PTFE gases; Printing higher temperature plastics

Posted by uGen

|

PTFE gases; Printing higher temperature plastics February 26, 2013 06:19PM |

Registered: 11 years ago Posts: 490 |

Hello everyone,

now that I am looking into more interesting materials like Nylon and Polycarbonate, one problem arises:

PTFE shows signs of thermal decomposition at around 200°C already. Pans get hotter than that, already, but I am still wondering whether it is advisable to subject the PTFE liner in our more standard Hot Ends to temperatures required for e.g. Nylon.

A quick measurement I made on the old style GRRF Hot End (featuring a longer brass nozzle, the newer versions moved the heater block closer to the heatsink and shortened the nozzle piece) on the outside just below the heatsink showed a temperature of nearly 190°C. Internal temperatures might be a little bit higher, still.

Another problem would be the PEEK becoming too soft to hold the nozzle in place.

I can think of two possible solutions:

- Actively cool the upper part of the Hot End (not absolutely necessary with the 3mm GRRF model right now) so that temperatures stay in the safe range.

- Use a Hot End entirely (or mostly) made of metal, like the Prusa Nozzle (is it even properly released yet?)

So if anyone has tried printing with higher temperature plastics, please share your insights and experiences.

Especially Nylon is extremely interesting as a material as you could (theoretically) print your own bearings that actually work as Nylon is hard wearing and exhibits low friction. It is already in use in commercial polymer plain bearings IIRC.

now that I am looking into more interesting materials like Nylon and Polycarbonate, one problem arises:

PTFE shows signs of thermal decomposition at around 200°C already. Pans get hotter than that, already, but I am still wondering whether it is advisable to subject the PTFE liner in our more standard Hot Ends to temperatures required for e.g. Nylon.

A quick measurement I made on the old style GRRF Hot End (featuring a longer brass nozzle, the newer versions moved the heater block closer to the heatsink and shortened the nozzle piece) on the outside just below the heatsink showed a temperature of nearly 190°C. Internal temperatures might be a little bit higher, still.

Another problem would be the PEEK becoming too soft to hold the nozzle in place.

I can think of two possible solutions:

- Actively cool the upper part of the Hot End (not absolutely necessary with the 3mm GRRF model right now) so that temperatures stay in the safe range.

- Use a Hot End entirely (or mostly) made of metal, like the Prusa Nozzle (is it even properly released yet?)

So if anyone has tried printing with higher temperature plastics, please share your insights and experiences.

Especially Nylon is extremely interesting as a material as you could (theoretically) print your own bearings that actually work as Nylon is hard wearing and exhibits low friction. It is already in use in commercial polymer plain bearings IIRC.

|

Re: PTFE gases; Printing higher temperature plastics February 26, 2013 07:34PM |

Registered: 11 years ago Posts: 374 |

You need a hotend without PEEK or PTFE in the hot section in order to print above 245C-250C.

As an individual you may be able to get away with experimenting at higher temperatures with a hotend that uses the above materials, but it is risky to do so. And recommending other people do the same is asking for trouble of a legal nature, IMHO.

There are at least 2 hotends besides JPrusa's that are all-metal construction. And if you move away from the one piece design, it should not be extremely difficult to manufacture your own, provided you have access to machine tools.

As an individual you may be able to get away with experimenting at higher temperatures with a hotend that uses the above materials, but it is risky to do so. And recommending other people do the same is asking for trouble of a legal nature, IMHO.

There are at least 2 hotends besides JPrusa's that are all-metal construction. And if you move away from the one piece design, it should not be extremely difficult to manufacture your own, provided you have access to machine tools.

|

Re: PTFE gases; Printing higher temperature plastics February 26, 2013 08:43PM |

Registered: 13 years ago Posts: 1,797 |

I am not sure it is a good idea to move away from 1 piece designed extruders that are all metal. Too many chances of leaks, and warping of materials. Perhaps if the parts were sealed with glass borosilicate and the metals were with the same rate of thermal expansion?

ptfe should not be used as a support structure, it becomes like jello at high temps, this is why designs that use the ptfe have peek block beneath them, so the peek can support the barrel and keep the ptfe in place.

