Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 12, 2013 07:52PM |

Registered: 12 years ago Posts: 313 |

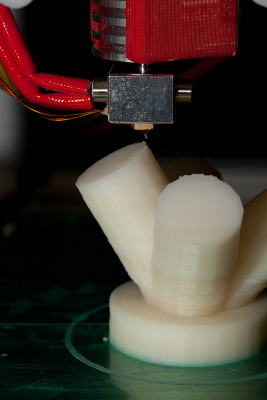

Got it in the mail already and printed a thing. This is an overhang test piece with cylinders tilted at 30, 40, 50 and 60 degrees, which my Arcol V4 failed to previously print from same plastic with same settings (due to massive curling up). Orbi-Tech ABS at 260 C (that ABS doesn't really seem happy at anything less than that)

First impressions:

+ Accurate output, no visible blobbing at perimeter breaks at all, with 0.8 mm retraction

- Over 20 mm longer than the Arcol V4 or the J-Head Mk-V

+ Low oozing tendency

+ Heats up crazy fast - considerably faster than a J-Head with 5.6 ohm heater resistor

+- Mounts in uniX-Carrier with tens of microns to spare , without modifying anything

, without modifying anything

First impressions:

+ Accurate output, no visible blobbing at perimeter breaks at all, with 0.8 mm retraction

- Over 20 mm longer than the Arcol V4 or the J-Head Mk-V

+ Low oozing tendency

+ Heats up crazy fast - considerably faster than a J-Head with 5.6 ohm heater resistor

+- Mounts in uniX-Carrier with tens of microns to spare

, without modifying anything

, without modifying anything

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 12, 2013 07:58PM |

Registered: 11 years ago Posts: 137 |

Mine is already in usps custody. I should have it Saturday or Monday. I bought some nylon, I will post my results when my new hotend arrives.

I'm glad to hear that it has a low ooze tenancy. My current J-head leaves artifacts all over from oozing while moving to another part and leaving a glob on the outside. This usually forces me to print 1 part at a time instead of filling my print bed.

I'm glad to hear that it has a low ooze tenancy. My current J-head leaves artifacts all over from oozing while moving to another part and leaving a glob on the outside. This usually forces me to print 1 part at a time instead of filling my print bed.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 13, 2013 02:55PM |

Registered: 12 years ago Posts: 177 |

ttsalo:

Awesome photo! Glad you have it printing nicely. The lack of blobbing is a big plus factor that people don't consider when buying a hotend. We put a lot of time into making flow controllable and precise by engineering the nozzle orifice carefully and creating a super sharp thermal break that locks the location of the melt point.

Awesome photo! Glad you have it printing nicely. The lack of blobbing is a big plus factor that people don't consider when buying a hotend. We put a lot of time into making flow controllable and precise by engineering the nozzle orifice carefully and creating a super sharp thermal break that locks the location of the melt point.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 13, 2013 08:42PM |

Registered: 11 years ago Posts: 67 |

I love the idea behind the sharp thermal break, with steady state boundary conditions (the heat sink at X temp and the nozzle at Y temp), allowing a consistent and controlled temp gradient and melt zone length. The one thing that I'm not necessarily the most stoked about, or rather that I have questions about and would love to hear some conversation on, is that the melt zone length is pre-determined, and it is whatever it is. With this hot end, you can't lengthen the melt zone if desired (or can you slide the heat sink upwards if you wanted to?). I've skimmed the Stratasys patents regarding nozzle design and melt zone length, but I'll have to go back and read them in depth to get a better grasp on the idiosyncrasies of melt zone length.

Is a short melt zone ALWAYS desired? Will there be any issues with the short melt zone when a relatively high extrusion rate is desired? Do different materials perform better with different melt zone lengths?

I know some of those thoughts might lead towards ideals that aren't very practicable (and this nozzle might be the best we can practically get), but I'd love to hear some technical discussion on it either way.

Is a short melt zone ALWAYS desired? Will there be any issues with the short melt zone when a relatively high extrusion rate is desired? Do different materials perform better with different melt zone lengths?

I know some of those thoughts might lead towards ideals that aren't very practicable (and this nozzle might be the best we can practically get), but I'd love to hear some technical discussion on it either way.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 13, 2013 08:44PM |

Registered: 11 years ago Posts: 67 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 13, 2013 09:20PM |

Registered: 12 years ago Posts: 177 |

I would be adverse to allowing the melt zone up past the thermal break. The junction between the sink and the break is not smooth and filament in a soft state will deform into the seam and jam. This is not a hypothesis but something I have investigated and experienced. The only viable way I can see to maintain both a sharp thermal transition and a longer melt zone (higher melt rate) is to elongate the nozzle. We are in talks with some notable people about producing custom hot ends that have a melt rate and nozzle geometry that matches their application.

