Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 /

Posted by deepbreath

|

Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 02, 2013 04:12PM |

Registered: 11 years ago Posts: 12 |

Hi guys,

I ordered a reprap kit from RepRapBCN a few months ago. To everyone (not enough experienced) - do not buy your kit from them: you will not receive any good documentation nor support to build it. I am a software developer, so assembling the reprap with the info from internet only was a big challenge for me. I assembled it and now I'm trying to test it with pronterface.

I'm able to connect to the printer, however I have two big problems.

Problem 1: Extruder heater

Both thermistors read the temperature ok (~20 C), but only the bed heater heats up.

When I set the temperature in pronterface I have ~ 11.3V on D8 (and a red LED blinking), but 0V on D10 (no blinking LED).

Problem 2: Motors not moving

All stepper motors are connected properly according to the schematics (http://reprap.org/wiki/RAMPS_1.4), but they simply don't move.

When I try to move along any axis I receive something like "echo:endstops hit: X:31.99" in pronterface console.

This happens with all motors.

The endstops are connected properly. However when I request the endstops' status, while none of them is touched, I receive the following:

x_min: TRIGGERED

x_max: open

y_min: TRIGGERED

y_max: open

z_min: TRIGGERED

z_max: open

I'm not sure that I understand the ?_min and ?_max values since I have only one endstop per axis. Anyway, I'm not sure if this is a problem, but it's however something I do not understand.

Can you assist me finally have my printer running ? Thanks.

? Thanks.

Edited 1 time(s). Last edit at 01/02/2013 04:25PM by deepbreath.

I ordered a reprap kit from RepRapBCN a few months ago. To everyone (not enough experienced) - do not buy your kit from them: you will not receive any good documentation nor support to build it. I am a software developer, so assembling the reprap with the info from internet only was a big challenge for me. I assembled it and now I'm trying to test it with pronterface.

I'm able to connect to the printer, however I have two big problems.

Problem 1: Extruder heater

Both thermistors read the temperature ok (~20 C), but only the bed heater heats up.

When I set the temperature in pronterface I have ~ 11.3V on D8 (and a red LED blinking), but 0V on D10 (no blinking LED).

Problem 2: Motors not moving

All stepper motors are connected properly according to the schematics (http://reprap.org/wiki/RAMPS_1.4), but they simply don't move.

When I try to move along any axis I receive something like "echo:endstops hit: X:31.99" in pronterface console.

This happens with all motors.

The endstops are connected properly. However when I request the endstops' status, while none of them is touched, I receive the following:

x_min: TRIGGERED

x_max: open

y_min: TRIGGERED

y_max: open

z_min: TRIGGERED

z_max: open

I'm not sure that I understand the ?_min and ?_max values since I have only one endstop per axis. Anyway, I'm not sure if this is a problem, but it's however something I do not understand.

Can you assist me finally have my printer running

? Thanks.

? Thanks.Edited 1 time(s). Last edit at 01/02/2013 04:25PM by deepbreath.

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 02, 2013 04:42PM |

Registered: 12 years ago Posts: 809 |

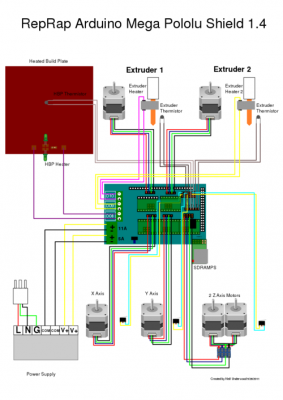

Issue 1 - Do you have the machine hooked up like the image below?

D8 = Heated Bed

D10 = Extruder

What board have you defined in firmware?

Issue 2 - The state of your endstops is probably reversed - wired NC (Normally Closed) instead of NO (Normally Open). If you close one of the switches does the state change in pronterface? Also you probably need to define the endstops in firmware.

You can have 6 endstops if you want, but 3 is normal.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

D8 = Heated Bed

D10 = Extruder

What board have you defined in firmware?

Issue 2 - The state of your endstops is probably reversed - wired NC (Normally Closed) instead of NO (Normally Open). If you close one of the switches does the state change in pronterface? Also you probably need to define the endstops in firmware.

You can have 6 endstops if you want, but 3 is normal.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 02, 2013 05:36PM |

Registered: 11 years ago Posts: 12 |

Thank you, akhlut.

"Issue 1 - Do you have the machine hooked up like the image below? "

Yes, exactly.

"What board have you defined in firmware?"

#define MOTHERBOARD 34

// 34 = RAMPS 1.3 (Power outputs: Extruder0, Extruder1, Bed)

I haven't found a constant for RAMPS 1.4

"Issue2 - If you close one of the switches does the state change in pronterface?"

As I've reported, the status of my endstops is:

x_min: TRIGGERED

x_max: open

y_min: TRIGGERED

y_max: open

z_min: TRIGGERED

z_max: open

When I close the x-endstop, I have:

x_min: TRIGGERED

x_max: TRIGGERED

However, the x_min stays always on TRIGGERED which is little confusing for me. If the software waits for all variables for an axis to become OPEN in order to power up the motor, then this is definitely a problem - x_min and x_max are never both OPEN.

