VIDEO POSTED! Details about the BerryBot3D

Posted by BerryBot3D

|

Re: VIDEO POSTED! Details about the BerryBot3D July 12, 2013 12:24AM |

Registered: 11 years ago Posts: 83 |

Hi Guys,

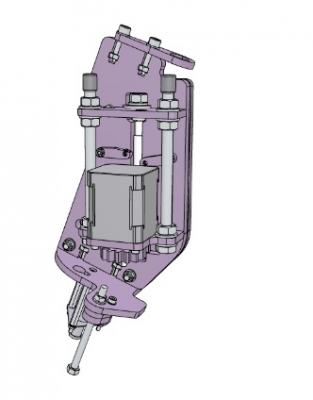

Sorry I was MIA for a bit, vacation and some major deadlines at work I just didn’t have time to play. I have been busier that a one armed wallpaper hanger! My problem is once I get started talking and thinking about 3D printing stuff I can stop thinking about it! It is hard to get any work done when my mind is designing 3D printer parts. I wanted to thank everybody for all the PM ‘s emails and other messages I have been getting. I read and listen to all of them but just don’t have the time to reply to all of them. I have managed to do some really cool prints. One of the coolest prints is this 15” tall 8” in diameter rocket nosecone with two camera cutouts. This thing is super cool and the dimensions came out dead nuts. I did take some video and if I ever get some time I will post it. I have a bunch of stuff I am playing with like a new filament drive unit that is mounted at the end effector using a small 5-1 Nema 11 gearmotor: [www.stepperonline.com] . I also have a new design using high precision linear bearings that is very high-end nice. I have an opportunity to sell quite a few BerryBot3D’s and my business partners suggested that I pull the design videos until I have decided if I want to jump into it. Since you Guys had already seen them I didn’t think it would be a big deal to pull them. The videos hit 15K views so fast I figured everyone and there whole family had already watched them. Just PM me if you are really stuck about something and I will help you out assuming there aren’t thousands of you. Haha…..

Happy Building/Printing!

Werner

Sorry I was MIA for a bit, vacation and some major deadlines at work I just didn’t have time to play. I have been busier that a one armed wallpaper hanger! My problem is once I get started talking and thinking about 3D printing stuff I can stop thinking about it! It is hard to get any work done when my mind is designing 3D printer parts. I wanted to thank everybody for all the PM ‘s emails and other messages I have been getting. I read and listen to all of them but just don’t have the time to reply to all of them. I have managed to do some really cool prints. One of the coolest prints is this 15” tall 8” in diameter rocket nosecone with two camera cutouts. This thing is super cool and the dimensions came out dead nuts. I did take some video and if I ever get some time I will post it. I have a bunch of stuff I am playing with like a new filament drive unit that is mounted at the end effector using a small 5-1 Nema 11 gearmotor: [www.stepperonline.com] . I also have a new design using high precision linear bearings that is very high-end nice. I have an opportunity to sell quite a few BerryBot3D’s and my business partners suggested that I pull the design videos until I have decided if I want to jump into it. Since you Guys had already seen them I didn’t think it would be a big deal to pull them. The videos hit 15K views so fast I figured everyone and there whole family had already watched them. Just PM me if you are really stuck about something and I will help you out assuming there aren’t thousands of you. Haha…..

Happy Building/Printing!

Werner

Attachments:

open | download - 2013-06-29 11.50.03_1024x577.jpg (402.3 KB)

open | download - 2013-06-29 10.46.49 - Copy_432x768.jpg (246.2 KB)

open | download - IMG_20130629_104544_226_432x768.jpg (295.3 KB)

open | download - 2013-06-29 13.20.03_432x768.jpg (278.2 KB)

open | download - 2013-05-25 11.46.30_1024x577.jpg (457.2 KB)

open | download - 2013-07-03 10.23.45_432x768.jpg (299.9 KB)

open | download - 2013-06-29 11.50.03_1024x577.jpg (402.3 KB)

