensive.

As for service life, I have never had a resistor that I put in myself fail and I have used some 24/7 for years. I have had two that I bought ready assembled fail. One was just held in with Kapton, the other silicone. They do need to be cemented, or wrapped in just the right thickness of aluminium foil to make them a tight fit. Glass rope glue works and so does exhaust putty.

I do spend a lot of time assembling hot ends for Mendel90 kits so a suitable cartridge heater would be great but not these 40W ones.

[www.hydraraptor.blogspot.com]

I don't understand why it needs to heat up quickly. 24W takes less than two of minutes, which is nothing compared to the bed and the total build time. Also you need to wait for everything to expand or the first layer height is inconsistent.

I did see a more suitable cartridge heater for sale in Australia. It was lower power and smaller but way too expensive.

As for service life, I have never had a resistor that I put in myself fail and I have used some 24/7 for years. I have had two that I bought ready assembled fail. One was just held in with Kapton, the other silicone. They do need to be cemented, or wrapped in just the right thickness of aluminium foil to make them a tight fit. Glass rope glue works and so does exhaust putty.

I do spend a lot of time assembling hot ends for Mendel90 kits so a suitable cartridge heater would be great but not these 40W ones.

[www.hydraraptor.blogspot.com]

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 11:07AM |

Registered: 12 years ago Posts: 539 |

Interesting point on the 40 watts. I do imagine thermal runaway on one of those would be... interesting

Do you recommend a particular glass rope glue? or exhaust putty? From reading the various "feather-cap" blogs, the latest intel I have on those products are that they are expensive and don't work as well (hard to remove) as simple aluminum tape. You have rekindled my interest though. What is the red rubbery substance that E3D and SeeMeCNC are using?

I have had one czech heater resistor fail on me. It blew out on both sides like a slinky. Granted this was a unique event.

FabberForge - Printing Happiness

[www.fabberforge.com]

Do you recommend a particular glass rope glue? or exhaust putty? From reading the various "feather-cap" blogs, the latest intel I have on those products are that they are expensive and don't work as well (hard to remove) as simple aluminum tape. You have rekindled my interest though. What is the red rubbery substance that E3D and SeeMeCNC are using?

I have had one czech heater resistor fail on me. It blew out on both sides like a slinky. Granted this was a unique event.

FabberForge - Printing Happiness

[www.fabberforge.com]

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 11:18AM |

Registered: 12 years ago Posts: 539 |

Here is a video of the nozzle in action

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 12:38PM |

Admin Registered: 15 years ago Posts: 1,470 |

Idolcrasher Wrote:

-------------------------------------------------------

> What is the red rubbery substance that

> E3D and SeeMeCNC are using?

That's RTV sealant. Not very thermally conductive.

-------------------------------------------------------

> What is the red rubbery substance that

> E3D and SeeMeCNC are using?

That's RTV sealant. Not very thermally conductive.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 01:10PM |

Registered: 11 years ago Posts: 939 |

NewPerfection Wrote:

-------------------------------------------------------

> Idolcrasher Wrote:

> --------------------------------------------------

> -----

> > What is the red rubbery substance that

> > E3D and SeeMeCNC are using?

>

> That's RTV sealant. Not very thermally

> conductive.

But at least in seemecnc's case it's not used to improve the thermal connection, they specify wrapping the resistor in tin foil for that.

-------------------------------------------------------

> Idolcrasher Wrote:

> --------------------------------------------------

> -----

> > What is the red rubbery substance that

> > E3D and SeeMeCNC are using?

>

> That's RTV sealant. Not very thermally

> conductive.

But at least in seemecnc's case it's not used to improve the thermal connection, they specify wrapping the resistor in tin foil for that.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 02:39PM |

Registered: 11 years ago Posts: 143 |

Traumflug Wrote:

-------------------------------------------------------

> My $0.02 regarding "efficiency":

>

> The AFAIK most common heater resistor is 5.6 ohms

> and with that you get 12V * 12V / 5.6 ohms = 25.7

> watts at 12V. This cartridge apparently has 40

> watts, so it heats up a lot quicker. Maybe this is

> recognized as "more efficient", because it simply

> has more power.

>

> The solution would be to use resistors with 3.3

> ohms, which would produce 44 watts of heat. And a

> reasonably heat conducting, temperature

> withstanding cement, like nophead already pointed

> out.

>

> There are also drawbacks in using oversized (as in

> high wattage) heaters: temperatures change

> quicker, local overheats are higher, so you get

> more material aging. With or without a cartridge.

I originally entered this thread on page one when I replied to your post that the heater elements were not as good as resistors at the task of heating up hot ends. Just because they are a higher wattage isn't the only important consideration here. Why are we not putting a resistor with the same wattage in the same hole? Probably because it would be too big and not fit, which would make it less suitable for the task than these heaters. I ramp up my hot end manually when I'm warming it up, and then I let Pronterface take over. Because of it's fast response time (making it more effective at heating), once it is up to temperature, and PID settles down, it has no problem keeping the hot end very smoothly on target. All of these things add up together to make it more "efficient" at its intend task. I personally believe that they are more efficient at that task, although some people prefer the word "effective". The definitions of "effective" and "efficient" aside, I think everyone understands my point of view there.

This assertion from me took off on another tangent - that of whether or not resistors can varying in their efficiency from one method to another. I still maintain that they can. 100 years ago, formulas were created to describe how conductors behave when electricity is passed through them and these are called "laws of Physics". Hundreds of years before that, formulas were devised to "prove" and describe the movements of the heavens and these too were called "laws of physics", and "everyone" accepted them as fact and they proved beyond irrefuteble doubt that the earth is the center of all things and that the heavens revolved around it - and that the earth was flat. Thinking changes with time, and you may find that there is a new point of view on all of this in 20 years that hadn't occured to you today. 40 years ago, I bet you didn't know how you would be printing anything in 3d, did you? All I'm saying is that because the primary role of a resistor in an electronic circuit is to impede the flow of electrons, and because we currently do that using simple conductors, that doesn't mean that is the only way of doing it, and it is possible that the same task could be done in ways that don't waste any electricity by sloughing off heat.