Having a Sharp thermal transition and having a variable length melt zone dependant on cooling are properties that seem mutually exclusive unless you are able to use some sort of linear actuator to physically move the heatsink. Even then this would be really sub optimal.

We will be producing a range of nozzles for retrofit that provide different orifice diameters as well as varying melt zone lengths. This should allow people to configure their hotend to meet their specific needs.

Some people seem to be conflating a short TRANSITION ZONE with a short MELT ZONE. They are not the same thing.

The e3d v4 has a very short transition zone but a fairly medium to long melt zone.

A short transition zone is always desirable in our research. The part that needs adjustment to suit the particular needs of the application is the length of the melt zone which dictates the maximum extrusion rate at the cost of ooze and precision.

I will post more info on this when it is not 2am in the morning and I can articulate what I mean more easily. Especially with regards to the stratasys information from their patent filings.

In brief:

Short thermal TRANSITION = GOOD

Length of MELT ZONE must be matched to user requirements.

Having a Sharp thermal transition and having a variable length melt zone dependant on cooling are properties that seem mutually exclusive unless you are able to use some sort of linear actuator to physically move the heatsink. Even then this would be really sub optimal.

We will be producing a range of nozzles for retrofit that provide different orifice diameters as well as varying melt zone lengths. This should allow people to configure their hotend to meet their specific needs.

Some people seem to be conflating a short TRANSITION ZONE with a short MELT ZONE. They are not the same thing.

The e3d v4 has a very short transition zone but a fairly medium to long melt zone.

A short transition zone is always desirable in our research. The part that needs adjustment to suit the particular needs of the application is the length of the melt zone which dictates the maximum extrusion rate at the cost of ooze and precision.

I will post more info on this when it is not 2am in the morning and I can articulate what I mean more easily. Especially with regards to the stratasys information from their patent filings.

In brief:

Short thermal TRANSITION = GOOD

Length of MELT ZONE must be matched to user requirements.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 13, 2013 09:40PM |

Registered: 11 years ago Posts: 67 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 15, 2013 01:12AM |

Registered: 11 years ago Posts: 21 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 15, 2013 09:35AM |

Registered: 12 years ago Posts: 40 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 15, 2013 02:33PM |

Registered: 11 years ago Posts: 47 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 15, 2013 05:42PM |

Registered: 12 years ago Posts: 177 |

Hi all,

So we are working as fast as possible to restock. We have now very nearly sold out of all versions/sizes.

We are looking at around a 2-3 week time to more coming in. We have ordered larger batches this time around. We are also much more geared up and have systems in place that make packing and shipping vastly quicker compared to our first batch where we were just finding our way.

We are a little swamped with orders, enquiries from customers, and the logistics of getting the next batch in and away ASAP. We are doing this all on top of full time teaching jobs, and we really have to be careful that we aren't neglecting our jobs for this - teaching kids engineering is what we do and it's important to us that it is done right.

To anyone who has sent an email or enquiry - we are working flat out 8am to 10pm answering everyone. Every order and question is important to us, you will be answered.

We are in the final development stages of a fully integrated bowden system that couples the tubing to the top of the hotend using a really nice Delrin (POM) push fit coupler. We will be selling an optional upgrade that adds 2 couplers (one for each end) and a metre of tubing that is appropriately sized for your chosen filament diameter. We should be able to get some really awesome PFA tubing that has better mechanical properties for a bowden system than PTFE. PFA is the stuff used by ultimaker on their bowden systems.

I am so happy to see others getting these running on their machines and being happy with the results. Would love to hear feedback from people and their impressions. Maybe prizes/upgrades for the best showoffs?

Anyway - back to answering emails!

Sanjay

So we are working as fast as possible to restock. We have now very nearly sold out of all versions/sizes.

We are looking at around a 2-3 week time to more coming in. We have ordered larger batches this time around. We are also much more geared up and have systems in place that make packing and shipping vastly quicker compared to our first batch where we were just finding our way.

We are a little swamped with orders, enquiries from customers, and the logistics of getting the next batch in and away ASAP. We are doing this all on top of full time teaching jobs, and we really have to be careful that we aren't neglecting our jobs for this - teaching kids engineering is what we do and it's important to us that it is done right.

To anyone who has sent an email or enquiry - we are working flat out 8am to 10pm answering everyone. Every order and question is important to us, you will be answered.

We are in the final development stages of a fully integrated bowden system that couples the tubing to the top of the hotend using a really nice Delrin (POM) push fit coupler. We will be selling an optional upgrade that adds 2 couplers (one for each end) and a metre of tubing that is appropriately sized for your chosen filament diameter. We should be able to get some really awesome PFA tubing that has better mechanical properties for a bowden system than PTFE. PFA is the stuff used by ultimaker on their bowden systems.

I am so happy to see others getting these running on their machines and being happy with the results. Would love to hear feedback from people and their impressions. Maybe prizes/upgrades for the best showoffs?

