3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it?

Posted by TooManyToys

|

3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 19, 2013 07:30AM |

Registered: 11 years ago Posts: 9 |

Hi all,

Another Aussie here who recently purchased one of the 3DStuffmaker Prusas from their Christmas promo.

Decided on this one because I was under the impression it would be shipped fairly quickly from Sydney (and it was well priced)....

Well, I got one out of two there.

Fun to build, but so far I'm undewhelmed with print quality.

Could I please get some opinions/advice from anyone here who has "been here and done that" to get this little beastie printing well?

Something that will help me plan my next moves.

Assembling and adjusting this little kit was no drama. I've many years professional experience as an engineer working on computer systems and electro-mechanical peripherals such as large laser printers, band printers (that's going back a way), and large format printers/plotters that needed to be calibrated within a nothingth of a millimeter.

What I've found from the printer as it is, assembled, adjusted, calibrations and some fine tuning done, is the print quality is very inconsistent.

Chopping and changing between the Pronterface /slic3r 0.7.1 that came with the printer and the latest Repetier/Skeinforge, I've managed to get a couple reasonable prints out of it, some of the first being replacement extruder gears, because I've already had one little acrylic drive gear break (very grateful to 3DStuffmaker for included spares). But the rest of the prints....

A large extruder gear I downloaded from Thingiverse printed with Repetier/Skeinforge came out near to perfect.

The small drive gear's I've tried have been whole other story. They come out looking like something designed by Salvadore Dali!

I've spent many evenings tuning slic3r & skeinforge, learning their settings, adjusting M-codes for the extruder steps, slowing prints down to 5mm/sec, you name it! Nothing seems to give me any consistency.

The way it appears to me is it's how the firmware in the stock Gen6 board that came with this unit is interpreting the slices that's causing the problem.

If it's not that then I can't understand why it is it that using Slic3r 0.9.8 on my machine causes the print path within a slice to jump around from point to point like a caffiene addicted rabbit on speed, yet other users seem to be getting good clean results with this latest version?

Or why it is that test print after test print of the small gear, with so many changed settings in both slic3r (old and new) and Skeinforge all end up producing the same basic lopsided some-of-the-teeth-missing results except for the one or two random prints that are almost useable?

Also tried Kisslicer. Nice in concept, but one print that worked mostly ok with Skienforge came out looking more like a bug after its hit a windshield. Again, it appears the firmware on the Gen6 is interpreting the instructions wrong.

The firmware is 3DStuffmaker's branded Marlin 1.0.0 RC2. I've been attempting to update it but I've now hit the bootloader brick wall.

What I'd really like to know is:

1/ For those of you who have been down this path, has upgrading/updating the firmware on the Gen6 board made an appreciable difference in print quality (once re-calibrated)?

2/ Is it justifiable to spend A$95 on 3DStuffmaker's firmware/software upgrade kit?

This seems a bit of a dodge to me, kinda like "pay us more or you'll just print crap". I assume this device is basically to provide the bootloader for updating.

Or would I be better off sinking that money into a new controller, say a Ramps, and just ditch the old locked out Gen6?

Thanks in advance for your ideas.

Another Aussie here who recently purchased one of the 3DStuffmaker Prusas from their Christmas promo.

Decided on this one because I was under the impression it would be shipped fairly quickly from Sydney (and it was well priced)....

Well, I got one out of two there.

Fun to build, but so far I'm undewhelmed with print quality.

Could I please get some opinions/advice from anyone here who has "been here and done that" to get this little beastie printing well?

Something that will help me plan my next moves.

Assembling and adjusting this little kit was no drama. I've many years professional experience as an engineer working on computer systems and electro-mechanical peripherals such as large laser printers, band printers (that's going back a way), and large format printers/plotters that needed to be calibrated within a nothingth of a millimeter.

What I've found from the printer as it is, assembled, adjusted, calibrations and some fine tuning done, is the print quality is very inconsistent.

Chopping and changing between the Pronterface /slic3r 0.7.1 that came with the printer and the latest Repetier/Skeinforge, I've managed to get a couple reasonable prints out of it, some of the first being replacement extruder gears, because I've already had one little acrylic drive gear break (very grateful to 3DStuffmaker for included spares). But the rest of the prints....

A large extruder gear I downloaded from Thingiverse printed with Repetier/Skeinforge came out near to perfect.

The small drive gear's I've tried have been whole other story. They come out looking like something designed by Salvadore Dali!

I've spent many evenings tuning slic3r & skeinforge, learning their settings, adjusting M-codes for the extruder steps, slowing prints down to 5mm/sec, you name it! Nothing seems to give me any consistency.

The way it appears to me is it's how the firmware in the stock Gen6 board that came with this unit is interpreting the slices that's causing the problem.

If it's not that then I can't understand why it is it that using Slic3r 0.9.8 on my machine causes the print path within a slice to jump around from point to point like a caffiene addicted rabbit on speed, yet other users seem to be getting good clean results with this latest version?

Or why it is that test print after test print of the small gear, with so many changed settings in both slic3r (old and new) and Skeinforge all end up producing the same basic lopsided some-of-the-teeth-missing results except for the one or two random prints that are almost useable?