-------------------------------------------------------

> My $0.02 regarding "efficiency":

>

> The AFAIK most common heater resistor is 5.6 ohms

> and with that you get 12V * 12V / 5.6 ohms = 25.7

> watts at 12V. This cartridge apparently has 40

> watts, so it heats up a lot quicker. Maybe this is

> recognized as "more efficient", because it simply

> has more power.

>

> The solution would be to use resistors with 3.3

> ohms, which would produce 44 watts of heat. And a

> reasonably heat conducting, temperature

> withstanding cement, like nophead already pointed

> out.

>

> There are also drawbacks in using oversized (as in

> high wattage) heaters: temperatures change

> quicker, local overheats are higher, so you get

> more material aging. With or without a cartridge.

I originally entered this thread on page one when I replied to your post that the heater elements were not as good as resistors at the task of heating up hot ends. Just because they are a higher wattage isn't the only important consideration here. Why are we not putting a resistor with the same wattage in the same hole? Probably because it would be too big and not fit, which would make it less suitable for the task than these heaters. I ramp up my hot end manually when I'm warming it up, and then I let Pronterface take over. Because of it's fast response time (making it more effective at heating), once it is up to temperature, and PID settles down, it has no problem keeping the hot end very smoothly on target. All of these things add up together to make it more "efficient" at its intend task. I personally believe that they are more efficient at that task, although some people prefer the word "effective". The definitions of "effective" and "efficient" aside, I think everyone understands my point of view there.

This assertion from me took off on another tangent - that of whether or not resistors can varying in their efficiency from one method to another. I still maintain that they can. 100 years ago, formulas were created to describe how conductors behave when electricity is passed through them and these are called "laws of Physics". Hundreds of years before that, formulas were devised to "prove" and describe the movements of the heavens and these too were called "laws of physics", and "everyone" accepted them as fact and they proved beyond irrefuteble doubt that the earth is the center of all things and that the heavens revolved around it - and that the earth was flat. Thinking changes with time, and you may find that there is a new point of view on all of this in 20 years that hadn't occured to you today. 40 years ago, I bet you didn't know how you would be printing anything in 3d, did you? All I'm saying is that because the primary role of a resistor in an electronic circuit is to impede the flow of electrons, and because we currently do that using simple conductors, that doesn't mean that is the only way of doing it, and it is possible that the same task could be done in ways that don't waste any electricity by sloughing off heat.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 02:53PM |

Registered: 11 years ago Posts: 143 |

nophead Wrote:

-------------------------------------------------------

> Electronic engineering is not a point of view. The

> simple equations governing how much heat a

> resistor makes were established more than 100

> years ago and are accepted by anyone working in

> that field.

>

> Your central argument is that resistors have

> difference "efficiencies" but no matter how you

> define what that is they simply don't. They all,

> without exception, convert electrical energy to

> heat 1:1.

Are you aware that Jules made his discoveries in this matter by accident? By experimentation and observation, many years before he even noticed anything was even there and figured out "why" all of this was working the way it does? He didn't start out with a concrete stance on the subject and then go on to create formulas and laws, he was trying to do one thing and stumbled upon these now "laws" that apply to conductors. Before that, he was working on this stuff following "earlier concrete, and accepted by everyone in the field laws". Later, engineers will undoubtably follow even newer, updated laws. Engineers work with the knowledge that is currently known to them. I'd prefer it that way myself, I wouldn't want to see engineers "experimenting" with elevators or gondola's or aircraft. They are the bricklayers, and experimentors should be left to do that sort of thing. But, I am not an engineer and I am free to explore outside of the box.

-------------------------------------------------------

> Electronic engineering is not a point of view. The

> simple equations governing how much heat a

> resistor makes were established more than 100

> years ago and are accepted by anyone working in

> that field.

>

> Your central argument is that resistors have

> difference "efficiencies" but no matter how you

> define what that is they simply don't. They all,

> without exception, convert electrical energy to

> heat 1:1.

Are you aware that Jules made his discoveries in this matter by accident? By experimentation and observation, many years before he even noticed anything was even there and figured out "why" all of this was working the way it does? He didn't start out with a concrete stance on the subject and then go on to create formulas and laws, he was trying to do one thing and stumbled upon these now "laws" that apply to conductors. Before that, he was working on this stuff following "earlier concrete, and accepted by everyone in the field laws". Later, engineers will undoubtably follow even newer, updated laws. Engineers work with the knowledge that is currently known to them. I'd prefer it that way myself, I wouldn't want to see engineers "experimenting" with elevators or gondola's or aircraft. They are the bricklayers, and experimentors should be left to do that sort of thing. But, I am not an engineer and I am free to explore outside of the box.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 03:09PM |

Registered: 11 years ago Posts: 143 |

Idolcrasher Wrote:

-------------------------------------------------------

> FYI: The Hong Kong based group "RepRap Discount"

> is selling heater cartridges on eBay. Heater

> Cartridges on eBay

>

> I have not tried these particular heater

> cartridges, but I would love to know what people

> think of them.

>

> Their stuff is cheaply made, but has always worked

> for me. They have very prompt customer service.