I can however invert the endstops in configuration.h. As a result I have the following endstops status (it's logical based on the status above):

x_min: open

x_max: TRIGGERED

y_min: open

y_max: TRIGGERED

z_min: open

z_max: TRIGGERED

"Issue 1 - Do you have the machine hooked up like the image below? "

Yes, exactly.

"What board have you defined in firmware?"

#define MOTHERBOARD 34

// 34 = RAMPS 1.3 (Power outputs: Extruder0, Extruder1, Bed)

I haven't found a constant for RAMPS 1.4

"Issue2 - If you close one of the switches does the state change in pronterface?"

As I've reported, the status of my endstops is:

x_min: TRIGGERED

x_max: open

y_min: TRIGGERED

y_max: open

z_min: TRIGGERED

z_max: open

When I close the x-endstop, I have:

x_min: TRIGGERED

x_max: TRIGGERED

However, the x_min stays always on TRIGGERED which is little confusing for me. If the software waits for all variables for an axis to become OPEN in order to power up the motor, then this is definitely a problem - x_min and x_max are never both OPEN.

I can however invert the endstops in configuration.h. As a result I have the following endstops status (it's logical based on the status above):

x_min: open

x_max: TRIGGERED

y_min: open

y_max: TRIGGERED

z_min: open

z_max: TRIGGERED

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 02, 2013 06:40PM |

Registered: 12 years ago Posts: 809 |

Are you sure you have the endstops on the correct pins? Also, what endstops are you using - mechanical or opto or hall-o?

Gotta run, but here's a copy of my configuration.h for reference:

#ifndef CONFIGURATION_H

#define CONFIGURATION_H

// This configurtion file contains the basic settings.

// Advanced settings can be found in Configuration_adv.h

// BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration

//User specified version info of this build to display in [Pronterface, etc] terminal window during startup.

//Implementation of an idea by Prof Braino to inform user that any changes made

//to this build by the user have been successfully uploaded into firmware.

#define STRING_VERSION_CONFIG_H __DATE__ " " __TIME__ // build date and time

#define STRING_CONFIG_H_AUTHOR "(none, default config)" //Who made the changes.

// SERIAL_PORT selects which serial port should be used for communication with the host.

// This allows the connection of wireless adapters (for instance) to non-default port pins.

// Serial port 0 is still used by the Arduino bootloader regardless of this setting.

#define SERIAL_PORT 0

// This determines the communication speed of the printer

#define BAUDRATE 250000

//#define BAUDRATE 115200

//// The following define selects which electronics board you have. Please choose the one that matches your setup

// 10 = Gen7 custom (Alfons3 Version) "https://github.com/Alfons3/Generation_7_Electronics"

// 11 = Gen7 v1.1, v1.2 = 11

// 12 = Gen7 v1.3

// 13 = Gen7 v1.4

// 3 = MEGA/RAMPS up to 1.2 = 3

// 33 = RAMPS 1.3 (Power outputs: Extruder, Bed, Fan)

// 34 = RAMPS 1.3 (Power outputs: Extruder0, Extruder1, Bed)

// 4 = Duemilanove w/ ATMega328P pin assignment

// 5 = Gen6

// 51 = Gen6 deluxe

// 6 = Sanguinololu < 1.2

// 62 = Sanguinololu 1.2 and above

// 63 = Melzi

// 7 = Ultimaker

// 71 = Ultimaker (Older electronics. Pre 1.5.4. This is rare)

// 8 = Teensylu

// 9 = Gen3+

// 70 = Megatronics

// 90 = Alpha OMCA board

// 91 = Final OMCA board

#ifndef MOTHERBOARD

#define MOTHERBOARD 33

#endif

//===========================================================================

//=============================Thermal Settings ============================

//===========================================================================

//

//--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table

//

//// Temperature sensor settings:

// -2 is thermocouple with MAX6675 (only for sensor 0)

// -1 is thermocouple with AD595

// 0 is not used

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup)

// 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup)

// 3 is mendel-parts thermistor (4.7k pullup)

// 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !!

// 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan) (4.7k pullup)

// 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup)

// 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup)

//

// 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k

// (but gives greater accuracy and more stable PID)

// 51 is 100k thermistor - EPCOS (1k pullup)

// 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup)

// 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan) (1k pullup)

#define TEMP_SENSOR_0 1

#define TEMP_SENSOR_1 0

#define TEMP_SENSOR_2 0

#define TEMP_SENSOR_BED 1

// Actual temperature must be close to target for this long before M109 returns success

#define TEMP_RESIDENCY_TIME 10 // (seconds)

#define TEMP_HYSTERESIS 3 // (degC) range of +/- temperatures considered "close" to the target one

#define TEMP_WINDOW 1 // (degC) Window around target to start the recidency timer x degC early.

// The minimal temperature defines the temperature below which the heater will not be enabled It is used

// to check that the wiring to the thermistor is not broken.

// Otherwise this would lead to the heater being powered on all the time.