Also tried Kisslicer. Nice in concept, but one print that worked mostly ok with Skienforge came out looking more like a bug after its hit a windshield. Again, it appears the firmware on the Gen6 is interpreting the instructions wrong.

The firmware is 3DStuffmaker's branded Marlin 1.0.0 RC2. I've been attempting to update it but I've now hit the bootloader brick wall.

What I'd really like to know is:

1/ For those of you who have been down this path, has upgrading/updating the firmware on the Gen6 board made an appreciable difference in print quality (once re-calibrated)?

2/ Is it justifiable to spend A$95 on 3DStuffmaker's firmware/software upgrade kit?

This seems a bit of a dodge to me, kinda like "pay us more or you'll just print crap". I assume this device is basically to provide the bootloader for updating.

Or would I be better off sinking that money into a new controller, say a Ramps, and just ditch the old locked out Gen6?

Thanks in advance for your ideas.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 19, 2013 09:25AM |

Registered: 11 years ago Posts: 477 |

"If it's not that then I can't understand why it is it that using Slic3r 0.9.8 on my machine causes the print path within a slice to jump around from point to point like a caffiene addicted rabbit on speed, yet other users seem to be getting good clean results with this latest version?"

idk. I'm pretty familiar with path generation pertaining to PCB design, dating back to the mid-late 1980s, and what I've noticed in my somewhat limited experience with the reprap project is that the algorithms used here are far less optimized than that of their predecessors in PCB/etc. IMO, it's just a natural symptom of the "youth" of this technology and also its specific nature (rhetorical ex: how does one apply hot plastic and ensure a lower layer is at the "proper" temp when the extrusion nozzle comes back too the same point?) and will improve as it matures.

idk. I'm pretty familiar with path generation pertaining to PCB design, dating back to the mid-late 1980s, and what I've noticed in my somewhat limited experience with the reprap project is that the algorithms used here are far less optimized than that of their predecessors in PCB/etc. IMO, it's just a natural symptom of the "youth" of this technology and also its specific nature (rhetorical ex: how does one apply hot plastic and ensure a lower layer is at the "proper" temp when the extrusion nozzle comes back too the same point?) and will improve as it matures.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 19, 2013 02:47PM |

Registered: 14 years ago Posts: 65 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 19, 2013 05:11PM |

Registered: 11 years ago Posts: 9 |

Hi Prober,

That's the point at which I've ground to a halt.

This particular Gen6 board has no bootloader, so I'll need a USB device to provide that before I can update the firmware.

3DSuffmaker sell their "upgrade kit" for $95, though I could possibly buy something like a USBTinyISP for much less that should (hopefully) do the same thing.

The question I have is - is it worth spending money on a bootloader for this Gen6 board?

How successful have others been with this particular make/model once it's been upgraded?

Xiando,

That makes sense. Having done maintenance work on plotters in the past used for circuit design I understand what you mean.

The thing that bothers me here is if I print the same object using Skienforge or Slic3r 0.7.1 I get a fairly optimised "minimal movement" print path. Slic3r 0.9.8 appears completely erratic and I suspect it shouldn't be.

That's the point at which I've ground to a halt.

This particular Gen6 board has no bootloader, so I'll need a USB device to provide that before I can update the firmware.

3DSuffmaker sell their "upgrade kit" for $95, though I could possibly buy something like a USBTinyISP for much less that should (hopefully) do the same thing.

The question I have is - is it worth spending money on a bootloader for this Gen6 board?

How successful have others been with this particular make/model once it's been upgraded?

Xiando,

That makes sense. Having done maintenance work on plotters in the past used for circuit design I understand what you mean.

The thing that bothers me here is if I print the same object using Skienforge or Slic3r 0.7.1 I get a fairly optimised "minimal movement" print path. Slic3r 0.9.8 appears completely erratic and I suspect it shouldn't be.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 19, 2013 05:30PM |

Registered: 11 years ago Posts: 104 |

Hi,

I'm close your path mate.

I bought a 3DStuffmaker Prusa Explorer last summer. With less chance till there, I had to do with an old, and not updated, repsnapper version.

Yet it hasn't been the only problem I had to face with that product... I won't make a whole review about my experience with 3DStuffmaker, cos this is not the topic, it would be long, but globaly it is not a positive one.

The most frustrating is when after many mails or skype sessions in order to try to treat a problem, their last message is "if it is still not working, tell us..." so my last message "problem still there, so what ?" and no more communication. Two different problems trying to solve with them, two same conclusions... I Do It Myself !

Their upgrade kit ? Damn, at this price if I had to fail changing the firmware, I would have bought another electronic.

I bought a USBtinyISP. This one : [www.ebay.com] .

I burned the bootloader and go for a new firmware (sprinter).

I'm at the calibration stage this night. X, Y and Z ok, I'm on extruder now.

Maybe I may be able to tell you and show if I'm making better than the rare good prints I made before, in the coming days...

I'm close your path mate.

I bought a 3DStuffmaker Prusa Explorer last summer. With less chance till there, I had to do with an old, and not updated, repsnapper version.

Yet it hasn't been the only problem I had to face with that product... I won't make a whole review about my experience with 3DStuffmaker, cos this is not the topic, it would be long, but globaly it is not a positive one.