> If you are going to sell your soul to the devil

> and buy from China, start by checking out RepRap

> Discount (eBay) or my other favorite cheap but

> reliable Chinese company, Repraper.com

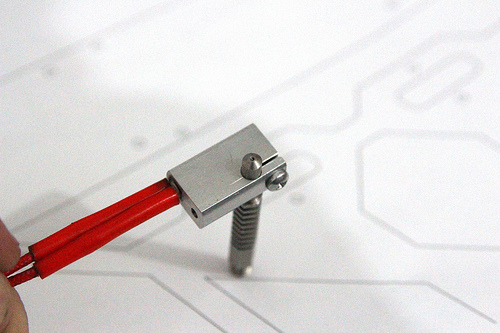

These look like the ones that I buy from China. I think there is only one manufacturer, because that's what one supplier told me, and they all buy from there. I've run them really hot 350 degrees plus for a few hours just to test them, using just ramps 1.4, and they just keep on ticking. The one you've linked to here has one meter of heat protected wire that's strong and flexible, and very nice to use. I put a dab of epoxy at the ends to stop fraying. Like you say, they are easy to use. They are exactly six millimeters in diameter, and fit snuggly into the hole and can be tightened in there with a grub screw rather tight because they are a stainless steel tube. I find that they are very nice to work with and you don't have to mess around with gluing them in with any kind of cement. They are easily swapped out too, you just loosen a screw. Very efficient. I have three, but I only use one because it is working fine. I should point out though, that the very first one I ever got was DOA and had to be replaced, so if anyone buys 10 like this, the first thing you should do is run them each for half an hour or so. My DOA worked for about 30 seconds. Once you've established that they work though, I think they are very reliable. This is a very good price.

-------------------------------------------------------

> FYI: The Hong Kong based group "RepRap Discount"

> is selling heater cartridges on eBay. Heater

> Cartridges on eBay

>

> I have not tried these particular heater

> cartridges, but I would love to know what people

> think of them.

>

> Their stuff is cheaply made, but has always worked

> for me. They have very prompt customer service.

> If you are going to sell your soul to the devil

> and buy from China, start by checking out RepRap

> Discount (eBay) or my other favorite cheap but

> reliable Chinese company, Repraper.com

These look like the ones that I buy from China. I think there is only one manufacturer, because that's what one supplier told me, and they all buy from there. I've run them really hot 350 degrees plus for a few hours just to test them, using just ramps 1.4, and they just keep on ticking. The one you've linked to here has one meter of heat protected wire that's strong and flexible, and very nice to use. I put a dab of epoxy at the ends to stop fraying. Like you say, they are easy to use. They are exactly six millimeters in diameter, and fit snuggly into the hole and can be tightened in there with a grub screw rather tight because they are a stainless steel tube. I find that they are very nice to work with and you don't have to mess around with gluing them in with any kind of cement. They are easily swapped out too, you just loosen a screw. Very efficient. I have three, but I only use one because it is working fine. I should point out though, that the very first one I ever got was DOA and had to be replaced, so if anyone buys 10 like this, the first thing you should do is run them each for half an hour or so. My DOA worked for about 30 seconds. Once you've established that they work though, I think they are very reliable. This is a very good price.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 03:19PM |

Registered: 11 years ago Posts: 143 |

nophead Wrote:

-------------------------------------------------------

> 40W is dangerous in most hot ends and should not

> be used unless the hot end can withstand about

> 600C, or there is thermal fuse. Safety regs

> require things to be safe under any single fault

> condition, such as a shorted MOSFET.

>

> I don't understand why it needs to heat up

> quickly. 24W takes less than two of minutes, which

> is nothing compared to the bed and the total build

> time. Also you need to wait for everything to

> expand or the first layer height is inconsistent.

>

> I did see a more suitable cartridge heater for

> sale in Australia. It was lower power and smaller

> but way too expensive.

>

> As for service life, I have never had a resistor

> that I put in myself fail and I have used some

> 24/7 for years. I have had two that I bought ready

> assembled fail. One was just held in with Kapton,

> the other silicone. They do need to be cemented,

> or wrapped in just the right thickness of

> aluminium foil to make them a tight fit. Glass

> rope glue works and so does exhaust putty.

>

> I do spend a lot of time assembling hot ends for

> Mendel90 kits so a suitable cartridge heater would

> be great but not these 40W ones.

They are a very nice design that is easy to swap in and out of a hot end - loosen a grub screw, slide it out. They are very well built and reliable and there is no messing around with wires because they come with one meter of heat resistant wire attached. They are easy for PID to maintain temperature once it's up to target because they have a fast response time. It would be nice if they made them in 24 watts because I have to bring my hot end up to temperature manually, in steps. These do get very hot though, and that is dangerous when something fails. I've actually wired in a big power resistor in series to limit current, but my resistor isn't very efficient ( ) and I have to use a cooling fan for it.

) and I have to use a cooling fan for it.

-------------------------------------------------------

> 40W is dangerous in most hot ends and should not

> be used unless the hot end can withstand about

> 600C, or there is thermal fuse. Safety regs

> require things to be safe under any single fault

> condition, such as a shorted MOSFET.

>

> I don't understand why it needs to heat up

> quickly. 24W takes less than two of minutes, which

> is nothing compared to the bed and the total build

> time. Also you need to wait for everything to

> expand or the first layer height is inconsistent.

>

> I did see a more suitable cartridge heater for

> sale in Australia. It was lower power and smaller

> but way too expensive.

>

> As for service life, I have never had a resistor

> that I put in myself fail and I have used some

> 24/7 for years. I have had two that I bought ready

> assembled fail. One was just held in with Kapton,

> the other silicone. They do need to be cemented,

> or wrapped in just the right thickness of

> aluminium foil to make them a tight fit. Glass

> rope glue works and so does exhaust putty.

>

> I do spend a lot of time assembling hot ends for

> Mendel90 kits so a suitable cartridge heater would

> be great but not these 40W ones.

They are a very nice design that is easy to swap in and out of a hot end - loosen a grub screw, slide it out. They are very well built and reliable and there is no messing around with wires because they come with one meter of heat resistant wire attached. They are easy for PID to maintain temperature once it's up to target because they have a fast response time. It would be nice if they made them in 24 watts because I have to bring my hot end up to temperature manually, in steps. These do get very hot though, and that is dangerous when something fails. I've actually wired in a big power resistor in series to limit current, but my resistor isn't very efficient (

) and I have to use a cooling fan for it.

) and I have to use a cooling fan for it.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 03:27PM |

Registered: 11 years ago Posts: 143 |

Idolcrasher Wrote:

-------------------------------------------------------

> Interesting point on the 40 watts. I do imagine

> thermal runaway on one of those would be...