open | download - 2013-06-29 10.46.49 - Copy_432x768.jpg (246.2 KB)

open | download - IMG_20130629_104544_226_432x768.jpg (295.3 KB)

open | download - 2013-06-29 13.20.03_432x768.jpg (278.2 KB)

open | download - 2013-05-25 11.46.30_1024x577.jpg (457.2 KB)

open | download - 2013-07-03 10.23.45_432x768.jpg (299.9 KB)

|

Re: VIDEO POSTED! Details about the BerryBot3D July 12, 2013 09:16AM |

Registered: 12 years ago Posts: 141 |

Werner,

Glad to see you made it back!! Hope you enjoyed your vacation. I kinda figured you may be going into "production" with the bot as why you pulled the "tech" vids. I cant speak for everyone, but I really enjoyed the tech videos - from a builder standpoint. If you don't jump in as you stated, then can you please put them up again?

I was wondering - is the Makerslide starting to fail? Im real curious about the industrial slides your looking into - why the change? How much more weight is that going to add to your effector by placing the extruder right on top? Are you having issues with the bowden style setup?

Thanks!

Jeff

Glad to see you made it back!! Hope you enjoyed your vacation. I kinda figured you may be going into "production" with the bot as why you pulled the "tech" vids. I cant speak for everyone, but I really enjoyed the tech videos - from a builder standpoint. If you don't jump in as you stated, then can you please put them up again?

I was wondering - is the Makerslide starting to fail? Im real curious about the industrial slides your looking into - why the change? How much more weight is that going to add to your effector by placing the extruder right on top? Are you having issues with the bowden style setup?

Thanks!

Jeff

|

Re: VIDEO POSTED! Details about the BerryBot3D July 12, 2013 03:48PM |

Registered: 13 years ago Posts: 1,797 |

+1 on videos. the videos really do increase your fan base, and your star status. pulling the videos will just not do what you would think it would. get some open source advisers. Also know the wolfs out there if starting to sell. Personally I think berry3d has potential, but should sit out for a few more months forming his selling strategy. possibly with kickstarter?

|

Re: VIDEO POSTED! Details about the BerryBot3D July 18, 2013 08:40PM |

Registered: 11 years ago Posts: 83 |

Hey Guys, The BerryBot3D is coming up on 1000 hours of printing and the machine is in perfect condition with absolutely no sign of looseness or wear. The Makerslides are working perfectly. I have not needed to made any adjustments. The only thing I do every now and again is wipe down the “V” area of the aluminum extrusion and rollers with a little denatured alcohol. There is no doubt that the Makerslide is the way to go to keep your costs down. My reasons for going with linear roller bearings is more to do with no maintenance and design appearance than performance.

The Bowden tube setup does work perfectly for most prints. Prints requiring a lot of pickups and moves will do better having the filament feeder just inches from the heat chamber. In my opinion the most you can effectively suck with a Bowden tube is about 5mm. Anything past that and the filament will just pull away from the hotend heat chamber, more like stretching than creating a vacuum/sucking. 5mm of suck on a Bowden is more like 1/ 1.5 with an end effector feeder. The added weight of the mini gear stepper is not a problem for the super mags I am using. One thing to note is that there is a small amount of drag/ force needed, getting the filament through the Bowden tube that is not needed for the end effector feeder another benefit.

I am working on putting the videos back up on YouTube, I really did not think it would be missed as much as it has!! Sorry!!

Happy Building!

Werner

The Bowden tube setup does work perfectly for most prints. Prints requiring a lot of pickups and moves will do better having the filament feeder just inches from the heat chamber. In my opinion the most you can effectively suck with a Bowden tube is about 5mm. Anything past that and the filament will just pull away from the hotend heat chamber, more like stretching than creating a vacuum/sucking. 5mm of suck on a Bowden is more like 1/ 1.5 with an end effector feeder. The added weight of the mini gear stepper is not a problem for the super mags I am using. One thing to note is that there is a small amount of drag/ force needed, getting the filament through the Bowden tube that is not needed for the end effector feeder another benefit.