The most frustrating is when after many mails or skype sessions in order to try to treat a problem, their last message is "if it is still not working, tell us..." so my last message "problem still there, so what ?" and no more communication. Two different problems trying to solve with them, two same conclusions... I Do It Myself !

Their upgrade kit ? Damn, at this price if I had to fail changing the firmware, I would have bought another electronic.

I bought a USBtinyISP. This one : [www.ebay.com] .

I burned the bootloader and go for a new firmware (sprinter).

I'm at the calibration stage this night. X, Y and Z ok, I'm on extruder now.

Maybe I may be able to tell you and show if I'm making better than the rare good prints I made before, in the coming days...

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 19, 2013 07:07PM |

Registered: 11 years ago Posts: 9 |

Hi Couby,

So the USBTinyISP worked. Excellent! I'll go with that.

I didn't want to spend $95 on 3DStuffmaker's upgrade kit without knowing what the end results might be, but $10 to $20 on a USBTinyISP is definitly worth a try.

Thanks for the tip!

"if it is still not working, tell us..."

That's funny!

In other words "we don't have a clue, you work it out yourself and tell is if you fix it".

I wish you all the best in resolving the problem. Hope you can get some decent prints!

So the USBTinyISP worked. Excellent! I'll go with that.

I didn't want to spend $95 on 3DStuffmaker's upgrade kit without knowing what the end results might be, but $10 to $20 on a USBTinyISP is definitly worth a try.

Thanks for the tip!

"if it is still not working, tell us..."

That's funny!

In other words "we don't have a clue, you work it out yourself and tell is if you fix it".

I wish you all the best in resolving the problem. Hope you can get some decent prints!

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 20, 2013 05:34AM |

Registered: 13 years ago Posts: 7,616 |

Quote

3DSuffmaker sell their "upgrade kit" for $95

$95 for upgrading open source software on open source hardware is pretty stiff. For me such an offering would question wether they're serious, to describe it friendly.

In-System-Programmers (ISPs) sell for something like $15 to $25. Fairly simple to use of you dive into the command line for a few minutes: [reprap.org] If you don't like one, get a whole new electronics for these $95. Gen6 isn't the only one available.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 20, 2013 07:03AM |

Registered: 11 years ago Posts: 5 |

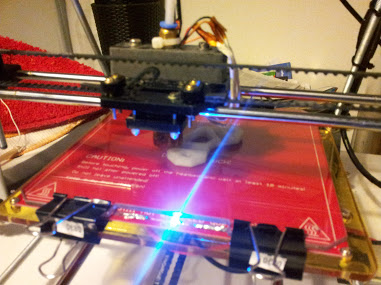

I received one of their printers in december, and have started getting good quality prints, after switching to Repitier firmware (flashed bootloader with arduino mini ~$10), modifying the extruder pressure plate, installing a hotend fan, and adding bed leveling thumbscrews.

The biggest issue I am facing at the moment is the acrylic print bed, which is warped and affecting adhesion.

The biggest issue I am facing at the moment is the acrylic print bed, which is warped and affecting adhesion.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 20, 2013 01:12PM |

Registered: 11 years ago Posts: 104 |

I'm interested in your bed leveling thumbscrews mod Paladin  . It is a pain leveling this bed. Do you have any references or links ?

. It is a pain leveling this bed. Do you have any references or links ?

On my side I added a heatbed Mk2a with a glass plate, and replaced the hotend by a J-Head MkV. The 3DSM hotend had a problem, maybe at the thermistor level.

For the heatbed powering I simply connected a manual PWM. This is not an automated regulation, but it works...

A small video (with former hotend) : [www.youtube.com] .

Mechanical calibration is ok. Right now my problem is the temperature control of hotend. There are two many oscillations (9-10 °C). I think PID regulation would help, but it is not well documented how to set it. PID theory doesn't help.

. It is a pain leveling this bed. Do you have any references or links ?

. It is a pain leveling this bed. Do you have any references or links ?On my side I added a heatbed Mk2a with a glass plate, and replaced the hotend by a J-Head MkV. The 3DSM hotend had a problem, maybe at the thermistor level.

For the heatbed powering I simply connected a manual PWM. This is not an automated regulation, but it works...

A small video (with former hotend) : [www.youtube.com] .

Mechanical calibration is ok. Right now my problem is the temperature control of hotend. There are two many oscillations (9-10 °C). I think PID regulation would help, but it is not well documented how to set it. PID theory doesn't help.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? February 20, 2013 05:25PM |

Registered: 11 years ago Posts: 9 |

Thanks PaladinCloudring, that's what I was hoping to hear.

If the only choice was a $95 upgrade kit I'd say stuff it and put that money towards a Ramps, but the under $20 solution sounds the way to go.

I've looked at the Marlin & Repetier config files at it looks like Repetier has put a fair bit more fine tuning in so I can see how it would be improving print quality.

Totally agree about the acrylic bed! I've already started seeing heat deformations appearing on mine and I haven't done a whole lot with it. A friend told me to grab a box of 200x200x5mm mirror tiles from the bathroom section of a hardware store and use one of them as the bed - dead flat & won't warp. That might be the way to go.

If the only choice was a $95 upgrade kit I'd say stuff it and put that money towards a Ramps, but the under $20 solution sounds the way to go.