> interesting

>

> Do you recommend a particular glass rope glue? or

> exhaust putty? From reading the various

> "feather-cap" blogs, the latest intel I have on

> those products are that they are expensive and

> don't work as well (hard to remove) as simple

> aluminum tape. You have rekindled my interest

> though. What is the red rubbery substance that

> E3D and SeeMeCNC are using?

>

> I have had one czech heater resistor fail on me.

> It blew out on both sides like a slinky. Granted

> this was a unique event.

The red rubbery stuff is high temperature sealant and you can buy it at a local automotive shop. It goes on like normal silicone but can withstand up to 343 degree celcius (650 F) . The one I use is made by Permatex. I used it to repair my hot end after the peek melted and I had to melt it back into place. I have not had any leaking, so it seems to be working very well considering my threads in the peek are no longer threads. I've been using this hot end this way for two months without issues. See attached photo. FIXED.bmp

-------------------------------------------------------

> Interesting point on the 40 watts. I do imagine

> thermal runaway on one of those would be...

> interesting

>

> Do you recommend a particular glass rope glue? or

> exhaust putty? From reading the various

> "feather-cap" blogs, the latest intel I have on

> those products are that they are expensive and

> don't work as well (hard to remove) as simple

> aluminum tape. You have rekindled my interest

> though. What is the red rubbery substance that

> E3D and SeeMeCNC are using?

>

> I have had one czech heater resistor fail on me.

> It blew out on both sides like a slinky. Granted

> this was a unique event.

The red rubbery stuff is high temperature sealant and you can buy it at a local automotive shop. It goes on like normal silicone but can withstand up to 343 degree celcius (650 F) . The one I use is made by Permatex. I used it to repair my hot end after the peek melted and I had to melt it back into place. I have not had any leaking, so it seems to be working very well considering my threads in the peek are no longer threads. I've been using this hot end this way for two months without issues. See attached photo. FIXED.bmp

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 04:02PM |

Registered: 12 years ago Posts: 539 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 04:38PM |

Registered: 11 years ago Posts: 143 |

Idolcrasher Wrote:

-------------------------------------------------------

> [forums.reprap.org]

> ename=FIXED.bmp

>

> Lol, I dig your fix. I am way to OCD to not have

> every little thing in perfect condition... It

> makes me an "ineffective maker" sometimes

This is how it used to look! Prefix2.bmp

Cursed efficient heaters

Looking forward to replacing it with one of Joseph's sleek new ones.

Edited 2 time(s). Last edit at 01/05/2013 04:42PM by Tekwizard.

-------------------------------------------------------

> [forums.reprap.org]

> ename=FIXED.bmp

>

> Lol, I dig your fix. I am way to OCD to not have

> every little thing in perfect condition... It

> makes me an "ineffective maker" sometimes

This is how it used to look! Prefix2.bmp

Cursed efficient heaters

Looking forward to replacing it with one of Joseph's sleek new ones.

Edited 2 time(s). Last edit at 01/05/2013 04:42PM by Tekwizard.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 07:38PM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

But, I am not an engineer and I am free to explore outside of the box.

Well I bet you won't find a way of making electrical energy simply disappear into nothing in your lifetime. If you had any understanding of physics you would realise an "efficient" resistor, that impedes electricity without converting it to heat cannot exist. You have a current flowing through it and a voltage across it. Therefore it is consuming electrical energy. If it comes out as heat it is a resistor or a heater (they are the same thing), if it comes out in some other form of energy it isn't a resistor it's a bulb, motor, loudspeaker, or some other form of transducer. If it simply disappears into nothing you are truly a wizard.

In the meantime I have done plenty of experiments with resistors as heaters and stainless steel as an insulator and was probably the first person in the reprap world to do either. However, I have never found anything that disobeyed the current laws of physics: [hydraraptor.blogspot.co.uk]

[www.hydraraptor.blogspot.com]

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 07:59PM |

Admin Registered: 11 years ago Posts: 1,063 |

nophead Wrote:

-------------------------------------------------------

> But, I am not an engineer and I am free to explore

> outside of the box.

>

> Well I bet you won't find a way of making

> electrical energy simply disappear into nothing in

> your lifetime. If you had any understanding of

> physics you would realise an "efficient" resistor,

> that impedes electricity without converting it to

> heat cannot exist. You have a current flowing

> through it and a voltage across it. Therefore it

> is consuming electrical energy. If it comes out

> as heat it is a resistor or a heater (they are the

> same thing), if it comes out in some other form of

> energy it isn't a resistor it's a bulb, motor,

> loudspeaker, or some other form of transducer. If

> it simply disappears into nothing you are truly a

> wizard.

>

> In the meantime I have done plenty of experiments

> with resistors as heaters and stainless steel as

> an insulator and was probably the first person in

> the reprap world to do either. However, I have

> never found anything that disobeyed the current

> laws of physics:

> [hydraraptor.blogspot.co.uk]

> s.html

you should have a talk to the local up! distributor, according to them filament that goes up to 1.85mm in diamater will still fit down a 1.8mm hole ......... i feel your pain

-------------------------------------------------------

> But, I am not an engineer and I am free to explore

> outside of the box.

>

> Well I bet you won't find a way of making

> electrical energy simply disappear into nothing in

> your lifetime. If you had any understanding of

> physics you would realise an "efficient" resistor,

> that impedes electricity without converting it to

> heat cannot exist. You have a current flowing

> through it and a voltage across it. Therefore it

> is consuming electrical energy. If it comes out

> as heat it is a resistor or a heater (they are the

> same thing), if it comes out in some other form of

> energy it isn't a resistor it's a bulb, motor,

> loudspeaker, or some other form of transducer. If

> it simply disappears into nothing you are truly a

> wizard.

