Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 27, 2013 12:57PM |

Admin Registered: 17 years ago Posts: 7,879 |

I still don't see how a 4C swing makes any difference. The one on the right looks like it has gaps due to inconsistent feed, but if 4C is enough to stop it feeding it must be right on the edge. Why not just add 5C to the target temp?

Does the MetalMagma need a fan?

Edited 1 time(s). Last edit at 04/27/2013 04:54PM by nophead.

[www.hydraraptor.blogspot.com]

Does the MetalMagma need a fan?

Edited 1 time(s). Last edit at 04/27/2013 04:54PM by nophead.

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 27, 2013 01:14PM |

Registered: 11 years ago Posts: 939 |

The heater block is aluminum, and the thermistor is fairly close to the brass nozzle, FWIW my hotend runs with less than 1 degree variance.

My experience pushing filament through by hand is that it requires very high initial force to extrude, likely because with filament sitting in the Hotend there is a relatively long soft section of PLA, once the filament is moving, it extrudes vey easily, intermediate length retracts probaly mirror the condition.

The purple PLA I can't print requires a higher temperature than the ultimachine stuff and that probaly means a longer soft section, which results in the jam when it's presented with any significant back pressure.

What was odd to me was getting a jam with long retracts in ABS, that mechanism has to be different.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

My experience pushing filament through by hand is that it requires very high initial force to extrude, likely because with filament sitting in the Hotend there is a relatively long soft section of PLA, once the filament is moving, it extrudes vey easily, intermediate length retracts probaly mirror the condition.

The purple PLA I can't print requires a higher temperature than the ultimachine stuff and that probaly means a longer soft section, which results in the jam when it's presented with any significant back pressure.

What was odd to me was getting a jam with long retracts in ABS, that mechanism has to be different.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 27, 2013 02:37PM |

Registered: 11 years ago Posts: 137 |

When I pull out the filament after a jam it has a small plug at the end, maybe 2-3mm. When it jams usually any amount of force I put on the filament by hand wont make it extrude, 1 out of 10x I can give it a good push and it will start extruding again.

I tried 3 different colors of PLA yesterday testing for jams, the green had to get to 250 and would jam after the first or 2nd layer. The black prints well at 200 but jammed after about 30 layers. The red prints well at 180 but jams after about 30 or 40 layers. I need to experiment more but it seems the higher the temp the PLA the more often it jams. This is all at 0.4mm retract. I need to do more testing with retracts off. This is all while printing around 40mm/s - 60mm/s.

ABS seems to print fine at 0.4mm retract but I have to keep the speed above 40mm/s or it jams, so small layers are almost impossible because the part isn't cool enough by the time it does the next layer and just causes a mess.

Here is what the plug looks like after I pull the filament out after a jam.

Edited 3 time(s). Last edit at 04/27/2013 03:07PM by hendo420.

I tried 3 different colors of PLA yesterday testing for jams, the green had to get to 250 and would jam after the first or 2nd layer. The black prints well at 200 but jammed after about 30 layers. The red prints well at 180 but jams after about 30 or 40 layers. I need to experiment more but it seems the higher the temp the PLA the more often it jams. This is all at 0.4mm retract. I need to do more testing with retracts off. This is all while printing around 40mm/s - 60mm/s.

ABS seems to print fine at 0.4mm retract but I have to keep the speed above 40mm/s or it jams, so small layers are almost impossible because the part isn't cool enough by the time it does the next layer and just causes a mess.

Here is what the plug looks like after I pull the filament out after a jam.

Edited 3 time(s). Last edit at 04/27/2013 03:07PM by hendo420.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 27, 2013 05:52PM |

Registered: 11 years ago Posts: 939 |

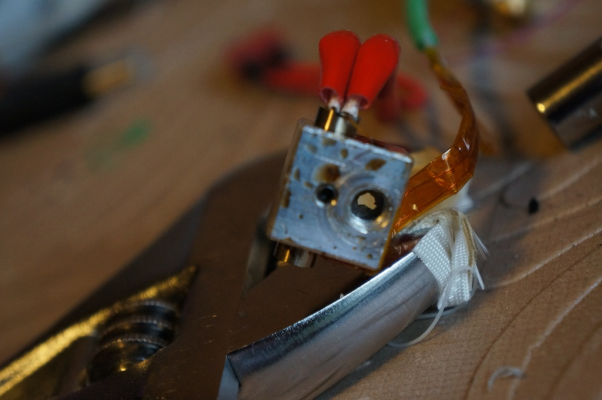

Took mine apart again, I still think at least part of the issue is the interface between the brass nozzle and the stainless thermal break.

When I put it together at 300C I really did torque down on the nozzle as much as feasible.

I ran the hot end up to 240 fed in some abs ans pulled it out before disassembly.

Taking it apart this time I didn't see any plastic on the nozzle or thermal break, but there was a nice ring of plastic at the interface as seen below.

I assume it's an M6 thread, I need to pick up a tap to clean the thread before I can reassemble.

At this point it's off my machine until I have some reason to believe it will work better.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

When I put it together at 300C I really did torque down on the nozzle as much as feasible.

I ran the hot end up to 240 fed in some abs ans pulled it out before disassembly.

Taking it apart this time I didn't see any plastic on the nozzle or thermal break, but there was a nice ring of plastic at the interface as seen below.

I assume it's an M6 thread, I need to pick up a tap to clean the thread before I can reassemble.

At this point it's off my machine until I have some reason to believe it will work better.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 27, 2013 07:36PM |

Admin Registered: 11 years ago Posts: 1,063 |

nophead Wrote:

-------------------------------------------------------

> I still don't see how a 4C swing makes any

> difference. The one on the right looks like it has

> gaps due to inconsistent feed, but if 4C is enough

> to stop it feeding it must be right on the edge.

