Bed material for nylon printing

Posted by netbear

|

Bed material for nylon printing January 06, 2013 10:07AM |

Registered: 11 years ago Posts: 2 |

Hello,

I have recently started to print using nylon (Taulman 618 to be precise). I get really nice prints but are having problems getting the nylon to stick to the build bed. I have tried both kapton and blue tape with different temperatures but are not satisfied with the stickiness, the object comes loose after 15-20 min printing.

Any ideas of what to try/use?

Thank you

/Björn

I have recently started to print using nylon (Taulman 618 to be precise). I get really nice prints but are having problems getting the nylon to stick to the build bed. I have tried both kapton and blue tape with different temperatures but are not satisfied with the stickiness, the object comes loose after 15-20 min printing.

Any ideas of what to try/use?

Thank you

/Björn

|

Re: Bed material for nylon printing January 06, 2013 01:54PM |

Admin Registered: 15 years ago Posts: 1,470 |

How hot are you trying the print bed at? I am also interested as I just got some Taulman nylon to play with, though I haven't had a chance to try printing with it yet.

Edited 1 time(s). Last edit at 01/06/2013 01:55PM by NewPerfection.

Edited 1 time(s). Last edit at 01/06/2013 01:55PM by NewPerfection.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Bed material for nylon printing January 06, 2013 08:48PM |

Registered: 11 years ago Posts: 374 |

Have you tried some of the other options people use for PLA, maybe they will work for your application?

Kapton Tape (expensive! like wow expensive)

Mixture of water and white (elmers) glue applied to bed with cloth or brush in a thin coat. (I've never done this and peoples recommended ratios vary, see the "printing" forum here.)

Kapton Tape (expensive! like wow expensive)

Mixture of water and white (elmers) glue applied to bed with cloth or brush in a thin coat. (I've never done this and peoples recommended ratios vary, see the "printing" forum here.)

|

Re: Bed material for nylon printing January 06, 2013 09:24PM |

Admin Registered: 15 years ago Posts: 1,470 |

I just tried PVA glue, while Nylon kind of sticks to it it's not enough to keep it from peeling up and coming free of the bed.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Bed material for nylon printing January 07, 2013 05:05AM |

Registered: 11 years ago Posts: 2 |

I have tried everytthing from 20C (room temperature) to around 100C.

Kapton: Not good at any temperature.

Blue tape (M3): Best so far but the tape itself comes loose if temperature is high (100C). Could be the texture that helps the nylon stick.

Thin layer of Bostik Primer 6000: Works great for PLA at 55C but looses its effect with higher temperatures. For Nylon it is better than Kapton but worse than blue tape.

I have some PET tape I haven't tried yet but my hopes for this tape to work are not high.

xclusive585: Check out dx.com they have Kapton (or similar) tape that I use successfully with ABS.

Kapton: Not good at any temperature.

Blue tape (M3): Best so far but the tape itself comes loose if temperature is high (100C). Could be the texture that helps the nylon stick.

Thin layer of Bostik Primer 6000: Works great for PLA at 55C but looses its effect with higher temperatures. For Nylon it is better than Kapton but worse than blue tape.

I have some PET tape I haven't tried yet but my hopes for this tape to work are not high.

xclusive585: Check out dx.com they have Kapton (or similar) tape that I use successfully with ABS.

|

Re: Bed material for nylon printing January 07, 2013 11:38AM |

Registered: 12 years ago Posts: 62 |

|

Re: Bed material for nylon printing January 13, 2013 02:54PM |

Registered: 16 years ago Posts: 824 |

If you printer's parts are NOT made from PLA, you can try covering the printer with a couple of thick towels, and print using normal ABS settings. This will make use of the heated bed to keep the air warm (around 70°C). A cold room won't help, so turn up the temperature a little if it is cold in your hemisphere this time of year.

|

Re: Bed material for nylon printing January 13, 2013 04:17PM |

Registered: 11 years ago Posts: 560 |

|

Re: Bed material for nylon printing January 21, 2013 05:20PM |

Registered: 12 years ago Posts: 62 |

I just saw that the taulman3D web page has been updated with some more bed materials.