Anyway - back to answering emails!

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 15, 2013 07:26PM |

Registered: 11 years ago Posts: 137 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 16, 2013 11:37AM |

Registered: 11 years ago Posts: 47 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 16, 2013 07:04PM |

Registered: 12 years ago Posts: 313 |

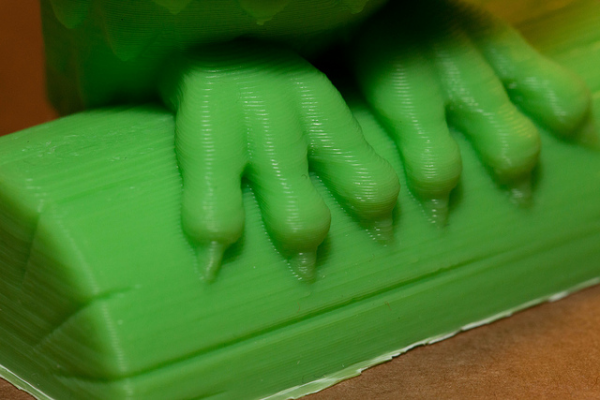

Printing 0.3 layers, 0.6 track width at 75 mm/s worked without any problems. That's the highest flow I use with 0.35 or 0.4 nozzles and there were no hiccups at all. Impressive.

Here's a closeup of the owl statue printed with 0.2 layers at 66% size (99 mm tall):

The side of the log looks a bit uneven, but I think the inconsistency of the filament is to blame.

And here's something interesting, printing side-inserting T-nuts for MendelMax from polycarbonate:

Polycarbonate printing

And yes, they seem work.

Edited 1 time(s). Last edit at 04/16/2013 07:06PM by ttsalo.

Here's a closeup of the owl statue printed with 0.2 layers at 66% size (99 mm tall):

The side of the log looks a bit uneven, but I think the inconsistency of the filament is to blame.

And here's something interesting, printing side-inserting T-nuts for MendelMax from polycarbonate:

Polycarbonate printing

And yes, they seem work.

Edited 1 time(s). Last edit at 04/16/2013 07:06PM by ttsalo.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 17, 2013 01:28PM |

Registered: 11 years ago Posts: 137 |

/offtopic and a rant.

I am so dissapointed in USPS. I checked the tracking on the UK side and it went from e3d to Chicago Illinois in 2 days. It spent 3 days in customs and left Chicago on Sunday. Its now Wednesday and its looking like I will receive it tomorrow.

So total times in shipping.

2 days from e3d to USA

3 days in customs

4 days from Chicago to near Springfield Illinois

So it takes 2x as long to get my package from Chicago Illinois to near Springfield Illinois(250miles) than it does from e3d to the USA(3500miles). The UK postal system is making the US postal system look like crap.

USPS sux.

I am so dissapointed in USPS. I checked the tracking on the UK side and it went from e3d to Chicago Illinois in 2 days. It spent 3 days in customs and left Chicago on Sunday. Its now Wednesday and its looking like I will receive it tomorrow.

So total times in shipping.

2 days from e3d to USA

3 days in customs

4 days from Chicago to near Springfield Illinois

So it takes 2x as long to get my package from Chicago Illinois to near Springfield Illinois(250miles) than it does from e3d to the USA(3500miles). The UK postal system is making the US postal system look like crap.

USPS sux.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 17, 2013 04:27PM |

Registered: 12 years ago Posts: 177 |

Hendo420

Yeah, it's really mystifying what goes on once packages hit the US border. USPS don't bother to update the tracking info at all in some cases once it gets to them, and they can take 5 or so days to get a package to even the most well infrastructured places.

Shipping to INDIA is quicker, and India Post is a totally corrupt mess of an organisation. Shipping to Europe takes 72 hours in most cases.

If anyone can suggest a better way I'm all ears.

Yeah, it's really mystifying what goes on once packages hit the US border. USPS don't bother to update the tracking info at all in some cases once it gets to them, and they can take 5 or so days to get a package to even the most well infrastructured places.

Shipping to INDIA is quicker, and India Post is a totally corrupt mess of an organisation. Shipping to Europe takes 72 hours in most cases.

If anyone can suggest a better way I'm all ears.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 17, 2013 08:17PM |

Registered: 11 years ago Posts: 137 |

I wish I had done an unboxing video but I was too excited to get it installed.

The hotend looks and works great. My first print with it is looking awesome.

I cranked it up to 260(the limit set in my firmware) and the fins weren't even warm. It also heated up very fast. Room temp to 250c took under a minute. My old hotend wouldn't even get over 225c let alone doing it in a minute. I'm very impressed so far. I was reluctant to cement the thermister in place so I'm using a liberal amount of kapton tape, its not pretty but it does the job. The only thing that was holding me back on speed was my old J-head losing heat during fast infil. Nothing like going from 220 all the way down to 180 during infil. I will have to do some speed tests and let you know how it goes.

