3D Metal Printer Projects?

Posted by Hazel1919

|

Re: 3D Metal Printer Projects? March 25, 2013 09:30AM |

Registered: 11 years ago Posts: 74 |

Hi everyone,

@ Madkite, I am also concerned about that. But after thinking about it, if we set up an organized effort, and just keep refining and adding to the information we already have, I am sure the spark will grow. I think that a 'community' will help kick start the effort. People will be much more inclined to get involved if they perceive an organized effort. At the very least, we can compile all our info in the wiki.

Our job is to make it 'less scary'. There are quite a few open source projects that, I imagine, looked pretty darn scary, but now they are leaders in their field, even compared to commercial endeavors.

As Simba has pointed out, this is the 'holy grail' of 3D Printing, and 3D printing is going to be big. That will be enough to get people highly interested in a community that is doing it.

As for a name, I was thinking of Metal Bot or 'MetaBot', M-Bot, perhaps that is too cheesy. We need something that is DIY.

Logo idea...

I have never started an open source project before, so any help you can provide in that regard will be much appreciated.

The website itself will have a forum, blogs and wiki though and I am working on that now.

Best,

Jethro Hazelhurst.

Edited 1 time(s). Last edit at 03/25/2013 09:34AM by Hazel1919.

@ Madkite, I am also concerned about that. But after thinking about it, if we set up an organized effort, and just keep refining and adding to the information we already have, I am sure the spark will grow. I think that a 'community' will help kick start the effort. People will be much more inclined to get involved if they perceive an organized effort. At the very least, we can compile all our info in the wiki.

Our job is to make it 'less scary'. There are quite a few open source projects that, I imagine, looked pretty darn scary, but now they are leaders in their field, even compared to commercial endeavors.

As Simba has pointed out, this is the 'holy grail' of 3D Printing, and 3D printing is going to be big. That will be enough to get people highly interested in a community that is doing it.

As for a name, I was thinking of Metal Bot or 'MetaBot', M-Bot, perhaps that is too cheesy. We need something that is DIY.

Logo idea...

I have never started an open source project before, so any help you can provide in that regard will be much appreciated.

The website itself will have a forum, blogs and wiki though and I am working on that now.

Best,

Jethro Hazelhurst.

Edited 1 time(s). Last edit at 03/25/2013 09:34AM by Hazel1919.

|

Re: 3D Metal Printer Projects? March 25, 2013 04:39PM |

Registered: 13 years ago Posts: 177 |

While cold spraying creates low malleability it also increases the tensile strength in tests when compared to other spray methods. Post heat treating can elevate some of this.

Also the porosity of the deposited material has much to do with the material you are looking at and the precise parameters used. Copper can be deposited with very low porosity's and very high purity too when inert gasses are used. Some metals will not work so well. Aluminium does work well and I can at least get it in pure form so that why I'm going with that currently.

I'm not looking to get the space age type components but useable strong enough metal components. Many manufacturing processes do not produce the highest strengths possible of a material but are good enough for many applications. Our current plastic methods are not as strong as injection moulding but we still find it useful.

It is absolutely not the right method if you want super high strength aerospace parts.

My aim is also to produce a mutimaterial printer and there are very few methods that allow you to selectively deposit lots of materials in one print or object. Plastics are much less well known about but if I can find any powdered plastics, easy enough to test. This is probably because there are already many satisfactory plastic coating systems. It happens to be of interest to me because of the unique application in a printer.

If it fails, then it fails, but I want to find out.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Also the porosity of the deposited material has much to do with the material you are looking at and the precise parameters used. Copper can be deposited with very low porosity's and very high purity too when inert gasses are used. Some metals will not work so well. Aluminium does work well and I can at least get it in pure form so that why I'm going with that currently.

I'm not looking to get the space age type components but useable strong enough metal components. Many manufacturing processes do not produce the highest strengths possible of a material but are good enough for many applications. Our current plastic methods are not as strong as injection moulding but we still find it useful.

It is absolutely not the right method if you want super high strength aerospace parts.

My aim is also to produce a mutimaterial printer and there are very few methods that allow you to selectively deposit lots of materials in one print or object. Plastics are much less well known about but if I can find any powdered plastics, easy enough to test. This is probably because there are already many satisfactory plastic coating systems. It happens to be of interest to me because of the unique application in a printer.

If it fails, then it fails, but I want to find out.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 25, 2013 11:10PM |

Registered: 11 years ago Posts: 5 |

Hi there,

I keep reading this thread and it looks very, very interesting to me. So far I have been one of the "hundreds of others, watching, waiting", but why not change that?! I would quite like to contribute to this one!

@Madkite - I can see the many hazards involved with the technology, as has been mentioned before. Suffocation from inert gas, metal powder, fumes, lasers, heat (risk of fire), etc... Maybe a weatherproof design that is specifically made to occupy a small area of your patio, balcony or garden can help with a couple of these problems? just thinking a small, weatherproof enclosure, pretty enough not to bother the rest of mankind?

@Madkite again - why not aim to make parts space-age-proof? I have seen and worked with parts made my DLMS in the past and they are space age and useful for even structural applications. I have worked with both parts from titanium and steel, what was surprising was that titanium had a MUCH better surface finish and did not need support in the bed, whereas the steel parts had a bit of an issue with proper support (needed lots of supporting structure). However, when I did tensile strength tests of the steel, both in direction of the layer and perpendicular to it, the results were slightly inconsistent, but about 90% of the samples achieved the material datasheet UTS and above. The surface finish on the titanium parts was astonishing, even a 8pt embossed text was well readable!