#define HEATER_0_MINTEMP 5

#define HEATER_1_MINTEMP 5

#define HEATER_2_MINTEMP 5

#define BED_MINTEMP 5

// When temperature exceeds max temp, your heater will be switched off.

// This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure!

// You should use MINTEMP for thermistor short/failure protection.

#define HEATER_0_MAXTEMP 275

#define HEATER_1_MAXTEMP 275

#define HEATER_2_MAXTEMP 275

#define BED_MAXTEMP 150

// If your bed has low resistance e.g. .6 ohm and throws the fuse you can duty cycle it to reduce the

// average current. The value should be an integer and the heat bed will be turned on for 1 interval of

// HEATER_BED_DUTY_CYCLE_DIVIDER intervals.

//#define HEATER_BED_DUTY_CYCLE_DIVIDER 4

// PID settings:

// Comment the following line to disable PID and enable bang-bang.

#define PIDTEMP

#define PID_MAX 255 // limits current to nozzle; 255=full current

#ifdef PIDTEMP

//#define PID_DEBUG // Sends debug data to the serial port.

//#define PID_OPENLOOP 1 // Puts PID in open loop. M104/M140 sets the output power from 0 to PID_MAX

#define PID_INTEGRAL_DRIVE_MAX 255 //limit for the integral term

#define K1 0.95 //smoothing factor withing the PID

#define PID_dT ((16.0 * 8.0)/(F_CPU / 64.0 / 256.0)) //sampling period of the

// If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it

// Ultimaker

// #define DEFAULT_Kp 22.2

// #define DEFAULT_Ki 1.08

// #define DEFAULT_Kd 114

// Makergear

// #define DEFAULT_Kp 7.0

// #define DEFAULT_Ki 0.1

// #define DEFAULT_Kd 12

// Mendel Parts V9 on 12V

// #define DEFAULT_Kp 63.0

// #define DEFAULT_Ki 2.25

// #define DEFAULT_Kd 440

// M303 autotune PID

#define DEFAULT_Kp 36.62

#define DEFAULT_Ki 2.90

#define DEFAULT_Kd 115.81

#endif // PIDTEMP

// Bed Temperature Control

// Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis

//

// uncomment this to enable PID on the bed. It uses the same ferquency PWM as the extruder.

// If your PID_dT above is the default, and correct for your hardware/configuration, that means 7.689Hz,

// which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating.

// This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater.

// If your configuration is significantly different than this and you don't understand the issues involved, you proabaly

// shouldn't use bed PID until someone else verifies your hardware works.

// If this is enabled, find your own PID constants below.

#define PIDTEMPBED

//

//#define BED_LIMIT_SWITCHING

// This sets the max power delived to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option.

// all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis)

// setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did,

// so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED)

#define MAX_BED_POWER 255 // limits duty cycle to bed; 255=full current

#ifdef PIDTEMPBED

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from FOPDT model - kp=.39 Tp=405 Tdead=66, Tc set to 79.2, argressive factor of .15 (vs .1, 1, 10)

#define DEFAULT_bedKp 86.68

#define DEFAULT_bedKi 6.36

#define DEFAULT_bedKd 295.39

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from pidautotune

// #define DEFAULT_bedKp 97.1

// #define DEFAULT_bedKi 1.41

// #define DEFAULT_bedKd 1675.16

// FIND YOUR OWN: "M303 E-1 C8 S90" to run autotune on the bed at 90 degreesC for 8 cycles.

#endif // PIDTEMPBED

//this prevents dangerous Extruder moves, i.e. if the temperature is under the limit

//can be software-disabled for whatever purposes by

#define PREVENT_DANGEROUS_EXTRUDE

//if PREVENT_DANGEROUS_EXTRUDE is on, you can still disable (uncomment) very long bits of extrusion separately.

#define PREVENT_LENGTHY_EXTRUDE

#define EXTRUDE_MINTEMP 170

#define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances.

//===========================================================================

//=============================Mechanical Settings===========================

//===========================================================================

// Uncomment the following line to enable CoreXY kinematics

// #define COREXY

// corse Endstop Settings

#define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors

#ifndef ENDSTOPPULLUPS

// fine Enstop settings: Individual Pullups. will be ignord if ENDSTOPPULLUPS is defined

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

//#define ENDSTOPPULLUP_ZMIN

#endif

#ifdef ENDSTOPPULLUPS

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

#define ENDSTOPPULLUP_ZMIN

#endif

// The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins.

const bool X_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops.

const bool Y_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops.

const bool Z_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops.

//#define DISABLE_MAX_ENDSTOPS

// For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define E_ENABLE_ON 0 // For all extruders

// Disables axis when it's not being used.

#define DISABLE_X false

#define DISABLE_Y false

#define DISABLE_Z true

#define DISABLE_E false // For all extruders

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

#define min_software_endstops true //If true, axis won't move to coordinates less than HOME_POS.

#define max_software_endstops true //If true, axis won't move to coordinates greater than the defined lengths below.