Edited 1 time(s). Last edit at 02/26/2013 10:06PM by jamesdanielv.

ptfe should not be used as a support structure, it becomes like jello at high temps, this is why designs that use the ptfe have peek block beneath them, so the peek can support the barrel and keep the ptfe in place.

Edited 1 time(s). Last edit at 02/26/2013 10:06PM by jamesdanielv.

|

Re: PTFE gases; Printing higher temperature plastics February 26, 2013 09:01PM |

Registered: 13 years ago Posts: 301 |

|

Re: PTFE gases; Printing higher temperature plastics February 27, 2013 06:43AM |

Registered: 11 years ago Posts: 490 |

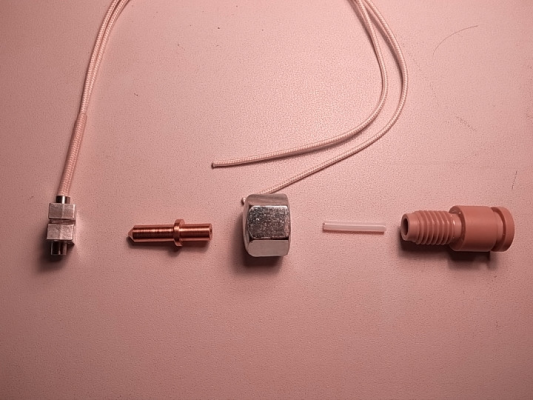

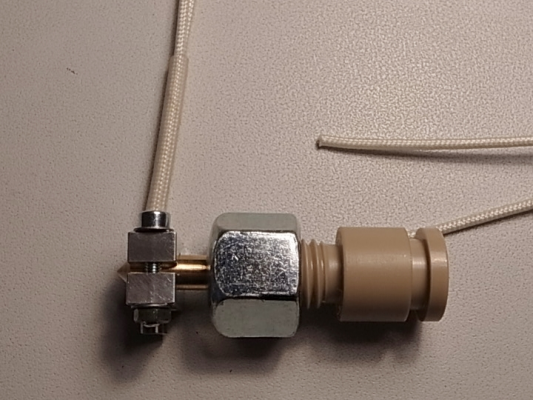

To explain things a little bit better (wrote the initial post when I was tired and could not concentrate), the hot end I will be using on my printer is the GRRF 1.75mm one. Below are some pictures of it disassembled and assembled.

As you can see, the interface between PTFE liner and nozzle piece is rather small, with the PTFE fitting into a recess in the PEEK part. The big nut holds the whole hot end together and acts as a heat sink, supporting the nozzle piece by holding the flange from below.

What I have to determine now is whether the nut is efficient enough in sinking the heat with the help of a fan.

I can think of the Arcol.hu v4 and the reprap-fab heaterbarrel v3 off the top of my head right now. Do you happen to know other designs?

Mechanical stability is not my main concern. Chemical stability is what is worrying me.

That sounds promising. Since the heat sinking nut of the GRRF hot end sits below the PEEK, I really should try actively cooling it and measure temperatures.

Edited 1 time(s). Last edit at 02/27/2013 06:44AM by uGen.

As you can see, the interface between PTFE liner and nozzle piece is rather small, with the PTFE fitting into a recess in the PEEK part. The big nut holds the whole hot end together and acts as a heat sink, supporting the nozzle piece by holding the flange from below.

What I have to determine now is whether the nut is efficient enough in sinking the heat with the help of a fan.

Quote

There are at least 2 hotends besides JPrusa's that are all-metal construction. And if you move away from the one piece design, it should not be extremely difficult to manufacture your own, provided you have access to machine tools.

I can think of the Arcol.hu v4 and the reprap-fab heaterbarrel v3 off the top of my head right now. Do you happen to know other designs?

Quote

ptfe should not be used as a support structure, it becomes like jello at high temps, this is why designs that use the ptfe have peek block beneath them, so the peek can support the barrel and keep the ptfe in place.

Mechanical stability is not my main concern. Chemical stability is what is worrying me.

Quote

If you are actively cooling the cold end then using something with low thermal conductivity like PEEK might make less sense. I use aluminum as my cold end and a 40mm video card fan is plenty powerful enough to keep it cool to the touch.

