Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  )

)

Posted by Idolcrasher

Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 02, 2013 06:32PM |

Registered: 12 years ago Posts: 539 |

Hi All,

I would like to get your input.

What are the best printer (or even independent axis) designs out which do not use belts?

I am weary of stretching, sagging belt slop decreasing my print quality over time.

I have been considering trying to custom build a rack & pinion Rostock or i3 Prusa; but before I go off trailblazing on some wild tangent, I thought I would see if anyone else is taking revenge on belts at the moment.

Thanks for your thoughts

FabberForge - Printing Happiness

[www.fabberforge.com]

I would like to get your input.

What are the best printer (or even independent axis) designs out which do not use belts?

I am weary of stretching, sagging belt slop decreasing my print quality over time.

I have been considering trying to custom build a rack & pinion Rostock or i3 Prusa; but before I go off trailblazing on some wild tangent, I thought I would see if anyone else is taking revenge on belts at the moment.

Thanks for your thoughts

FabberForge - Printing Happiness

[www.fabberforge.com]

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 02, 2013 08:50PM |

Registered: 11 years ago Posts: 374 |

Rack and pinion has been done before by at least 3 people. No word on if the print quality is better. I would think that the meshing of the gear teeth would need to be very good, otherwise you would get artifacts in the print. This means you would need "real" tooth profiles, not simplistic triangles. Good tooth profiles are non-trivial to generate from scratch.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 02, 2013 09:00PM |

Registered: 12 years ago Posts: 1,611 |

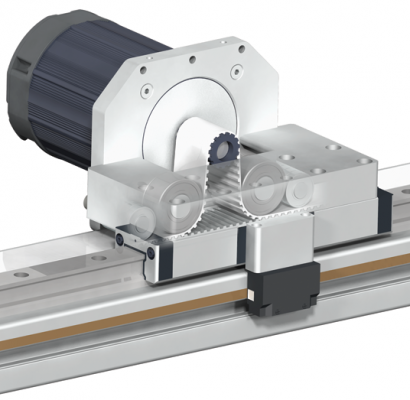

I've thought about this too. I've been looking for an application for a rack and pinion system I've seen, though you may not like it... It uses belts! [bell-everman.com] and a video [m.youtube.com]

You could build a Rostock with the motors on the carriage using this system. It was always a bit to cumbersome for fitting on a normal reprap, but could work well on a Rostock. I understand that lots of CNC machines are going over to rack and pinion, and some to systems similar to this, too.

You could build a Rostock with the motors on the carriage using this system. It was always a bit to cumbersome for fitting on a normal reprap, but could work well on a Rostock. I understand that lots of CNC machines are going over to rack and pinion, and some to systems similar to this, too.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 02, 2013 11:04PM |

Registered: 12 years ago Posts: 539 |

Belts are just... missing a certain je ne sais quoi

They just don't really feel like a GREAT idea... They work... But do they work great?

I suppose it depends on your definition of work great.

But man, when trying to calibrate the movement of a hot-end within sub-fractions of millimeters belts just leave much to be desired.

I know that belts are cheaper than a lot of fancier solutions... but I think I am done with them.

They just don't really feel like a GREAT idea... They work... But do they work great?

I suppose it depends on your definition of work great.

But man, when trying to calibrate the movement of a hot-end within sub-fractions of millimeters belts just leave much to be desired.

I know that belts are cheaper than a lot of fancier solutions... but I think I am done with them.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 02, 2013 11:07PM |

Registered: 12 years ago Posts: 539 |

@Droftarts That belt application looks cool. It looks like they are going out of their way to compensate for traditional belt problems

Edited 1 time(s). Last edit at 02/02/2013 11:21PM by Idolcrasher.

Edited 1 time(s). Last edit at 02/02/2013 11:21PM by Idolcrasher.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 02:32AM |

Registered: 11 years ago Posts: 525 |

Steel wire has to be the way to go. It doesn't stretch (normally) and is flexible enough to do a couple of turns around the drive motor.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 06:51AM |

Registered: 13 years ago Posts: 818 |

Don't overlook the use of Spectra fishing line, it's working well on Tantillus and Rostock based machines. It's easy to tension and seems to stay very tight, I only have about 80 hours printing on Tantillus but they still ping without having any further adjustment from initial setup.