// Travel limits after homing

#define X_MAX_POS 310

#define X_MIN_POS 0

#define Y_MAX_POS 300

#define Y_MIN_POS 0

#define Z_MAX_POS 250

#define Z_MIN_POS 0

#define X_MAX_LENGTH (X_MAX_POS - X_MIN_POS)

#define Y_MAX_LENGTH (Y_MAX_POS - Y_MIN_POS)

#define Z_MAX_LENGTH (Z_MAX_POS - Z_MIN_POS)

// The position of the homing switches

//#define MANUAL_HOME_POSITIONS // If defined, manualy programed locations will be used

//#define BED_CENTER_AT_0_0 // If defined the center of the bed is defined as (0,0)

//Manual homing switch locations:

#define MANUAL_X_HOME_POS 0

#define MANUAL_Y_HOME_POS 0

#define MANUAL_Z_HOME_POS 0

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

#define HOMING_FEEDRATE {50*60, 50*60, 3*60, 0} // set the homing speeds (mm/min)

// default settings

//#define DEFAULT_AXIS_STEPS_PER_UNIT {78.7402,78.7402,200*8/3,760*1.1} // default steps per unit for ultimaker

//#define DEFAULT_AXIS_STEPS_PER_UNIT {78.7402,78.7402,200*8/3,760*1.1} // default

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.51113623516111,78.7402,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.32055783646431,78.7402,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.462838921011546,78.7402,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.498437671148466,43.841982182628065,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.498437671148466,44.41943483548943,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.498437671148466,44.47725526733697,1513.4317063942487,977.1776000000001}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.46731055376084,44.47725526733697,1513.4317063942487,977.1776000000001} // 3/8" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.46731055376084,44.47725526733697,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.35641950499834,44.47725526733697,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,44.47725526733697,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,43.93249236204758,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,44.46158522623984,2025.4477465791708,977.1776000000001} // 1/4" ACME

#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,44.43936554346811,2025.4477465791708,936.4618666666669} // 1/4" ACME

#define DEFAULT_MAX_FEEDRATE {500, 500, 3, 45} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000,1000,30,5000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 750 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 750 // X, Y, Z and E max acceleration in mm/s^2 for r retracts

//

#define DEFAULT_XYJERK 5.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

//===========================================================================

//=============================Additional Features===========================

//===========================================================================

// EEPROM

// the microcontroller can store settings in the EEPROM, e.g. max velocity...

// M500 - stores paramters in EEPROM

// M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily).

// M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to.

//define this to enable eeprom support

//#define EEPROM_SETTINGS

//to disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out:

// please keep turned on if you can.

//#define EEPROM_CHITCHAT

//LCD and SD support

//#define ULTRA_LCD //general lcd support, also 16x2

//#define SDSUPPORT // Enable SD Card Support in Hardware Console

//#define ULTIMAKERCONTROLLER //as available from the ultimaker online store.

//#define ULTIPANEL //the ultipanel as on thingiverse

// The RepRapDiscount Smart Controller

// [reprap.org]

//#define REPRAP_DISCOUNT_SMART_CONTROLLER

//automatic expansion

#if defined(ULTIMAKERCONTROLLER) || defined(REPRAP_DISCOUNT_SMART_CONTROLLER)

#define ULTIPANEL

#define NEWPANEL

#endif

// Preheat Constants

#define PLA_PREHEAT_HOTEND_TEMP 180

#define PLA_PREHEAT_HPB_TEMP 70

#define PLA_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

#define ABS_PREHEAT_HOTEND_TEMP 240

#define ABS_PREHEAT_HPB_TEMP 100

#define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

#ifdef ULTIPANEL

// #define NEWPANEL //enable this if you have a click-encoder panel

#define SDSUPPORT

#define ULTRA_LCD

#define LCD_WIDTH 20

#define LCD_HEIGHT 4

#else //no panel but just lcd

#ifdef ULTRA_LCD

#define LCD_WIDTH 16

#define LCD_HEIGHT 2

#endif

#endif

// Increase the FAN pwm frequency. Removes the PWM noise but increases heating in the FET/Arduino

//#define FAST_PWM_FAN

// M240 Triggers a camera by emulating a Canon RC-1 Remote

// Data from: [www.doc-diy.net]

// #define PHOTOGRAPH_PIN 23

// SF send wrong arc g-codes when using Arc Point as fillet procedure

//#define SF_ARC_FIX

#include "Configuration_adv.h"

#include "thermistortables.h"

#endif //__CONFIGURATION_H

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Gotta run, but here's a copy of my configuration.h for reference:

#ifndef CONFIGURATION_H

#define CONFIGURATION_H

// This configurtion file contains the basic settings.

// Advanced settings can be found in Configuration_adv.h

// BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration

//User specified version info of this build to display in [Pronterface, etc] terminal window during startup.

//Implementation of an idea by Prof Braino to inform user that any changes made

//to this build by the user have been successfully uploaded into firmware.

#define STRING_VERSION_CONFIG_H __DATE__ " " __TIME__ // build date and time

#define STRING_CONFIG_H_AUTHOR "(none, default config)" //Who made the changes.

// SERIAL_PORT selects which serial port should be used for communication with the host.

// This allows the connection of wireless adapters (for instance) to non-default port pins.

