3D Metal Printer Projects?

Posted by Hazel1919

|

Re: 3D Metal Printer Projects? April 04, 2013 11:02AM |

Registered: 11 years ago Posts: 74 |

I can see the direction we should head, for the Laser Sintering machine at least (talking short term)... we need a laser engraver. It is as simple as that. All of the galvos and programming have been engineered alreadyt. We just need to interface the engraving software with a slicer. Bring the 2D to 3D.

These machines already cost $5k-20k brand new from alibaba (50W/75W Yag laser engraver). We only need the laser, laser power supply and scanner plus software.

Here is a fine example... YAG Engraver Alibaba

All we need to do is put the engraving part into an inert gas frame, sort out the powder roller and Z-Axis and Voila! We have a nice little (al be it expensive) hacked 3D Metal printer. I think Viktor is closest to this, in that he already has the equipment.

Of course, it's not as easy as that! But it can definitely be done. From a cost perspective, the hardware for the powder shaker, gas frame, Z-Axis etc will only be a fraction of the cost of a laser scanner, so, in theory only, a Metalbot would only cost slightly more than a Metal Engraver!

One of the interesting things I spotted while parusing the item descriptions is the engraving depth of the particular machine... 'Carving depth ≤0.3mm'. If we are printing in 100 micron layers, then will this particular machine have enough power to fuse the top layer to the bottom layer (since it can 'carve' to a depth of 300 microns)?

----

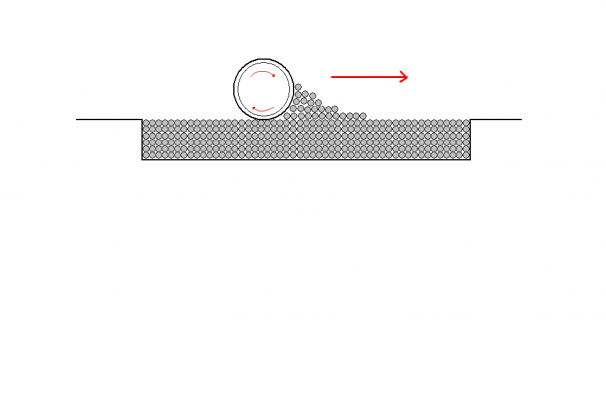

I have been thinking about the powder distribution system. We want something that is bomb proof, that does not go out of tune and that can't go wrong. Matt's suggestion is exactly where we need to go. A simple roller is perfect.

The roller method is really fool proof! There is no need to drop a precision amount of powder, no complex mechanisms! If you drop too much powder, the excess just falls into the recycle box at the end.

This Reprap project here Reprap Wax Sintering is very interesting in that the project developer has succeeded to make very even layers with what looks like a very rough DIY setup. With that in mind, Imagine what we could do with precision metal parts! Really I think this is quite doable.

One question that I am not too sure about is this: How do you move the powder bed down such a fine amount? What motor/software do you use for such precise increments?

I have tested a powder distributer with flour, and the setup that provided the best results was that of a roller rotating slightly forward.

----

In other news: I have the website, wiki and forum up and running. Right now I am working on content and pretty soon will go live. After that I will provide the reprap forum access. Once the posting activity goes up I will advertise the project on a few other forums that will be very interested.

Many thanks.

Jethro.

These machines already cost $5k-20k brand new from alibaba (50W/75W Yag laser engraver). We only need the laser, laser power supply and scanner plus software.

Here is a fine example... YAG Engraver Alibaba

All we need to do is put the engraving part into an inert gas frame, sort out the powder roller and Z-Axis and Voila! We have a nice little (al be it expensive) hacked 3D Metal printer. I think Viktor is closest to this, in that he already has the equipment.

Of course, it's not as easy as that! But it can definitely be done. From a cost perspective, the hardware for the powder shaker, gas frame, Z-Axis etc will only be a fraction of the cost of a laser scanner, so, in theory only, a Metalbot would only cost slightly more than a Metal Engraver!

One of the interesting things I spotted while parusing the item descriptions is the engraving depth of the particular machine... 'Carving depth ≤0.3mm'. If we are printing in 100 micron layers, then will this particular machine have enough power to fuse the top layer to the bottom layer (since it can 'carve' to a depth of 300 microns)?

----

I have been thinking about the powder distribution system. We want something that is bomb proof, that does not go out of tune and that can't go wrong. Matt's suggestion is exactly where we need to go. A simple roller is perfect.