I am working on putting the videos back up on YouTube, I really did not think it would be missed as much as it has!! Sorry!!

Happy Building!

Werner

|

Re: VIDEO POSTED! Details about the BerryBot3D July 18, 2013 08:56PM |

Registered: 11 years ago Posts: 28 |

Hehe great to have News from you Berry!

Its great to know your effector is still gooing well after 1000 hour and that the maker slide is a good choice.

Did you pic a 1 meter maker slide for you build?

Cant wait to see your New and old video (some of witch I can almost know what you are gona say before you do )

)

I have no time for my build but still mentaly planning. Today i had to ask our designer at work to print me some spair part for my cell phone holder its almost shameful

Keep us posted on your work its so motivating!!!

Frank

''Bathroom renovator for the next few week...''

Its great to know your effector is still gooing well after 1000 hour and that the maker slide is a good choice.

Did you pic a 1 meter maker slide for you build?

Cant wait to see your New and old video (some of witch I can almost know what you are gona say before you do

)

)I have no time for my build but still mentaly planning. Today i had to ask our designer at work to print me some spair part for my cell phone holder its almost shameful

Keep us posted on your work its so motivating!!!

Frank

''Bathroom renovator for the next few week...''

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 04:24PM |

Registered: 12 years ago Posts: 141 |

Hey guys, Just a quick note in case anyone is interested in Following Werners lead using magnetic balls for the pivots. I placed an order last Sunday from Fridgedoor.com as he linked, and STILL havent seen them, nor did I get a response from my email I sent on Friday. So I just called them. Turns out even though they show in stock they only have THE ONE PACK OF 3 LEFT! they wont be getting any more in as the vender isn't producing them due to some lawsuit or something. I guess Mr Berry bought them all!! LOL!!

In any case I was able to find them at amazingmagnets.com. Same size, not sure about the holding force - We shall see!!

In any case I was able to find them at amazingmagnets.com. Same size, not sure about the holding force - We shall see!!

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 04:49PM |

Registered: 11 years ago Posts: 83 |

Thanks for the update Parabolic, You can always get them from Magcraft direct although the price it a couple of bucks more per 3 pack. : [www.rare-earth-magnets.com]

Happy Building!

Werner

Happy Building!

Werner

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 04:53PM |

Registered: 12 years ago Posts: 141 |

Hmm - well Chris at Fridgedoor said that the manufacturer (Magcraft I assume), isnt making them any more due to a lawsuit.

Well I hope they are still as this is a FANTASTIC idea you stumbled upon!!

Werner, any pics/vids on that new extruder yet? Im getting frustrated with my Bowden...

Jeff

Well I hope they are still as this is a FANTASTIC idea you stumbled upon!!

Werner, any pics/vids on that new extruder yet? Im getting frustrated with my Bowden...

Jeff

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 06:05PM |

Registered: 11 years ago Posts: 67 |

BerryBot3D Wrote:

-------------------------------------------------------

> The

> added weight of the mini gear stepper is not a

> problem for the super mags I am using.

Hey Werner, anything you're willing to share about the super mags? I am going to be running a heated chamber (which deteriorates the magnetic performance of the magnets) as well as multiple nozzles on the end effector, so I'm in search of some higher-powered spherical magnets. Any leads or advice would be appreciated.

-------------------------------------------------------

> The

> added weight of the mini gear stepper is not a

> problem for the super mags I am using.

Hey Werner, anything you're willing to share about the super mags? I am going to be running a heated chamber (which deteriorates the magnetic performance of the magnets) as well as multiple nozzles on the end effector, so I'm in search of some higher-powered spherical magnets. Any leads or advice would be appreciated.

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 06:11PM |

Registered: 11 years ago Posts: 12 |

I can say this, because I've got a set (actually, 4 sets, since you need 12 for a single printer), that these magnets are _strong_. Like, über strong. Don't give these to your young children to play with strong. From what I can tell, I don't at all think these are on the verge of not doing the job - they're perhaps on the verge of being too strong!