I now have a job ahead of me, I have never modified the firmware on this machine. I'm going to try to find some guides and just get it done.

If anyone knows of a good guide on downloading, modifying, and reuploading marlin firmware let me know.

The hotend looks and works great. My first print with it is looking awesome.

I cranked it up to 260(the limit set in my firmware) and the fins weren't even warm. It also heated up very fast. Room temp to 250c took under a minute. My old hotend wouldn't even get over 225c let alone doing it in a minute. I'm very impressed so far. I was reluctant to cement the thermister in place so I'm using a liberal amount of kapton tape, its not pretty but it does the job. The only thing that was holding me back on speed was my old J-head losing heat during fast infil. Nothing like going from 220 all the way down to 180 during infil. I will have to do some speed tests and let you know how it goes.

I now have a job ahead of me, I have never modified the firmware on this machine. I'm going to try to find some guides and just get it done.

If anyone knows of a good guide on downloading, modifying, and reuploading marlin firmware let me know.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 17, 2013 09:07PM |

Registered: 11 years ago Posts: 137 |

Ok, just ran into my first hiccup.

Its jamming 30 mins into the print. I think I found out how its jamming, it feels like there is a ledge in the hotend. When I push the filament in it hits a spot that I have to fiddle with it for a min to get it to go all the way to the bottom. I think its retracting and getting caught on that. I'm going to test this by disabling retraction, not a perm fix but I hope it will stop it for now.

Ok, 0.4 retraction seems to not jam, still experimenting. I just took it down to try to update the firmware. Wish me luck.

Firmware modification complete and test print underway. I cranked the temp up to 300 and it got to about 287 and started smoking and smelling of burnt PLA so I cut the heat.

Test print is looking the right size so stock steps/min will work for now. After this test print its on to test some Nylon.

I'll post some pics in a bit.

This is the first test print with PLA.

[www.youtube.com]

I'm doing my first test print in Nylon. It steams alot but the print is looking ok.

Edited 3 time(s). Last edit at 04/18/2013 12:53AM by hendo420.

Its jamming 30 mins into the print. I think I found out how its jamming, it feels like there is a ledge in the hotend. When I push the filament in it hits a spot that I have to fiddle with it for a min to get it to go all the way to the bottom. I think its retracting and getting caught on that. I'm going to test this by disabling retraction, not a perm fix but I hope it will stop it for now.

Ok, 0.4 retraction seems to not jam, still experimenting. I just took it down to try to update the firmware. Wish me luck.

Firmware modification complete and test print underway. I cranked the temp up to 300 and it got to about 287 and started smoking and smelling of burnt PLA so I cut the heat.

Test print is looking the right size so stock steps/min will work for now. After this test print its on to test some Nylon.

I'll post some pics in a bit.

This is the first test print with PLA.

[www.youtube.com]

I'm doing my first test print in Nylon. It steams alot but the print is looking ok.

Edited 3 time(s). Last edit at 04/18/2013 12:53AM by hendo420.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 18, 2013 05:39PM |

Registered: 14 years ago Posts: 142 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 18, 2013 05:59PM |

Admin Registered: 15 years ago Posts: 1,470 |

I just got my E3D hot end yesterday, and got it all fit in my printer. It is a very tight fit in my carriage as I am using 10mm x rods with LM10UU's. I had to trim away some of the bearing holder to get it to fit. Got it PID-tuned and fed some plastic through by hand, all seems good. Tonight will be the first test print.

Just a couple small gripes right now:

1. The printed fan duct was cracked a bit, and cracked a bit more when I screwed the fan in. Not a big deal, I can print another.

2. The groove mount area does not match the drawing posted on the E3D website. Luckily I hadn't printed my new carriage designed around this hot end yet. It doesn't work with a standard wooden or aluminum groove mount plate, but does work by attaching it directly to a Wade extruder using m3 screws.

Just a couple small gripes right now:

1. The printed fan duct was cracked a bit, and cracked a bit more when I screwed the fan in. Not a big deal, I can print another.

2. The groove mount area does not match the drawing posted on the E3D website. Luckily I hadn't printed my new carriage designed around this hot end yet. It doesn't work with a standard wooden or aluminum groove mount plate, but does work by attaching it directly to a Wade extruder using m3 screws.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 18, 2013 07:06PM |

Registered: 12 years ago Posts: 177 |

Hendo420

Jamming seems odd, the internal profile should pass filament very smoothly along all areas. Where abouts along the hot-end is it sticking? We have tested super long retractions of 10mm, and everything in between as a torture test of sorts and all was flawless. My thoughts are that it could be a badly bulged piece of filament? What diameter filament are you running (True diameter measured with calipers)? Alternatively it could be some sort of machining burr that wasn't properly cleaned away that is catching. See if you can figure out if it is filament issue, or an internal error in our stuff. If it is something wrong on our end we will make it right.