@simba - ceramics are nice, I agree. Not everything can be made out of them, however. If you look at properties like impact toughness or tensile strength, or failure modes (yield before break, for example), or further joining options (welding, brazing, tapping and bolting, etc), a world without metals is a difficult task. Just about anything that has to withstand a meaningful inside pressure (think tubes or pressure vessels) is not very practicable in ceramics. I think metal printing is definitely worth bothering with - after all there is a reason many parts of daily use are made from metal. Ceramic 3D printing has definitely a place in the RepRap world (in fact see paste extruder, many people are already doing it), but IMHO it is no replacement for metal 3D printing

@Hazel - like the logo!

cheers,

Rusty

I keep reading this thread and it looks very, very interesting to me. So far I have been one of the "hundreds of others, watching, waiting", but why not change that?! I would quite like to contribute to this one!

@Madkite - I can see the many hazards involved with the technology, as has been mentioned before. Suffocation from inert gas, metal powder, fumes, lasers, heat (risk of fire), etc... Maybe a weatherproof design that is specifically made to occupy a small area of your patio, balcony or garden can help with a couple of these problems? just thinking a small, weatherproof enclosure, pretty enough not to bother the rest of mankind?

@Madkite again - why not aim to make parts space-age-proof? I have seen and worked with parts made my DLMS in the past and they are space age and useful for even structural applications. I have worked with both parts from titanium and steel, what was surprising was that titanium had a MUCH better surface finish and did not need support in the bed, whereas the steel parts had a bit of an issue with proper support (needed lots of supporting structure). However, when I did tensile strength tests of the steel, both in direction of the layer and perpendicular to it, the results were slightly inconsistent, but about 90% of the samples achieved the material datasheet UTS and above. The surface finish on the titanium parts was astonishing, even a 8pt embossed text was well readable!

@simba - ceramics are nice, I agree. Not everything can be made out of them, however. If you look at properties like impact toughness or tensile strength, or failure modes (yield before break, for example), or further joining options (welding, brazing, tapping and bolting, etc), a world without metals is a difficult task. Just about anything that has to withstand a meaningful inside pressure (think tubes or pressure vessels) is not very practicable in ceramics. I think metal printing is definitely worth bothering with - after all there is a reason many parts of daily use are made from metal. Ceramic 3D printing has definitely a place in the RepRap world (in fact see paste extruder, many people are already doing it), but IMHO it is no replacement for metal 3D printing

@Hazel - like the logo!

cheers,

Rusty

|

Re: 3D Metal Printer Projects? March 26, 2013 03:25AM |

Admin Registered: 16 years ago Posts: 13,886 |

... I've recently bought two 'kitchen-knifes' with ceramic blades - the bigger one for 7€, the smalle one for 6€ ... so ceramic can replace metal by some means

An interesting part with sintering is 'soaking' the porous body in a fluid material - either molten metal or solidifying chemistry.

AFAIK the ceramic blades used in the knifes are a blend of ceramic and a polymer (so more elastic than normal ceramics), but don't know, how they are made ... maybe an intersting point to research and acquire for DIY too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

An interesting part with sintering is 'soaking' the porous body in a fluid material - either molten metal or solidifying chemistry.

AFAIK the ceramic blades used in the knifes are a blend of ceramic and a polymer (so more elastic than normal ceramics), but don't know, how they are made ... maybe an intersting point to research and acquire for DIY too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 26, 2013 03:26AM |

Registered: 13 years ago Posts: 177 |

As I said I want a multi material printer. Metal printing is a big part of that but not the only thing I'm considering. Think more printed circuit board as well as metal parts. Technically I don't really belong in this category but I have nowhere else to talk about it. The final strength may also be a bit better than I'm making out as tests to repair aluminium aircraft parts with sprayed aluminium were very suggestive. Flexible no, but weak not necessarily. The porosity is not necessarily bad either.

That would be ok in a nice sunny place. I live in the UK.

Make your Mendel twice as accurate.

[www.thingiverse.com]

That would be ok in a nice sunny place. I live in the UK.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 26, 2013 08:10AM |

Registered: 13 years ago Posts: 177 |

Got any good links about the ceramics VDX. I'm an ignoramus when it comes to them.

High temperature components are of grate interest to me. The best cost effective material I could manage was fire cement to insulate parts. Nicely made ceramic components would be awesome. Even just as heat shields.

Make your Mendel twice as accurate.

[www.thingiverse.com]

High temperature components are of grate interest to me. The best cost effective material I could manage was fire cement to insulate parts. Nicely made ceramic components would be awesome. Even just as heat shields.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 26, 2013 08:42AM |

Admin Registered: 16 years ago Posts: 13,886 |

... I've made some melting/sintering testst with mineralic black microspheres with 0.2mm diameters with powers below 10 Watts on 0.2mm focus size - they behaves like Obsidian (vulcano-glass) and melts to a dark-green glass body ... when overheated, the vapour recondenses to even smaller micro- and nanospheres with light green or complete clear body! Haven't done tests for bulk and mechanical stresses and brittleness - maybe later, until summer ...

have some more potentially interesting materials:

- different glass dust types, normally used for glass-soldering - some of them melts the first time below 400 Centigrades, then remelt above 600 centigrades. The glass dusts are white, so won't absorb much NIR, but perfect with CO2-lasers ... the melted glass is brown or black ...