The roller method is really fool proof! There is no need to drop a precision amount of powder, no complex mechanisms! If you drop too much powder, the excess just falls into the recycle box at the end.

This Reprap project here Reprap Wax Sintering is very interesting in that the project developer has succeeded to make very even layers with what looks like a very rough DIY setup. With that in mind, Imagine what we could do with precision metal parts! Really I think this is quite doable.

One question that I am not too sure about is this: How do you move the powder bed down such a fine amount? What motor/software do you use for such precise increments?

I have tested a powder distributer with flour, and the setup that provided the best results was that of a roller rotating slightly forward.

----

In other news: I have the website, wiki and forum up and running. Right now I am working on content and pretty soon will go live. After that I will provide the reprap forum access. Once the posting activity goes up I will advertise the project on a few other forums that will be very interested.

Many thanks.

Jethro.

|

Re: 3D Metal Printer Projects? April 04, 2013 01:45PM |

Registered: 13 years ago Posts: 177 |

The precise z movement is extremely easy. All you need is a screw.

As the speed is almost irrelevant it can just be a screw system like on the current reprap Z axis. Drive it with a stepper motor and just work out the steps. It will be more then accurate enough and if you want more accuracy then just gear down the drive to it or use a finer screw.

The accuracy of the screw is the most important factor. But even cheep studding is probably good enough.

Make your Mendel twice as accurate.

[www.thingiverse.com]

As the speed is almost irrelevant it can just be a screw system like on the current reprap Z axis. Drive it with a stepper motor and just work out the steps. It will be more then accurate enough and if you want more accuracy then just gear down the drive to it or use a finer screw.

The accuracy of the screw is the most important factor. But even cheep studding is probably good enough.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 04, 2013 04:50PM |

Admin Registered: 16 years ago Posts: 13,884 |

... I have all the needed hardware bits but the Argon support - think to restart with the SLS theme in May/June ... have actually to negotiate some serious aspects, related to this and further developments ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? April 04, 2013 06:06PM |

Admin Registered: 13 years ago Posts: 730 |

Hazel1919, you may want to take a look at Peter's Boot-strappable Open Laser Cutter if you are not already aware of it. It uses a high power (some tens of watts, I think) CO2 laser.

|

Re: 3D Metal Printer Projects? April 05, 2013 02:39AM |

Registered: 11 years ago Posts: 7 |

Hi everyone.

I am new to this forum, so forgive my ignorance.

I think this is a great idea, and thought I could add some thoughts.

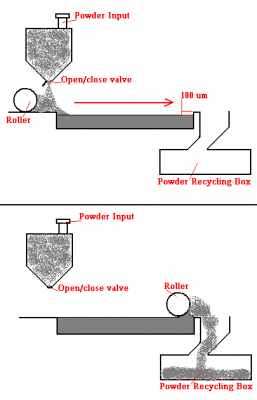

There is a manufacturing process known as selective inkjet binding. And it may be worth looking into for the purposes your talking about without having to use lasers and air-tight chambers. Acording to the resource I am looking at it is very versitile and can print in a variety of materials "virtually any material that can be obtained as powder"

A roller puts down a layer of the powdered material, but then instead of being laser sintered, an inkjet head selectively injects a binder material such as Colloidal Silica and repeates this layer by layer. For metal powders, this process is completed by sintering in a furnace.

The problems I see are that I have no idea what the cost or ease of getting the binder material is, nor am I familiar with what temperatures home funaces/ kilns can achieve.

Sintering temps for some metals are:

Aluminum alloys 590-620C (the lowest temps i have listed)

tungsten 2200-2300C (the highest)

with brass, copper, steel, etc. in between those

I know it is a bit off topic, but i thought this information might be helpful

I have attached a highly detailed, engineering quality doodle-that-a-ten-year-old-might-make for a little added clarity.

edit:

I also wanted to say that the roller idea for distrubuting the powder is very wise, and is commonly used in these processes.I should also say that I am not an expert by any means. All the above information came from "Degarmos materials and manufacturing processes" and the class that went with it

Edited 1 time(s). Last edit at 04/05/2013 02:49AM by nickw.

I am new to this forum, so forgive my ignorance.

I think this is a great idea, and thought I could add some thoughts.