// Serial port 0 is still used by the Arduino bootloader regardless of this setting.

#define SERIAL_PORT 0

// This determines the communication speed of the printer

#define BAUDRATE 250000

//#define BAUDRATE 115200

//// The following define selects which electronics board you have. Please choose the one that matches your setup

// 10 = Gen7 custom (Alfons3 Version) "https://github.com/Alfons3/Generation_7_Electronics"

// 11 = Gen7 v1.1, v1.2 = 11

// 12 = Gen7 v1.3

// 13 = Gen7 v1.4

// 3 = MEGA/RAMPS up to 1.2 = 3

// 33 = RAMPS 1.3 (Power outputs: Extruder, Bed, Fan)

// 34 = RAMPS 1.3 (Power outputs: Extruder0, Extruder1, Bed)

// 4 = Duemilanove w/ ATMega328P pin assignment

// 5 = Gen6

// 51 = Gen6 deluxe

// 6 = Sanguinololu < 1.2

// 62 = Sanguinololu 1.2 and above

// 63 = Melzi

// 7 = Ultimaker

// 71 = Ultimaker (Older electronics. Pre 1.5.4. This is rare)

// 8 = Teensylu

// 9 = Gen3+

// 70 = Megatronics

// 90 = Alpha OMCA board

// 91 = Final OMCA board

#ifndef MOTHERBOARD

#define MOTHERBOARD 33

#endif

//===========================================================================

//=============================Thermal Settings ============================

//===========================================================================

//

//--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table

//

//// Temperature sensor settings:

// -2 is thermocouple with MAX6675 (only for sensor 0)

// -1 is thermocouple with AD595

// 0 is not used

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup)

// 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup)

// 3 is mendel-parts thermistor (4.7k pullup)

// 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !!

// 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan) (4.7k pullup)

// 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup)

// 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup)

//

// 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k

// (but gives greater accuracy and more stable PID)

// 51 is 100k thermistor - EPCOS (1k pullup)

// 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup)

// 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan) (1k pullup)

#define TEMP_SENSOR_0 1

#define TEMP_SENSOR_1 0

#define TEMP_SENSOR_2 0

#define TEMP_SENSOR_BED 1

// Actual temperature must be close to target for this long before M109 returns success

#define TEMP_RESIDENCY_TIME 10 // (seconds)

#define TEMP_HYSTERESIS 3 // (degC) range of +/- temperatures considered "close" to the target one

#define TEMP_WINDOW 1 // (degC) Window around target to start the recidency timer x degC early.

// The minimal temperature defines the temperature below which the heater will not be enabled It is used

// to check that the wiring to the thermistor is not broken.

// Otherwise this would lead to the heater being powered on all the time.

#define HEATER_0_MINTEMP 5

#define HEATER_1_MINTEMP 5

#define HEATER_2_MINTEMP 5

#define BED_MINTEMP 5

// When temperature exceeds max temp, your heater will be switched off.

// This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure!

// You should use MINTEMP for thermistor short/failure protection.

#define HEATER_0_MAXTEMP 275

#define HEATER_1_MAXTEMP 275

#define HEATER_2_MAXTEMP 275

#define BED_MAXTEMP 150

// If your bed has low resistance e.g. .6 ohm and throws the fuse you can duty cycle it to reduce the

// average current. The value should be an integer and the heat bed will be turned on for 1 interval of

// HEATER_BED_DUTY_CYCLE_DIVIDER intervals.

//#define HEATER_BED_DUTY_CYCLE_DIVIDER 4

// PID settings:

// Comment the following line to disable PID and enable bang-bang.

#define PIDTEMP

#define PID_MAX 255 // limits current to nozzle; 255=full current

#ifdef PIDTEMP

//#define PID_DEBUG // Sends debug data to the serial port.

//#define PID_OPENLOOP 1 // Puts PID in open loop. M104/M140 sets the output power from 0 to PID_MAX

#define PID_INTEGRAL_DRIVE_MAX 255 //limit for the integral term

#define K1 0.95 //smoothing factor withing the PID

#define PID_dT ((16.0 * 8.0)/(F_CPU / 64.0 / 256.0)) //sampling period of the

// If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it

// Ultimaker

// #define DEFAULT_Kp 22.2

// #define DEFAULT_Ki 1.08

// #define DEFAULT_Kd 114

// Makergear

// #define DEFAULT_Kp 7.0

// #define DEFAULT_Ki 0.1

// #define DEFAULT_Kd 12

// Mendel Parts V9 on 12V

// #define DEFAULT_Kp 63.0

// #define DEFAULT_Ki 2.25

// #define DEFAULT_Kd 440

// M303 autotune PID

#define DEFAULT_Kp 36.62

#define DEFAULT_Ki 2.90

#define DEFAULT_Kd 115.81

#endif // PIDTEMP

// Bed Temperature Control

// Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis

//

// uncomment this to enable PID on the bed. It uses the same ferquency PWM as the extruder.

// If your PID_dT above is the default, and correct for your hardware/configuration, that means 7.689Hz,

// which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating.

// This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater.