Jeremy

Jeremy

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 06:37PM |

Registered: 11 years ago Posts: 253 |

In a search for spheres, I found this company has some, and I saw this.

Has anyone thought to try a ring magnet with a countersunk hole?

magnet

This is a 3.5lb holding ring for $0.25 each.

Should be able to find steel balls on the cheap to go with it.

Glued into a carbon fiber tube?

Just thinking out loud.

Has anyone thought to try a ring magnet with a countersunk hole?

magnet

This is a 3.5lb holding ring for $0.25 each.

Should be able to find steel balls on the cheap to go with it.

Glued into a carbon fiber tube?

Just thinking out loud.

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 07:45PM |

Registered: 12 years ago Posts: 141 |

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 07:52PM |

Registered: 12 years ago Posts: 141 |

Oh, heres a direct link to what I ordered. Each ball has 7lbs of grip force. I tried to look on the other site, and there are no specs other than the size and "super strong". This company offers a ton of other mangets as well - in case someone comes up with a weird idea - CUSTOM magnets!

I ordered at 4:30 est, and I already got a ship conformation! I had to track the other company down after a week to tell me they were on backorder!

No im not affiliated with any of these companies, I just like letting people know when I have a company do me good - or bad.

Jeff

I ordered at 4:30 est, and I already got a ship conformation! I had to track the other company down after a week to tell me they were on backorder!

No im not affiliated with any of these companies, I just like letting people know when I have a company do me good - or bad.

Jeff

|

Re: VIDEO POSTED! Details about the BerryBot3D July 22, 2013 08:32PM |

Registered: 11 years ago Posts: 1,171 |

A bit more money but this place has them that are a bit stronger (by specs anyway) [www.forcefieldmagnets.com]

|

Re: VIDEO POSTED! Details about the BerryBot3D July 23, 2013 02:55PM |

Registered: 11 years ago Posts: 18 |

|

Re: VIDEO POSTED! Details about the BerryBot3D July 23, 2013 05:16PM |

Registered: 11 years ago Posts: 12 |

Hey Werner, thanks for putting that platen video up again!

Here's a link for those that haven't subscribed: [www.youtube.com].

Jeremy

Here's a link for those that haven't subscribed: [www.youtube.com].

Jeremy

|

Re: VIDEO POSTED! Details about the BerryBot3D July 31, 2013 08:33PM |

Great to have you back indeed Mr Berry.

Congratulations on getting commercial interest, for those of us building (or about to build) Deltas I think there was never a doubt someone would be along pretty quick when they saw the quality of your machine. Hope it can fund you to keep you doing what you (and your fans) really dig!

Congratulations on getting commercial interest, for those of us building (or about to build) Deltas I think there was never a doubt someone would be along pretty quick when they saw the quality of your machine. Hope it can fund you to keep you doing what you (and your fans) really dig!

|

Re: VIDEO POSTED! Details about the BerryBot3D August 03, 2013 10:03PM |

Registered: 11 years ago Posts: 83 |

Hi Guys,

I hope everyone is building or printing like I am! I have been having more fun than you can imagine! I made a recent mod to the BerryBotRouter that is super cool. I basically chopped the end of my aluminum T slot table in order to install a ¾” x 12” x 36” steel plate this thing is mucho heavy!! I machined the plate to accept two Glacern premium 6” milling vises and even a 6” Kurt vise. I have a grid of ½”-13 threaded holes through out to aid in holding things down. This is something I have wanted to do for at least 10 years. I am so happy I can hardly stand it!! The really cool thing is that I machined the plate in my CNC router so that I have alignment slots to key the vises. I am only getting a maximum deviation from perfect square and alignment of .003” in every direction, using just the keys! Wahoo…. I have been printing like a mad man doing a lot of experimentation with slicing programs. I will soon be one with the plastic like you Guys! Haha. Thanks for the nice comments! Here are just a few pics to share. I have a ton of video but just haven’t wanted to take the time to process and post them. Maybe this week.