There is a manufacturing process known as selective inkjet binding. And it may be worth looking into for the purposes your talking about without having to use lasers and air-tight chambers. Acording to the resource I am looking at it is very versitile and can print in a variety of materials "virtually any material that can be obtained as powder"

A roller puts down a layer of the powdered material, but then instead of being laser sintered, an inkjet head selectively injects a binder material such as Colloidal Silica and repeates this layer by layer. For metal powders, this process is completed by sintering in a furnace.

The problems I see are that I have no idea what the cost or ease of getting the binder material is, nor am I familiar with what temperatures home funaces/ kilns can achieve.

Sintering temps for some metals are:

Aluminum alloys 590-620C (the lowest temps i have listed)

tungsten 2200-2300C (the highest)

with brass, copper, steel, etc. in between those

I know it is a bit off topic, but i thought this information might be helpful

I have attached a highly detailed, engineering quality doodle-that-a-ten-year-old-might-make for a little added clarity.

edit:

I also wanted to say that the roller idea for distrubuting the powder is very wise, and is commonly used in these processes.I should also say that I am not an expert by any means. All the above information came from "Degarmos materials and manufacturing processes" and the class that went with it

Edited 1 time(s). Last edit at 04/05/2013 02:49AM by nickw.

|

Re: 3D Metal Printer Projects? April 05, 2013 04:32AM |

Registered: 13 years ago Posts: 177 |

I have an electric furnace that will go to 1600c. I did suggest that method earlier but its not ideal to make really accurate parts. It also does not for fill my requirements for multiple material prints.

Hazel. I noticed you put the focusing lens after the galvo. Would it not distort the angle of the beam when it is not passing through the lens at precisely 90 degrees? Why not start focusing of the beam before the galvo by passing the beam through the lens first. You will need a long focal length lens anyway so just make the focal length a bit longer. That way the angle of the beam will be exactly what the mirrors are directing it to be.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Hazel. I noticed you put the focusing lens after the galvo. Would it not distort the angle of the beam when it is not passing through the lens at precisely 90 degrees? Why not start focusing of the beam before the galvo by passing the beam through the lens first. You will need a long focal length lens anyway so just make the focal length a bit longer. That way the angle of the beam will be exactly what the mirrors are directing it to be.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 05, 2013 08:47AM |

Registered: 11 years ago Posts: 89 |

|

Re: 3D Metal Printer Projects? April 05, 2013 12:54PM |

Registered: 11 years ago Posts: 74 |

It is lovely to see people who are getting interested!

@Madkite, thank you for making that clear! I find it remarkable that all of the machinery is in place and works so well! The only major hurdle seems to be the laser! Imagine the precision we can get with purpose machined parts (and later printing your own).

Regarding your second point... I was just emulating commercial laser scanners, which seem to have a lens of some sort. I am not sure on this point though.

@Viktor, I am very interested to see your results!

@Matt, what a golden find! Thank you for that! I am putting it straight into the forum.

@Nick, interesting concept! That would definitely be interesting to those who want to print in multi materials! I would love to put the link in the forum as I am trying to build up relevant content. As Madkite said, the only issue with processes that use binders is loss in resolution. Shapeways I think uses binders to print their metal parts and their resolution is not excellent, however all of these processes should be looked at very carefully indeed because in them lie a paradigm shift in manufacture.

@Sheldon, this is another method of printing that needs to be looked at... I have put in subforum that deals with induction printing. This may be one way to heat the wire filament inside the nozzle! Very interesting!

Once again though, I like the look of DMLS or SLS because you can print any geometry.

Just to keep you all posted, there is allot of work that needs to be done on the wiki! In the form of safety pages info pages etc... so this is where the bulk of the work will lie when we go live.

Again many thanks for your patience!

Jethro.

@Madkite, thank you for making that clear! I find it remarkable that all of the machinery is in place and works so well! The only major hurdle seems to be the laser! Imagine the precision we can get with purpose machined parts (and later printing your own).

Regarding your second point... I was just emulating commercial laser scanners, which seem to have a lens of some sort. I am not sure on this point though.

@Viktor, I am very interested to see your results!

@Matt, what a golden find! Thank you for that! I am putting it straight into the forum.

@Nick, interesting concept! That would definitely be interesting to those who want to print in multi materials! I would love to put the link in the forum as I am trying to build up relevant content. As Madkite said, the only issue with processes that use binders is loss in resolution. Shapeways I think uses binders to print their metal parts and their resolution is not excellent, however all of these processes should be looked at very carefully indeed because in them lie a paradigm shift in manufacture.