I've looked at the Marlin & Repetier config files at it looks like Repetier has put a fair bit more fine tuning in so I can see how it would be improving print quality.

Totally agree about the acrylic bed! I've already started seeing heat deformations appearing on mine and I haven't done a whole lot with it. A friend told me to grab a box of 200x200x5mm mirror tiles from the bathroom section of a hardware store and use one of them as the bed - dead flat & won't warp. That might be the way to go.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 06, 2013 03:50AM |

Registered: 11 years ago Posts: 104 |

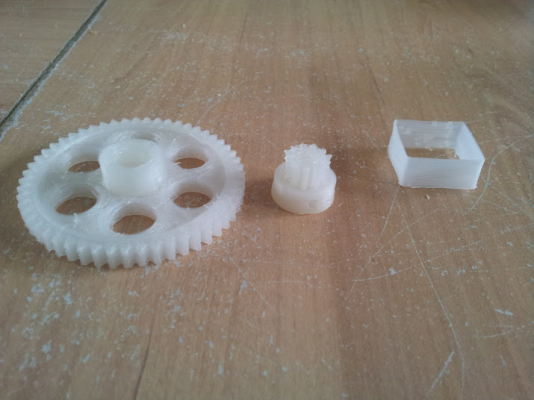

Back, and with a picture.

It's been a bit longer than expected, but I'm printing again correct pieces .

.

That's a real pleasure to use updated softwares and slicers. At the moment I'm with Repetier firmware, host and I use slic3r.

It's been a bit longer than expected, but I'm printing again correct pieces

.

.That's a real pleasure to use updated softwares and slicers. At the moment I'm with Repetier firmware, host and I use slic3r.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 07, 2013 06:38PM |

Registered: 11 years ago Posts: 5 |

Sorry for the late reply, I never check the forums sadly. I'm using [www.thingiverse.com] for thumbscrews (the slim ones printed best for me). I have removed the top locking nut and upgraded my bed springs for a more forceful hold.

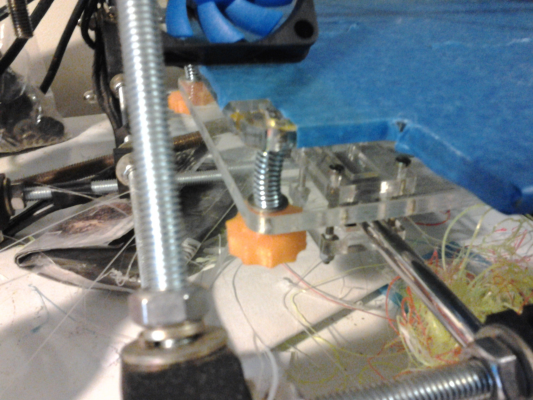

Here you can see my thumb-screws

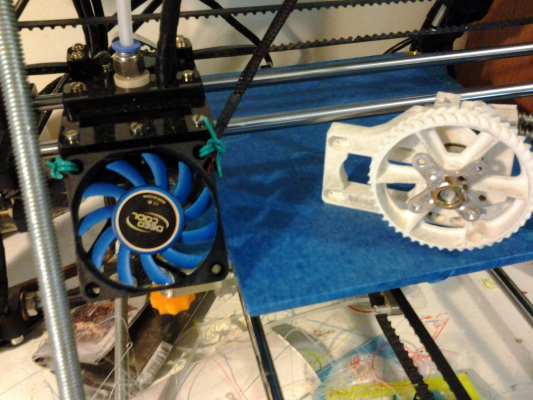

And here's the 60mm fan I've just started using, next to a Uni-X Wades which I'm just hobbing a bolt for. I've found it to help a ton! It's constantly on, powered off the GEN-6 electronics, I've been meaning to add a switch, but just havent gotten around to it.

Here you can see my thumb-screws

And here's the 60mm fan I've just started using, next to a Uni-X Wades which I'm just hobbing a bolt for. I've found it to help a ton! It's constantly on, powered off the GEN-6 electronics, I've been meaning to add a switch, but just havent gotten around to it.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 08, 2013 03:40AM |

Registered: 11 years ago Posts: 104 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 08, 2013 04:25AM |

Registered: 11 years ago Posts: 5 |

The next step for me is adding one of my Raspberry Pi's as a print-server and LCD screen, and using that to control a heated bed and fans.

I grabbed a Hard Disk Cooler from MSY for $6, and that gave me two cheap fans to play with.

I haven't noticed any negative effects to running my fan all the time, but only time will tell

I grabbed a Hard Disk Cooler from MSY for $6, and that gave me two cheap fans to play with.

I haven't noticed any negative effects to running my fan all the time, but only time will tell

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 09, 2013 03:17AM |

Registered: 11 years ago Posts: 104 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 29, 2013 09:53PM |

Registered: 11 years ago Posts: 23 |

I would be very VERY wary with this company. I bought this model lured into their "free shipping to the USA". It's literally the worst purchase I've made in my life. First, there are MANY engineering flaws with their product, beginning with their manual that doesn't even show the electrical wire hookups correctly. Either they sell none of these so no thought to tell me, or they sell a ton but the user magically knows how to switch around cables to the correct positions (which are actually incorrect when you take what they write on the connectors in marker and plug them into where they are 'supposed' to go). Next, the gears are made of flimsy acrylic and will break just about every other print. After working with this vendor their only solution was to continue to send me more gears when the last one breaks and to tighten down the extruder harder - which would in fact break the gears faster! When you're 7 hours into a 10 hour print... what kind of solution is that???