// If your configuration is significantly different than this and you don't understand the issues involved, you proabaly

// shouldn't use bed PID until someone else verifies your hardware works.

// If this is enabled, find your own PID constants below.

#define PIDTEMPBED

//

//#define BED_LIMIT_SWITCHING

// This sets the max power delived to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option.

// all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis)

// setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did,

// so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED)

#define MAX_BED_POWER 255 // limits duty cycle to bed; 255=full current

#ifdef PIDTEMPBED

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from FOPDT model - kp=.39 Tp=405 Tdead=66, Tc set to 79.2, argressive factor of .15 (vs .1, 1, 10)

#define DEFAULT_bedKp 86.68

#define DEFAULT_bedKi 6.36

#define DEFAULT_bedKd 295.39

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from pidautotune

// #define DEFAULT_bedKp 97.1

// #define DEFAULT_bedKi 1.41

// #define DEFAULT_bedKd 1675.16

// FIND YOUR OWN: "M303 E-1 C8 S90" to run autotune on the bed at 90 degreesC for 8 cycles.

#endif // PIDTEMPBED

//this prevents dangerous Extruder moves, i.e. if the temperature is under the limit

//can be software-disabled for whatever purposes by

#define PREVENT_DANGEROUS_EXTRUDE

//if PREVENT_DANGEROUS_EXTRUDE is on, you can still disable (uncomment) very long bits of extrusion separately.

#define PREVENT_LENGTHY_EXTRUDE

#define EXTRUDE_MINTEMP 170

#define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances.

//===========================================================================

//=============================Mechanical Settings===========================

//===========================================================================

// Uncomment the following line to enable CoreXY kinematics

// #define COREXY

// corse Endstop Settings

#define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors

#ifndef ENDSTOPPULLUPS

// fine Enstop settings: Individual Pullups. will be ignord if ENDSTOPPULLUPS is defined

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

//#define ENDSTOPPULLUP_ZMIN

#endif

#ifdef ENDSTOPPULLUPS

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

#define ENDSTOPPULLUP_ZMIN

#endif

// The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins.

const bool X_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops.

const bool Y_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops.

const bool Z_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops.

//#define DISABLE_MAX_ENDSTOPS

// For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define E_ENABLE_ON 0 // For all extruders

// Disables axis when it's not being used.

#define DISABLE_X false

#define DISABLE_Y false

#define DISABLE_Z true

#define DISABLE_E false // For all extruders

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

#define min_software_endstops true //If true, axis won't move to coordinates less than HOME_POS.

#define max_software_endstops true //If true, axis won't move to coordinates greater than the defined lengths below.

// Travel limits after homing

#define X_MAX_POS 310

#define X_MIN_POS 0

#define Y_MAX_POS 300

#define Y_MIN_POS 0

#define Z_MAX_POS 250

#define Z_MIN_POS 0

#define X_MAX_LENGTH (X_MAX_POS - X_MIN_POS)

#define Y_MAX_LENGTH (Y_MAX_POS - Y_MIN_POS)

#define Z_MAX_LENGTH (Z_MAX_POS - Z_MIN_POS)

// The position of the homing switches

//#define MANUAL_HOME_POSITIONS // If defined, manualy programed locations will be used

//#define BED_CENTER_AT_0_0 // If defined the center of the bed is defined as (0,0)

//Manual homing switch locations:

#define MANUAL_X_HOME_POS 0

#define MANUAL_Y_HOME_POS 0

#define MANUAL_Z_HOME_POS 0

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

#define HOMING_FEEDRATE {50*60, 50*60, 3*60, 0} // set the homing speeds (mm/min)

// default settings

//#define DEFAULT_AXIS_STEPS_PER_UNIT {78.7402,78.7402,200*8/3,760*1.1} // default steps per unit for ultimaker

//#define DEFAULT_AXIS_STEPS_PER_UNIT {78.7402,78.7402,200*8/3,760*1.1} // default

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.51113623516111,78.7402,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.32055783646431,78.7402,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.462838921011546,78.7402,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.498437671148466,43.841982182628065,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.498437671148466,44.41943483548943,200*8/3,760*1.1}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.498437671148466,44.47725526733697,1513.4317063942487,977.1776000000001}

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.46731055376084,44.47725526733697,1513.4317063942487,977.1776000000001} // 3/8" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.46731055376084,44.47725526733697,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.35641950499834,44.47725526733697,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,44.47725526733697,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,43.93249236204758,2025.4477465791708,977.1776000000001} // 1/4" ACME

//#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,44.46158522623984,2025.4477465791708,977.1776000000001} // 1/4" ACME

#define DEFAULT_AXIS_STEPS_PER_UNIT {44.37860880940305,44.43936554346811,2025.4477465791708,936.4618666666669} // 1/4" ACME

#define DEFAULT_MAX_FEEDRATE {500, 500, 3, 45} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000,1000,30,5000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 750 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 750 // X, Y, Z and E max acceleration in mm/s^2 for r retracts

//

#define DEFAULT_XYJERK 5.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

//===========================================================================

//=============================Additional Features===========================

//===========================================================================

// EEPROM

// the microcontroller can store settings in the EEPROM, e.g. max velocity...