Have a great day and happy building or printing!

Werner

Edited 1 time(s). Last edit at 08/03/2013 11:33PM by BerryBot3D.

I hope everyone is building or printing like I am! I have been having more fun than you can imagine! I made a recent mod to the BerryBotRouter that is super cool. I basically chopped the end of my aluminum T slot table in order to install a ¾” x 12” x 36” steel plate this thing is mucho heavy!! I machined the plate to accept two Glacern premium 6” milling vises and even a 6” Kurt vise. I have a grid of ½”-13 threaded holes through out to aid in holding things down. This is something I have wanted to do for at least 10 years. I am so happy I can hardly stand it!! The really cool thing is that I machined the plate in my CNC router so that I have alignment slots to key the vises. I am only getting a maximum deviation from perfect square and alignment of .003” in every direction, using just the keys! Wahoo…. I have been printing like a mad man doing a lot of experimentation with slicing programs. I will soon be one with the plastic like you Guys! Haha. Thanks for the nice comments! Here are just a few pics to share. I have a ton of video but just haven’t wanted to take the time to process and post them. Maybe this week.

Have a great day and happy building or printing!

Werner

Edited 1 time(s). Last edit at 08/03/2013 11:33PM by BerryBot3D.

Attachments:

open | download - lathe Dog Hook.jpg (42.1 KB)

open | download - 2013-08-02 13.00.07_1024x577.jpg (375.7 KB)

open | download - Hammer hook_1024x717.jpg (176.4 KB)

open | download - 2013-08-01 08.30.06_432x768.jpg (275.6 KB)

open | download - 2013-07-31 09.45.47_432x768.jpg (227.3 KB)

open | download - 2013-08-03 17.27.07_1024x577.jpg (400 KB)

open | download - 2013-07-25 19.34.21_1024x577.jpg (365.4 KB)

open | download - lathe Dog Hook.jpg (42.1 KB)

open | download - 2013-08-02 13.00.07_1024x577.jpg (375.7 KB)

open | download - Hammer hook_1024x717.jpg (176.4 KB)

open | download - 2013-08-01 08.30.06_432x768.jpg (275.6 KB)

open | download - 2013-07-31 09.45.47_432x768.jpg (227.3 KB)

open | download - 2013-08-03 17.27.07_1024x577.jpg (400 KB)

open | download - 2013-07-25 19.34.21_1024x577.jpg (365.4 KB)

|

Re: VIDEO POSTED! Details about the BerryBot3D August 04, 2013 07:35PM |

Registered: 11 years ago Posts: 83 |

|

Re: VIDEO POSTED! Details about the BerryBot3D August 04, 2013 08:14PM |

Registered: 13 years ago Posts: 1,797 |

that's a great idea, you can read up about bfb designs on how to drive it and assemble it with stepper. the main reason i believe it never made it far past the Darwin days is because it is a rather huge assembly especially for mass that moves. but if it is used with a bowman setup successfully it could work great on a rosteck delta design.

I think it is a lot less efficient at pushing the feedstock forward, most of the energy goes into creating the grooves. so you may need to up the stepper motor size.

look here [cubify.com] and look for 'Rapman 3.0 extruder manual'. file is too big for me to attach here. if you want me too i can email it to you directly.

here is a pic of it fully assembled.

Edited 3 time(s). Last edit at 08/04/2013 08:16PM by jamesdanielv.

I think it is a lot less efficient at pushing the feedstock forward, most of the energy goes into creating the grooves. so you may need to up the stepper motor size.

look here [cubify.com] and look for 'Rapman 3.0 extruder manual'. file is too big for me to attach here. if you want me too i can email it to you directly.

here is a pic of it fully assembled.