>

> In the meantime I have done plenty of experiments

> with resistors as heaters and stainless steel as

> an insulator and was probably the first person in

> the reprap world to do either. However, I have

> never found anything that disobeyed the current

> laws of physics:

> [hydraraptor.blogspot.co.uk]

> s.html

you should have a talk to the local up! distributor, according to them filament that goes up to 1.85mm in diamater will still fit down a 1.8mm hole ......... i feel your pain

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 08:53PM |

Registered: 11 years ago Posts: 143 |

nophead Wrote:

-------------------------------------------------------

> But, I am not an engineer and I am free to explore

> outside of the box.

>

> Well I bet you won't find a way of making

> electrical energy simply disappear into nothing in

> your lifetime. If you had any understanding of

> physics you would realise an "efficient" resistor,

> that impedes electricity without converting it to

> heat cannot exist. You have a current flowing

> through it and a voltage across it. Therefore it

> is consuming electrical energy. If it comes out

> as heat it is a resistor or a heater (they are the

> same thing), if it comes out in some other form of

> energy it isn't a resistor it's a bulb, motor,

> loudspeaker, or some other form of transducer. If

> it simply disappears into nothing you are truly a

> wizard.

>

> In the meantime I have done plenty of experiments

> with resistors as heaters and stainless steel as

> an insulator and was probably the first person in

> the reprap world to do either. However, I have

> never found anything that disobeyed the current

> laws of physics:

> [hydraraptor.blogspot.co.uk]

> s.html

What about a transistor?

I believe that a transistor can control the flow of current without heating up as much as a resistor does.

-------------------------------------------------------

> But, I am not an engineer and I am free to explore

> outside of the box.

>

> Well I bet you won't find a way of making

> electrical energy simply disappear into nothing in

> your lifetime. If you had any understanding of

> physics you would realise an "efficient" resistor,

> that impedes electricity without converting it to

> heat cannot exist. You have a current flowing

> through it and a voltage across it. Therefore it

> is consuming electrical energy. If it comes out

> as heat it is a resistor or a heater (they are the

> same thing), if it comes out in some other form of

> energy it isn't a resistor it's a bulb, motor,

> loudspeaker, or some other form of transducer. If

> it simply disappears into nothing you are truly a

> wizard.

>

> In the meantime I have done plenty of experiments

> with resistors as heaters and stainless steel as

> an insulator and was probably the first person in

> the reprap world to do either. However, I have

> never found anything that disobeyed the current

> laws of physics:

> [hydraraptor.blogspot.co.uk]

> s.html

What about a transistor?

I believe that a transistor can control the flow of current without heating up as much as a resistor does.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 05, 2013 09:16PM |

Registered: 12 years ago Posts: 156 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 01:01AM |

Registered: 11 years ago Posts: 143 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 01:06AM |

Registered: 11 years ago Posts: 143 |

miso Wrote:

-------------------------------------------------------

> No, even transistor can't break fundamental laws

> of physics. That's why linear voltage regulators

> heats a lot. "In fact, the power loss due to

> heating in the transistor is the current times the

> voltage dropped across the transistor" wikipedia

Damn!

-------------------------------------------------------

> No, even transistor can't break fundamental laws

> of physics. That's why linear voltage regulators

> heats a lot. "In fact, the power loss due to

> heating in the transistor is the current times the

> voltage dropped across the transistor" wikipedia

Damn!

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 01:30AM |

Registered: 11 years ago Posts: 24 |

miso Wrote:

-------------------------------------------------------

> No, even transistor can't break fundamental laws

> of physics. That's why linear voltage regulators

> heats a lot. "In fact, the power loss due to

> heating in the transistor is the current times the

> voltage dropped across the transistor" wikipedia

Miso has it right. The difference between a resistor and a transistor is that the resistor can only control the flow of current by converting some of it to heat, specifically the product of the current and the voltage drop. The transistor is a nonlinear, non-ohmic (basically the same thing here) device that uses the base current to control the emitter current. When in full conduction, the current is large but the voltage drop across it is negligible, and hence the heating is small. When in non conduction, the voltage gets large but the current is small. In between it gets interesting.

But the key point to anyone who has build a transistor circuit is that you MUST put current limiting resistors on the base and on the collector-emitter path. If you put the transistor directly between two different voltages with no dropping resistor, as soon as it goes into conduction, the current goes way up, and then the transistor experiences a moment of heat, a small puff of smoke and the smell of burnt plastic, and then becomes some flavor of diode (if you're lucky) or useless (if unlucky).

Even new discoveries don't break the fundamental laws of physics, they encapsulate them. For example, take Newtonian Mechanics (NM) and Special Relativity (SR). SR didn't overthrow NM, it just subsumed it - NM is a special case of SP where the velocities of things are small compared to the velocity of light. All the stuff we know about NM still is true at low speeds, and that's why we still teach it in introductory physics classes.

So to try and close one end of this argument - Tekwizard, if you put 25 watts of heat into a resistor, the efficiency is perfect. 25 W of power is consumed (that is, 25 Joules per second), and 25 watts of heat is produced. Period. The laws of thermodynamics are pretty clear cut on that point, and perfect efficiency is possible because heat is the most entropic form of energy. Converting one type of energy to another that isn't heat, or converting heat into some other type, is never perfectly efficient (unless you have a cold end at absolute zero, which is impossible). But making heat is easy. Put your hands together and rub briskly. Neglecting deformation of the surface layers of your skin, all the mechanical energy turns into heat, some in your palms, some in the muscles moving your arms around.

That said, what I hope Tekwizard was addressing with his question about efficiency was the idea that not all of the power we put into the resistor goes straight into the plastic to be melted. Some heats the resistor, the nozzle, etc. But frankly, it doesn't take a lot of power to melt plastic, and we can just throw some more power at it if need be. Way too much would be bad, but there's considerable wiggle room here. A deeper analysis would indicate that the hotter the heater is relative to ambient air, the more rapid the heat loss to the atmosphere would be, which would cool the heater some. There's a stable equilibrium point, and a simple mechanism to raise and lower the temperature (add more power or take away some power.) Adjusting for the moving vs. static PLA or ABS filament is another variable that suggests an active control mechanism is in order, not just passive radiation to the environment. But if you're really worried about those few precious watts trickling away into space, put a ceramic insulator around the hot end to keep the heat in. As long as it's not too thick, it should decrease heat-up times and allow for a higher max temperature, or save a little power. Easier to just use a bigger supply.