For the nylon - this stuff suck moisture out of the air, when you print it that water becomes steam and gives you horrible bubbly inconsistent dribbly extrusion. Put it in the oven on low (<100C) for a few hours, and it prints beautifully.

Craig

Yep, we just jumped over to our new website and hosting system, its much much better than the old one, but still new - if you notice any mistakes let us know!

The DNS records are just changing and pinging around the internet to other servers, just refresh now, and it might well be up, if not its just a matter of waiting a little longer while the DNS servers propogate records.

Check back on e3d-online.com soon and it should go live soonish.

NewPerfection

Really sorry about the drawing mismatch, that is just something that we failed to update in the crazy rush of orders and shipping. Our bad. The drawings will be updated over the weekend, and we will also be releasing STEP/IGES/ParaSolid/Solidworks models too - all should pop up under the downloads section soon.

The ducts are annoying, we didn't have time to redesign and reprint hundreds of them before shipping. They are too delicate. You can find a replacement STL on thingiverse for your printing pleasure. Anyone who wants to make improvements to the duct should be able to use the solid models we release over the weekend. We will try and get a better duct sorted out as soon as possible, quite probably 618 nylon for flexibility and heat resistance. You could reprint the duct with the free nylon sample sent out with your order even - should solve the cracking issue.

The groovemount is a tricky beast, it is designed for PEEK. When going to harder aluminium you need to make some allowance for the fact that aluminium doesnt deform as easily. I had not truly considered plate-mounts in honesty. I am open to suggestions about how to make an aluminium groovemount that can be used in a wades with M3 screws, and in a plate mount. It seems to me these may be mutually exclusive in this case.

Perhaps we could go to an M16 male thread on the top of the hotend, which should screw right into a 16mm hole of a wades self tapping as it goes, and then have a fully compliant groovemount cut for plate mounting? Thoughts on this idea?

Hope you get it up and running just fine, and I will do whatever it takes to get you running - get in touch if you have any more queries.

Sanjay

Edited 4 time(s). Last edit at 04/18/2013 07:15PM by SanjayM.

Jamming seems odd, the internal profile should pass filament very smoothly along all areas. Where abouts along the hot-end is it sticking? We have tested super long retractions of 10mm, and everything in between as a torture test of sorts and all was flawless. My thoughts are that it could be a badly bulged piece of filament? What diameter filament are you running (True diameter measured with calipers)? Alternatively it could be some sort of machining burr that wasn't properly cleaned away that is catching. See if you can figure out if it is filament issue, or an internal error in our stuff. If it is something wrong on our end we will make it right.

For the nylon - this stuff suck moisture out of the air, when you print it that water becomes steam and gives you horrible bubbly inconsistent dribbly extrusion. Put it in the oven on low (<100C) for a few hours, and it prints beautifully.

Craig

Yep, we just jumped over to our new website and hosting system, its much much better than the old one, but still new - if you notice any mistakes let us know!

The DNS records are just changing and pinging around the internet to other servers, just refresh now, and it might well be up, if not its just a matter of waiting a little longer while the DNS servers propogate records.

Check back on e3d-online.com soon and it should go live soonish.

NewPerfection

Really sorry about the drawing mismatch, that is just something that we failed to update in the crazy rush of orders and shipping. Our bad. The drawings will be updated over the weekend, and we will also be releasing STEP/IGES/ParaSolid/Solidworks models too - all should pop up under the downloads section soon.

The ducts are annoying, we didn't have time to redesign and reprint hundreds of them before shipping. They are too delicate. You can find a replacement STL on thingiverse for your printing pleasure. Anyone who wants to make improvements to the duct should be able to use the solid models we release over the weekend. We will try and get a better duct sorted out as soon as possible, quite probably 618 nylon for flexibility and heat resistance. You could reprint the duct with the free nylon sample sent out with your order even - should solve the cracking issue.

The groovemount is a tricky beast, it is designed for PEEK. When going to harder aluminium you need to make some allowance for the fact that aluminium doesnt deform as easily. I had not truly considered plate-mounts in honesty. I am open to suggestions about how to make an aluminium groovemount that can be used in a wades with M3 screws, and in a plate mount. It seems to me these may be mutually exclusive in this case.

Perhaps we could go to an M16 male thread on the top of the hotend, which should screw right into a 16mm hole of a wades self tapping as it goes, and then have a fully compliant groovemount cut for plate mounting? Thoughts on this idea?

Hope you get it up and running just fine, and I will do whatever it takes to get you running - get in touch if you have any more queries.

Sanjay

Edited 4 time(s). Last edit at 04/18/2013 07:15PM by SanjayM.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 18, 2013 09:03PM |

Realy Nice work!

I Have redraw all your part except the heater block whit your drawing was not on the net But I kind of figure it out ;oP

I am learning Solidworks and have acces to an semi numeric Lathe. I will be Machining those part verry soon!