// M500 - stores paramters in EEPROM

// M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily).

// M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to.

//define this to enable eeprom support

//#define EEPROM_SETTINGS

//to disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out:

// please keep turned on if you can.

//#define EEPROM_CHITCHAT

//LCD and SD support

//#define ULTRA_LCD //general lcd support, also 16x2

//#define SDSUPPORT // Enable SD Card Support in Hardware Console

//#define ULTIMAKERCONTROLLER //as available from the ultimaker online store.

//#define ULTIPANEL //the ultipanel as on thingiverse

// The RepRapDiscount Smart Controller

// [reprap.org]

//#define REPRAP_DISCOUNT_SMART_CONTROLLER

//automatic expansion

#if defined(ULTIMAKERCONTROLLER) || defined(REPRAP_DISCOUNT_SMART_CONTROLLER)

#define ULTIPANEL

#define NEWPANEL

#endif

// Preheat Constants

#define PLA_PREHEAT_HOTEND_TEMP 180

#define PLA_PREHEAT_HPB_TEMP 70

#define PLA_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

#define ABS_PREHEAT_HOTEND_TEMP 240

#define ABS_PREHEAT_HPB_TEMP 100

#define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

#ifdef ULTIPANEL

// #define NEWPANEL //enable this if you have a click-encoder panel

#define SDSUPPORT

#define ULTRA_LCD

#define LCD_WIDTH 20

#define LCD_HEIGHT 4

#else //no panel but just lcd

#ifdef ULTRA_LCD

#define LCD_WIDTH 16

#define LCD_HEIGHT 2

#endif

#endif

// Increase the FAN pwm frequency. Removes the PWM noise but increases heating in the FET/Arduino

//#define FAST_PWM_FAN

// M240 Triggers a camera by emulating a Canon RC-1 Remote

// Data from: [www.doc-diy.net]

// #define PHOTOGRAPH_PIN 23

// SF send wrong arc g-codes when using Arc Point as fillet procedure

//#define SF_ARC_FIX

#include "Configuration_adv.h"

#include "thermistortables.h"

#endif //__CONFIGURATION_H

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 03, 2013 06:38AM |

Registered: 11 years ago Posts: 12 |

"Are you sure you have the endstops on the correct pins?" - Yes, there are two possible situations  - one is correct, the other one - incorrect. I already checked the forum for solutions. Another guy had similar problems, but he had really connected the endstops wrong. However, I connected them correctly, otherwise my RAMPS wouldn't have powered up.

- one is correct, the other one - incorrect. I already checked the forum for solutions. Another guy had similar problems, but he had really connected the endstops wrong. However, I connected them correctly, otherwise my RAMPS wouldn't have powered up.

I think I have mechanical endstops. How can I check this?

I'll test my printer with your configuration this evening.

- one is correct, the other one - incorrect. I already checked the forum for solutions. Another guy had similar problems, but he had really connected the endstops wrong. However, I connected them correctly, otherwise my RAMPS wouldn't have powered up.

- one is correct, the other one - incorrect. I already checked the forum for solutions. Another guy had similar problems, but he had really connected the endstops wrong. However, I connected them correctly, otherwise my RAMPS wouldn't have powered up.I think I have mechanical endstops. How can I check this?

I'll test my printer with your configuration this evening.

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 03, 2013 09:25AM |

Registered: 11 years ago Posts: 64 |

Deepbreath,

Take a deep breath.

Your setup is the same as mine except for the software. I'm not using Pronterface, I'm using Repetier Host which allows you to use Slic3r or Skeinforge but you can send commands through to the board and get a response with any of these.

Did you build all of the boards (Ramps and the Polulu drivers) or did they come pre-assembled?

You said you don't find an option for the RAMPS 1.4 in your firmware setup, but in my Sprinter/Marlin configuration I see this:

//// The following define selects which electronics board you have. Please choose the one that matches your setup

// MEGA/RAMPS up to 1.2 = 3,

// RAMPS 1.3/1.4 = 33

You said you had motherboard defined as 34, Akhlut's and mine are set this way:

#define MOTHERBOARD 33

You might try that and see how it goes.

In answer to your question about the end stops: If they're mechanical they are just micro switches with a little lever that pushes a button when tripped (You can hear them click). An opto type stop needs to have something slide in between the little optical transmitter and the receiver to break the beam. I think a piece of tin can or aluminum is often used.

Once you know which kind you have you'll be able to figure out how to deal with it in the firmware.

Take a deep breath.

Your setup is the same as mine except for the software. I'm not using Pronterface, I'm using Repetier Host which allows you to use Slic3r or Skeinforge but you can send commands through to the board and get a response with any of these.

Did you build all of the boards (Ramps and the Polulu drivers) or did they come pre-assembled?

You said you don't find an option for the RAMPS 1.4 in your firmware setup, but in my Sprinter/Marlin configuration I see this:

//// The following define selects which electronics board you have. Please choose the one that matches your setup

// MEGA/RAMPS up to 1.2 = 3,

// RAMPS 1.3/1.4 = 33

You said you had motherboard defined as 34, Akhlut's and mine are set this way:

#define MOTHERBOARD 33

You might try that and see how it goes.