I can't imaging belts working as well for small machines like Tantillus. I have stretched and damaged enough belts over the years to really appreciate the use of Spectra line.

I believe more recent Sumpod machines have a rack and pinion system, if that's the way you want to go.

[richrap.blogspot.com]

I can't imaging belts working as well for small machines like Tantillus. I have stretched and damaged enough belts over the years to really appreciate the use of Spectra line.

I believe more recent Sumpod machines have a rack and pinion system, if that's the way you want to go.

[richrap.blogspot.com]

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 10:10AM |

Registered: 11 years ago Posts: 374 |

Quote

Steel wire has to be the way to go. It doesn't stretch (normally) and is flexible enough to do a couple of turns around the drive motor.

Until you realize it has a minimum bend radius that has to be respected, or it will fatigue and break very rapidly.

For a steel wire strong enough to carry the tension loads we typically put on our belts, the minimum bend radius is in excess of 1.5 inches. And when you add in a reasonable factor of safety, the bend radius was in the neighborhood of 2 inches.

Now, this was for common steel cable. I imagine if you cared to get into more esoteric designs you could find something with a small BR and high load capacity... But then you run into availability issues, cost issues, etc.

My conclusion, in the end, was spectra beats out steel cable. In addition to the above, it's cheaper, it's safer, and it's easier to work with.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 10:59AM |

Registered: 11 years ago Posts: 253 |

torqspline from Roton maybe? I made a sample axis and it moves quickly. Unless you use anti-backlash nuts, the frequency of steps at the end of moves is heard. [www.youtube.com] TrinityLabs has screws working on their production printer.

ball screws? there are plenty of fast lead screws to get speeds up. Not too much more expensive than belts and aluminum pulleys.

You can avoid those costly end bearing parts with a little ingenuity.

I don't like rack/pinion, and not sure why. Someone did a Prusa with printed up rack/pinion for the X and Y. Bulky but did work.

I did consider/purchase spectra and steel line for my large Ultimaker styled machine. Went with XL belts in the end.

Didn't want to lace it up and worried about long term breaks.

There needs to be someone working on cost reducing the linear stepper/linear bearing concept. Just the block moves and coils are charged to create movements. Scientific and assembly line equipment uses them. Usually paired with linear encoders for feedback also.

[www.intellidrives.com]

ball screws? there are plenty of fast lead screws to get speeds up. Not too much more expensive than belts and aluminum pulleys.

You can avoid those costly end bearing parts with a little ingenuity.

I don't like rack/pinion, and not sure why. Someone did a Prusa with printed up rack/pinion for the X and Y. Bulky but did work.

I did consider/purchase spectra and steel line for my large Ultimaker styled machine. Went with XL belts in the end.

Didn't want to lace it up and worried about long term breaks.

There needs to be someone working on cost reducing the linear stepper/linear bearing concept. Just the block moves and coils are charged to create movements. Scientific and assembly line equipment uses them. Usually paired with linear encoders for feedback also.

[www.intellidrives.com]

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 11:06AM |

Registered: 12 years ago Posts: 539 |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 11:19AM |

Registered: 12 years ago Posts: 539 |

found a video explaining the fishing wire on a Kossel Fishing Line Explanation

Edited 1 time(s). Last edit at 02/03/2013 03:21PM by Idolcrasher.

Edited 1 time(s). Last edit at 02/03/2013 03:21PM by Idolcrasher.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 12:05PM |

Registered: 12 years ago Posts: 539 |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 03:15PM |

Admin Registered: 15 years ago Posts: 1,470 |

Idolcrasher Wrote:

-------------------------------------------------------

> Where are STLs for fishing line motor and idler

> ends? (As seen in that video)

>

> Those could be used on any RepRap.

[github.com]

-------------------------------------------------------

> Where are STLs for fishing line motor and idler

> ends? (As seen in that video)

>

> Those could be used on any RepRap.

[github.com]

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 03:22PM |

Registered: 12 years ago Posts: 539 |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 03:23PM |

Registered: 12 years ago Posts: 539 |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 03:28PM |

Registered: 12 years ago Posts: 539 |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 03, 2013 09:17PM |

Registered: 11 years ago Posts: 374 |

I'm really surprised that a hardened steel and metal bushing setup is not more popular here... It has almost as little friction as bearings and less slop than LM8UUs and regular smooth rod... And is lighter as well...