I was looking all around the net for the nicest Hot end for my (planing/building first 3d printer) I didnt like the J-head comment some love it some dont...

keep up the good work! And I am interested by all the Idea you sugest earlyer : 4 tip extruder, bowden set-up, witch I was planing to modify...

Have you tried to reduce the mass of the Heater bloc so less thermal inertia is afecting the aluminum heat shimk?

Did you run some Solidworks simulation?

Thank's again!

Frank_the_rock

p.s. btw your link to the heater bloc drawing is not working...

I Have redraw all your part except the heater block whit your drawing was not on the net But I kind of figure it out ;oP

I am learning Solidworks and have acces to an semi numeric Lathe. I will be Machining those part verry soon!

I was looking all around the net for the nicest Hot end for my (planing/building first 3d printer) I didnt like the J-head comment some love it some dont...

keep up the good work! And I am interested by all the Idea you sugest earlyer : 4 tip extruder, bowden set-up, witch I was planing to modify...

Have you tried to reduce the mass of the Heater bloc so less thermal inertia is afecting the aluminum heat shimk?

Did you run some Solidworks simulation?

Thank's again!

Frank_the_rock

p.s. btw your link to the heater bloc drawing is not working...

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 18, 2013 09:59PM |

Registered: 11 years ago Posts: 939 |

I just got mine, I'll assemble it over the weekend.

I live in the US and ordered one of the trinity labs metalmagma hotends a few days earlier, still no sign of that and no update from the seller.

Interested to see how they compare when I get them both running.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

I live in the US and ordered one of the trinity labs metalmagma hotends a few days earlier, still no sign of that and no update from the seller.

Interested to see how they compare when I get them both running.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 18, 2013 10:43PM |

Registered: 11 years ago Posts: 137 |

[www.thingiverse.com]

This is what I'm using to mount to my extruder. I just had to drill 2 holes and buy a few screws.

On a side note. I bought some nylon b4 this hotend even got here. I have been doing test prints. This Nylon filament is like trying to push wet spaghetti through a garden hose. It constantly wants to coil up instead of going into the hotend where it belongs. I have tried multiple ideas to fix the problem but still haven't found a good fix. Any ideas would help. lol

Also, what do you guys use to keep nylon from warping and coming off of the print bed? Heat doesn't seem to be enough or maybe I'm not getting it hot enough. right now I'm printing on blue painters tape on a pane of glass over a MK2 PCB heated bed. I heard I should try wood, I just haven't got to the hardware store to pick up a piece.

SanjayM

Its not the filament, it does it on everything I stick into the hotend. The "ledge" is almost all the way down a few mm from the nozzle, I have a feeling its the part that screws into the heatsink, I have it hand tight but I think that the tolerance might be off just a bit causing this "ledge"

This is what I'm using to mount to my extruder. I just had to drill 2 holes and buy a few screws.

On a side note. I bought some nylon b4 this hotend even got here. I have been doing test prints. This Nylon filament is like trying to push wet spaghetti through a garden hose. It constantly wants to coil up instead of going into the hotend where it belongs. I have tried multiple ideas to fix the problem but still haven't found a good fix. Any ideas would help. lol

Also, what do you guys use to keep nylon from warping and coming off of the print bed? Heat doesn't seem to be enough or maybe I'm not getting it hot enough. right now I'm printing on blue painters tape on a pane of glass over a MK2 PCB heated bed. I heard I should try wood, I just haven't got to the hardware store to pick up a piece.

SanjayM

Its not the filament, it does it on everything I stick into the hotend. The "ledge" is almost all the way down a few mm from the nozzle, I have a feeling its the part that screws into the heatsink, I have it hand tight but I think that the tolerance might be off just a bit causing this "ledge"

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 18, 2013 11:02PM |

Registered: 11 years ago Posts: 89 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 19, 2013 12:09AM |

Registered: 11 years ago Posts: 137 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 19, 2013 01:13PM |

Admin Registered: 11 years ago Posts: 3,096 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 19, 2013 01:40PM |

Registered: 11 years ago Posts: 6 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 19, 2013 06:17PM |

Registered: 12 years ago Posts: 177 |

Frank_The_Rock (And others wanting to see/use our drawings)

Sorry about the block link not working - we have just moved to an entirely new web-host and online selling platform, we might take a few days to iron out the kinks. I am afraid time sorting the tiny things like downloads has to come after shipping parts to people who has paid for products. I know this isn't perfect, but we are trying our best, working full time jobs, and spending until 11pm at night doing our E3D stuff!

Also be aware that some slight revisions have been made in between the drawings on the site and the shipped parts, mainly tiny bits like chamfer angles and clearance on the groovemount. We also have decided to change the licence to be fully open-source compliant (We were CC-NC-SA before, but going to CC-SA). The next batch we have ordered have thinned heatsink fins for less weight and better cooling too. Drawings will be coming as soon as possible - I promise.

