A "Z"axis homing problem.

Posted by BobHewson

|

A "Z"axis homing problem. January 16, 2013 09:01PM |

Registered: 11 years ago Posts: 62 |

I have a new Prusa/Mendel printer that I am having some start-up problems with.

Most problems have been solved, but two remain. My "Z" homing is acting strangely. I adjust the Exruder nozzle to be a paper"s thickness above the glass plate on my heated bed. It tracks up and down manually, but when I send it to "home" it cycles up and down. About 3-4 full turns of the threaded rod up, then only about 2 turns down, remaining about 1/8" above the glass.

If I reset to the paper's thickness above the glass and run a job, again in its positioning the "Z" cycles again ending above the glass an 1/8" and of course drips plastic not printing it. The "X" and "Y" movements are OK, and the "Z" steps up as it should, it just doesn't home /start correctly.

I use Repentier-Host and Slic3r (latest versions). I've tried slicing using the bundled Slic3r and separate stand alone version.

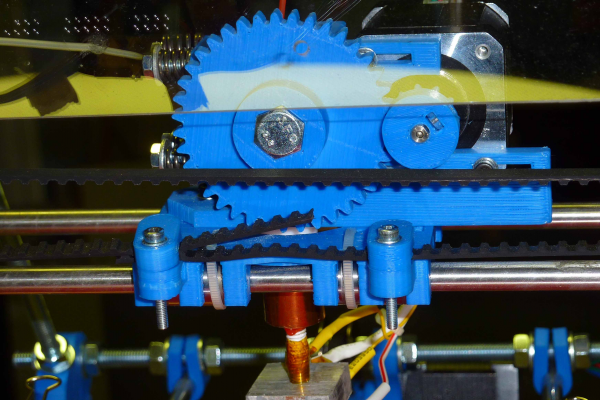

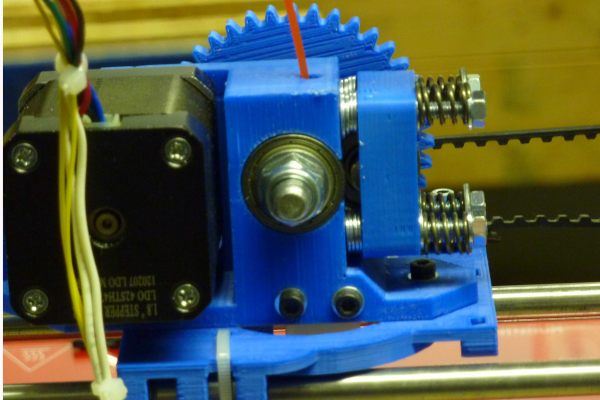

My second problem is the feeding of filament into the extruder. Mine is a blind entry hole leading to the hobbed bolt and bearing (see photo). The feed is virtually impossible to start (one success out of many tries).

Anyone have any suggestions?

Bob

Most problems have been solved, but two remain. My "Z" homing is acting strangely. I adjust the Exruder nozzle to be a paper"s thickness above the glass plate on my heated bed. It tracks up and down manually, but when I send it to "home" it cycles up and down. About 3-4 full turns of the threaded rod up, then only about 2 turns down, remaining about 1/8" above the glass.

If I reset to the paper's thickness above the glass and run a job, again in its positioning the "Z" cycles again ending above the glass an 1/8" and of course drips plastic not printing it. The "X" and "Y" movements are OK, and the "Z" steps up as it should, it just doesn't home /start correctly.

I use Repentier-Host and Slic3r (latest versions). I've tried slicing using the bundled Slic3r and separate stand alone version.

My second problem is the feeding of filament into the extruder. Mine is a blind entry hole leading to the hobbed bolt and bearing (see photo). The feed is virtually impossible to start (one success out of many tries).

Anyone have any suggestions?

Bob

|

Re: A "Z"axis homing problem. January 16, 2013 11:13PM |

Registered: 13 years ago Posts: 1,797 |

when I start to feed new feedstock thru extruder I diagonally cut it to allow for a sharp edge, then straighten it out by bending it in the opposite direction it wants to go, then hold onto it and guide its direction until it is past the hobbled bolt, and thru to the hot end, then I slowly feed it with software at about 10mm at 20 or 50mm/minute until it flows out the end of the hot end as filament. keep in mind that when feedstock is being reloaded it is a common time for nozzle to clog, so as practice i also take a tiny drill bit and push thru the nozzle pulling out the build up.

The homing is working correctly. It is the best way to ensure homing is consistent. In fact many firmware have x,y,z switches disabled during print runs!

As for how to setup z axis correctly.

The distance up can be the open contact point for your homing switch. This is the correct setting, so I would only adjust z height using +10 z and home z. home of x y z is the very first move as a print job begins, not down z.

The homing is working correctly. It is the best way to ensure homing is consistent. In fact many firmware have x,y,z switches disabled during print runs!

As for how to setup z axis correctly.