[www.taulman3d.com]

I found a printed circuit board at radio shack that was big enough to give a try but even on a small 0.75 in diameter cylinder the plastic was distorting the circuit board, it did stay down but the thin board did not have enough strength to keep a larger part from deforming the circuit board. Perhaps a thicker circuit board or one that was mechanically attached to a sheet of aluminum or something else.

The updated taulman3D page suggested Garolite (LE) from McMaster Carr, I am going to give that a shot and if it works well I will test it with PLA ABS and PC.

Anyone have any other ideas?

[www.taulman3d.com]

I found a printed circuit board at radio shack that was big enough to give a try but even on a small 0.75 in diameter cylinder the plastic was distorting the circuit board, it did stay down but the thin board did not have enough strength to keep a larger part from deforming the circuit board. Perhaps a thicker circuit board or one that was mechanically attached to a sheet of aluminum or something else.

The updated taulman3D page suggested Garolite (LE) from McMaster Carr, I am going to give that a shot and if it works well I will test it with PLA ABS and PC.

Anyone have any other ideas?

|

Re: Bed material for nylon printing January 21, 2013 09:55PM |

Registered: 11 years ago Posts: 939 |

My best prints are with a large raft on blue painters tape at ~50C.

The raft seems to stick pretty well, but I still get some warping. The amazing thing is how easy to remove the raft is, it literally just peels off.

I'm considering printing the raft, then stopping the print, letting the raft cool and printing on the cooled raft.

I also ordered some nylon plate to try.

It's a pity the warping is so hard to deal with, the material looks and feels great.

The raft seems to stick pretty well, but I still get some warping. The amazing thing is how easy to remove the raft is, it literally just peels off.

I'm considering printing the raft, then stopping the print, letting the raft cool and printing on the cooled raft.

I also ordered some nylon plate to try.

It's a pity the warping is so hard to deal with, the material looks and feels great.

|

Re: Bed material for nylon printing January 29, 2013 05:42PM |

Registered: 12 years ago Posts: 62 |

I have tested the Garolite (LE) from McMaster Carr and it sticks to well. The first print I did I had the Z height a little to low and the nylon got really squished into the garolite. The warnings posted on taulmans web site are correct, not only will you destroy your part but the top layer of epoxy and cotton stayed attached to the now broken nylon print that is sitting across the room because that's where is landed after the hammer came out.

In the end I found that an approximately 1%ABS/acetone solution spread as even as possible will usually allow the part to release when cooled. If I miss a spot the Nylon bonds to the garolite and destroys it, likewise if there is to much ABS the print will fail.

ABS will not stick to bare garolit however an ABS/acetone mix spread before hand works well, I have not tried other materials yet.

Overall I have made several good prints at this point but would like a better surface.

One last warning, it's not flat. My small 6" x 6" piece was rather crowned with a high spot in the center.

I also tried to print onto Corian, it dosn't stick well enough.

Edited 1 time(s). Last edit at 01/29/2013 07:06PM by Gulf.

In the end I found that an approximately 1%ABS/acetone solution spread as even as possible will usually allow the part to release when cooled. If I miss a spot the Nylon bonds to the garolite and destroys it, likewise if there is to much ABS the print will fail.

ABS will not stick to bare garolit however an ABS/acetone mix spread before hand works well, I have not tried other materials yet.

Overall I have made several good prints at this point but would like a better surface.

One last warning, it's not flat. My small 6" x 6" piece was rather crowned with a high spot in the center.

I also tried to print onto Corian, it dosn't stick well enough.

Edited 1 time(s). Last edit at 01/29/2013 07:06PM by Gulf.

|

Re: Bed material for nylon printing January 29, 2013 06:40PM |

Registered: 11 years ago Posts: 939 |

I tried a Nylon sheet 1/4 inch, it bonds well, but you need to get the first layer hight right for the part to release and it's not even pretending to be flat.

I might try and pick up a pieve of 1/2 or 1 inch Nylon sheet, it should be rigid enough to stay flat once it it and if it isn't I can at least machine it flat.