@Sheldon, this is another method of printing that needs to be looked at... I have put in subforum that deals with induction printing. This may be one way to heat the wire filament inside the nozzle! Very interesting!

Once again though, I like the look of DMLS or SLS because you can print any geometry.

Just to keep you all posted, there is allot of work that needs to be done on the wiki! In the form of safety pages info pages etc... so this is where the bulk of the work will lie when we go live.

Again many thanks for your patience!

Jethro.

|

Re: 3D Metal Printer Projects? April 05, 2013 03:13PM |

Admin Registered: 16 years ago Posts: 13,884 |

... another interesting methode is "Selective Inhibition of Sintering" - read though the threads and discussions about this:

[forums.reprap.org]

It's simply a combination of salt-ink and local heating ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[forums.reprap.org]

It's simply a combination of salt-ink and local heating ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? April 06, 2013 05:59AM |

Registered: 11 years ago Posts: 74 |

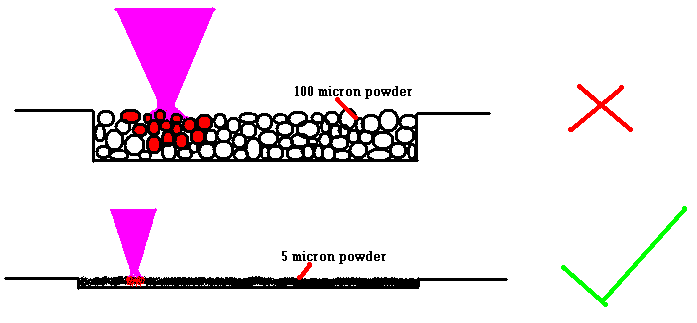

I think that one of the main issues regarding the SLS process that needs to be proved is this:

For a type of powder, call it powder x, and a given powder thickness (thickness y), what is the minimum amount of beam energy e required to fuse it to the layer below for a given time t.

If it can be proved that a laser engraver with an engraving depth of 300micron can fuse layers of metal powder together, then making a 3D Metal Printer will be easier than first thought.

For a type of powder, call it powder x, and a given powder thickness (thickness y), what is the minimum amount of beam energy e required to fuse it to the layer below for a given time t.

If it can be proved that a laser engraver with an engraving depth of 300micron can fuse layers of metal powder together, then making a 3D Metal Printer will be easier than first thought.

|

Re: 3D Metal Printer Projects? April 07, 2013 12:29PM |

Registered: 13 years ago Posts: 177 |

Hazel that seems to largely depend on the wavelength of the laser too. So that's another variable.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 07, 2013 01:02PM |

Registered: 11 years ago Posts: 74 |

Madkite, on your last point. I think we should standardize everything so that we can have clear reference point. Alot of the work will involve getting clear reference points, standard specs etc...

I think that the standard wavelength we should look at is that of 1064nm, the frequency of a Yeg laser. The reason is simple and can bee seen when comparing CO2 lasers to Yag Lasers COMPARISON . The wavelength of a CO2 laser is exactly 10 times greater than a Yag laser. For this reason CO2 lasers have very little effect on metals!

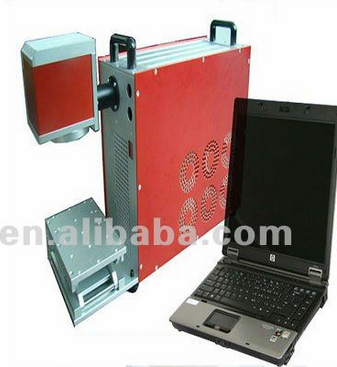

On this point... I have stumbled across a very interesting mini laser engraver! Here is the link: [www.alibaba.com]

Here is a picture of the unit:

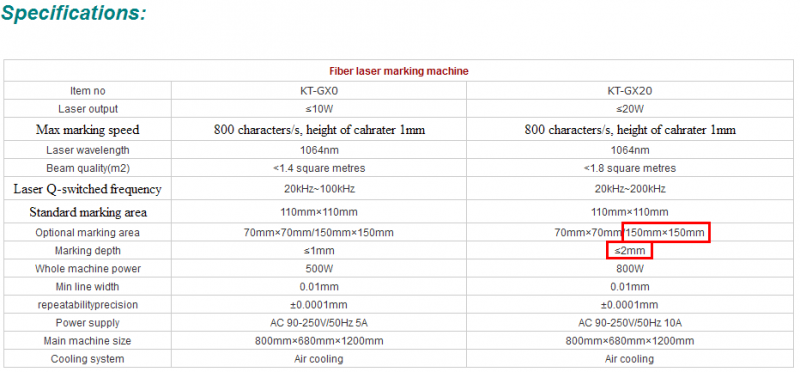

There are two models, the KT-GX0 and the KT-GX20. The first one is a 10w laser with an engraving depth of 100um. The latter is 20w and has an engraving depth of 200 microns.