- red/brown clay dust too, but melting is different for brands and colours, have to do some more tests ...

And a source of stone-powder for free (a local company making grave-olates) and some grey and black dust from them, but not tested yet ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

have some more potentially interesting materials:

- different glass dust types, normally used for glass-soldering - some of them melts the first time below 400 Centigrades, then remelt above 600 centigrades. The glass dusts are white, so won't absorb much NIR, but perfect with CO2-lasers ... the melted glass is brown or black ...

- red/brown clay dust too, but melting is different for brands and colours, have to do some more tests ...

And a source of stone-powder for free (a local company making grave-olates) and some grey and black dust from them, but not tested yet ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 26, 2013 08:55AM |

Registered: 13 years ago Posts: 177 |

VDX you should film this stuff.

Even badly shot wobbly vision videos can convey so much more information. Its also just great to actually see things.

I intend to try and film what I am doing especially when testing for my own records as well as for the interest of others. You can so easily forget something that later is important but just seemed nothing at the time.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Even badly shot wobbly vision videos can convey so much more information. Its also just great to actually see things.

I intend to try and film what I am doing especially when testing for my own records as well as for the interest of others. You can so easily forget something that later is important but just seemed nothing at the time.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 26, 2013 09:21AM |

Admin Registered: 16 years ago Posts: 13,886 |

... I'm actually refurbishing a chinese CO2-laserengraver - either manage to clear the original board and software (MoshiDraw left), or replace it completelly with an Isel-IF or Arduino board.

In the next day's i should get a comercial marking laser with a 100Watts NdYAG-laser with disfunctional pumping lamp ... could be perfect for replacing the 1064nm-NdYAG-Laser with a 1070nm-fiberlaser

So different types of lasers beside the diode-heads I'm hooking to the CNC-mill with 1Watt@445nm and 9Watt@975nm.

Have to find some time to setup the dust experiments again, then I'll make some videos too - bought a small fullHD-camcorder as dash-cam for my car last month, should be perfect here too

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

In the next day's i should get a comercial marking laser with a 100Watts NdYAG-laser with disfunctional pumping lamp ... could be perfect for replacing the 1064nm-NdYAG-Laser with a 1070nm-fiberlaser

So different types of lasers beside the diode-heads I'm hooking to the CNC-mill with 1Watt@445nm and 9Watt@975nm.

Have to find some time to setup the dust experiments again, then I'll make some videos too - bought a small fullHD-camcorder as dash-cam for my car last month, should be perfect here too

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 26, 2013 11:27AM |

Registered: 11 years ago Posts: 482 |

VDX, I love you work but I wish I could relate to it on an "I could do that too" sort of level. : / I'm a simple man, I just want to melt and stick things together. Lasers and vacuums and metal evaporators just remind me of the clean room I worked in, where everything was big, expensive, and broke down all the time. The beauty of reprap is its simplicity, surely I can find a way to do it with metal too.

BTW, I am convinced the metal is the first killer app of 3DP. This will prove it is not just a bubble of child like toys and fixer upper parts, but really something that is here to stay. Metal means heat sinks, electronics, bearings, heavy parts that feel valuable, jewlery, razor blades, cooking parts, etc.. the list never ends

BTW, I am convinced the metal is the first killer app of 3DP. This will prove it is not just a bubble of child like toys and fixer upper parts, but really something that is here to stay. Metal means heat sinks, electronics, bearings, heavy parts that feel valuable, jewlery, razor blades, cooking parts, etc.. the list never ends

|

Re: 3D Metal Printer Projects? March 27, 2013 03:56AM |

Registered: 13 years ago Posts: 177 |

The unfortunate thing with metals is as soon as you start looking in to it the problems to overcome make it complex.

Firstly, its advantage of needing high temperatures to melt means you need high energy concentrations to melt it too. Difficult, expensive and dangerous are normally the result of this requirement.

If you want to melt it then oxidisation is a problem. So you end up needing an inert atmosphere or vacuum. Probably one of the most safe parts of potential dangers.

To print it it needs to be added bit by bit so you need it in some kind of small unit to get high detail. That's dust. Another health danger though a good respirator and extraction solves that when handling the powder.

Then you need to combine all these elements. Even though my printer avoids the gas and lasers or e beams it is basically using rocket science! Theirs nothing that safe or simper about it either as each material has critical velocity's to bond and not just sand blast. But too fast and the particles plough through the material like microscopic meteorites and make deposits all porous. Its why temperature control of the propellant gas is so crucial. And a partial that can plough in to any strong metal will do untold damage to you!

I have not yet seen any viable simple solutions. Or one that does not become complex too.

The best thing may be to accept the necessary complexity's and achieve then as simply as possible.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Firstly, its advantage of needing high temperatures to melt means you need high energy concentrations to melt it too. Difficult, expensive and dangerous are normally the result of this requirement.

If you want to melt it then oxidisation is a problem. So you end up needing an inert atmosphere or vacuum. Probably one of the most safe parts of potential dangers.

To print it it needs to be added bit by bit so you need it in some kind of small unit to get high detail. That's dust. Another health danger though a good respirator and extraction solves that when handling the powder.