Let's get back to talking about 3d printers, and stop trying to break thermodynamics.

Regards,

aeronaut

-------------------------------------------------------

> No, even transistor can't break fundamental laws

> of physics. That's why linear voltage regulators

> heats a lot. "In fact, the power loss due to

> heating in the transistor is the current times the

> voltage dropped across the transistor" wikipedia

Miso has it right. The difference between a resistor and a transistor is that the resistor can only control the flow of current by converting some of it to heat, specifically the product of the current and the voltage drop. The transistor is a nonlinear, non-ohmic (basically the same thing here) device that uses the base current to control the emitter current. When in full conduction, the current is large but the voltage drop across it is negligible, and hence the heating is small. When in non conduction, the voltage gets large but the current is small. In between it gets interesting.

But the key point to anyone who has build a transistor circuit is that you MUST put current limiting resistors on the base and on the collector-emitter path. If you put the transistor directly between two different voltages with no dropping resistor, as soon as it goes into conduction, the current goes way up, and then the transistor experiences a moment of heat, a small puff of smoke and the smell of burnt plastic, and then becomes some flavor of diode (if you're lucky) or useless (if unlucky).

Even new discoveries don't break the fundamental laws of physics, they encapsulate them. For example, take Newtonian Mechanics (NM) and Special Relativity (SR). SR didn't overthrow NM, it just subsumed it - NM is a special case of SP where the velocities of things are small compared to the velocity of light. All the stuff we know about NM still is true at low speeds, and that's why we still teach it in introductory physics classes.

So to try and close one end of this argument - Tekwizard, if you put 25 watts of heat into a resistor, the efficiency is perfect. 25 W of power is consumed (that is, 25 Joules per second), and 25 watts of heat is produced. Period. The laws of thermodynamics are pretty clear cut on that point, and perfect efficiency is possible because heat is the most entropic form of energy. Converting one type of energy to another that isn't heat, or converting heat into some other type, is never perfectly efficient (unless you have a cold end at absolute zero, which is impossible). But making heat is easy. Put your hands together and rub briskly. Neglecting deformation of the surface layers of your skin, all the mechanical energy turns into heat, some in your palms, some in the muscles moving your arms around.

That said, what I hope Tekwizard was addressing with his question about efficiency was the idea that not all of the power we put into the resistor goes straight into the plastic to be melted. Some heats the resistor, the nozzle, etc. But frankly, it doesn't take a lot of power to melt plastic, and we can just throw some more power at it if need be. Way too much would be bad, but there's considerable wiggle room here. A deeper analysis would indicate that the hotter the heater is relative to ambient air, the more rapid the heat loss to the atmosphere would be, which would cool the heater some. There's a stable equilibrium point, and a simple mechanism to raise and lower the temperature (add more power or take away some power.) Adjusting for the moving vs. static PLA or ABS filament is another variable that suggests an active control mechanism is in order, not just passive radiation to the environment. But if you're really worried about those few precious watts trickling away into space, put a ceramic insulator around the hot end to keep the heat in. As long as it's not too thick, it should decrease heat-up times and allow for a higher max temperature, or save a little power. Easier to just use a bigger supply.

Let's get back to talking about 3d printers, and stop trying to break thermodynamics.

Regards,

aeronaut

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 04:07AM |

Registered: 11 years ago Posts: 143 |

aeronaut Wrote:

-------------------------------------------------------

> miso Wrote:

> --------------------------------------------------

> -----

> > No, even transistor can't break fundamental

> laws

> > of physics. That's why linear voltage

> regulators

> > heats a lot. "In fact, the power loss due to

> > heating in the transistor is the current times

> the

> > voltage dropped across the transistor"

> wikipedia

>

> Miso has it right. The difference between a

> resistor and a transistor is that the resistor can

> only control the flow of current by converting

> some of it to heat, specifically the product of

> the current and the voltage drop. The transistor

> is a nonlinear, non-ohmic (basically the same

> thing here) device that uses the base current to

> control the emitter current. When in full

> conduction, the current is large but the voltage

> drop across it is negligible, and hence the

> heating is small. When in non conduction, the

> voltage gets large but the current is small. In

> between it gets interesting.

>

> But the key point to anyone who has build a

> transistor circuit is that you MUST put current

> limiting resistors on the base and on the

> collector-emitter path. If you put the transistor

> directly between two different voltages with no

> dropping resistor, as soon as it goes into

> conduction, the current goes way up, and then the

> transistor experiences a moment of heat, a small

> puff of smoke and the smell of burnt plastic, and

> then becomes some flavor of diode (if you're

> lucky) or useless (if unlucky).

>

> Even new discoveries don't break the fundamental

> laws of physics, they encapsulate them. For

> example, take Newtonian Mechanics (NM) and Special

> Relativity (SR). SR didn't overthrow NM, it just

> subsumed it - NM is a special case of SP where the

> velocities of things are small compared to the

> velocity of light. All the stuff we know about NM

> still is true at low speeds, and that's why we

> still teach it in introductory physics classes.

>

> So to try and close one end of this argument -

> Tekwizard, if you put 25 watts of heat into a

> resistor, the efficiency is perfect. 25 W of

> power is consumed (that is, 25 Joules per second),

> and 25 watts of heat is produced. Period. The

> laws of thermodynamics are pretty clear cut on

> that point, and perfect efficiency is possible

> because heat is the most entropic form of energy.

> Converting one type of energy to another that

> isn't heat, or converting heat into some other

> type, is never perfectly efficient (unless you

> have a cold end at absolute zero, which is

> impossible). But making heat is easy. Put your

> hands together and rub briskly. Neglecting

> deformation of the surface layers of your skin,

> all the mechanical energy turns into heat, some in

> your palms, some in the muscles moving your arms

> around.