We will be releasing solidworks files, IGES, STEP and ParaSolid files soon, so frank if you are using solidworks this might be of interest to you.

We did a bunch of really helpful simulations on solidworks, such as the mechanical strength of the break resisting rotational shear (Over-twisting), and plain orthogonal loads - these were quite accurate when empirically confirmed. Our thermal testing was less accurate, it seems solidworks cannot adequately simulate the thermal properties of an object experiencing conduction, radiation, and convection from a fan focussing on the heatsink, as well as convection experienced by movement of the head. We found our actual heat transfer to the heatsink was higher than simulated. However I am no solidworks simulation expert and there may be errors in my setup of simulation.

I don't quite understand your comment about heater-block thermal inertia. Having a larger or small heater block does not affect how much heat is transmitted to the heatsink, only the thermal break and convection affect this. In fact we find having a slightly larger thermal mass at the nozzle results in better, smoother temperatures due to the block storing heat during long fast extrusions and blasts of air from fans etc.

Polygonhell

Would be very interested to see comparisons, particularly with regards to extrusion force, precision of extrusion, and how much heat gets up the barrel when printing at 300C or so for Polycarbonate. I have chatted a tiny bit with one of the guys from TL and it seems like they have a well made product. Their design philosophy differs from ours, but different doesnt mean better or worse - I think in the future of RepRap it's going to be a matter of choosing a hotend with properties that suits your printer and your needs. Up to now we have had the concept of "Extruder X is better than Extruder Y", but now we are moving towards "If you want to do X choose Extruder 1, if you prefer Y then choose Extruder 2". I think this is progression, and a good thing.

Hendo420

Nylon was also a real pain when I started with it. But I have it sorted now. Two main factors:

1) Dry your filament, otherwise it comes out the nozzle foamy, inconsistent, stringy and drippy as the water in it boils and expands. I have a special plastics oven that I set to 60C and put the filament in for a few hours, results afterwards were like night and day. You can probably use an oven on very low, or an airing cupboard overnight or longer.

2) Use a Garolite/Tufnol-Whale print bed. Sticks like the proverbial, and you can flex a 2mm sheet of it in your hands to make the prints pop/peel off easily after printing.

That 'Ledge' issue is suspicious. It is something that we spent a long time optimising out with varying methods, it should be absolutely impossible to make filament catch or stick on its path to the hot-zone. Main culprit for this I can see is the break not screwed far into the heatsink enough - but fingertight is usually enough. Or maybe some sort of burr left from machining, or another machining error on our part. If you have a chance to take it apart and find out if it is something wrong on our end we will get it sorted for you free of charge. This 'catching' absolutely should not be happening.

Ohmarinus

We have a pre-order available, but DIY units only - assembly isnt terribly hard and you can read the assembly manual here: [www.scribd.com]

We expect to be shipping again in 3 weeks or so.

CozyGirrrl

Again sorry about the block drawing thing, we are sorting it asap.

The multi-head bowden thing is definitely in the pipeline. But first I need to do a few things on the way to that design -

First is a little optimisation of the current design to cut weight mainly. This is pretty much done, just testing samples from the manufacturer left to do.

Next is to get bowden integration completely sorted, I am 80% of the way there on this, I have samples of several types of fluoropolymer tubing, various push-fit couplers etc, just a little "putting together" needed. This development is also aimed at the ultimaker crowd, so they can start extruding cool plastics etc on their high speed bowden machines.

Once I have bowden fully sorted then it's on to finishing/prototyping the Quadstrusion concept. 4x because I am thinking of a use case for 3 colours + soluble support (R,G,B, PVA), or 4 colours (C,M,Y,K). Also 4 is a square number so easily arranged under a carriage. There remains a little work to be done on fitting 4 heater-blocks under a carriage while still being able to screw them in and tighten them up. As well as heatsinking+Cooling.

Cheers,

Sanjay

Sorry about the block link not working - we have just moved to an entirely new web-host and online selling platform, we might take a few days to iron out the kinks. I am afraid time sorting the tiny things like downloads has to come after shipping parts to people who has paid for products. I know this isn't perfect, but we are trying our best, working full time jobs, and spending until 11pm at night doing our E3D stuff!

Also be aware that some slight revisions have been made in between the drawings on the site and the shipped parts, mainly tiny bits like chamfer angles and clearance on the groovemount. We also have decided to change the licence to be fully open-source compliant (We were CC-NC-SA before, but going to CC-SA). The next batch we have ordered have thinned heatsink fins for less weight and better cooling too. Drawings will be coming as soon as possible - I promise.

We will be releasing solidworks files, IGES, STEP and ParaSolid files soon, so frank if you are using solidworks this might be of interest to you.