I also picked up an untreated Polar board to try and I've had my most success with that, it's not really flat, but it's better than the nylon sheet, again print height is really important, and it can stick so hard that you end up scarping wood off the bottom of the part.

I might try and pick up a pieve of 1/2 or 1 inch Nylon sheet, it should be rigid enough to stay flat once it it and if it isn't I can at least machine it flat.

I also picked up an untreated Polar board to try and I've had my most success with that, it's not really flat, but it's better than the nylon sheet, again print height is really important, and it can stick so hard that you end up scarping wood off the bottom of the part.

|

Re: Bed material for nylon printing January 30, 2013 01:59PM |

Registered: 13 years ago Posts: 818 |

I'm Printing with Taulman 618 (1.75mm) on a Tantillus, no heated bed, just blue 3M tape - I was wondering if anyone else has started to reduce the print temperature?

I started at 240 (calibrated with a thermocouple) and have lowered down to 200 degrees, the parts seem as strong as the higher temp prints, so I don't think Nylon needs such high temperatures people seem to be using.

Anyone else have any feedback on temp v strength.

[richrap.blogspot.com]

I started at 240 (calibrated with a thermocouple) and have lowered down to 200 degrees, the parts seem as strong as the higher temp prints, so I don't think Nylon needs such high temperatures people seem to be using.

Anyone else have any feedback on temp v strength.

[richrap.blogspot.com]

|

Re: Bed material for nylon printing January 30, 2013 07:35PM |

Registered: 11 years ago Posts: 939 |

I'm pretty sure my Hotend is reading hot, possibly by as much as 25 degrees, but I need to dismantle it so I can get the thermocouple in the nozzle to verify.

At 230 as reported by my hotend I can print, but with significant infill it trends to delaminates, much like ABS at too low a temperature, at 245 again with the dodgy heat reporting it doesn't do that.

The issue I has with blue tape is although the nylon stuck to it, as the print progressed the warping would simply pull the tape off the glass sheet.

At 230 as reported by my hotend I can print, but with significant infill it trends to delaminates, much like ABS at too low a temperature, at 245 again with the dodgy heat reporting it doesn't do that.

The issue I has with blue tape is although the nylon stuck to it, as the print progressed the warping would simply pull the tape off the glass sheet.

|

Re: Bed material for nylon printing May 03, 2013 06:12PM |

Registered: 11 years ago Posts: 43 |

Aside from Garolite, what has everyone found?

I'm just starting to play with some 618, and now worried about attempting a longer print....

Right now I'm running my Onyx bed at 75c and using 3" wide blue tape on glass. I found on a previous printer that wider blue tape can help preven the print from pulling the tape away from the bed (especially if you watch where you place the tape seams in relation to the print)

I'm just starting to play with some 618, and now worried about attempting a longer print....

Right now I'm running my Onyx bed at 75c and using 3" wide blue tape on glass. I found on a previous printer that wider blue tape can help preven the print from pulling the tape away from the bed (especially if you watch where you place the tape seams in relation to the print)

|

Re: Bed material for nylon printing May 03, 2013 09:12PM |

Registered: 11 years ago Posts: 137 |

I think ive nailed printing to blue tape. I start the print with the bed at 100c then after about 5-10 layers I cut the heat to the bed. I also use a 25mm brim, I haven't tested with smaller brim yet.

I had the problem with the tape pulling off, Its because the glue on the tape isnt very effective at high temps. So i get the bed hot for the first couple layers to help adhesion and prevent as much warping as possible on the first 5-10 layers. By cutting the heat it allows the tape to stick properly and as the bed cools the bottom of the part cools evenly and doesn't warp.

Let me know if this works for you guys.

I had the problem with the tape pulling off, Its because the glue on the tape isnt very effective at high temps. So i get the bed hot for the first couple layers to help adhesion and prevent as much warping as possible on the first 5-10 layers. By cutting the heat it allows the tape to stick properly and as the bed cools the bottom of the part cools evenly and doesn't warp.