Edited 3 time(s). Last edit at 08/04/2013 08:16PM by jamesdanielv.

|

Re: VIDEO POSTED! Details about the BerryBot3D August 05, 2013 05:27AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes that is how Reprap extruders started out, although generally with studding rather than screws. See [hydraraptor.blogspot.co.uk] for the last design like that I used.

It gives more grip, especially on soft plastics like HDPE. The downsides are a lot of friction cutting the thread and also on the surface applying pressure to the filament. I think BFB used a ball bearing to apply the pressure but then you are only using a small number of teeth again. They also use a specially made screw. They angle it so the teeth are orthogonal to the filament.

Other issues are it tends to make the filament rotate so you need to feed it round a bend or it will make it tangle. Enclosing it in a tube all the way to the spool may fix that issue. It also creates more dust than a pinch wheel system as it cuts indentations, rather than just pressing them.

[www.hydraraptor.blogspot.com]

It gives more grip, especially on soft plastics like HDPE. The downsides are a lot of friction cutting the thread and also on the surface applying pressure to the filament. I think BFB used a ball bearing to apply the pressure but then you are only using a small number of teeth again. They also use a specially made screw. They angle it so the teeth are orthogonal to the filament.

Other issues are it tends to make the filament rotate so you need to feed it round a bend or it will make it tangle. Enclosing it in a tube all the way to the spool may fix that issue. It also creates more dust than a pinch wheel system as it cuts indentations, rather than just pressing them.

[www.hydraraptor.blogspot.com]

|

Re: VIDEO POSTED! Details about the BerryBot3D August 05, 2013 12:04PM |

Registered: 12 years ago Posts: 141 |

hmm....

well guys I cant say that I agree. Yes similar things have been attempted and abandoned before, however if others don't revisit those attempts then we may be missing out on a breakthrough!

Didn't Werner already prove that by perfecting the magnet u joints? Werent those tried (and failed?) by someone else before? I really don't like when people are quick to dispel things so easily because something similar has been tried before.

I like his proof of concept, and there are more ways to perfect something than has already been attempted. Im glad he shared that with us - weather it works or not, its a different way of looking at it. Thats why the RepRap scene keeps evolving - thinking outside of the box! Otherwise wed all have Makerbot Cupcakes!

If anyone can make it work I think Werner has a good shot at it!

Sorry for the rant - just wanted to voice my opinion.

Jeff

well guys I cant say that I agree. Yes similar things have been attempted and abandoned before, however if others don't revisit those attempts then we may be missing out on a breakthrough!

Didn't Werner already prove that by perfecting the magnet u joints? Werent those tried (and failed?) by someone else before? I really don't like when people are quick to dispel things so easily because something similar has been tried before.

I like his proof of concept, and there are more ways to perfect something than has already been attempted. Im glad he shared that with us - weather it works or not, its a different way of looking at it. Thats why the RepRap scene keeps evolving - thinking outside of the box! Otherwise wed all have Makerbot Cupcakes!

If anyone can make it work I think Werner has a good shot at it!

Sorry for the rant - just wanted to voice my opinion.

Jeff

|

Re: VIDEO POSTED! Details about the BerryBot3D August 05, 2013 12:27PM |

Registered: 13 years ago Posts: 1,797 |

I think your getting it wrong, I like the fact that Werner is trying this, I'm just showing him the reasoning behind its failure, and a method to improve it. such as using larger stepper motor. Also by providing past work he does not need to reinvent it all over.

I believe nophead is doing the same by providing links to his research.

Edited 2 time(s). Last edit at 08/05/2013 12:30PM by jamesdanielv.

I believe nophead is doing the same by providing links to his research.

Edited 2 time(s). Last edit at 08/05/2013 12:30PM by jamesdanielv.

|

Re: VIDEO POSTED! Details about the BerryBot3D August 05, 2013 02:50PM |

Registered: 14 years ago Posts: 142 |

jamesdanielv Wrote:

-------------------------------------------------------

> I think your getting it wrong, I like the fact

> that Werner is trying this, I'm just showing him

> the reasoning behind its failure, and a method to

> improve it. such as using larger stepper motor.

