Is it possible to repair a stepper motor that has internal stressed wires?

Posted by hendo420

|

Is it possible to repair a stepper motor that has internal stressed wires? March 23, 2013 05:54PM |

Registered: 11 years ago Posts: 137 |

I started a thread a few days ago asking for help because my extruder was acting weird. sometimes extruding and sometimes not. I figured out if i moved the wire a certain way it would work and let it go and it would stop extruding. I figured a wire was bad. After a few days screwing with it and having mixed results I finally found the culprit. When I push the wires into the motor it extrudes when I let off it stops. There is no stress relief for the wire going into the extruders stepper motor. It pulled on the wires going into the motor and caused an intermitent connection. I took the back off thinking maybe there were connectors inside that I could just reconnect the wires. I was wrong. The wires go into the motor and connect somewhere on the coils. Fkn great... So I think i may need a new stepper motor.

Unless someone else has another solution. Like repairing the motor.

I also need to know what stepper motor to buy, mine has 4 wires. I dont know much else about it, I cant find any writing on it such as model number ect.

My printer is a Rapidbot 3.0

[makemendel.com]

My printer has a printrboard Rev D

Edited 2 time(s). Last edit at 03/23/2013 06:15PM by hendo420.

Unless someone else has another solution. Like repairing the motor.

I also need to know what stepper motor to buy, mine has 4 wires. I dont know much else about it, I cant find any writing on it such as model number ect.

My printer is a Rapidbot 3.0

[makemendel.com]

My printer has a printrboard Rev D

Edited 2 time(s). Last edit at 03/23/2013 06:15PM by hendo420.

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 23, 2013 06:18PM |

Registered: 11 years ago Posts: 349 |

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 23, 2013 07:14PM |

Registered: 11 years ago Posts: 137 |

Well I got it working for now.

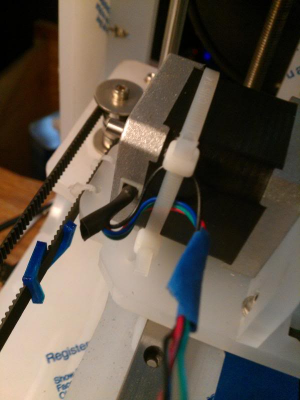

Check out my (not so) Elegant fix.

Ive been looking for motors to replace this one with. All of the ones I have seen have plugs on the motor so it will break away if its stressed. This one does not, they go right into the motor. This must be a really cheap stepper motor. Maybe I will just replace them all with better stepper motors, Ive seen some prety good 5x motor bundles on ebay.

what specs should I be looking for in a stepper motor? Ive never had to buy one before. lol

Btw, the blue painters tape is only there temporarily because I cut off the heat shrink tubing to insprect the wires.

Edited 1 time(s). Last edit at 03/23/2013 07:16PM by hendo420.

Check out my (not so) Elegant fix.

Ive been looking for motors to replace this one with. All of the ones I have seen have plugs on the motor so it will break away if its stressed. This one does not, they go right into the motor. This must be a really cheap stepper motor. Maybe I will just replace them all with better stepper motors, Ive seen some prety good 5x motor bundles on ebay.

what specs should I be looking for in a stepper motor? Ive never had to buy one before. lol

Btw, the blue painters tape is only there temporarily because I cut off the heat shrink tubing to insprect the wires.

Edited 1 time(s). Last edit at 03/23/2013 07:16PM by hendo420.

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 23, 2013 07:29PM |

Admin Registered: 11 years ago Posts: 1,063 |

most of us use the 17HS8401 it's a pretty common stepper and can be for wayy less than an arm

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 23, 2013 07:38PM |

Registered: 11 years ago Posts: 137 |

Would this one work?

[www.ebay.com]

Its the cheapest NEMA 17 4wire motor I could find on ebay in the US.

Or this one? Its in the same state, so wouldnt take long to get here.

[www.ebay.com]

Edited 1 time(s). Last edit at 03/23/2013 08:09PM by hendo420.

[www.ebay.com]

Its the cheapest NEMA 17 4wire motor I could find on ebay in the US.

Or this one? Its in the same state, so wouldnt take long to get here.

[www.ebay.com]

Edited 1 time(s). Last edit at 03/23/2013 08:09PM by hendo420.