I worked on getting their machine into decent shape for 3 months and after every fix, something else would break. The nozzle plate holder broke because they couldn't even send me the right diameter nozzle to snap in. Imagine having a pen and paper, yet you cannot write on it because your hand broke from trying to hold the pen. That's what their machine did.

I have won a Claim against them through Paypal and I would suggest doing the same if you have owned it less than 45 days and not "work" with these people to get it working the way it should have been working in the first place or you will lose your time to do anything about it like I did. I have shown the machine to the American Express Claims department and they won't cover the cost because they called it "a direct and inherent manufacturer defect".

You may like them, you may not like them, but I'm out $699AUD for a non working machine from people who say they are honest and work with their customers. Their solution was for me to spend my money to send a completely broken machine held together with glue, screws and rubber bands (yes, I'm not joking, I can show you pictures) from the US all the way back to the AU, which, if you look at their own website seems to cost: "FREE FREIGHT - save between $250 and $450 for a limited time only." I looked it up and UPS/FEDEX can easily cost you $600 to ship it to Australia from the US.

It is your choice if you want to buy from these people. They seem nice and friendly and will answer every email promptly... until they have your money. Then, at best, they offer to send you parts the rest of your life to fix problems that continue to break over and over (i.e. an engineering flaw) and you sit with downtime waiting weeks for the shipments. Or you can pay to send them your junk which is refunds you nearly nothing. Be sure to factor my story in your decision making process when you choose to buy from this vendor or not.

PS - and I've got a lot lot more about the product and company and can go on and on that I'm not going to do here. I think you get the picture. There are other vendors out there and I found an AWESOME printer that is like comparing a Cadillac to their broken down imprecise Yugo.

PPS - the owner will say he "rejects" my assessment of his engineering flaws, but I have printed documentation they've given me that shows otherwise and the fact that the fix is to keep putting new parts on that break every other print.... any layman can see that as an engineering issue. He also doesn't factor in that I have 3 post graduate Electrical Engineering degrees to backup what I am saying.

I worked on getting their machine into decent shape for 3 months and after every fix, something else would break. The nozzle plate holder broke because they couldn't even send me the right diameter nozzle to snap in. Imagine having a pen and paper, yet you cannot write on it because your hand broke from trying to hold the pen. That's what their machine did.

I have won a Claim against them through Paypal and I would suggest doing the same if you have owned it less than 45 days and not "work" with these people to get it working the way it should have been working in the first place or you will lose your time to do anything about it like I did. I have shown the machine to the American Express Claims department and they won't cover the cost because they called it "a direct and inherent manufacturer defect".

You may like them, you may not like them, but I'm out $699AUD for a non working machine from people who say they are honest and work with their customers. Their solution was for me to spend my money to send a completely broken machine held together with glue, screws and rubber bands (yes, I'm not joking, I can show you pictures) from the US all the way back to the AU, which, if you look at their own website seems to cost: "FREE FREIGHT - save between $250 and $450 for a limited time only." I looked it up and UPS/FEDEX can easily cost you $600 to ship it to Australia from the US.

It is your choice if you want to buy from these people. They seem nice and friendly and will answer every email promptly... until they have your money. Then, at best, they offer to send you parts the rest of your life to fix problems that continue to break over and over (i.e. an engineering flaw) and you sit with downtime waiting weeks for the shipments. Or you can pay to send them your junk which is refunds you nearly nothing. Be sure to factor my story in your decision making process when you choose to buy from this vendor or not.

PS - and I've got a lot lot more about the product and company and can go on and on that I'm not going to do here. I think you get the picture. There are other vendors out there and I found an AWESOME printer that is like comparing a Cadillac to their broken down imprecise Yugo.

PPS - the owner will say he "rejects" my assessment of his engineering flaws, but I have printed documentation they've given me that shows otherwise and the fact that the fix is to keep putting new parts on that break every other print.... any layman can see that as an engineering issue. He also doesn't factor in that I have 3 post graduate Electrical Engineering degrees to backup what I am saying.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 29, 2013 11:08PM |

Registered: 11 years ago Posts: 23 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 30, 2013 05:45AM |

Registered: 11 years ago Posts: 89 |

Keith Jones,

If you are not satisfied with our product that is fine.

We are happy to refund you in full on return of our printer kit in the same packaging as ordered, this offer still stands.

In relation to return shipping, we are happy to assist you.

Thank You

Edited 2 time(s). Last edit at 03/30/2013 07:35AM by 3dstuffmaker.

If you are not satisfied with our product that is fine.

We are happy to refund you in full on return of our printer kit in the same packaging as ordered, this offer still stands.

In relation to return shipping, we are happy to assist you.

