Toothed Idlers  love'em or hate'em

love'em or hate'em

Posted by Idolcrasher

Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 04:02PM |

Registered: 12 years ago Posts: 539 |

Any opinion on toothed idlers?

I have been thinking about giving these a shot GT2 Idlers

FabberForge - Printing Happiness

[www.fabberforge.com]

I have been thinking about giving these a shot GT2 Idlers

FabberForge - Printing Happiness

[www.fabberforge.com]

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 04:29PM |

Registered: 12 years ago Posts: 809 |

I've been thinking about these lately. I've flipped my belting so the smooth side goes over the idler, but I think I'd like to try something along these lines. Problem is that I'm pretty happy with my current setup! Don't mess with it if it isn't broken...

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 04:53PM |

Registered: 14 years ago Posts: 689 |

Toothed idlers are a bad idea in my opinion. Depending on how you mount it it might restrict how precise you can tighten the belt. And depending on how accurate you manage to print it, even a slightly oval idler will decrease overall quality. This is the same reason most people prefer machined pulleys over printed ones. (In time, as overall quality increase even more, this will probably change).

Better to twist the belt like akhlut.

--

-Nudel

Blog with RepRap Comic

Better to twist the belt like akhlut.

--

-Nudel

Blog with RepRap Comic

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 06:00PM |

Registered: 13 years ago Posts: 301 |

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 06:33PM |

Registered: 11 years ago Posts: 477 |

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 06:57PM |

Registered: 12 years ago Posts: 539 |

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 07:37PM |

Registered: 15 years ago Posts: 332 |

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 08:20PM |

Registered: 12 years ago Posts: 132 |

Something I've been wondering- does the diameter of an idler bearing have to match the pulley, or does it not make any difference? My Solidoodle uses pulleys freely spinning on a bolt for the Y axis idlers, and I want to replace them with bearings. Would 608s like in the link be ok, or would I need to find a bearing with an OD that matches the pulley?

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 08:24PM |

Registered: 12 years ago Posts: 539 |

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 12, 2013 08:31PM |

Registered: 12 years ago Posts: 539 |

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 13, 2013 02:52AM |

Registered: 12 years ago Posts: 132 |

The Solidoodle's idlers are pulleys that match the pulleys on the drive rod, so they are toothed idlers I suppose. The pulleys spin on bolts with plenty of lube, rather than being fixed to a rod mounted in a bearing. I would prefer that the tension of the belt be supported by a bearing, so I am wondering if replacing the pulleys with larger 608s would be ok, or if idler ODs need to match the pulley ODs.

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 13, 2013 03:03AM |

Registered: 11 years ago Posts: 374 |

Idolcrasher Wrote:

-------------------------------------------------------

> Not everything works out in practice like it does

> in theory... I have a printer that uses T5 belts

> that outclasses most GT2 belt using printers. I

> bet toothed idlers have potential to be a good

> thing...

Again, looking at machine designs in industry.... Always always always a toothed idler for timing belts. And typically yes the idler is the same size as the pulley, though it shouldn't be that important. But the idler is only going to do you any good if it's machined accurately.

I'm happy with the flipped belt method for Reprap purposes. But for an industrial design I would use machined metal toothed idlers.

Edited 1 time(s). Last edit at 02/13/2013 03:04AM by xclusive585.

-------------------------------------------------------

> Not everything works out in practice like it does

> in theory... I have a printer that uses T5 belts

> that outclasses most GT2 belt using printers. I

> bet toothed idlers have potential to be a good

> thing...

Again, looking at machine designs in industry.... Always always always a toothed idler for timing belts. And typically yes the idler is the same size as the pulley, though it shouldn't be that important. But the idler is only going to do you any good if it's machined accurately.

I'm happy with the flipped belt method for Reprap purposes. But for an industrial design I would use machined metal toothed idlers.

Edited 1 time(s). Last edit at 02/13/2013 03:04AM by xclusive585.