We just need to find out if the 0.1mm or 0.2mm (100-200 micron) engraving depth will fuse one layer of powder to another. If the answer is yes, then a 3D Metal printer is really closer than first thought!

Perhaps the answer is to use extremely fine metal powders (10 microns) and extremely thin layers (30 microns). The benefits to this are twofold: 1 - you need a lower power laser to melt the layers and 2 - The part resolution will be incredibly fine!

The drawback would only be build time. To begin with this is not the end of the world!

Here is the specs sheet:

If we were to mod one of these machines (which would solve the hardest parts, for example, laser scanners, scanner software and laser power supplies) we would only need to work out the powder system, housing the scanner head and build platform in a gas proof enclosure and creating a software interface between the already functioning scanner software and a 3D Slicer.

Best regards!

Jethro.

I think that the standard wavelength we should look at is that of 1064nm, the frequency of a Yeg laser. The reason is simple and can bee seen when comparing CO2 lasers to Yag Lasers COMPARISON . The wavelength of a CO2 laser is exactly 10 times greater than a Yag laser. For this reason CO2 lasers have very little effect on metals!

On this point... I have stumbled across a very interesting mini laser engraver! Here is the link: [www.alibaba.com]

Here is a picture of the unit:

There are two models, the KT-GX0 and the KT-GX20. The first one is a 10w laser with an engraving depth of 100um. The latter is 20w and has an engraving depth of 200 microns.

We just need to find out if the 0.1mm or 0.2mm (100-200 micron) engraving depth will fuse one layer of powder to another. If the answer is yes, then a 3D Metal printer is really closer than first thought!

Perhaps the answer is to use extremely fine metal powders (10 microns) and extremely thin layers (30 microns). The benefits to this are twofold: 1 - you need a lower power laser to melt the layers and 2 - The part resolution will be incredibly fine!

The drawback would only be build time. To begin with this is not the end of the world!

Here is the specs sheet:

If we were to mod one of these machines (which would solve the hardest parts, for example, laser scanners, scanner software and laser power supplies) we would only need to work out the powder system, housing the scanner head and build platform in a gas proof enclosure and creating a software interface between the already functioning scanner software and a 3D Slicer.

Best regards!

Jethro.

|

Re: 3D Metal Printer Projects? April 07, 2013 04:34PM |

Registered: 12 years ago Posts: 1,236 |

I have been following this thread with interest, I also think metal printing of some sort is a key step forward.

I think most of the stuff is out of my field, but I have become interested in the scanning part. Over in the Electronics forum, rskelton and I have been discussing scanners for SLA. To that end I have ordered some cheap galvo scanners for the purpose of developing some software.

I'm not sure how transferable the development will be to metal printing application, but it looks to me similar in principle. I don't think I will be able to afford $5000 for a laser engraver(!), but maybe I can help out somewhere.

I think most of the stuff is out of my field, but I have become interested in the scanning part. Over in the Electronics forum, rskelton and I have been discussing scanners for SLA. To that end I have ordered some cheap galvo scanners for the purpose of developing some software.

I'm not sure how transferable the development will be to metal printing application, but it looks to me similar in principle. I don't think I will be able to afford $5000 for a laser engraver(!), but maybe I can help out somewhere.

|

Re: 3D Metal Printer Projects? April 10, 2013 12:44PM |

Admin Registered: 13 years ago Posts: 730 |

|

Re: 3D Metal Printer Projects? April 10, 2013 01:14PM |

Registered: 11 years ago Posts: 80 |

Hi, I also wanted to add this link to some interesting replies I got when I posted on another forum:

[www.finishing.com]

So apparently IBM did some fundamental research work back in the 1980s which sounds very interesting.

[www.finishing.com]

So apparently IBM did some fundamental research work back in the 1980s which sounds very interesting.

|

Re: 3D Metal Printer Projects? April 11, 2013 02:48AM |

Registered: 13 years ago Posts: 177 |

Got some more bits for my project.