>

> That said, what I hope Tekwizard was addressing

> with his question about efficiency was the idea

> that not all of the power we put into the resistor

> goes straight into the plastic to be melted. Some

> heats the resistor, the nozzle, etc. But frankly,

> it doesn't take a lot of power to melt plastic,

> and we can just throw some more power at it if

> need be. Way too much would be bad, but there's

> considerable wiggle room here. A deeper analysis

> would indicate that the hotter the heater is

> relative to ambient air, the more rapid the heat

> loss to the atmosphere would be, which would cool

> the heater some. There's a stable equilibrium

> point, and a simple mechanism to raise and lower

> the temperature (add more power or take away some

> power.) Adjusting for the moving vs. static PLA

> or ABS filament is another variable that suggests

> an active control mechanism is in order, not just

> passive radiation to the environment. But if

> you're really worried about those few precious

> watts trickling away into space, put a ceramic

> insulator around the hot end to keep the heat in.

> As long as it's not too thick, it should decrease

> heat-up times and allow for a higher max

> temperature, or save a little power. Easier to

> just use a bigger supply.

>

> Let's get back to talking about 3d printers, and

> stop trying to break thermodynamics.

>

> Regards,

> aeronaut

Oh...that all makes perfect sense now.

You have a good way of explaining it, thanks.

Ok, on to better things...

Thanks

Edited 2 time(s). Last edit at 01/06/2013 04:33AM by Tekwizard.

-------------------------------------------------------

> miso Wrote:

> --------------------------------------------------

> -----

> > No, even transistor can't break fundamental

> laws

> > of physics. That's why linear voltage

> regulators

> > heats a lot. "In fact, the power loss due to

> > heating in the transistor is the current times

> the

> > voltage dropped across the transistor"

> wikipedia

>

> Miso has it right. The difference between a

> resistor and a transistor is that the resistor can

> only control the flow of current by converting

> some of it to heat, specifically the product of

> the current and the voltage drop. The transistor

> is a nonlinear, non-ohmic (basically the same

> thing here) device that uses the base current to

> control the emitter current. When in full

> conduction, the current is large but the voltage

> drop across it is negligible, and hence the

> heating is small. When in non conduction, the

> voltage gets large but the current is small. In

> between it gets interesting.

>

> But the key point to anyone who has build a

> transistor circuit is that you MUST put current

> limiting resistors on the base and on the

> collector-emitter path. If you put the transistor

> directly between two different voltages with no

> dropping resistor, as soon as it goes into

> conduction, the current goes way up, and then the

> transistor experiences a moment of heat, a small

> puff of smoke and the smell of burnt plastic, and

> then becomes some flavor of diode (if you're

> lucky) or useless (if unlucky).

>

> Even new discoveries don't break the fundamental

> laws of physics, they encapsulate them. For

> example, take Newtonian Mechanics (NM) and Special

> Relativity (SR). SR didn't overthrow NM, it just

> subsumed it - NM is a special case of SP where the

> velocities of things are small compared to the

> velocity of light. All the stuff we know about NM

> still is true at low speeds, and that's why we

> still teach it in introductory physics classes.

>

> So to try and close one end of this argument -

> Tekwizard, if you put 25 watts of heat into a

> resistor, the efficiency is perfect. 25 W of

> power is consumed (that is, 25 Joules per second),

> and 25 watts of heat is produced. Period. The

> laws of thermodynamics are pretty clear cut on

> that point, and perfect efficiency is possible

> because heat is the most entropic form of energy.

> Converting one type of energy to another that

> isn't heat, or converting heat into some other

> type, is never perfectly efficient (unless you

> have a cold end at absolute zero, which is

> impossible). But making heat is easy. Put your

> hands together and rub briskly. Neglecting

> deformation of the surface layers of your skin,

> all the mechanical energy turns into heat, some in

> your palms, some in the muscles moving your arms

> around.

>

> That said, what I hope Tekwizard was addressing

> with his question about efficiency was the idea

> that not all of the power we put into the resistor

> goes straight into the plastic to be melted. Some

> heats the resistor, the nozzle, etc. But frankly,

> it doesn't take a lot of power to melt plastic,

> and we can just throw some more power at it if

> need be. Way too much would be bad, but there's

> considerable wiggle room here. A deeper analysis

> would indicate that the hotter the heater is

> relative to ambient air, the more rapid the heat

> loss to the atmosphere would be, which would cool

> the heater some. There's a stable equilibrium

> point, and a simple mechanism to raise and lower

> the temperature (add more power or take away some

> power.) Adjusting for the moving vs. static PLA

> or ABS filament is another variable that suggests

> an active control mechanism is in order, not just

> passive radiation to the environment. But if

> you're really worried about those few precious

> watts trickling away into space, put a ceramic

> insulator around the hot end to keep the heat in.

> As long as it's not too thick, it should decrease

> heat-up times and allow for a higher max

> temperature, or save a little power. Easier to

> just use a bigger supply.

>

> Let's get back to talking about 3d printers, and

> stop trying to break thermodynamics.

>

> Regards,

> aeronaut

Oh...that all makes perfect sense now.

You have a good way of explaining it, thanks.

Ok, on to better things...

Thanks

Edited 2 time(s). Last edit at 01/06/2013 04:33AM by Tekwizard.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 05:30AM |

Hello guys. I am new in this forum. I can see that are people with a lot of mechanical experience. I got an idea. What about making a hight temperature nozzle from an used old benzine engine spark plug. It is cheep, sustain very hight temperatures,

mechanical stress, vibrations etc. It may hold easily 550 C for a very long time.It has a cooper or a metal inner rod which can be drilled to make a nozzle. It is somebody wiling to try and post the results?

Best regards,

Octavian

mechanical stress, vibrations etc. It may hold easily 550 C for a very long time.It has a cooper or a metal inner rod which can be drilled to make a nozzle. It is somebody wiling to try and post the results?

Best regards,

Octavian

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 07:57AM |

Registered: 13 years ago Posts: 7,616 |

Quote

They are easy for PID to maintain temperature once it's up to target because they have a fast response time.