Re: Toothed Idlers  love'em or hate'em love'em or hate'em February 13, 2013 07:11AM |

Registered: 12 years ago Posts: 2,470 |

For T5 the change from bearing to toothed idler was a huge increase in print quality for me. With GT2 or HTD the effect should be way less dramatic due to the shape of the belt teeth. They roll much smoother over a bearing than T5.

As for size, it's not important. What is important is that the belt remains in a straight line on the side where there carriage is connected, otherwise the movement becomes non linear if you get near the idler.

As for size, it's not important. What is important is that the belt remains in a straight line on the side where there carriage is connected, otherwise the movement becomes non linear if you get near the idler.

Re: Toothed Idlers  love'em or hate'em love'em or hate'em December 23, 2014 03:19PM |

Registered: 9 years ago Posts: 11 |

Hello everyone,

I am running into the same area of thinking; to use toothed idlers or not. I think it is a good idea; not for timing obviously but because I feel it would just add better control, guidance, and syncing all around.

Plus, could it be possible to compress or tire out the teeth of the belt by having it roll over a perfectly round surface, like a bearing OD? I haven't actually gotten to do any tests yet, but I feel that if tension was added to the system the lobes or teeth could compress against the idler a little (multiplied by each pulley and you have a significant slop stack-up?)

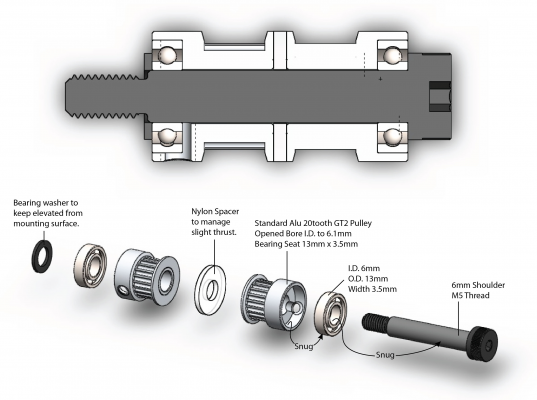

I modeled a dual idler assembly that I think I might try and make by modifying some timing pulleys to accept small bearings.

Thoughts?

Thanks,

-B

Edited 1 time(s). Last edit at 12/23/2014 03:20PM by Rectangled.

I am running into the same area of thinking; to use toothed idlers or not. I think it is a good idea; not for timing obviously but because I feel it would just add better control, guidance, and syncing all around.

Plus, could it be possible to compress or tire out the teeth of the belt by having it roll over a perfectly round surface, like a bearing OD? I haven't actually gotten to do any tests yet, but I feel that if tension was added to the system the lobes or teeth could compress against the idler a little (multiplied by each pulley and you have a significant slop stack-up?)

I modeled a dual idler assembly that I think I might try and make by modifying some timing pulleys to accept small bearings.

Thoughts?

Thanks,

-B

Edited 1 time(s). Last edit at 12/23/2014 03:20PM by Rectangled.

Re: Toothed Idlers  love'em or hate'em love'em or hate'em December 23, 2014 06:47PM |

Registered: 10 years ago Posts: 64 |

I disagree that idler pulleys are necessary with the GT2 tooth profile. The only thing they could really do is add a small bit of binding and create uneven tension. Also, and especially in printed pulleys, if the distance between the two catching teeth of a pulley is not EXACTLY divisible by the spacing between the teeth (on top AND bottom), you'll get uneven tension as you switch directions.

xclusive is right, no industrial machine would just use a bearing but that's because in most applications the belts undergo much much more wear. I really don't think it's done because of positioning.

The only reason I can think of would be to decrease wear on the teeth, but the the teeth going over the idler won't ever be used anyway.

Good thought rectangled, but you have to keep in mind that the pulleys are usually made up of three parts with the aluminum crimped or press fir or brazed together...it's pretty tough to machine those little pulleys. I had a few with a 3/16" bore and our machinist couldn't even open them up to 1/4" without coming apart and breaking.

Sidenote: Did you grab those off of Mcmaster? I love how they have STL's of almost everything.

Edited 1 time(s). Last edit at 12/23/2014 06:52PM by SamS.

xclusive is right, no industrial machine would just use a bearing but that's because in most applications the belts undergo much much more wear. I really don't think it's done because of positioning.