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 24, 2013 12:01AM |

Registered: 12 years ago Posts: 809 |

Get the one from automation technologies. More torque. Especially for the extruder.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 26, 2013 06:34AM |

Registered: 15 years ago Posts: 332 |

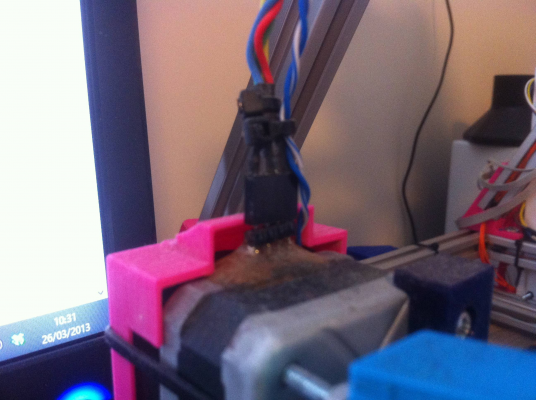

If you want to use motors like this - just blob some silicone glue/hot glue around where the cables come out, they'll act like strain relief. Have you repaired it just by holding the wires in a known-good location? Beware that loose connections can fry stepper drivers due to inductive surges. What I do is solder pin headers to the motor, then epoxy the headers to the body:

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 26, 2013 07:33AM |

Registered: 11 years ago Posts: 137 |

I just pushed the wire into the motor a bit and then used zip ties to hold the wire tight but leave slack where it goes into the motor. I have been having a few weird issues with my printer not wanting to connect after restarting it, also its been missing steps on both Y and X axis, it wasnt doing this b4 i started having issues with this motor. I sure hope I don't fry my printrboard. This motor only has to last until my new motor gets here.

Edited 1 time(s). Last edit at 03/26/2013 07:34AM by hendo420.

Edited 1 time(s). Last edit at 03/26/2013 07:34AM by hendo420.

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 26, 2013 09:51PM |

Registered: 12 years ago Posts: 82 |

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 27, 2013 03:48AM |

Registered: 13 years ago Posts: 486 |

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 27, 2013 10:12AM |

Registered: 15 years ago Posts: 332 |

I was interested in finding this out, and there's not a huge amount of information I could find. Lots of posts saying how it used to be an issue/now isn't with new motors, or the other way around :s The only reasonable sounding explanation I found was that the permanent magnets will experience a greater magnetic field gradient when disassembled, which can demagnetise them somewhat. No idea if that's true, or if that's the reason. Personally I've take apart all the stepper motors I've ever used (to fit custom connectors or cabling), and this is the first I've heard about it being an issue, and I haven't noticed any effect (not saying it isn't there, but hasn't been significant enough to notice).

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 27, 2013 11:25AM |

Admin Registered: 16 years ago Posts: 13,884 |

... it's true for the new strong magnetized hybrid steppers.

If you pull the rotor and touch with the magnets a metallic (ferromagnetic) edge, then the field gradient in the gap is strong enough to 'reshuffle' the local magnetic domains.

You need a tube (preferrably aluminium) slightly wider then the rotor diameter to extract the rotor without touching the surrounding iron or steel edges ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

If you pull the rotor and touch with the magnets a metallic (ferromagnetic) edge, then the field gradient in the gap is strong enough to 'reshuffle' the local magnetic domains.

You need a tube (preferrably aluminium) slightly wider then the rotor diameter to extract the rotor without touching the surrounding iron or steel edges ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 27, 2013 11:57AM |

Registered: 11 years ago Posts: 137 |

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? March 27, 2013 05:38PM |

Registered: 12 years ago Posts: 82 |

From a post on the web (If it is on the web, it has to be true...). All kidding aside and references to old, young, husbands or wives tales be darn....

"Sorry, but that is absolutely NOT true. Stepper motors are very different from brushless DC motors, and WILL be significantly damaged simply by being disassembled, no matter how carefully it's done. Do some Googling, and you will see this is 100% true, and is very well known to those who work with stepper motors on a regular basis.

From Anaheim Automation:

"Q: Is there any damage caused by a stepper motor that is disassembled?

A: Yes! Up to 60% magnetizing loss can be the result if the rotor is pulled apart. If all parts are replaced properly, the motor can be remagnetized at the factory, but the charge is substantial. If you have a motor failure, or are concerned about the performance, contact Anaheim Automation. Please note that the warranty period is 12 months from the date of invoice. "

From ServoRepair.com:

"First, any time a motor is disassembled, there is a high probability that the magnets will be discharged to a point where the torque will be diminished. The results vary and may or may not initially be noticeable. With some motors, the results will be immediate. In fact, disassembly of a stepper motor will typically demagnetize the magnets to a point that the motor is useless until it has been properly remagnetized."