We did a bunch of really helpful simulations on solidworks, such as the mechanical strength of the break resisting rotational shear (Over-twisting), and plain orthogonal loads - these were quite accurate when empirically confirmed. Our thermal testing was less accurate, it seems solidworks cannot adequately simulate the thermal properties of an object experiencing conduction, radiation, and convection from a fan focussing on the heatsink, as well as convection experienced by movement of the head. We found our actual heat transfer to the heatsink was higher than simulated. However I am no solidworks simulation expert and there may be errors in my setup of simulation.

I don't quite understand your comment about heater-block thermal inertia. Having a larger or small heater block does not affect how much heat is transmitted to the heatsink, only the thermal break and convection affect this. In fact we find having a slightly larger thermal mass at the nozzle results in better, smoother temperatures due to the block storing heat during long fast extrusions and blasts of air from fans etc.

Polygonhell

Would be very interested to see comparisons, particularly with regards to extrusion force, precision of extrusion, and how much heat gets up the barrel when printing at 300C or so for Polycarbonate. I have chatted a tiny bit with one of the guys from TL and it seems like they have a well made product. Their design philosophy differs from ours, but different doesnt mean better or worse - I think in the future of RepRap it's going to be a matter of choosing a hotend with properties that suits your printer and your needs. Up to now we have had the concept of "Extruder X is better than Extruder Y", but now we are moving towards "If you want to do X choose Extruder 1, if you prefer Y then choose Extruder 2". I think this is progression, and a good thing.

Hendo420

Nylon was also a real pain when I started with it. But I have it sorted now. Two main factors:

1) Dry your filament, otherwise it comes out the nozzle foamy, inconsistent, stringy and drippy as the water in it boils and expands. I have a special plastics oven that I set to 60C and put the filament in for a few hours, results afterwards were like night and day. You can probably use an oven on very low, or an airing cupboard overnight or longer.

2) Use a Garolite/Tufnol-Whale print bed. Sticks like the proverbial, and you can flex a 2mm sheet of it in your hands to make the prints pop/peel off easily after printing.

That 'Ledge' issue is suspicious. It is something that we spent a long time optimising out with varying methods, it should be absolutely impossible to make filament catch or stick on its path to the hot-zone. Main culprit for this I can see is the break not screwed far into the heatsink enough - but fingertight is usually enough. Or maybe some sort of burr left from machining, or another machining error on our part. If you have a chance to take it apart and find out if it is something wrong on our end we will get it sorted for you free of charge. This 'catching' absolutely should not be happening.

Ohmarinus

We have a pre-order available, but DIY units only - assembly isnt terribly hard and you can read the assembly manual here: [www.scribd.com]

We expect to be shipping again in 3 weeks or so.

CozyGirrrl

Again sorry about the block drawing thing, we are sorting it asap.

The multi-head bowden thing is definitely in the pipeline. But first I need to do a few things on the way to that design -

First is a little optimisation of the current design to cut weight mainly. This is pretty much done, just testing samples from the manufacturer left to do.

Next is to get bowden integration completely sorted, I am 80% of the way there on this, I have samples of several types of fluoropolymer tubing, various push-fit couplers etc, just a little "putting together" needed. This development is also aimed at the ultimaker crowd, so they can start extruding cool plastics etc on their high speed bowden machines.

Once I have bowden fully sorted then it's on to finishing/prototyping the Quadstrusion concept. 4x because I am thinking of a use case for 3 colours + soluble support (R,G,B, PVA), or 4 colours (C,M,Y,K). Also 4 is a square number so easily arranged under a carriage. There remains a little work to be done on fitting 4 heater-blocks under a carriage while still being able to screw them in and tighten them up. As well as heatsinking+Cooling.

Cheers,

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 19, 2013 09:15PM |

Registered: 11 years ago Posts: 28 |

Thanks' Sanjay ALL your great work for you and your team its realy appreciated!

Keep up the good work its motivating!

Of course you gonna put time to your store its normal!

I am in a planing stage of my 3d printer and have much to do! Having no printer yet i might order a quadstrusion ;o)

Have you tried Sand blast whit Glass beed? it can probably create a bigger surface like those ceramic coating they put on electronic heat sink... just a thought..

For the heat bloc I think it was late when I wrote that lol : But I think your right the the thermal break must do the trick (your far more knowledgeable in that Mather ;o)

Cheer!

Frank_The_Rock

Keep up the good work its motivating!

Of course you gonna put time to your store its normal!

I am in a planing stage of my 3d printer and have much to do! Having no printer yet i might order a quadstrusion ;o)

Have you tried Sand blast whit Glass beed? it can probably create a bigger surface like those ceramic coating they put on electronic heat sink... just a thought..

For the heat bloc I think it was late when I wrote that lol : But I think your right the the thermal break must do the trick (your far more knowledgeable in that Mather ;o)

Cheer!

Frank_The_Rock

Sorry, only registered users may post in this forum.