Thank You

Edited 2 time(s). Last edit at 03/30/2013 07:35AM by 3dstuffmaker.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? March 30, 2013 02:19PM |

Registered: 11 years ago Posts: 23 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? April 12, 2013 06:34AM |

Registered: 11 years ago Posts: 200 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? April 15, 2013 01:30AM |

Registered: 11 years ago Posts: 23 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? April 15, 2013 02:21AM |

Registered: 11 years ago Posts: 67 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 13, 2013 06:20AM |

Registered: 10 years ago Posts: 4 |

Hi Couby, I'm not sure how else to contact you except by submitting a reply in this topic. I have had similar problems to you with a printer purchased from 3D stuffmakers, and had the same sort of inept support from them. It was only on reading of your experiences that I finally found out why I have been unable to upgrade the 5D firmware on my Gen6 to Marlin. No bootloader!! Like you, I pondered the question of whether to get a USBASP, AVRISP, or some other device to reprogram the Gen6, or just buy a new board altogether. Having read of your success with the USBtinyISP this afternoon I immediately ordered one from Hong Kong. What I would like to know is how you went about reprogramming the Gen6. Any information would be appreciated. Thanks, Denis.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 14, 2013 02:13AM |

Registered: 11 years ago Posts: 104 |

Hi Denis,

No problem to share about my journey on that point, will be a pleasure.

Once I had the USBtinyISP I followed the wiki instructions : [www.reprap.org] .

Then through a lot of research about Gen6 (before having the USBtinyISP...) I found makerfarm instructions pretty clear and usefull :

[www.makerfarm.com]

[docs.google.com]

So at the begining I followed these and installed Sprinter firmware.

As I was not really happy with the temperature regulation, and also convinced by Repetier explanation about communications between computer and printer, I decided to change for Repetier one.

I encountered some difficulties, because using one endstop as max endstop instead of min, and misunderstanding one Repetier firmware field. I reported about all this in Repetier dedicated forum here and he helped me to sort all this out.

I'm still using Repetier firmware and I'm happy with it.

Hope these orientations will be helpfull .

.

No problem to share about my journey on that point, will be a pleasure.

Once I had the USBtinyISP I followed the wiki instructions : [www.reprap.org] .

Then through a lot of research about Gen6 (before having the USBtinyISP...) I found makerfarm instructions pretty clear and usefull :

[www.makerfarm.com]

[docs.google.com]

So at the begining I followed these and installed Sprinter firmware.

As I was not really happy with the temperature regulation, and also convinced by Repetier explanation about communications between computer and printer, I decided to change for Repetier one.

I encountered some difficulties, because using one endstop as max endstop instead of min, and misunderstanding one Repetier firmware field. I reported about all this in Repetier dedicated forum here and he helped me to sort all this out.

I'm still using Repetier firmware and I'm happy with it.

Hope these orientations will be helpfull

.

.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 15, 2013 03:55AM |

Registered: 11 years ago Posts: 313 |

hey guys, im in the same boat with this company,

support is pretty good,

the printer, pretty poor, maybe 1 in 10 prints or 1 in 20 prints come out OK, nothing that great tho, always getting extruder jams

I purchased the upgrade kits which is software and the avr programmer,

really did not do much, just allowed me to use pronterface,

The biggest flaw with these guys

- print plates warps, changed mine to a tile with kepton covered, works well..

-extruder is just an annoying , the amount of PLA i have wasted i should of purchased another printer from else where ( they should use ball bearings instead of plastic plate tom apply pressure onto the PLA)

-nozzles are terrible, iv had about 5 or 6 of these nozzles, and the only decent one that works well is the .7mm nozzle.

LITERALLY all of my .4mm nozzle have stuffed up, thermistor or consistent jamming

- they go on about being able to print up to 38mm per second, this is more like 10- 20 mm per second ( 10 for perimeters, 20 for the infill... FRIKEN SLOW)

-they also advised they would have ABS SUPPORT,.. sounds like they will never use ABS its just for their specs sheet to make it look better

paying over $1200 for this machine, i expected it to be better,

if i cannot get it to work effectively with their new 1.75mm extruder, i might be doing a consumer law claim, i honestly feel that i got ripped off with dodgy products..

it really is a shame,

i also believed this company was aussie owned, to find out the printer is actually made in india, I wanted to send my nozzles back but the shipping to india is expensive...

also, when i first opened my machine, i had a cracked side plate, also mine did not work out of the box, had to immediately get the programmer to reflash the board

Edited 3 time(s). Last edit at 07/15/2013 04:08AM by nechaus.

support is pretty good,

the printer, pretty poor, maybe 1 in 10 prints or 1 in 20 prints come out OK, nothing that great tho, always getting extruder jams

I purchased the upgrade kits which is software and the avr programmer,

really did not do much, just allowed me to use pronterface,

The biggest flaw with these guys

- print plates warps, changed mine to a tile with kepton covered, works well..

-extruder is just an annoying , the amount of PLA i have wasted i should of purchased another printer from else where ( they should use ball bearings instead of plastic plate tom apply pressure onto the PLA)

-nozzles are terrible, iv had about 5 or 6 of these nozzles, and the only decent one that works well is the .7mm nozzle.