Let me know if this works for you guys.

|

Re: Bed material for nylon printing May 03, 2013 09:24PM |

Admin Registered: 15 years ago Posts: 1,470 |

I use a sheet of 1/8" (about 3mm) nylon I bought from McMaster clamped to my heated bed. Seems to work well now. I did have to score the surface of the sheet so it wasn't so shiny though.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Bed material for nylon printing January 08, 2014 12:22AM |

Registered: 10 years ago Posts: 7 |

after read in other post that mention to put a thin coat of a glue stick brand UHU, I am try to print dirrect to my heatbed covered with kapton tape, BUT with bed not powered on (no heat at all at the bed, only room temperature) and the result is WOW...it's stick very well in the kapton tape.

To relase the printed nyilon from the bed is another story, since it's quite hard to peal off (even with hard force that can be damaging the printed parts), the thin layer of glue is bonding soo much I feels like glueing the thin paper with strong adhesive glue, so I use a tap water with a sponge and rub it all arround together with a litle force to lift the printed part.

So far so good with this solution, next time will try to use this glue dirrect to the glass and will post the result.

the only problem to deal with is the wraping at the bottom layers, may be I need to turn on and heated to specific temperature, can some one ever play with this ? also un-dried the nyilon filament, the printing result is looks like a foamie.

Nyilon material I used is the cheap and cheerfull regular nyilon 2 - 2.5mm diameter which is available at a local markets here (they are ussually use these for fishing / big fish fishing line and they worth for $4 (converted to US$) sold per 6 rols (approx 50meters long) -- so cheap and worth to try.

and they worth for $4 (converted to US$) sold per 6 rols (approx 50meters long) -- so cheap and worth to try.

or may be it a must to use a Taulman 618 Natural Nylon Filament to get a perfect result ? duno since there is no way to get these taulman nyilon here.

Edited 1 time(s). Last edit at 01/08/2014 12:35AM by delokaver.

To relase the printed nyilon from the bed is another story, since it's quite hard to peal off (even with hard force that can be damaging the printed parts), the thin layer of glue is bonding soo much I feels like glueing the thin paper with strong adhesive glue, so I use a tap water with a sponge and rub it all arround together with a litle force to lift the printed part.

So far so good with this solution, next time will try to use this glue dirrect to the glass and will post the result.

the only problem to deal with is the wraping at the bottom layers, may be I need to turn on and heated to specific temperature, can some one ever play with this ? also un-dried the nyilon filament, the printing result is looks like a foamie.

Nyilon material I used is the cheap and cheerfull regular nyilon 2 - 2.5mm diameter which is available at a local markets here (they are ussually use these for fishing / big fish fishing line

and they worth for $4 (converted to US$) sold per 6 rols (approx 50meters long) -- so cheap and worth to try.

and they worth for $4 (converted to US$) sold per 6 rols (approx 50meters long) -- so cheap and worth to try. or may be it a must to use a Taulman 618 Natural Nylon Filament to get a perfect result ? duno since there is no way to get these taulman nyilon here.

Edited 1 time(s). Last edit at 01/08/2014 12:35AM by delokaver.

|

Re: Bed material for nylon printing January 08, 2014 05:27AM |

Admin Registered: 12 years ago Posts: 2,569 |

|

Re: Bed material for nylon printing January 08, 2014 06:27AM |

Registered: 12 years ago Posts: 2,470 |

I use a Whale Tufnol plate. Nylon sticks at basically every temperature to it. The problem is getting the printed part of the plate. So far the best result i got was by using a fairly large distance from the plate for the first layer so the contact surface isn't printed to tight. A very loose raft sometimes works as well. Be prepared to remove the layer that directly is in contact with the tufnol with a chisel though.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Bed material for nylon printing January 08, 2014 08:54AM |

Registered: 10 years ago Posts: 34 |

Cardboard from a cereal box works very well:

[coherent-reprap.blogspot.com]

I got a nice looking print the first time I used that surface even though my nylon wasn't super dry.

[coherent-reprap.blogspot.com]

I got a nice looking print the first time I used that surface even though my nylon wasn't super dry.

|

Re: Bed material for nylon printing January 18, 2014 10:23AM |

Registered: 10 years ago Posts: 3 |

I tried different materials and bed temperature (glass fiber, 3M blue tape, capton). I don't have access to Garolit yet. Blue tape comes off the bed together with printed part, fiber glass keep Nylow while hot after printing and left material after short timeI). I found that Nyton stick good enough on capton, but not always. It looks like it stisks good at 110C bed temperature and more. I am investiaging the real reason.

