Rep-strapping using a CNC Mill

Posted by Luis.Freeman

|

Rep-strapping using a CNC Mill May 15, 2007 03:07PM |

Registered: 16 years ago Posts: 26 |

Hi,

I have a Taig CNC mill at home. It's basically a very small mill as you can see on the attached picture file. I'm planning to use the Mill to machine the extruder parts out of PTFE and or Aluminum?

Once the extruder is ready then I plan to attach it to the Mill head and use the mill as the cartesian bed to Rapid Prototype all the Cartesian Assembly parts.

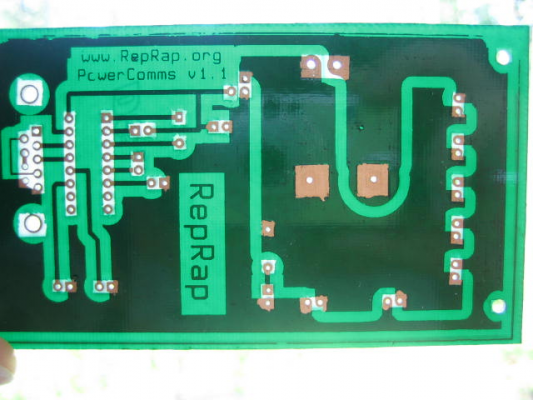

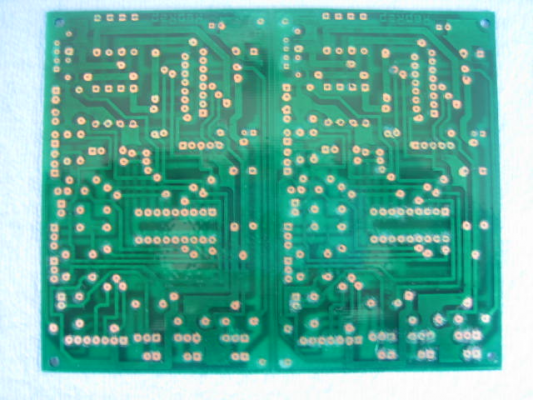

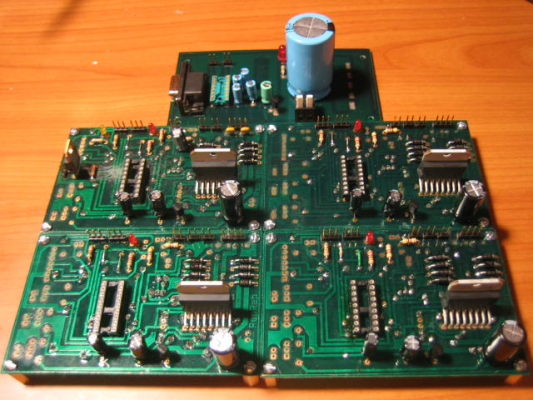

Over the last 2 weeks I've been working on the PCBs (Don't be fooled by the look... I made them at home) and the card assembly. I'm attaching some pictures files of the PCBs and the cards assembled. This weekend I'm planning to test all the cards and start ordering the raw materials for the extruder.

I'm logging my progress on my web page at www.Luis-Freeman.com. Unfortunately my server has been having problems and you may or may not be able to access it until I get a chance this weekend to fix it.

Now... that being said, the only concern I have is that the stepper motors on the mill require 2.5 Amps each, so I'm not sure how the RepRap cards will behave if I connect them to these steppers as my understanding is that the cartesian bed is using 1 Amp steppers. Would the RepRap cards be able to deliver 2.5 Amp?

Luis Freeman

I have a Taig CNC mill at home. It's basically a very small mill as you can see on the attached picture file. I'm planning to use the Mill to machine the extruder parts out of PTFE and or Aluminum?

Once the extruder is ready then I plan to attach it to the Mill head and use the mill as the cartesian bed to Rapid Prototype all the Cartesian Assembly parts.

Over the last 2 weeks I've been working on the PCBs (Don't be fooled by the look... I made them at home) and the card assembly. I'm attaching some pictures files of the PCBs and the cards assembled. This weekend I'm planning to test all the cards and start ordering the raw materials for the extruder.