Then you need to combine all these elements. Even though my printer avoids the gas and lasers or e beams it is basically using rocket science! Theirs nothing that safe or simper about it either as each material has critical velocity's to bond and not just sand blast. But too fast and the particles plough through the material like microscopic meteorites and make deposits all porous. Its why temperature control of the propellant gas is so crucial. And a partial that can plough in to any strong metal will do untold damage to you!

I have not yet seen any viable simple solutions. Or one that does not become complex too.

The best thing may be to accept the necessary complexity's and achieve then as simply as possible.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 27, 2013 05:02AM |

Admin Registered: 16 years ago Posts: 13,886 |

... look at one of this cheapish chinese CO2-laserengravers, actually sold everywhere for below 1k€ - they use a CO2-laser with 40 to 60 Watts of power, what's enough to start with powder-sintering - stronger units are bigger and expensiver, but built similar. Cut a hole in the bottom and insert a powder bin if free space below the working plane isn't enough ...

When applying the inert gas through a nozzle flooding the working range and 30mm around it's enough 'shielding', so the hot spot didn't see oxygene until cooling down to ambient temperature. With 'spot-working' you haven't to flood the complete working range as in the comercial devices

For the 'normal' toxic fumes it's enough to filter them with activated charcoal filters -- but with inert gas the exhausting of the engraver (with or without filter) should go through the next window -- then you're safe in respect to breathing air ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

When applying the inert gas through a nozzle flooding the working range and 30mm around it's enough 'shielding', so the hot spot didn't see oxygene until cooling down to ambient temperature. With 'spot-working' you haven't to flood the complete working range as in the comercial devices

For the 'normal' toxic fumes it's enough to filter them with activated charcoal filters -- but with inert gas the exhausting of the engraver (with or without filter) should go through the next window -- then you're safe in respect to breathing air ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 27, 2013 06:57AM |

Registered: 11 years ago Posts: 74 |

|

Re: 3D Metal Printer Projects? March 27, 2013 09:10AM |

Registered: 13 years ago Posts: 177 |

By brother has one of those laser engravers/cutters.

Bit fiddly to set up but works ok. Would need to work out the electronics and programming.

I would still go with the full chamber of inert gas. Otherwise you may end up blowing the powder around too and wasting lots of gas on long prints. Its almost made for it already as you only have to keep a tiny constant feed to stop air coming in. Few seals and rubber bits should do it good enough. Doesn't have to be hermetically sealed to keep the air out just a small internal pressure.

The focus is normally set by moving the entire bed up and down so the powder bed top bit needs to be adjustable. Turning the power down would defiantly do some plastic easy. Maybe aluminium on high power? Who knows. Needs water cooling too but the come with all the pumps and such.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Bit fiddly to set up but works ok. Would need to work out the electronics and programming.

I would still go with the full chamber of inert gas. Otherwise you may end up blowing the powder around too and wasting lots of gas on long prints. Its almost made for it already as you only have to keep a tiny constant feed to stop air coming in. Few seals and rubber bits should do it good enough. Doesn't have to be hermetically sealed to keep the air out just a small internal pressure.

The focus is normally set by moving the entire bed up and down so the powder bed top bit needs to be adjustable. Turning the power down would defiantly do some plastic easy. Maybe aluminium on high power? Who knows. Needs water cooling too but the come with all the pumps and such.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 27, 2013 09:46AM |

Admin Registered: 16 years ago Posts: 13,886 |

... when dealing with inert gas for laser-fusing metal wires and Kovar-fittings I ejected a soft stream of Argon over the spot area, that wasn't senseable with the hand in the stream, so wouldn't blow away powder ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 27, 2013 03:32PM |

Registered: 11 years ago Posts: 137 |

Has anyone tried printing with a ferrous metal powder infused filament and a magnetized print bed?

With the proper set up you could print upside down or even in space.

Or magnetic filament. Print your own fridge magnets with the magnet already integrated. I can also think of a few experiments I could do with magnetic filament.

Just thought of a good one. Printed motor housing with magnets already integrated, just insert copper bits.

Edited 1 time(s). Last edit at 03/27/2013 03:35PM by hendo420.

With the proper set up you could print upside down or even in space.

Or magnetic filament. Print your own fridge magnets with the magnet already integrated. I can also think of a few experiments I could do with magnetic filament.

Just thought of a good one. Printed motor housing with magnets already integrated, just insert copper bits.

Edited 1 time(s). Last edit at 03/27/2013 03:35PM by hendo420.

|

Re: 3D Metal Printer Projects? March 27, 2013 03:43PM |

Registered: 11 years ago Posts: 482 |

hendo420 Wrote:

-------------------------------------------------------

> Has anyone tried printing with a ferrous metal

> powder infused filament and a magnetized print

> bed?

>

> With the proper set up you could print upside down

> or even in space.

>

>

> Or magnetic filament. Print your own fridge

> magnets with the magnet already integrated. I can

> also think of a few experiments I could do with

> magnetic filament.

>

> Just thought of a good one. Printed motor housing

> with magnets already integrated, just insert

> copper bits.

We tried this. However, no manufacturer is willing to make it for us. The magnetic particles risk damaging their molder, and risk clogging out machines just as badly. The metal basically scrapes the insides of your machine.

Look to inventibles for a cool "squishy" magnet.

-------------------------------------------------------

> Has anyone tried printing with a ferrous metal

> powder infused filament and a magnetized print

> bed?

>

> With the proper set up you could print upside down

> or even in space.