The only reason I can think of would be to decrease wear on the teeth, but the the teeth going over the idler won't ever be used anyway.

Good thought rectangled, but you have to keep in mind that the pulleys are usually made up of three parts with the aluminum crimped or press fir or brazed together...it's pretty tough to machine those little pulleys. I had a few with a 3/16" bore and our machinist couldn't even open them up to 1/4" without coming apart and breaking.

Sidenote: Did you grab those off of Mcmaster? I love how they have STL's of almost everything.

Edited 1 time(s). Last edit at 12/23/2014 06:52PM by SamS.

Re: Toothed Idlers  love'em or hate'em love'em or hate'em December 24, 2014 01:47AM |

Registered: 9 years ago Posts: 11 |

I am a little skeptical about how the toothed pulleys would lend themselves to 'binding and uneven tension' as you mentioned. You might have to help me understand the concept a little more.

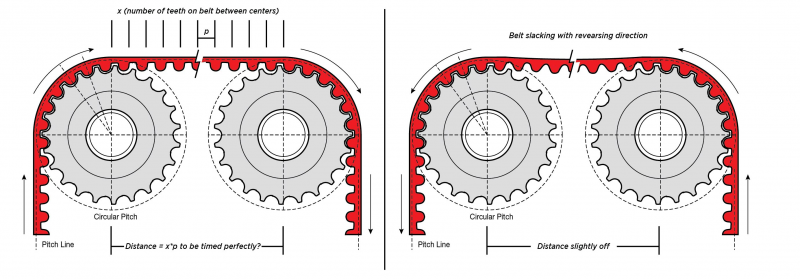

However, I thought about it and I could imagine that maybe if the pulleys where at a slightly off distance from each other that the belt segment in between the pulleys is forced to become slack (say when reversing) due to its teeth. Almost as if there where too many teeth on the belt to fit between each pulley, I illustrated it:

Please, do not take these diagrams serious as they have not been proven.

So basically, it is like what you said the pulleys themselves have to be spaced at the exact distance (belt teeth pitch x how many teeth between pulleys) to mesh perfectly with belt. I am actually starting to see how this could suck. Could it be not fixed by allowing one of the pulleys to have some adjust-ability in where you put them?

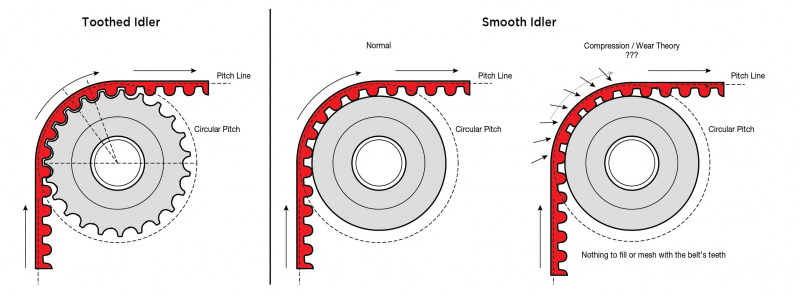

Also, to illustrated what I mentioned earlier about if the teeth would compress when running the belt over smooth idlers, over time:

Please, do not take these diagrams serious as they have not been proven.

I am trying to weight the pros/cons of each but this might be an imaginary fear of my'n? I see lots of people doing the smooth idler as less has to be considered about pulley placement.

Thoughts?

-B

Edited 1 time(s). Last edit at 12/24/2014 01:48AM by Rectangled.

However, I thought about it and I could imagine that maybe if the pulleys where at a slightly off distance from each other that the belt segment in between the pulleys is forced to become slack (say when reversing) due to its teeth. Almost as if there where too many teeth on the belt to fit between each pulley, I illustrated it:

Please, do not take these diagrams serious as they have not been proven.

So basically, it is like what you said the pulleys themselves have to be spaced at the exact distance (belt teeth pitch x how many teeth between pulleys) to mesh perfectly with belt. I am actually starting to see how this could suck. Could it be not fixed by allowing one of the pulleys to have some adjust-ability in where you put them?