Can start collecting the pipe fittings now but will be waiting for bits from China for quite some time.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Can start collecting the pipe fittings now but will be waiting for bits from China for quite some time.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 11, 2013 05:42AM |

Registered: 11 years ago Posts: 74 |

It is absolutely awesome and encouraging to see that this thread has taken a life of its own!! This is one of those rare things that will be truly greater than the sum of it's parts.

I really think we can condense the DMLS printer design into an almost desktop size... the key to success will be the powder systems. Specifically powder granule size and powder layer thickness... so you can see, the answer is not bigger lasers, but smaller layers.

You can use lower wattages to sinter smaller layers. This will require precise engineering in the powder system in order to get such fine layers.

----

With regard to the Forum

Currently the forum has the following categories. If there are any changes you would like to see, please say so!

--Forum

New members

General

Your Printers

--Laser Sintering

Laser System

Powder System

Software and Electronics

Frames

--Further Printing Systems

Direct Deposition

Hypersonic Deposition

Induction Printer

Electron Beam Melting

--Materials

Materials

--Suggestions

Suggestions Box

As for the wiki, there is so much work to do. I currently have the main Page almost done, however other pages need a lot more work...

The site will most likely go live this weekend.

best regards!

Jethro.

Edited 1 time(s). Last edit at 04/11/2013 05:46AM by Hazel1919.

I really think we can condense the DMLS printer design into an almost desktop size... the key to success will be the powder systems. Specifically powder granule size and powder layer thickness... so you can see, the answer is not bigger lasers, but smaller layers.

You can use lower wattages to sinter smaller layers. This will require precise engineering in the powder system in order to get such fine layers.

----

With regard to the Forum

Currently the forum has the following categories. If there are any changes you would like to see, please say so!

--Forum

New members

General

Your Printers

--Laser Sintering

Laser System

Powder System

Software and Electronics

Frames

--Further Printing Systems

Direct Deposition

Hypersonic Deposition

Induction Printer

Electron Beam Melting

--Materials

Materials

--Suggestions

Suggestions Box

As for the wiki, there is so much work to do. I currently have the main Page almost done, however other pages need a lot more work...

The site will most likely go live this weekend.

best regards!

Jethro.

Edited 1 time(s). Last edit at 04/11/2013 05:46AM by Hazel1919.

|

Re: 3D Metal Printer Projects? April 11, 2013 05:57AM |

Admin Registered: 16 years ago Posts: 13,884 |

... with finer powders you'll get some more issues with self-ignition, adhesion and electrostatics -- but yes, "finer is better"

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? April 11, 2013 12:58PM |

Registered: 13 years ago Posts: 177 |

Got the thermocouple today so can now continue to construct the gas heating chamber now. May have a chance this weekend to do some. May film some of it.

Self ignition! Surly not in an inert atmosphere.

Precise components for the roller and the parts to guide it are essential.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Self ignition! Surly not in an inert atmosphere.

Precise components for the roller and the parts to guide it are essential.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 13, 2013 03:39PM |

Registered: 13 years ago Posts: 177 |

Got the thermocouple fittings installed. Now can line the heat chamber with fire cement tomorrow. Then can start the heating element construction. Will try to take some film tomorrow.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 13, 2013 04:06PM |

Registered: 12 years ago Posts: 1,236 |

|

Re: 3D Metal Printer Projects? April 13, 2013 04:20PM |

Registered: 13 years ago Posts: 93 |

|

Re: 3D Metal Printer Projects? April 14, 2013 05:44AM |

Registered: 11 years ago Posts: 74 |

Hi bobc! I am waiting for the hosting services to activate at the moment. Perhaps this will be completed in a few days. I look forward to that! There will be a forum section dealing with that subject.

Also the wiki would benefit from any information you have!

@ Rooski, absolutely fantastic video! Very clever. I am sure that, while metal printing is the primary focus here, a machine could be modified to print in ceramics also, using the sintering process.

One question I do have, perhaps someone knows the answer. A laser engraver vaporizes the metal using a laser. Why would a similar laser not just 'evaporate' the powder instead of sintering it?

Best regards, I hope everyone is having a good weekend.

Jethro.

Also the wiki would benefit from any information you have!

@ Rooski, absolutely fantastic video! Very clever. I am sure that, while metal printing is the primary focus here, a machine could be modified to print in ceramics also, using the sintering process.

One question I do have, perhaps someone knows the answer. A laser engraver vaporizes the metal using a laser. Why would a similar laser not just 'evaporate' the powder instead of sintering it?