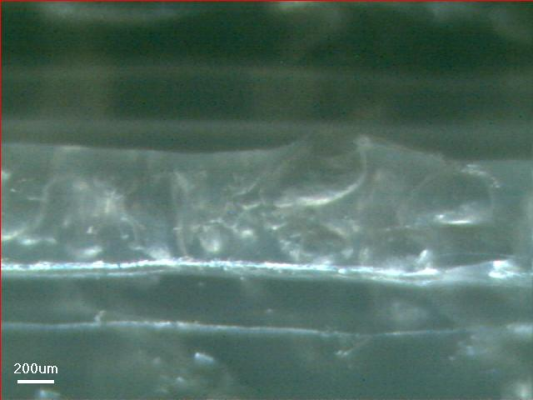

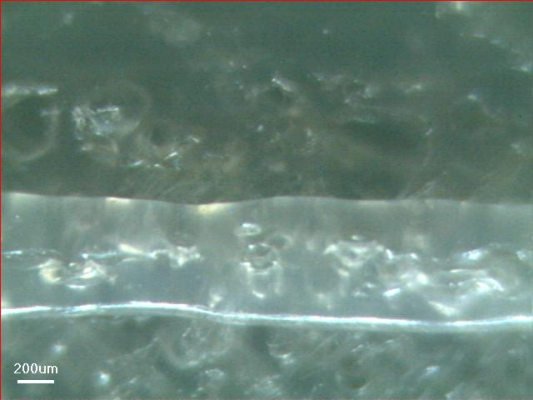

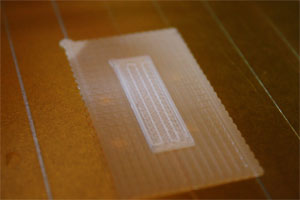

By the way, expriment shows that foaming factor (material volume after extrusion to before extrusin ratio) of non-dried Nylon618 from Taulman is about 2. See photo from microscope and find steam bubbles inside bonded extrusion. Length of bottom marker is 0.2mm (200um). I share results of dried Nylon after testing when I have it.

Edited 1 time(s). Last edit at 01/18/2014 10:24AM by SergeyA.

By the way, expriment shows that foaming factor (material volume after extrusion to before extrusin ratio) of non-dried Nylon618 from Taulman is about 2. See photo from microscope and find steam bubbles inside bonded extrusion. Length of bottom marker is 0.2mm (200um). I share results of dried Nylon after testing when I have it.

Edited 1 time(s). Last edit at 01/18/2014 10:24AM by SergeyA.