>

>

> Or magnetic filament. Print your own fridge

> magnets with the magnet already integrated. I can

> also think of a few experiments I could do with

> magnetic filament.

>

> Just thought of a good one. Printed motor housing

> with magnets already integrated, just insert

> copper bits.

We tried this. However, no manufacturer is willing to make it for us. The magnetic particles risk damaging their molder, and risk clogging out machines just as badly. The metal basically scrapes the insides of your machine.

Look to inventibles for a cool "squishy" magnet.

|

Re: 3D Metal Printer Projects? March 27, 2013 05:03PM |

Registered: 13 years ago Posts: 177 |

Been trying some CFD tests to see what speeds I can get out of a basic convergent divergent nozzle over temperature and if a defector to stop component overheating is effective and does not alter the speed.

Not the best modelling but is good enough to see what temperature to air velocity I can get.

Tested this one at 800c.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Not the best modelling but is good enough to see what temperature to air velocity I can get.

Tested this one at 800c.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 27, 2013 10:26PM |

Registered: 12 years ago Posts: 80 |

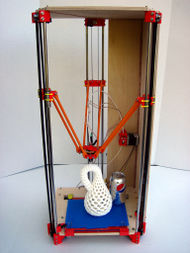

Has anyone considered the rostock delta style of gantry?

If used, the end effector could be not only for the laser. It could also deposit and spread the powder layer. It could even have a "rake" on the bottom for such, correct?

I just wanted to throw the idea out there, everyone seems to have the Cartesian style gantry in mind.

If used, the end effector could be not only for the laser. It could also deposit and spread the powder layer. It could even have a "rake" on the bottom for such, correct?

I just wanted to throw the idea out there, everyone seems to have the Cartesian style gantry in mind.

|

Re: 3D Metal Printer Projects? March 28, 2013 03:32AM |

Admin Registered: 16 years ago Posts: 13,886 |

... I've then designed my Tripod as carrier for laser, pastedispenser and micromachining with small and ultra-lightweight tools.

the Rostock is more rigid (or can be made), so can carry heavier loads - it can be used for any positioning task, that won't overpower or bend the kinematics.

With a feeder tube and pressurized air for powder support and a laserhead it could be used not only for SLS, but for DLM too ... with a tilt+pan-table on the base maybe even better than common gantry or robot-arm types

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

the Rostock is more rigid (or can be made), so can carry heavier loads - it can be used for any positioning task, that won't overpower or bend the kinematics.

With a feeder tube and pressurized air for powder support and a laserhead it could be used not only for SLS, but for DLM too ... with a tilt+pan-table on the base maybe even better than common gantry or robot-arm types

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 28, 2013 06:10AM |

Registered: 13 years ago Posts: 177 |

And if the tooling is too heavy for it then why not make it move the build platform and fix the tooling.

If my project fails there is always using the collimator technology to fire dust in a narrow stream at low speed in to a laser melt pool.

Make your Mendel twice as accurate.

[www.thingiverse.com]

If my project fails there is always using the collimator technology to fire dust in a narrow stream at low speed in to a laser melt pool.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 28, 2013 07:23AM |

Admin Registered: 16 years ago Posts: 13,886 |

Madkite Wrote:

-------------------------------------------------------

> If my project fails there is always using the

> collimator technology to fire dust in a narrow

> stream at low speed in to a laser melt pool.

... this is the used methode in DLM (or CLAD)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

-------------------------------------------------------

> If my project fails there is always using the

> collimator technology to fire dust in a narrow

> stream at low speed in to a laser melt pool.

... this is the used methode in DLM (or CLAD)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 28, 2013 08:12AM |

Registered: 13 years ago Posts: 177 |

I have seen it but all the ones I have seen are quite large on the aria being added. So the detail as very poor.

The aim would be to make it a tiny spot so you could make small parts of reasonable detail. It is another possible approach in making a multiple material printer. But inert gas shielding would be essential with this approach where it is not with my current approach. And different lasers may be required for different materials. Only the velocity need to alter in my current method.

Make your Mendel twice as accurate.

[www.thingiverse.com]

The aim would be to make it a tiny spot so you could make small parts of reasonable detail. It is another possible approach in making a multiple material printer. But inert gas shielding would be essential with this approach where it is not with my current approach. And different lasers may be required for different materials. Only the velocity need to alter in my current method.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? March 28, 2013 08:45AM |

Admin Registered: 16 years ago Posts: 13,886 |

... one major point in comercial solutions is the "time is money"-sermon ... so most used lasers have powers of hundreds of Watts to some ten Kilowatts, so they can melt dust 'seriously' and even with high-speed scanning.

The focus diameters with lasers of this powers are 0.5mm best ... and with pre-melting the surface for a good 'melting pool' you'll get smallest details of 1mm, mostly bigger ...

I was testing with NdYAG-lasers in the CW-ranges of 30Watts (pulsing up to 2kW) with 0.07 to 0.2mm spot size and with a dsik-laser with 3Watt CW, pulsing with 500mJ and best spot size of 0.03mm for fusing thin wires to surfaces ... the thinenst wires I was working then were 10 microns with platin and 25 microns with steel, nickel and gold.