You have a seemingly fast response time, because you measure the temperature inside the cartridge. This says not much about the temperature response in the nozzle. If there were a poor flow of heat from the cartridge to the nozzle, you wouldn't even recognize it.

It's an advantage of resistor based heaters they measure temperature elsewhere on the block. This makes them seemingly less accurate, but in fact they're just closer to the truth.

And to many of the posters here: please try to keep your quotations short. Makes following the thread much easier.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 09:38AM |

Registered: 12 years ago Posts: 1,236 |

Trying to answer a couple of questions, the alu base plate : (also seems earlier version used power resistor heater)

Location of the thermistor, there is a hole for it next to heater :

Additionally, this video shows a fan blowing across the hot end [www.youtube.com]

Whether the purpose is to cool the barrel, the plastic or both is not clear.

To summarize the debate on heater cartrdige vs resistor: the advantage of a heater cartridge is that it can run hotter. The disadvantage of a heater cartridge is that it can run too hot.

Location of the thermistor, there is a hole for it next to heater :

Additionally, this video shows a fan blowing across the hot end [www.youtube.com]

Whether the purpose is to cool the barrel, the plastic or both is not clear.

To summarize the debate on heater cartrdige vs resistor: the advantage of a heater cartridge is that it can run hotter. The disadvantage of a heater cartridge is that it can run too hot.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 09:43AM |

Registered: 12 years ago Posts: 539 |

Traumflug Wrote:

-------------------------------------------------------

> You have a seemingly fast response time, because

> you measure the temperature inside the cartridge.

I don't think the temp is measured in the cartridge. I believe the temp is measured in the heater block beside the cartridge.

-------------------------------------------------------

> You have a seemingly fast response time, because

> you measure the temperature inside the cartridge.

I don't think the temp is measured in the cartridge. I believe the temp is measured in the heater block beside the cartridge.

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 12:45PM |

Registered: 11 years ago Posts: 374 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 03:12PM |

Registered: 11 years ago Posts: 143 |

Traumflug Wrote:

-------------------------------------------------------

> They are easy for PID to maintain temperature once

> it's up to target because they have a fast

> response time.

>

> You have a seemingly fast response time, because

> you measure the temperature inside the cartridge.

> This says not much about the temperature response

> in the nozzle. If there were a poor flow of heat

> from the cartridge to the nozzle, you wouldn't

> even recognize it.

>

> It's an advantage of resistor based heaters they

> measure temperature elsewhere on the block. This

> makes them seemingly less accurate, but in fact

> they're just closer to the truth.

No, that's not true.

I use a separate thermistor installed in the block beside the nozzle, just like everyone else.

The heater cartridge doesn't have it's own thermistor.

Why would you think it did?

-------------------------------------------------------

> They are easy for PID to maintain temperature once

> it's up to target because they have a fast

> response time.

>

> You have a seemingly fast response time, because

> you measure the temperature inside the cartridge.

> This says not much about the temperature response

> in the nozzle. If there were a poor flow of heat

> from the cartridge to the nozzle, you wouldn't

> even recognize it.

>

> It's an advantage of resistor based heaters they

> measure temperature elsewhere on the block. This

> makes them seemingly less accurate, but in fact

> they're just closer to the truth.

No, that's not true.

I use a separate thermistor installed in the block beside the nozzle, just like everyone else.

The heater cartridge doesn't have it's own thermistor.

Why would you think it did?

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 06, 2013 10:24PM |

Registered: 11 years ago Posts: 374 |

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 07, 2013 05:15AM |

Registered: 12 years ago Posts: 300 |

I have a question: I often read that a good nozzle should have a very short transition between solid and melted plastic. This is why most designs use PTFE and PEEK.

What happens in an entirely metal hot-end? Is not the temperature gradiant too large? Where does the plastic really melt?

Frédéric

What happens in an entirely metal hot-end? Is not the temperature gradiant too large? Where does the plastic really melt?

Frédéric

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 07, 2013 06:27AM |

Admin Registered: 17 years ago Posts: 7,879 |

In my experience a long transition zone in stainless steel does not work. [hydraraptor.blogspot.co.uk] but a short one does [hydraraptor.blogspot.co.uk].

Perhaps Josef got round it by lapping and polishing the inside as stated, or perhaps it is tapered outwards slightly. That makes a huge difference, see [hydraraptor.blogspot.co.uk] and [hydraraptor.blogspot.co.uk] but isn't easy to achieve in a single piece. I think it would need to be done with a tiny boring bar on a CNC lathe.

[www.hydraraptor.blogspot.com]

Perhaps Josef got round it by lapping and polishing the inside as stated, or perhaps it is tapered outwards slightly. That makes a huge difference, see [hydraraptor.blogspot.co.uk] and [hydraraptor.blogspot.co.uk] but isn't easy to achieve in a single piece. I think it would need to be done with a tiny boring bar on a CNC lathe.

[www.hydraraptor.blogspot.com]

|

Re: Josef Prusa's Next Gen Hot-End (Print Nylon, Peek & PC) January 07, 2013 06:59AM |

Admin Registered: 11 years ago Posts: 1,063 |

I found if you want to make a practically non existant transition zonea long constriction works very effectively and so far i've managed to get a meltzone down to 7mm long with abs and pla flowing like it was butter on my last prototype i flared the inside just after the constriction and interestingly even though there was more molten plastic in the meltzone it reduced the extrusion force a little bit, the problem then being is that retraction wasn't as effective,

i think the ideal hotend should have less than a 5mm meltzone with a heater block that acts more like a heat capacitor than just a mounting for a heater cartridge or a resistor, and this is where heater blocks could be made of brass or somthing that "holds" the heat rather than dissipating it anyway and everywhere,

i think the ideal hotend should have less than a 5mm meltzone with a heater block that acts more like a heat capacitor than just a mounting for a heater cartridge or a resistor, and this is where heater blocks could be made of brass or somthing that "holds" the heat rather than dissipating it anyway and everywhere,

Sorry, only registered users may post in this forum.