LITERALLY all of my .4mm nozzle have stuffed up, thermistor or consistent jamming

- they go on about being able to print up to 38mm per second, this is more like 10- 20 mm per second ( 10 for perimeters, 20 for the infill... FRIKEN SLOW)

-they also advised they would have ABS SUPPORT,.. sounds like they will never use ABS its just for their specs sheet to make it look better

paying over $1200 for this machine, i expected it to be better,

if i cannot get it to work effectively with their new 1.75mm extruder, i might be doing a consumer law claim, i honestly feel that i got ripped off with dodgy products..

it really is a shame,

i also believed this company was aussie owned, to find out the printer is actually made in india, I wanted to send my nozzles back but the shipping to india is expensive...

also, when i first opened my machine, i had a cracked side plate, also mine did not work out of the box, had to immediately get the programmer to reflash the board

Edited 3 time(s). Last edit at 07/15/2013 04:08AM by nechaus.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 15, 2013 04:22AM |

Registered: 11 years ago Posts: 313 |

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 15, 2013 11:25AM |

Registered: 11 years ago Posts: 104 |

Hi Nechaus.

Mods I made on my Prusa Explorer :

- added heatbed mk2a to solve bed problems, with a manual electronic PWM as I didn't find clear and simple explanations on how to do with Gen6 (need to add a Mofset managed by I2C ++...); manual PWM works fine even if less sexy than regulated via the host.

- made a new knurling bolt, as the 3DSM doesn't grip enough; I made this thing for that [www.thingiverse.com], this one would be better [www.thingiverse.com] .

- I changed the firmware thanks to the USBTinyISP bootloading the Gen6

- not happy with 3DSM hotend, I replaced it by a J-Head mk5b 0.5

- last thing, I'm using a fan I simply attached on the frame, it helps in the global quality of prints and bridges.

On software side I'm using Repetier host and Repetier firmware. I used Slic3r till the last two months where I found I had better quality for results using Cura, just for slices. Maybe this is just a question of settings, I plan some tests in order to find them as I appreciate Slic3r.

At the end I may be close to 900$ with all mods, far from what I was expecting... but it works. So now I'm making a new printer thanks to this modified Prusa Explorer. I choosed the Lulzbot TAZ as I'm interested in larger prints.

If you need more information about mods I did I'll share with pleasure .

.

Mods I made on my Prusa Explorer :

- added heatbed mk2a to solve bed problems, with a manual electronic PWM as I didn't find clear and simple explanations on how to do with Gen6 (need to add a Mofset managed by I2C ++...); manual PWM works fine even if less sexy than regulated via the host.

- made a new knurling bolt, as the 3DSM doesn't grip enough; I made this thing for that [www.thingiverse.com], this one would be better [www.thingiverse.com] .

- I changed the firmware thanks to the USBTinyISP bootloading the Gen6

- not happy with 3DSM hotend, I replaced it by a J-Head mk5b 0.5

- last thing, I'm using a fan I simply attached on the frame, it helps in the global quality of prints and bridges.

On software side I'm using Repetier host and Repetier firmware. I used Slic3r till the last two months where I found I had better quality for results using Cura, just for slices. Maybe this is just a question of settings, I plan some tests in order to find them as I appreciate Slic3r.

At the end I may be close to 900$ with all mods, far from what I was expecting... but it works. So now I'm making a new printer thanks to this modified Prusa Explorer. I choosed the Lulzbot TAZ as I'm interested in larger prints.

If you need more information about mods I did I'll share with pleasure

.

.|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 15, 2013 10:22PM |

Registered: 11 years ago Posts: 313 |

Hey mate, thanks for the time in replying, you got no idea how much i appreciate it

First of all, well done, very nice upgrades....

Here are my questions

- What did you have to do to change your hot end? a new carriage ? looks like you have integrated something to the existing

- did you change the thermistor/resistor ? is it roughly 6.8 Ohms?

Ideally with mine i have the ecreator evolution, 200mm x 200mm x 200mm build area... I would like to change the hot end so it can do higher temps so i can print with nylon and abs, But i would certainly settle with decent quality consistent PLA prints, my current max temp is 250c, but id say the thermistor would fail eventually.

- A manual PWM controller for a heated bed would be fine, hell id even do that for the hot end if needed.

-Are these extruder gears the same diameter as wades?

My prints start fine, but eventually my extruder just chews into the filament, i have to be so careful of any bends in my filament, This is the reason i was thinking of changing to 3dstuffmakers 1.75mm extruder, looks like the hobbed bolt is better and the extruder design is better, think the hot ends are still the same tho... the extruder looks like it uses springs, looks better to me..

See my prints need to be quite durable, i cant have dodgy layers as it will just come apart during use, for e.g. a simple bike light bracket for my ebike...

i have only ever had luck with the .7mm nozzle, which does not even seem to be the correct diameter, unless my machine is not calibrated, i have to adjust the nozzle diamter and extrusion multiplier to get good looking prints...

such a hassle for me, i just recently wasted 2kg of black PLA, i have nothing to show for it, just a few small gears that i could print well,

I always have to use a fan, but i need to attach it to the carriage, atm i just have it blowing over the entire print bed, using a 140mm fan 12volt running at 6 volt for roughly half the rpm.

Edited 1 time(s). Last edit at 07/15/2013 10:27PM by nechaus.

First of all, well done, very nice upgrades....

Here are my questions

- What did you have to do to change your hot end? a new carriage ? looks like you have integrated something to the existing

- did you change the thermistor/resistor ? is it roughly 6.8 Ohms?