In answer to your question about the end stops: If they're mechanical they are just micro switches with a little lever that pushes a button when tripped (You can hear them click). An opto type stop needs to have something slide in between the little optical transmitter and the receiver to break the beam. I think a piece of tin can or aluminum is often used.

Once you know which kind you have you'll be able to figure out how to deal with it in the firmware.

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 03, 2013 11:33AM |

Registered: 11 years ago Posts: 42 |

I have the same setup as you (but I made the frame etc). I found that the default pinout in Marlin are incorrect for ramps1.4. I had to switch some of the endstops around, and the extruder / bed / fan outputs are wrong too. I used a volt meter to figure out which one controled which output. And I use the serial port monitor in the arduino software and gcode M119 to figure out which endstops go where.

When I get home I can post my configuration file, if it would help.

When I get home I can post my configuration file, if it would help.

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 03, 2013 11:39AM |

Registered: 12 years ago Posts: 809 |

Deepbreath,

Can you post an image of the endstops you're using as well as a closeup of the RAMPS wiring?

It would be most helpful.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Can you post an image of the endstops you're using as well as a closeup of the RAMPS wiring?

It would be most helpful.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 03, 2013 12:09PM |

Registered: 11 years ago Posts: 12 |

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 03, 2013 02:53PM |

Registered: 11 years ago Posts: 12 |

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 03, 2013 04:25PM |

Registered: 12 years ago Posts: 809 |

OK!

Well, I think your hotend isn't heating up because you don't have a set of leads coming from your power supply to the 5A terminal. If you hook up 12V and GND to the appropriate terminals you'll be in business.

Those are mechanical endstops. Looks like they're wired correctly - to "S" and "-"

Can you post your configuration.h?

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Well, I think your hotend isn't heating up because you don't have a set of leads coming from your power supply to the 5A terminal. If you hook up 12V and GND to the appropriate terminals you'll be in business.

Those are mechanical endstops. Looks like they're wired correctly - to "S" and "-"

Can you post your configuration.h?

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 24, 2013 01:11PM |

Hi guys,

just reading your post. I'm building a prusa mendel v2, arduino mega 2560, ramps 1.4. I'm using repetier host.

I've got the same problem as deepbreath with my endstops (mech endstop v1.2 from makerbot).

I can move the x carrier along its axis but in only one direction (away from the endstop), it won't move in the other direction. When I click the endstop myself, I can then move the x carrier in both direction through repetierhost. Same problem for Y and Z axis. I don't know how to get my endstop status up either.

Having read your conversation above, I think my problem is something to do with the state of my endstops (wired NC (Normally Closed) instead of NO (Normally Open)).

The thing is I can't find how to change this in repetierhost, nor can I find it on the firmware. If someone has an answer, it would be greatly appreciated!

Thanks

just reading your post. I'm building a prusa mendel v2, arduino mega 2560, ramps 1.4. I'm using repetier host.

I've got the same problem as deepbreath with my endstops (mech endstop v1.2 from makerbot).

I can move the x carrier along its axis but in only one direction (away from the endstop), it won't move in the other direction. When I click the endstop myself, I can then move the x carrier in both direction through repetierhost. Same problem for Y and Z axis. I don't know how to get my endstop status up either.

Having read your conversation above, I think my problem is something to do with the state of my endstops (wired NC (Normally Closed) instead of NO (Normally Open)).

The thing is I can't find how to change this in repetierhost, nor can I find it on the firmware. If someone has an answer, it would be greatly appreciated!

Thanks

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / January 25, 2013 01:22AM |

Registered: 11 years ago Posts: 1,592 |

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / February 26, 2013 02:57PM |

Hi

I am using Arduino 2560 and RAMPS1.4, I have mendel software, I had the same problem as you guys, My problem solved it self by re soldering the microswitches, I found out that it was NOT all microswithches that shorted at the outer pins, Two of mine shorted at he two ones closest to the arms connection ????!!!!! ater mesuring this with an ohm meter I got it right.

I am using Arduino 2560 and RAMPS1.4, I have mendel software, I had the same problem as you guys, My problem solved it self by re soldering the microswitches, I found out that it was NOT all microswithches that shorted at the outer pins, Two of mine shorted at he two ones closest to the arms connection ????!!!!! ater mesuring this with an ohm meter I got it right.

|

Re: Troubleshooting: RepRap Mendel Prusa + Greg's Extruder /Arduino 2560 + RAMPS 1.4 / April 23, 2013 02:28AM |

I had a similar issue with the motors only moving in one direction. I think there is probably a setting in the firmware that has all (Six total) end stops enabled, but I'm only using three. The result was the motors only moving in one direction. Instead of fixing it in the firmware though I just did a different hackish fix. I put jumpers on the end stop connectors I wasn't using since I have a bunch of jumpers from old PCs laying around. Worked like a charm.

Sorry, only registered users may post in this forum.