Actually I have an even better IR-fiberlaser at home with 50Watts CW and a spot of 20 microns normal and maybe 5 microns with expanded beam ... so seems to be best time to do some tests for high-accuracy/fine-detail limitations

With all the other laser types i have a broad basis of wavelengths and powers:

- @337nm, 400kW pulsing (200ps/30Hz) -- N2-TAE-laser from DARPA-development

- @405nm, 300mW -- BluRay-diodes

- @445nm, 1Watt -- 'Casio-DLP-beamer'-diodes

- @808nm, 1Watt (0.05mm fiber) / 25Watt (0.8mm fiber) -- IR-diodes

- @975nm, 5 / 9 / 25Watt (0.1mm fiber) -- IR-diodes

- @1070nm, 50W -- fiberlaser

- @10600nm, 40W -- chinese laserengraver

... and should receive tomorrow a NdYAG-marking laser with 100Watts @1064nm, but not running pumping system .. either I'll get it working or replace the NdYAG with a pulsing fiberlaser ...

So I'm planning to get some free time for restarting the melting/fusing development with this 'low-power'-lasers with higher accuracies than in common SLS setups

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The focus diameters with lasers of this powers are 0.5mm best ... and with pre-melting the surface for a good 'melting pool' you'll get smallest details of 1mm, mostly bigger ...

I was testing with NdYAG-lasers in the CW-ranges of 30Watts (pulsing up to 2kW) with 0.07 to 0.2mm spot size and with a dsik-laser with 3Watt CW, pulsing with 500mJ and best spot size of 0.03mm for fusing thin wires to surfaces ... the thinenst wires I was working then were 10 microns with platin and 25 microns with steel, nickel and gold.

Actually I have an even better IR-fiberlaser at home with 50Watts CW and a spot of 20 microns normal and maybe 5 microns with expanded beam ... so seems to be best time to do some tests for high-accuracy/fine-detail limitations

With all the other laser types i have a broad basis of wavelengths and powers:

- @337nm, 400kW pulsing (200ps/30Hz) -- N2-TAE-laser from DARPA-development

- @405nm, 300mW -- BluRay-diodes

- @445nm, 1Watt -- 'Casio-DLP-beamer'-diodes

- @808nm, 1Watt (0.05mm fiber) / 25Watt (0.8mm fiber) -- IR-diodes

- @975nm, 5 / 9 / 25Watt (0.1mm fiber) -- IR-diodes

- @1070nm, 50W -- fiberlaser

- @10600nm, 40W -- chinese laserengraver

... and should receive tomorrow a NdYAG-marking laser with 100Watts @1064nm, but not running pumping system .. either I'll get it working or replace the NdYAG with a pulsing fiberlaser ...

So I'm planning to get some free time for restarting the melting/fusing development with this 'low-power'-lasers with higher accuracies than in common SLS setups

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 29, 2013 06:09PM |

Admin Registered: 16 years ago Posts: 13,886 |

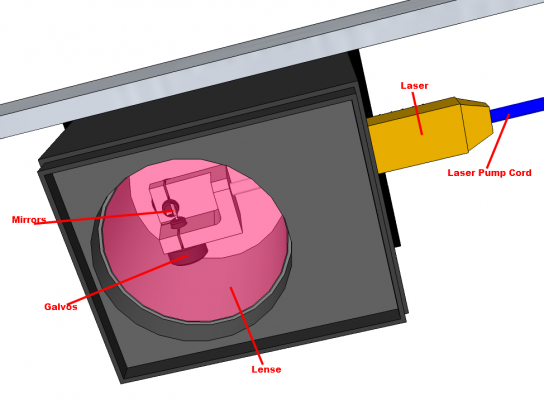

... got the old NdYAG marking laser -- images of PS+controller, laser and XY-galvo-head attached ...

It's in a worser 'mood' than hoped, so I have to rewire the cables and test, if the electronics and pump-lamp will work.

If not, then I'll try to get only the XY-scanner working with my fiber-laser ... it has 1070nm @50Watts, so similar enough to the 1064nm-NdYAG @100Watts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

It's in a worser 'mood' than hoped, so I have to rewire the cables and test, if the electronics and pump-lamp will work.

If not, then I'll try to get only the XY-scanner working with my fiber-laser ... it has 1070nm @50Watts, so similar enough to the 1064nm-NdYAG @100Watts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? March 31, 2013 09:55AM |

Registered: 13 years ago Posts: 177 |

|

Re: 3D Metal Printer Projects? March 31, 2013 04:40PM |

Registered: 11 years ago Posts: 74 |

Hi everyone!

Update:

Please be patient with me, I am trying to set up Mediawiki as well as the phpBB forum and information site. I am brand new to all of these procedures and it could take a while.

When all the donkey work has been completed we will hopefully have a really integrated and neat place to work, where it is possible to document everything in a constructive way .

There will be clear space for all of the projects in this thread, I don't want to limit the community to just Metals, but anything that will paradigm shift 3D Printing (plastics, ceramics, multimaterials etc...). So any new novel methods are encouraged.

I am trying to put up a content skeleton at the moment so that when our user count increases we can grow nicely. Therefore If you can think of any subjects, articles, tag lines , headers or ANY IDEAS you want to see in the site, just say so! I would be extremely grateful to you.

I like the name 'MetalBot'. If you don't, please tell me.

Here is the preliminary logo, tell me if you like it or not also.