Best regards, I hope everyone is having a good weekend.

Jethro.

|

Re: 3D Metal Printer Projects? April 14, 2013 06:51AM |

Registered: 11 years ago Posts: 74 |

Here is a screen shot of the Front Page...

Of the Forum...

And Wiki...

Of the Forum...

And Wiki...

|

Re: 3D Metal Printer Projects? April 14, 2013 05:22PM |

Registered: 13 years ago Posts: 177 |

Sites looking nice. Made a video of me messing about in the workshop today.

Edited 1 time(s). Last edit at 04/14/2013 05:23PM by Madkite.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Edited 1 time(s). Last edit at 04/14/2013 05:23PM by Madkite.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 18, 2013 03:17AM |

Registered: 13 years ago Posts: 177 |

Vaporising instead of melting would be because of too much power for too long I would think. Also there is not a base like another layer of powder underneath in cutters. The layers beneath will absorb the heat so you would still need the power.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 18, 2013 03:36AM |

Admin Registered: 16 years ago Posts: 13,884 |

... for reducing the needed amount of power (and for better fusion) the complete powder volume should be heated to some ten degs below melting temp ... so the heat dissipation is negelectible and you can go with much 'weaker' lasers or electron beams.

Another alternative is a two-laser head, where one with higher power and bigger focus (eventually different wavelength too) will preheat a zone of some mm in diameter below melting temp, and the second, good focussed, will start sintering/melting only the powder in the center of the preheated area.

I'm planning to do this with a laserdiode with 25Watts @808nm (and 'bad' focus, as it emits out of 19 combined fibers with a bundle-diameter of 0.8mm) for preheating and then sintering in the center with a 0.1mm wide spot from another laserdiode with 9Watts @975nm out from a single fiber with 0.1mm diameter ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Another alternative is a two-laser head, where one with higher power and bigger focus (eventually different wavelength too) will preheat a zone of some mm in diameter below melting temp, and the second, good focussed, will start sintering/melting only the powder in the center of the preheated area.

I'm planning to do this with a laserdiode with 25Watts @808nm (and 'bad' focus, as it emits out of 19 combined fibers with a bundle-diameter of 0.8mm) for preheating and then sintering in the center with a 0.1mm wide spot from another laserdiode with 9Watts @975nm out from a single fiber with 0.1mm diameter ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? April 18, 2013 07:05AM |

Registered: 13 years ago Posts: 177 |

I wouldn't recommend trying to preheat the whole material bed. Engineering a mechanically complex chamber to heat and function at 1200c might be a little impossible not to mention ridiculously power hungry. Even anything over 150c can start to cause real problems with mechanics let alone electrics.

A preheat laser is a much better idea if you can't economically obtain laser powerful enough.

Make your Mendel twice as accurate.

[www.thingiverse.com]

A preheat laser is a much better idea if you can't economically obtain laser powerful enough.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: 3D Metal Printer Projects? April 18, 2013 07:38AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I think, even if you have a laser powerfull enough, then lokal preheating the volume around the spot should help enormous!

When 'instantly' heating the volume in the spot from room-temp to melting/fusing, then the thermal 'shock' and sharp temperature gradients will most likely induce mechanical stress in the solid, what's massive reduced with a surrounding preheating zone -- think on tempering and lower needed energies to overcome the critical values.

I have IR-lasers with energy-densities strong enough to cut/evaporate all metals and ceramics - 50Watts on a spot of 0.01mm diameter is the same energy density as 500kW on a 1mm-spot! ... but the heat-dissipation (cooling effect) is much stronger in solid, so I can't cut thick steel-sheets or such ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

When 'instantly' heating the volume in the spot from room-temp to melting/fusing, then the thermal 'shock' and sharp temperature gradients will most likely induce mechanical stress in the solid, what's massive reduced with a surrounding preheating zone -- think on tempering and lower needed energies to overcome the critical values.

I have IR-lasers with energy-densities strong enough to cut/evaporate all metals and ceramics - 50Watts on a spot of 0.01mm diameter is the same energy density as 500kW on a 1mm-spot! ... but the heat-dissipation (cooling effect) is much stronger in solid, so I can't cut thick steel-sheets or such ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 3D Metal Printer Projects? April 18, 2013 10:30AM |

Registered: 11 years ago Posts: 74 |

Sorry, only registered users may post in this forum.