I'm logging my progress on my web page at www.Luis-Freeman.com. Unfortunately my server has been having problems and you may or may not be able to access it until I get a chance this weekend to fix it.

Now... that being said, the only concern I have is that the stepper motors on the mill require 2.5 Amps each, so I'm not sure how the RepRap cards will behave if I connect them to these steppers as my understanding is that the cartesian bed is using 1 Amp steppers. Would the RepRap cards be able to deliver 2.5 Amp?

Luis Freeman

|

Re: Rep-strapping using a CNC Mill May 15, 2007 03:43PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Rep-strapping using a CNC Mill May 15, 2007 06:09PM |

Registered: 16 years ago Posts: 246 |

|

Re: Rep-strapping using a CNC Mill May 15, 2007 07:02PM |

Admin Registered: 17 years ago Posts: 7,879 |

Impressive!

I have not seen home made PCB's with solder resist before. What technique did you use?

Regarding the stepper motors, if they are 2.5A per winding then I think that exceeds the maximum for the driver chip which is 2A. [www.st.com]

[www.hydraraptor.blogspot.com]

I have not seen home made PCB's with solder resist before. What technique did you use?

Regarding the stepper motors, if they are 2.5A per winding then I think that exceeds the maximum for the driver chip which is 2A. [www.st.com]

[www.hydraraptor.blogspot.com]

|

Anonymous User

Re: Rep-strapping using a CNC Mill May 15, 2007 07:58PM |

|

Re: Rep-strapping using a CNC Mill May 15, 2007 08:47PM |

|

Re: Rep-strapping using a CNC Mill May 15, 2007 09:03PM |

Registered: 16 years ago Posts: 26 |

Nophead,

The Solder Mask is made of paint used to decorate glass and Metal. I found the method on a PCB DYI forum. The paint has to be baked for 40 minutes at 275 Farenheit. The paint brand is Pebeo Vitrea 160 and I got mine at Michaels but is available almost everywhere. The color I used is "Oriental Green" but there are many colors to choose. I used strips of masking tape to cover the vias and then painted using an airbrush. Make sure you use FR-4 Material on your copper-clad so that it can stand the 275 Farenheit.

I checked on the steppers and the current they need is actually 2 Amp per phase so I think I'm good to go, right?

dOubled,

I tried milling PCBs a while ago and didn't like it mainly because the bits are expensive and they wear out very fast as the material is vey abrasive. It's easier, faster and more cost efective in my opinion to toner transfer, and etch.

Drilling thou may be better on the mill specially if you have many cards to do.

The Solder Mask is made of paint used to decorate glass and Metal. I found the method on a PCB DYI forum. The paint has to be baked for 40 minutes at 275 Farenheit. The paint brand is Pebeo Vitrea 160 and I got mine at Michaels but is available almost everywhere. The color I used is "Oriental Green" but there are many colors to choose. I used strips of masking tape to cover the vias and then painted using an airbrush. Make sure you use FR-4 Material on your copper-clad so that it can stand the 275 Farenheit.

I checked on the steppers and the current they need is actually 2 Amp per phase so I think I'm good to go, right?

dOubled,

I tried milling PCBs a while ago and didn't like it mainly because the bits are expensive and they wear out very fast as the material is vey abrasive. It's easier, faster and more cost efective in my opinion to toner transfer, and etch.

Drilling thou may be better on the mill specially if you have many cards to do.

|

Re: Rep-strapping using a CNC Mill May 15, 2007 09:03PM |

Registered: 17 years ago Posts: 25 |

Awesome, dude!

I'll be really interested in your progress to adapt the extrusion head to a millable design, its something I need to work on soon I think. Adapted extrusion head for milling would mean that anyone can get stuff milled fairly cheaply.. hope you'll contribute them to the project!

I'll be really interested in your progress to adapt the extrusion head to a millable design, its something I need to work on soon I think. Adapted extrusion head for milling would mean that anyone can get stuff milled fairly cheaply.. hope you'll contribute them to the project!

Sorry, only registered users may post in this forum.