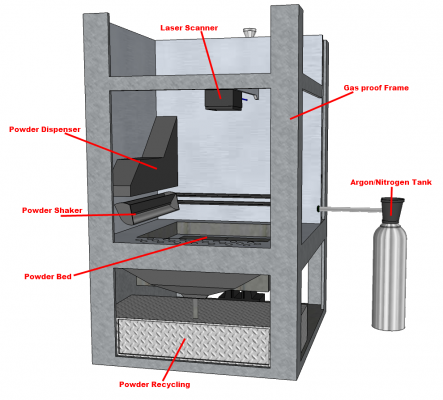

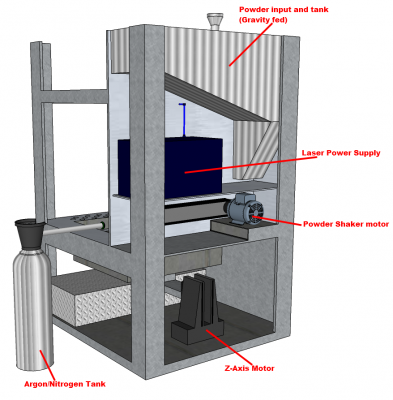

@ Madkite, your suggestions were absolutely ace, I went ahead and changed my google sketchup diagram to reflect the better design...

Here is a close up of the laser scanner

And the back of the unit...

The main changes are to do with the powder distribution, using a laser scanner instead of a CNC and the external gas container.

As you can see, the powder dispenser is gravity fed, we just need to connect some servos to open and close valves at the right time. The powder dispenser drops the powder into the powder shaker, which then goes on to put down the layer.

I encourage you to download google sketchup here: Sketchup

This way you can take a tour around the printer. Here is the link to the sketchup files: Sketchup Metalbot

I really think that one of the most important areas of work will be to document the properties of different materials in powder form. This means documenting material, particle sizes, wavelength of laser used, thickness of powder layer... these are just some of the variables we need to graph.

EOS say they are doing tests on 5um powder granules!!

I have been researching the limitations of 3D Printing and, really, the only thing keeping this technology as a prototyping tech is material strength (perhaps also build time but this can be solved with parallel printing once we have affordable machines).

For some things, such as tubes and sheets, the traditional method is the only way to go from an economic point of view. Using metal as a 3D Printing material, and making that accessible however, will propel 3D Printing into a whole new, very big, very interesting area.

It would be good to be there from the beginning!

Jethro.

Update:

Please be patient with me, I am trying to set up Mediawiki as well as the phpBB forum and information site. I am brand new to all of these procedures and it could take a while.

When all the donkey work has been completed we will hopefully have a really integrated and neat place to work, where it is possible to document everything in a constructive way .

There will be clear space for all of the projects in this thread, I don't want to limit the community to just Metals, but anything that will paradigm shift 3D Printing (plastics, ceramics, multimaterials etc...). So any new novel methods are encouraged.

I am trying to put up a content skeleton at the moment so that when our user count increases we can grow nicely. Therefore If you can think of any subjects, articles, tag lines , headers or ANY IDEAS you want to see in the site, just say so! I would be extremely grateful to you.

I like the name 'MetalBot'. If you don't, please tell me.

Here is the preliminary logo, tell me if you like it or not also.

@ Madkite, your suggestions were absolutely ace, I went ahead and changed my google sketchup diagram to reflect the better design...

Here is a close up of the laser scanner

And the back of the unit...

The main changes are to do with the powder distribution, using a laser scanner instead of a CNC and the external gas container.

As you can see, the powder dispenser is gravity fed, we just need to connect some servos to open and close valves at the right time. The powder dispenser drops the powder into the powder shaker, which then goes on to put down the layer.

I encourage you to download google sketchup here: Sketchup

This way you can take a tour around the printer. Here is the link to the sketchup files: Sketchup Metalbot

I really think that one of the most important areas of work will be to document the properties of different materials in powder form. This means documenting material, particle sizes, wavelength of laser used, thickness of powder layer... these are just some of the variables we need to graph.

- How does the thickness of the powder granules in um affect the strength of the sintered material?

- How long does the laser beam have to stay over one spot to fully sinter the area for a given material/layer thickness/granule size/power/wavelength?

- What is the minimum we need to achieve 99 percent density?

EOS say they are doing tests on 5um powder granules!!

I have been researching the limitations of 3D Printing and, really, the only thing keeping this technology as a prototyping tech is material strength (perhaps also build time but this can be solved with parallel printing once we have affordable machines).

For some things, such as tubes and sheets, the traditional method is the only way to go from an economic point of view. Using metal as a 3D Printing material, and making that accessible however, will propel 3D Printing into a whole new, very big, very interesting area.

It would be good to be there from the beginning!

Jethro.

|

Re: 3D Metal Printer Projects? April 01, 2013 04:13AM |

Registered: 13 years ago Posts: 177 |

That's looking very nice. You could make a card or thin aluminium mock of the dispenser unit and test it with some powdered material to see if it will work like you hope. Perhaps flour or something. These things can sometimes be a little tricky to get just right.

One method to really speed up printing (Tough this would be potentially super expensive.) Is to have multiple lasers doing different items or bits of items. Two would have the layer draw time of any part cut in half.

Make your Mendel twice as accurate.

[www.thingiverse.com]

One method to really speed up printing (Tough this would be potentially super expensive.) Is to have multiple lasers doing different items or bits of items. Two would have the layer draw time of any part cut in half.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 01, 2013 12:27PM |

Admin Registered: 13 years ago Posts: 730 |

Hi Hazel1919,

It is great to see so much enthusiasm for this project. Two questions:

1) Is there any reason not to use a double-bin powder handler, like this one? It seems that if you use a "tried and true" powder handler you will have more time to spend on the more challenging parts of the project. As they say, "Don't fix it if it isn't broken".