That sounds promising. Since the heat sinking nut of the GRRF hot end sits below the PEEK, I really should try actively cooling it and measure temperatures.

Edited 1 time(s). Last edit at 02/27/2013 06:44AM by uGen.

|

Re: PTFE gases; Printing higher temperature plastics February 27, 2013 02:46PM |

Registered: 13 years ago Posts: 301 |

|

Re: PTFE gases; Printing higher temperature plastics February 28, 2013 06:26AM |

Registered: 12 years ago Posts: 313 |

Yes. The brass nozzle attaches directly to the PEEK body, and it will soften the PEEK and fall off sooner or later at PC (270-300 C) temperatures. The massive nut will only mean that the heater needs more power to maintain the hot end at printing temperature. Forget trying to cool it, there's a way too efficient heat conductor from the nozzle to it (the brass nozzle tube).

Just get an all metal hot end if you want to go above PEEK's maximum operating temperature (which is 248 C, from several sources).

Just get an all metal hot end if you want to go above PEEK's maximum operating temperature (which is 248 C, from several sources).

|

Re: PTFE gases; Printing higher temperature plastics February 28, 2013 01:26PM |

Registered: 11 years ago Posts: 482 |

|

Re: PTFE gases; Printing higher temperature plastics February 28, 2013 05:49PM |

Registered: 11 years ago Posts: 490 |

Thanks guys, guess all-metal hot end it is, then! Do you happen to have any suggestions other than what I have found so far?

I am a little bit paranoid about the mechanical stability of the Arcol.hu v4.1, but other than that, it looks like I would be happy with it.

Another option I have found today is the E3D hot end, pretty cheap and apparently mechanically stronger than the Arcol one. Does anyone use this hot end? The ones who developed it posted rather extensively about their progress in the forums. Unfortunately, they did not explicitly state the nozzle diameter in the product page, but if they did not change it since their initial design, it should be .4mm.

The third hot end I currently consider is made by Stoffel15 and comes with two nozzles. The filament size is 1.75mm only, though and many interesting materials seem to be available in 3 or 4 mm from plastic welding shops.

I am a little bit paranoid about the mechanical stability of the Arcol.hu v4.1, but other than that, it looks like I would be happy with it.

Another option I have found today is the E3D hot end, pretty cheap and apparently mechanically stronger than the Arcol one. Does anyone use this hot end? The ones who developed it posted rather extensively about their progress in the forums. Unfortunately, they did not explicitly state the nozzle diameter in the product page, but if they did not change it since their initial design, it should be .4mm.

The third hot end I currently consider is made by Stoffel15 and comes with two nozzles. The filament size is 1.75mm only, though and many interesting materials seem to be available in 3 or 4 mm from plastic welding shops.

|

Re: PTFE gases; Printing higher temperature plastics March 01, 2013 06:32PM |

Registered: 11 years ago Posts: 205 |

|

Re: PTFE gases; Printing higher temperature plastics March 01, 2013 06:38PM |

Registered: 11 years ago Posts: 490 |

yes, you are absolutely right about the PTFE in the arcol.hu hot end. I can imagine just not using the PTFE tape on the heater block since it is only needed to keep the aluminium parts from being weld together. The liner in the heatsink part of the hot end should not pose any danger to one's health since this part of the hot end is supposed to be cool enough to be safe for PTFE.

|

Re: PTFE gases; Printing higher temperature plastics March 30, 2013 10:43AM |

Registered: 12 years ago Posts: 177 |

Hi uGen,

Just so you know, the nozzle orifice is still 0.4mm, and all the drawings for every little detail and dimension are up on our site under the downloads tab.

[e3d-online.com]

Cheers, Sanjay from e3d-online

Just so you know, the nozzle orifice is still 0.4mm, and all the drawings for every little detail and dimension are up on our site under the downloads tab.

[e3d-online.com]

Cheers, Sanjay from e3d-online

|

Re: PTFE gases; Printing higher temperature plastics March 30, 2013 02:07PM |

Registered: 11 years ago Posts: 490 |

Sorry, only registered users may post in this forum.