As far as the drive for axis, I really think belts are the way to go. I'm not sure what people have against them, they can be very accurate when used properly.

Edited 1 time(s). Last edit at 02/03/2013 09:23PM by xclusive585.

As far as the drive for axis, I really think belts are the way to go. I'm not sure what people have against them, they can be very accurate when used properly.

Edited 1 time(s). Last edit at 02/03/2013 09:23PM by xclusive585.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 04, 2013 10:03AM |

Registered: 11 years ago Posts: 253 |

a great plastic bushing is from Igus, called iGlide, and about $1.50 each for 8mm diameters. The J material or G are both good.

They have CAD models online and discounts for quantity orders.

They've also got an aluminum rod, precision ground, really straight and light. AWM shafts work with J.

They have CAD models online and discounts for quantity orders.

They've also got an aluminum rod, precision ground, really straight and light. AWM shafts work with J.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 04, 2013 08:43PM |

Registered: 11 years ago Posts: 374 |

Quote

I'm really surprised that a hardened steel and metal bushing setup is not more popular here... It has almost as little friction as bearings and less slop than LM8UUs and regular smooth rod... And is lighter as well...

I did find the bushings to be smoother than the linear bearings. However, they are less tolerant of off-axis loads in that they are more inclined to jam or stick and enter "stick-slip" motion.

My main problem with belts is that they are rather expensive and difficult to source. And you either need to have toothed idlers or run the smooth side of the belt over the idler in order to eliminate the tooth artifacts from prints.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 05, 2013 04:20AM |

Registered: 12 years ago Posts: 38 |

How about Synchromesh?

[www.thingiverse.com]

I kinda want to try them out in my next printer project.

[www.thingiverse.com]

I kinda want to try them out in my next printer project.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 05, 2013 08:38AM |

Registered: 11 years ago Posts: 374 |

Quote

How about Synchromesh?

[www.thingiverse.com]

I kinda want to try them out in my next printer project.

According to an applications engineer at SDP-SI, synchromesh is not a good choice for our application because it is not anit-backlash like GT2 belts are.

If you want more details you'll need to poke into the IRC and ask around - I wasn't the person who asked SDP-SI, and my memory on who did is a bit fuzzy.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 05, 2013 11:34AM |

Registered: 12 years ago Posts: 539 |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 05, 2013 11:50AM |

Registered: 12 years ago Posts: 147 |

Idolcrasher Wrote:

-------------------------------------------------------

> Synchro mesh looks pretty cool

>

> I use GT2 Belts and they stretched on me over 3-4

> months.

>

> Are they done stretching? Maybe?

>

> Would I prefer a product that does not stretch at

> all? Certainly.

How much did it stretch? I haven't witnessed any myself in over a year and I have used steel wire belts as well as more flexible (and more common) PU fibers. Perhaps you have them significantly over tensioned.

-------------------------------------------------------

> Synchro mesh looks pretty cool

>

> I use GT2 Belts and they stretched on me over 3-4

> months.

>

> Are they done stretching? Maybe?

>

> Would I prefer a product that does not stretch at

> all? Certainly.

How much did it stretch? I haven't witnessed any myself in over a year and I have used steel wire belts as well as more flexible (and more common) PU fibers. Perhaps you have them significantly over tensioned.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 05, 2013 09:09PM |

Registered: 12 years ago Posts: 38 |

crispy1 Wrote:

-------------------------------------------------------

> How about Synchromesh?

>

>

> I kinda want to try them out in my next printer

> project.

>

> According to an applications engineer at SDP-SI,

> synchromesh is not a good choice for our

> application because it is not anit-backlash like

> GT2 belts are.

>

> If you want more details you'll need to poke into

> the IRC and ask around - I wasn't the person who

> asked SDP-SI, and my memory on who did is a bit

> fuzzy.

I think I might have heard that before. And I think I've heard of counter-arguements that they are a good fit for our application. Seeing the website, it seems to be specifically designed for small belt driven machines.

[sdp-si.com]

Also, how on earth do u design anti-backlashing into a belt? I don't see how mechanically superior can a GT2 belt be. At least in terms of handling backlashing.

Edited 1 time(s). Last edit at 02/05/2013 09:31PM by Pazu.