Ideally with mine i have the ecreator evolution, 200mm x 200mm x 200mm build area... I would like to change the hot end so it can do higher temps so i can print with nylon and abs, But i would certainly settle with decent quality consistent PLA prints, my current max temp is 250c, but id say the thermistor would fail eventually.

- A manual PWM controller for a heated bed would be fine, hell id even do that for the hot end if needed.

-Are these extruder gears the same diameter as wades?

My prints start fine, but eventually my extruder just chews into the filament, i have to be so careful of any bends in my filament, This is the reason i was thinking of changing to 3dstuffmakers 1.75mm extruder, looks like the hobbed bolt is better and the extruder design is better, think the hot ends are still the same tho... the extruder looks like it uses springs, looks better to me..

See my prints need to be quite durable, i cant have dodgy layers as it will just come apart during use, for e.g. a simple bike light bracket for my ebike...

i have only ever had luck with the .7mm nozzle, which does not even seem to be the correct diameter, unless my machine is not calibrated, i have to adjust the nozzle diamter and extrusion multiplier to get good looking prints...

such a hassle for me, i just recently wasted 2kg of black PLA, i have nothing to show for it, just a few small gears that i could print well,

I always have to use a fan, but i need to attach it to the carriage, atm i just have it blowing over the entire print bed, using a 140mm fan 12volt running at 6 volt for roughly half the rpm.

Edited 1 time(s). Last edit at 07/15/2013 10:27PM by nechaus.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 16, 2013 02:13AM |

Registered: 11 years ago Posts: 104 |

Hi, you're welcome. Reprap spirit powa  .

.

I didn't change anything for the use of a new hotend. 3DSM hotend was also a J-Head but MkIIIb like (or real ???) hotend. So the MkVb have the same "print" at the top in order to be hold in the carriage. This hotend is a bit shorter but it didn't imply any problem, at the opposite you're winning some vertical print space .

.

I used the thermistor/resistor provided with the new hotend, as far as I remember it was also a 6.8 ohms. Would need to check but I'll be back home in two weeks.

My extruder gear higher in the topic are reprappro mendel gears. It was just for test, I don't use them in fact.

I also thought about 1.75 use. Maybe I'll come to, I don't know for the moment. Just a thing I know, is I wouldn't buy again 3DSM stuff.

Another point as I think about it. Sometimes I had jamming in hotend. Each time it was due to something contaminating the melt chamber.

Applying the reprappro procedure solved the problem each time [www.reprap.org] .

Yet I noticed it was not working well with all types of PLA. Typically it doesn't work with 3DSM PLA I had. At step 1.iii the filament brakes before getting out entirely. With other PLA I bought in France (don't know the exact furnisher/producer) it is working well.

The point is the procedure works well, but depends on the PLA used.

Good luck .

.

.

.I didn't change anything for the use of a new hotend. 3DSM hotend was also a J-Head but MkIIIb like (or real ???) hotend. So the MkVb have the same "print" at the top in order to be hold in the carriage. This hotend is a bit shorter but it didn't imply any problem, at the opposite you're winning some vertical print space

.

.I used the thermistor/resistor provided with the new hotend, as far as I remember it was also a 6.8 ohms. Would need to check but I'll be back home in two weeks.

My extruder gear higher in the topic are reprappro mendel gears. It was just for test, I don't use them in fact.

I also thought about 1.75 use. Maybe I'll come to, I don't know for the moment. Just a thing I know, is I wouldn't buy again 3DSM stuff.

Another point as I think about it. Sometimes I had jamming in hotend. Each time it was due to something contaminating the melt chamber.

Applying the reprappro procedure solved the problem each time [www.reprap.org] .

Yet I noticed it was not working well with all types of PLA. Typically it doesn't work with 3DSM PLA I had. At step 1.iii the filament brakes before getting out entirely. With other PLA I bought in France (don't know the exact furnisher/producer) it is working well.

The point is the procedure works well, but depends on the PLA used.

Good luck

.

.

|

Re: 3DStuffmaker Prusa Gen6 controller - worth getting bootloader or better to replace it? July 16, 2013 02:40AM |

Registered: 11 years ago Posts: 313 |

yeah, i also get alot of issue's with different PLA, it seems the slightly smaller in diameter works alot better then stuff that is around 3.0mm or so, i prefer 2.8mm kinda filament

Your right, been thinking of buying another printer, i got one more roll of PLA to waste.

im still trying to decide if its worth buying the 1.75mm extruder, if it was to solve my issues it would be good, even tho my printer should be working well now..

My options

test the new extruder, if it works well, id be happy..

if it fails still, same kinda issues, id just buy a whole new printer,

Does anyone want to recommend a good printer for under $2000 ? obviously the cheaper the better

Edited 1 time(s). Last edit at 07/16/2013 04:11AM by nechaus.

Your right, been thinking of buying another printer, i got one more roll of PLA to waste.

im still trying to decide if its worth buying the 1.75mm extruder, if it was to solve my issues it would be good, even tho my printer should be working well now..

My options

test the new extruder, if it works well, id be happy..

if it fails still, same kinda issues, id just buy a whole new printer,

Does anyone want to recommend a good printer for under $2000 ? obviously the cheaper the better

Edited 1 time(s). Last edit at 07/16/2013 04:11AM by nechaus.

Sorry, only registered users may post in this forum.