> Also by providing past work he does not need to

> reinvent it all over.

>

> I believe nophead is doing the same by providing

> links to his research.

+1 Agreed. Its always worth understanding what was done before in order to focus efforts on trying to overcome those issues rather than encountering the same issues.

-------------------------------------------------------

> I think your getting it wrong, I like the fact

> that Werner is trying this, I'm just showing him

> the reasoning behind its failure, and a method to

> improve it. such as using larger stepper motor.

> Also by providing past work he does not need to

> reinvent it all over.

>

> I believe nophead is doing the same by providing

> links to his research.

+1 Agreed. Its always worth understanding what was done before in order to focus efforts on trying to overcome those issues rather than encountering the same issues.

|

Re: VIDEO POSTED! Details about the BerryBot3D August 05, 2013 03:32PM |

Registered: 11 years ago Posts: 83 |

Hi Guys, this is all good! This is still an original idea at least for me… Haha. I had never seen those designs that you mentioned not surprising though, I am glad you shared them with me. Like Jeff was alluding to, I think you will find what I am talking about to be quite different. The total size of mine design is about 1/10 the size and weight of the one you show. Looking at what the other Guys have done never would have even occurred to me. I just see too much parasitic drag in a design like that. I am working on some other really fun stuff at the moment but when I get time I will show you more of what I was talking about.

Happy printing!

Werner

Happy printing!

Werner

|

Re: VIDEO POSTED! Details about the BerryBot3D August 06, 2013 01:12AM |

Registered: 15 years ago Posts: 2 |

BerryBot3D Wrote:

-------------------------------------------------------

>I am working on some other really fun stuff at the moment...

Stuff having to do with that huge nose cone and those fins you've printed? Just what corner of the web has your postings discussing that "little" play project of yours, Werner? You're not just trying to leap frog all those silly "Look ma, I just 3D printed me a real live gun!" stories, are you? :-)

Mike

-------------------------------------------------------

>I am working on some other really fun stuff at the moment...

Stuff having to do with that huge nose cone and those fins you've printed? Just what corner of the web has your postings discussing that "little" play project of yours, Werner? You're not just trying to leap frog all those silly "Look ma, I just 3D printed me a real live gun!" stories, are you? :-)

Mike

|

Re: VIDEO POSTED! Details about the BerryBot3D August 06, 2013 09:12PM |

Registered: 11 years ago Posts: 205 |

|

Re: VIDEO POSTED! Details about the BerryBot3D August 10, 2013 06:16PM |

|

Re: VIDEO POSTED! Details about the BerryBot3D August 10, 2013 07:40PM |

Registered: 13 years ago Posts: 1,797 |

-edit- off the current direction of topic. sorry.

there is a simplicity here. it may not be perfect but the magnetic attraction alleviates the effects of wear and backlash. I want to be neutral here but must say that this magnetic solution solves a lot of mechanical issues with precision yet allows the play needed for a machine to have speed and not bind up. I would tend to think that any magnet solution that eliminates force in all directions but in the direction of motion required would work well, up till the point of failure. In Berrybots performance and videos. i would say the magnetic solution suffice.

Edited 2 time(s). Last edit at 08/10/2013 07:43PM by jamesdanielv.

there is a simplicity here. it may not be perfect but the magnetic attraction alleviates the effects of wear and backlash. I want to be neutral here but must say that this magnetic solution solves a lot of mechanical issues with precision yet allows the play needed for a machine to have speed and not bind up. I would tend to think that any magnet solution that eliminates force in all directions but in the direction of motion required would work well, up till the point of failure. In Berrybots performance and videos. i would say the magnetic solution suffice.

Edited 2 time(s). Last edit at 08/10/2013 07:43PM by jamesdanielv.

|

Re: VIDEO POSTED! Details about the BerryBot3D August 11, 2013 04:30AM |

Registered: 12 years ago Posts: 1,450 |

Sorry, only registered users may post in this forum.