-------------------------------------------------------

> How about Synchromesh?

>

>

> I kinda want to try them out in my next printer

> project.

>

> According to an applications engineer at SDP-SI,

> synchromesh is not a good choice for our

> application because it is not anit-backlash like

> GT2 belts are.

>

> If you want more details you'll need to poke into

> the IRC and ask around - I wasn't the person who

> asked SDP-SI, and my memory on who did is a bit

> fuzzy.

I think I might have heard that before. And I think I've heard of counter-arguements that they are a good fit for our application. Seeing the website, it seems to be specifically designed for small belt driven machines.

[sdp-si.com]

Also, how on earth do u design anti-backlashing into a belt? I don't see how mechanically superior can a GT2 belt be. At least in terms of handling backlashing.

Edited 1 time(s). Last edit at 02/05/2013 09:31PM by Pazu.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 05, 2013 10:14PM |

Registered: 11 years ago Posts: 374 |

Quote

Also, how on earth do u design anti-backlashing into a belt? I don't see how mechanically superior can a GT2 belt be. At least in terms of handling backlashing.

Disclaimer: I'm not a belt engineer, this is my understanding which could certainly be flawed.

It has to do with the tooth profile, and how the teeth on the belt engage with the pulley. This is why GT2, with its semicircular teeth, is superior to T5, with its larger and trapezoidal teeth.

Keep in mind there is a difference between what T5 was designed for - light duty power transmission, where positional accuracy is not extremely important, and what we need for our printers. For us, positional accuracy is paramount, so any slop in the teeth paying on or off the pulley when the motor reverses direction is not desirable.

My interpretation is that synchromesh is designed more as a replacement for T5 than for GT2.

And before anyone objects - yes, you can get good results from T5 belts. But you end up applying so much tension it basically acts like a piece of cable - the teeth are no longer what keeps the belt from slipping, friction is.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 06, 2013 02:58AM |

Registered: 12 years ago Posts: 38 |

@crispy1, quite right you are. I found the some info here

[reprap.org]

Anyway, Synchromesh is interesting enough for me to give it a try.

[reprap.org]

Anyway, Synchromesh is interesting enough for me to give it a try.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 06, 2013 09:54AM |

Registered: 11 years ago Posts: 490 |

For anyone interested in fast lead screws: I have contacted Igus about theirs because their online calculator showed extremely short service life (the screw nuts would wear out after some few prints). The representative explained to me that wear indeed is quite high the higher the lead gets and that these leadscrews certainly would not fit our applications.

The good news: There is another manufacturer located in the UK: Reliance Precision Mechatronics. I don't exactly know what they do differently, but some of their leadscrews are rated for up to 7000km service life, which would last some years even if one were to print one medium sized to large object per day.

What I would do about belt stretch is to take broader belts or to build a pulley system that also doubles your theoretical resolution while putting less strain on your belt.

The good news: There is another manufacturer located in the UK: Reliance Precision Mechatronics. I don't exactly know what they do differently, but some of their leadscrews are rated for up to 7000km service life, which would last some years even if one were to print one medium sized to large object per day.

What I would do about belt stretch is to take broader belts or to build a pulley system that also doubles your theoretical resolution while putting less strain on your belt.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 07, 2013 09:25PM |

Registered: 12 years ago Posts: 539 |

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 07, 2013 09:58PM |

Registered: 11 years ago Posts: 374 |

@ uGen and Idolcrasher, Re: leadscrews

Have you guys been living under a rock? :-P

[trinitylabs.com]

[trinitylabs.com]

[trinitylabs.com]

and

[trinitylabs.com]

Edited 1 time(s). Last edit at 02/07/2013 09:59PM by crispy1.

Have you guys been living under a rock? :-P

[trinitylabs.com]

[trinitylabs.com]

[trinitylabs.com]

and

[trinitylabs.com]

Edited 1 time(s). Last edit at 02/07/2013 09:59PM by crispy1.

Re: Best Belt-Less RepRap and Printer Designs (Rack & Pinion Rostock  ) ) February 07, 2013 10:17PM |

Registered: 11 years ago Posts: 525 |

Yes.

Must use these on the next printer, wonder if they are as good as they claim.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

Must use these on the next printer, wonder if they are as good as they claim.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

Sorry, only registered users may post in this forum.