2) You say you are building a new forum and new wiki. Is there anything wrong with the reprap forum we are posting in right now? It has an entire subforum dedicated to powder printing and SLS, not to mention an entire subforum for metalicarap.

The reprap wiki works and is full of relevant projects and background research (for example see the MetalicaRap wiki page and Metal Deposition Print Head). Reprap.org is frequented by a large group of like-minded people. Is the reprap forum/wiki so broken that you need to create a new community somewhere else?

Please note: I am not saying that you should donate your work, or relinquish control of it, for free to the reprap community. There is nothing wrong with keeping and controlling your work on your own site (and indeed many reprappers release their work on their own personal blogs, github, etc). What I am questioning is the need to build a separate community.

It is common for people to post technical work to their blog, and then come here to discuss it in the existing forums and document it on the existing wiki...

Yours respectfully,

Matt Moses

It is great to see so much enthusiasm for this project. Two questions:

1) Is there any reason not to use a double-bin powder handler, like this one? It seems that if you use a "tried and true" powder handler you will have more time to spend on the more challenging parts of the project. As they say, "Don't fix it if it isn't broken".

2) You say you are building a new forum and new wiki. Is there anything wrong with the reprap forum we are posting in right now? It has an entire subforum dedicated to powder printing and SLS, not to mention an entire subforum for metalicarap.

The reprap wiki works and is full of relevant projects and background research (for example see the MetalicaRap wiki page and Metal Deposition Print Head). Reprap.org is frequented by a large group of like-minded people. Is the reprap forum/wiki so broken that you need to create a new community somewhere else?

Please note: I am not saying that you should donate your work, or relinquish control of it, for free to the reprap community. There is nothing wrong with keeping and controlling your work on your own site (and indeed many reprappers release their work on their own personal blogs, github, etc). What I am questioning is the need to build a separate community.

It is common for people to post technical work to their blog, and then come here to discuss it in the existing forums and document it on the existing wiki...

Yours respectfully,

Matt Moses

|

Re: 3D Metal Printer Projects? April 02, 2013 05:09AM |

Registered: 11 years ago Posts: 74 |

Hi guys...

@madkite: That would be ideal, but very expensive, I think for now anyway, we should focus on just getting a proof of concept working. I do remember watching a video interviewing one of these companies, and the representative said that, while there was research going into multiple beams, it was more practical to just have multiple machines going. I am not sure about the technical reasons why though.

@Matt, first off, absolutely fantastic suggestion. I think that the powder system is over complicated as is. A simple roller is really as simple as it gets! The only problem is that the width/depth of the machine will have to be at least doubled... but as long as build complexity goes down, the number of things that can go wrong also reduces.

With regard to your second point. I have been thinking about this carefully. I understand that, with open source projects, it is undesirable to 'splinter' the community. That is the last thing that I want to do.

From what I can see in the reprap community, the vast majority of contributors are focused on extruders and plastics. While there is a 'metallicarap' forum, it is very buried as a sub forum. As for the wiki pages, they are relatively difficult to find and then are not as clearly laid out as they could be..

The name 'Metallicarap' is also ill chosen, if you try and search for it, you only get rap music, or metal music as a result. Bad choice.

It is my conviction that a project like this, if it is to be successful, needs a paradigm shift in thinking. This is hard to do when the key information is buried in a site that is focused on really different methods. Lasers, argon, etc are not what the reprap is about at the moment.

Therefore a community that is focused on that. A network where the goals are very clearly laid out and not buried within another project, is required for this 'paradigm shift'. It is to do with public perception, you may or may not agree...

----

I am working on forum content at the moment, please let me know what forums and subforum categories you want to see.

Many thanks!

Jethro.

@madkite: That would be ideal, but very expensive, I think for now anyway, we should focus on just getting a proof of concept working. I do remember watching a video interviewing one of these companies, and the representative said that, while there was research going into multiple beams, it was more practical to just have multiple machines going. I am not sure about the technical reasons why though.

@Matt, first off, absolutely fantastic suggestion. I think that the powder system is over complicated as is. A simple roller is really as simple as it gets! The only problem is that the width/depth of the machine will have to be at least doubled... but as long as build complexity goes down, the number of things that can go wrong also reduces.

With regard to your second point. I have been thinking about this carefully. I understand that, with open source projects, it is undesirable to 'splinter' the community. That is the last thing that I want to do.

From what I can see in the reprap community, the vast majority of contributors are focused on extruders and plastics. While there is a 'metallicarap' forum, it is very buried as a sub forum. As for the wiki pages, they are relatively difficult to find and then are not as clearly laid out as they could be..

The name 'Metallicarap' is also ill chosen, if you try and search for it, you only get rap music, or metal music as a result. Bad choice.

It is my conviction that a project like this, if it is to be successful, needs a paradigm shift in thinking. This is hard to do when the key information is buried in a site that is focused on really different methods. Lasers, argon, etc are not what the reprap is about at the moment.

Therefore a community that is focused on that. A network where the goals are very clearly laid out and not buried within another project, is required for this 'paradigm shift'. It is to do with public perception, you may or may not agree...

----

I am working on forum content at the moment, please let me know what forums and subforum categories you want to see.

Many thanks!

Jethro.

Sorry, only registered users may post in this forum.