Also, to illustrated what I mentioned earlier about if the teeth would compress when running the belt over smooth idlers, over time:

Please, do not take these diagrams serious as they have not been proven.

I am trying to weight the pros/cons of each but this might be an imaginary fear of my'n? I see lots of people doing the smooth idler as less has to be considered about pulley placement.

Thoughts?

-B

Edited 1 time(s). Last edit at 12/24/2014 01:48AM by Rectangled.

Re: Toothed Idlers  love'em or hate'em love'em or hate'em December 24, 2014 06:35AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Rectangled

So basically, it is like what you said the pulleys themselves have to be spaced at the exact distance (belt teeth pitch x how many teeth between pulleys) to mesh perfectly with belt.

I see no reason why this whould be neccessary. We talk about idlers, not pulleys. Idlers rotate freely and, if there are two, independent of each other. If distance doesn't match perfectly, one of the idlers whould simply rotate a bit and everything is fine.

Quote

Rectangled

[attachment 45728 CompressionTheory-01.jpg]

Yes, this compression certainly happens. In bad cases it's also a problem, e.g. T5 belts with weak, pure silicone teeth. The idea of GT2 belts is to reduce this compression and also to make the difference between tooth on the edge vs. tooth not yet on the edge small enough to not cause visible artefacts on the printed parts.

A printed toothed idler might be not precise enough to show the advantage of a toothed idler, but I'm pretty sure toothed idlers have some precision gain when machined well.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

Re: Toothed Idlers  love'em or hate'em love'em or hate'em December 24, 2014 07:34AM |

Admin Registered: 11 years ago Posts: 3,096 |

What's most importance is the experience in practice. And in practice, I can say that it doesn't matter! The lifespan of a belt running on toother idler vs idler bearing is hard to measure. I can see no wear or tear whatsoever on any of my printers.

They both use different solutions for the idler.

My MendelMax even uses very small bearings for an idler on the X-axis and I see not wear at all. We can of course keep on talking about hypotheses, and it can be fun at times, but real scale tests don't really show much difference between the two solutions.

The only thing I can say is that it probably will make a difference on huge CNC routers that make use of very heavy tools and work all day and night in factories. I think it is safe to say that on most* 3D printers it doesn't matter what you use.

One thing is for certain, if you use the wrong spaced tooth idler (for example T2.5 idler with a GT2 belt) you will surely have worse prints and shorter belt life than if you use a belt on a bearing. And since I don't like the printed toothed idlers, I would suggest using a bearing.

Edited 1 time(s). Last edit at 12/24/2014 07:35AM by Ohmarinus.

http://www.marinusdebeer.nl/

They both use different solutions for the idler.

My MendelMax even uses very small bearings for an idler on the X-axis and I see not wear at all. We can of course keep on talking about hypotheses, and it can be fun at times, but real scale tests don't really show much difference between the two solutions.

The only thing I can say is that it probably will make a difference on huge CNC routers that make use of very heavy tools and work all day and night in factories. I think it is safe to say that on most* 3D printers it doesn't matter what you use.

One thing is for certain, if you use the wrong spaced tooth idler (for example T2.5 idler with a GT2 belt) you will surely have worse prints and shorter belt life than if you use a belt on a bearing. And since I don't like the printed toothed idlers, I would suggest using a bearing.

Edited 1 time(s). Last edit at 12/24/2014 07:35AM by Ohmarinus.

http://www.marinusdebeer.nl/

Re: Toothed Idlers  love'em or hate'em love'em or hate'em December 24, 2014 11:29PM |

Registered: 10 years ago Posts: 64 |

Yeah you nailed exactly what I was talking about in the first diagram. And why does the compression matter? It would theoretically stay the same the whole time and not affect amything, just like how a little stretch in the belt doesn't matter because it's uniformly distributed.

Ohm is right. In situations where you want your belt to do 20 years instead of 15 under heavy loads it's probably important, but for our purposes there's not really a point.

Ohm is right. In situations where you want your belt to do 20 years instead of 15 under heavy loads it's probably important, but for our purposes there's not really a point.

Sorry, only registered users may post in this forum.