From Lin Engineering:

"Do not disassemble motors; a significant reduction in motor performance will occur."

From a post by Mariis Freimaniss, of Gecko, who knows as much about stepper motors as anyone in the world:

"This topic came up in another group. The stator acts as a magnetic "keeper" for the rotor.

Nothing like running an experiment to know if something is true or not.

I had a motor I didn't care for (MO62-FD04), so I ran dyno tests on it that showed 112 in-oz low-speed torque. I removed the rotor for 5 seconds, then replaced it and re-ran the dyno test.

The low-speed torque now was 70 in-oz, or only 62% of what it was before disassemby.

You may not notice the loss in torque but it is real and it is there.

Mariss"

Disassembly of a stepper motor WILL damage it! Guaranteed!"

"Sorry, but that is absolutely NOT true. Stepper motors are very different from brushless DC motors, and WILL be significantly damaged simply by being disassembled, no matter how carefully it's done. Do some Googling, and you will see this is 100% true, and is very well known to those who work with stepper motors on a regular basis.

From Anaheim Automation:

"Q: Is there any damage caused by a stepper motor that is disassembled?

A: Yes! Up to 60% magnetizing loss can be the result if the rotor is pulled apart. If all parts are replaced properly, the motor can be remagnetized at the factory, but the charge is substantial. If you have a motor failure, or are concerned about the performance, contact Anaheim Automation. Please note that the warranty period is 12 months from the date of invoice. "

From ServoRepair.com:

"First, any time a motor is disassembled, there is a high probability that the magnets will be discharged to a point where the torque will be diminished. The results vary and may or may not initially be noticeable. With some motors, the results will be immediate. In fact, disassembly of a stepper motor will typically demagnetize the magnets to a point that the motor is useless until it has been properly remagnetized."

From Lin Engineering:

"Do not disassemble motors; a significant reduction in motor performance will occur."

From a post by Mariis Freimaniss, of Gecko, who knows as much about stepper motors as anyone in the world:

"This topic came up in another group. The stator acts as a magnetic "keeper" for the rotor.

Nothing like running an experiment to know if something is true or not.

I had a motor I didn't care for (MO62-FD04), so I ran dyno tests on it that showed 112 in-oz low-speed torque. I removed the rotor for 5 seconds, then replaced it and re-ran the dyno test.

The low-speed torque now was 70 in-oz, or only 62% of what it was before disassemby.

You may not notice the loss in torque but it is real and it is there.

Mariss"

Disassembly of a stepper motor WILL damage it! Guaranteed!"

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? May 29, 2013 03:20PM |

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? May 29, 2013 06:54PM |

Registered: 11 years ago Posts: 544 |

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? May 29, 2013 07:22PM |

Registered: 11 years ago Posts: 82 |

I did open a stepper motor once and I could feel big difference in the resistance when spinning the motor shaft by hand. Before I open it, I could feel the cog of each step when I spin the shaft with my fingers.

After opening and reassembling the motor back (though I didn't put any metal thing near the rotor) the shaft can be spin almost freely like nothing holding it back. I thought something went wrong.I opened it again to check if I miss anything. Nothing was missing, the washer is still there at the shaft ends. Putting the motor back, it still spin smoothly with very weak cog. I was so puzzled, until I read this thread.

After opening and reassembling the motor back (though I didn't put any metal thing near the rotor) the shaft can be spin almost freely like nothing holding it back. I thought something went wrong.I opened it again to check if I miss anything. Nothing was missing, the washer is still there at the shaft ends. Putting the motor back, it still spin smoothly with very weak cog. I was so puzzled, until I read this thread.

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? May 29, 2013 08:56PM |

Registered: 11 years ago Posts: 544 |

as far as demagnetizing, that sounds like bs, ive taken apart a bunch of motors and all of them work just as good as when i bought them new, infact i had to take one apart that had a bad bearing, and now it works even better than new, the motor would cog and then spin freely randomly. i took it apart and replaced the bearing and its been fine ever since, zero problems.

until someone does an independent test(non-manufacturer) i wont believe it.

until someone does an independent test(non-manufacturer) i wont believe it.

|

Re: Is it possible to repair a stepper motor that has internal stressed wires? August 29, 2014 08:51PM |

Registered: 9 years ago Posts: 16 |

Sorry, only registered users may post in this forum.