|

Re: Bed material for nylon printing January 19, 2014 11:07AM |

Registered: 10 years ago Posts: 3 |

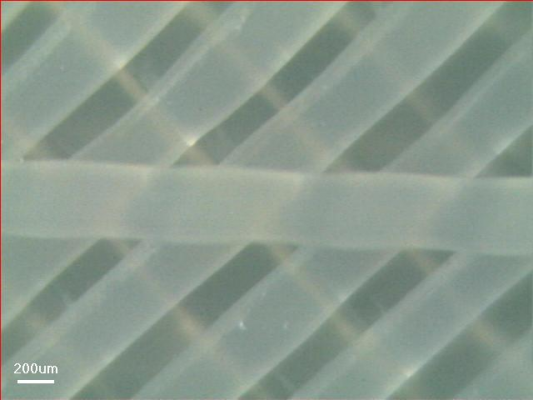

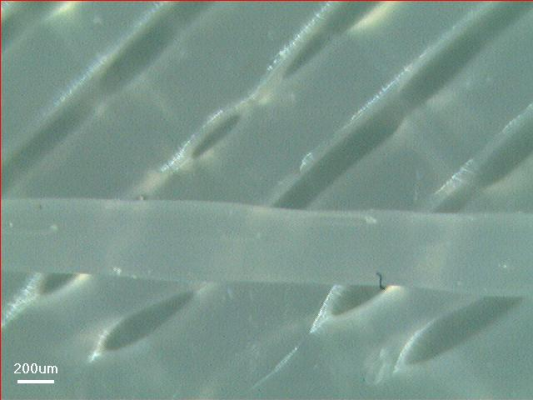

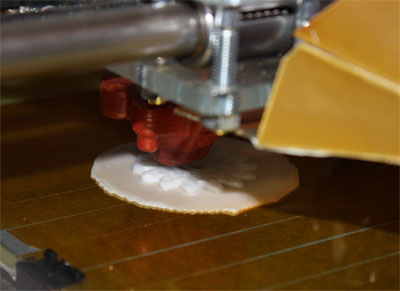

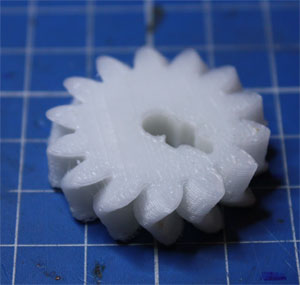

As I promised... I can show you the same material after drying. Amazing result.

I dried it in kitchen oven like this (150C during 4 hours):

I use capton on heated bed (104-110C) BUT it should be clean. Print at the same place second time if it doesn't stick first time - it works. Or you can clean capton sufarce from fat and dust.

BR,

Sergey

Edited 1 time(s). Last edit at 01/19/2014 11:08AM by SergeyA.

I dried it in kitchen oven like this (150C during 4 hours):

I use capton on heated bed (104-110C) BUT it should be clean. Print at the same place second time if it doesn't stick first time - it works. Or you can clean capton sufarce from fat and dust.

BR,

Sergey

Edited 1 time(s). Last edit at 01/19/2014 11:08AM by SergeyA.

|

Re: Bed material for nylon printing February 26, 2014 11:36AM |

Registered: 10 years ago Posts: 1 |

Sergey I find these results outstanding. I have a makerbot that I am going to try this on. This nylon definitely requires a lot of prep work but the results are worth it.

I have tried 3" painters tape and taken some sandpaper to scuff the surface (doesn't need much), then just a simple wipe with a damp cloth (make sure to let it dry before printing) and came out with good results and minimal curling while printing a phone case (1.5 to 2 hour print @ 0.2mm layers, 240C print head, no raft, bed heat turned off). This was also with un-dried nylon so I would imagine drying it would give a better outcome. I did find that after 2-3 prints, replacing the tape is inevitable because of it sticking and pulling the tape off the bed (deforming it, rendering it unusable).

I have tried 3" painters tape and taken some sandpaper to scuff the surface (doesn't need much), then just a simple wipe with a damp cloth (make sure to let it dry before printing) and came out with good results and minimal curling while printing a phone case (1.5 to 2 hour print @ 0.2mm layers, 240C print head, no raft, bed heat turned off). This was also with un-dried nylon so I would imagine drying it would give a better outcome. I did find that after 2-3 prints, replacing the tape is inevitable because of it sticking and pulling the tape off the bed (deforming it, rendering it unusable).

|

Re: Bed material for nylon printing February 26, 2014 12:49PM |

Registered: 10 years ago Posts: 553 |

Quote

Gulf

I just saw that the taulman3D web page has been updated with some more bed materials.

[www.taulman3d.com]

I found a printed circuit board at radio shack that was big enough to give a try but even on a small 0.75 in diameter cylinder the plastic was distorting the circuit board, it did stay down but the thin board did not have enough strength to keep a larger part from deforming the circuit board. Perhaps a thicker circuit board or one that was mechanically attached to a sheet of aluminum or something else.

The updated taulman3D page suggested Garolite (LE) from McMaster Carr, I am going to give that a shot and if it works well I will test it with PLA ABS and PC.

Anyone have any other ideas?

Using double sided tape to hold the PCB to glass would probably work fine.

|

Re: Bed material for nylon printing August 25, 2015 01:50AM |

Registered: 9 years ago Posts: 65 |

Sorry, only registered users may post in this forum.