The distance up can be the open contact point for your homing switch. This is the correct setting, so I would only adjust z height using +10 z and home z. home of x y z is the very first move as a print job begins, not down z.

|

Re: A "Z"axis homing problem. January 17, 2013 06:01AM |

Admin Registered: 17 years ago Posts: 7,879 |

It looks like you are trying to use 1.75mm filament in a Wades block designed for 3mm. That isn't going to work very well as it can buckle in the filament path and might be why you find it hard to start.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: A "Z"axis homing problem. January 17, 2013 06:42AM |

Registered: 11 years ago Posts: 251 |

nophead Wrote:

-------------------------------------------------------

> It looks like you are trying to use 1.75mm

> filament in a Wades block designed for 3mm. That

> isn't going to work very well as it can buckle in

> the filament path and might be why you find it

> hard to start.

If this is the problem, you can insert a thin brass/ptfe tube just below the hobbed bolt to save you from requiring a different extruder.

-------------------------------------------------------

> It looks like you are trying to use 1.75mm

> filament in a Wades block designed for 3mm. That

> isn't going to work very well as it can buckle in

> the filament path and might be why you find it

> hard to start.

If this is the problem, you can insert a thin brass/ptfe tube just below the hobbed bolt to save you from requiring a different extruder.

|

Re: A "Z"axis homing problem. January 18, 2013 12:53PM |

Registered: 11 years ago Posts: 62 |

I wasn't aware that there were different versions of extruder for 3mm and 1.75mm. Shouldn't my kit supplier have known that? The suggestion of a supplemental tube sound like a good idea. I will take the extruder apart and refresh my memory on how it works in detail (first tarted this project a year ago).

I really don't understand the explanation James gives on my homing problem. Can you explain further.

Thanks,

Bob

Edited 1 time(s). Last edit at 01/18/2013 01:46PM by BobHewson.

I really don't understand the explanation James gives on my homing problem. Can you explain further.

Thanks,

Bob

Edited 1 time(s). Last edit at 01/18/2013 01:46PM by BobHewson.

|

Re: A "Z"axis homing problem. January 19, 2013 09:58AM |

Registered: 13 years ago Posts: 1,797 |

it seems like you were homing just by moving z to bed. in some cases this is different than homing z. you want to calibrate your z height based on what it is when it prints. so raise z 10mm, then home it, then reset your homing switch position. where it homes is where it will start. it should be consistent, if not look at the homing switch holder, make sure it is not flexing.

|

Re: A "Z"axis homing problem. February 01, 2013 04:37PM |

Registered: 11 years ago Posts: 62 |

James, Konwiddak, and Nophead,

Thanks, have my machine operating now and have a couple of prints completed, not bd, but not great either. Your advise was key to getting everything going.

Re feeding extruder. The entry hole is smaller than 3mm, but you suggestion that the feedstock might buckle by missing the hole was right on. That did happen, but had to take it apart to find this out. Looks like feed in a couple of inches through holeand if only a little goes in then I will remove the front end and handfeed. A nuicanse but only takes a few minutes.

Konwiddak's suggestion of a feed tube insert sound feasable, will look for some small tube stock.

Thanks again to you both,

Bob

Thanks, have my machine operating now and have a couple of prints completed, not bd, but not great either. Your advise was key to getting everything going.

Re feeding extruder. The entry hole is smaller than 3mm, but you suggestion that the feedstock might buckle by missing the hole was right on. That did happen, but had to take it apart to find this out. Looks like feed in a couple of inches through holeand if only a little goes in then I will remove the front end and handfeed. A nuicanse but only takes a few minutes.

Konwiddak's suggestion of a feed tube insert sound feasable, will look for some small tube stock.

Thanks again to you both,

Bob

|

Re: A "Z"axis homing problem. February 06, 2013 08:38PM |

Registered: 16 years ago Posts: 824 |

You might consider printing a new extruder for yourself once you get the hang of it. The Wade's extruder (which you have) is a bit dated, although I have to admit that I have been using one reliably for about three years.

There are new designs that address the issues associated with changing filament. My current favorite is the UniX-Wade by Chri, coupled with my own addons [www.thingiverse.com] and [www.thingiverse.com] and [www.thingiverse.com] and [www.thingiverse.com]

There are new designs that address the issues associated with changing filament. My current favorite is the UniX-Wade by Chri, coupled with my own addons [www.thingiverse.com] and [www.thingiverse.com] and [www.thingiverse.com] and [www.thingiverse.com]

|

Re: A "Z"axis homing problem. February 07, 2013 11:33AM |

Registered: 11 years ago Posts: 62 |

|

Re: A "Z"axis homing problem. February 08, 2013 01:55AM |

Registered: 15 years ago Posts: 123 |

I would also suggest putting a Z max endstop and homing to max Z. In marlin it is just a simple flag on the config page. Then, all you have to do is adjust the amount the axis moves back down (to zero) to set your start z height.

Also be advised that the hot end and bed will expand a bit when heated, so i find it's best to set the z with the printer heated to operating temperatures. Just use your pronterface or LCD display to jog the head/bed down to accomplish the correct height, while hot. Remmeber that and use it every time.

I haven't touched my z axis before printing for at least five or six prints after doing this.

It also helps to have a really stable bed mounting system, with very strong/very compressed springs.

Also be advised that the hot end and bed will expand a bit when heated, so i find it's best to set the z with the printer heated to operating temperatures. Just use your pronterface or LCD display to jog the head/bed down to accomplish the correct height, while hot. Remmeber that and use it every time.

I haven't touched my z axis before printing for at least five or six prints after doing this.

It also helps to have a really stable bed mounting system, with very strong/very compressed springs.

Sorry, only registered users may post in this forum.