> Why not just add 5C to the target temp?

>

> Does the MetalMagma need a fan?

because in a destabilised pid loop all you will get is fluctuation around the higher target temperatures, you'll still get a variable amount of back pressure provided by the plastic trying to give off it's usual gasses, bearing in mind the 4c swing is what your thermistor sees not nessarily what is going on inside the meltzone, which depending on thermistor location could be much higher or much lower,

-------------------------------------------------------

> I still don't see how a 4C swing makes any

> difference. The one on the right looks like it has

> gaps due to inconsistent feed, but if 4C is enough

> to stop it feeding it must be right on the edge.

> Why not just add 5C to the target temp?

>

> Does the MetalMagma need a fan?

because in a destabilised pid loop all you will get is fluctuation around the higher target temperatures, you'll still get a variable amount of back pressure provided by the plastic trying to give off it's usual gasses, bearing in mind the 4c swing is what your thermistor sees not nessarily what is going on inside the meltzone, which depending on thermistor location could be much higher or much lower,

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 28, 2013 05:09PM |

Just wanted to add, in between all reports on jams and temperature issues, that I am happily printing PLA with my 1.75 mm E3D-hotend at 185-190 C (supplied thermistor and table 1 in Marlin). Never had a jam and I have tried feed rates between 10-60 mm/s. My old extruder from mendel-parts required at least 230 C for the same PLA but also lots of current for the stepper to avoid stalling. With the E3D extruder I have turned the stepper current way down which also allowed micro-stepping to work properly.

PID regulation also works very well. During printing the temperature varies less than 1 degree C and the PWM value is very stable at 35-45% despite having an 80 mm fan at full power blowing indiscriminately at the printer.

My only problem right now is that I have more difficulty with overhangs curling up. I am guessing this is either related to having the heater block much closer to the nozzle (radiating heat at the freshly printed PLA), or to the flat shape of the E3D nozzle sticking to the still warm PLA (30 degree angle as compared to 45 degrees on the mendel-parts nozzle). I saw a drawing on the E3D site of a nozzle with 55 degree angle instead. Is this maybe a solution to the overhang issues? I would be interested in hearing others experience on this.

Overall, very happy and not switching back again (unless the heat-break breaks)!

PID regulation also works very well. During printing the temperature varies less than 1 degree C and the PWM value is very stable at 35-45% despite having an 80 mm fan at full power blowing indiscriminately at the printer.

My only problem right now is that I have more difficulty with overhangs curling up. I am guessing this is either related to having the heater block much closer to the nozzle (radiating heat at the freshly printed PLA), or to the flat shape of the E3D nozzle sticking to the still warm PLA (30 degree angle as compared to 45 degrees on the mendel-parts nozzle). I saw a drawing on the E3D site of a nozzle with 55 degree angle instead. Is this maybe a solution to the overhang issues? I would be interested in hearing others experience on this.

Overall, very happy and not switching back again (unless the heat-break breaks)!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 09:09AM |

Registered: 13 years ago Posts: 818 |

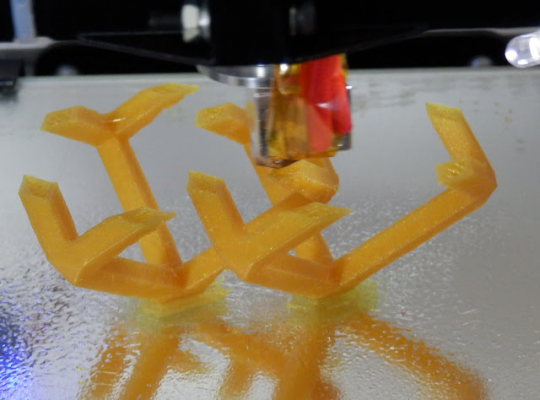

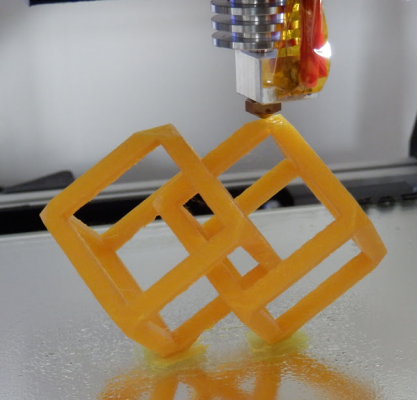

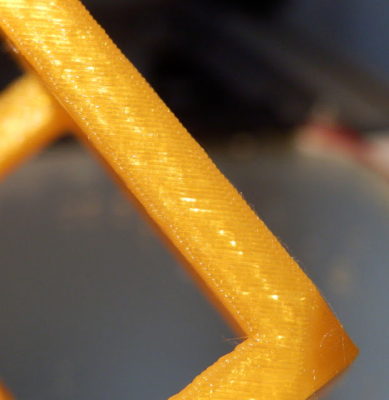

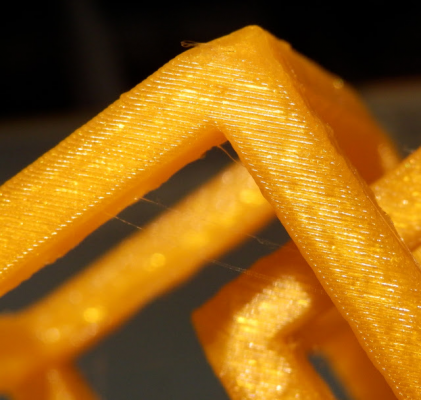

I'll add my week of testing to this thread -

I'm basically running it in exactly the same way as a J-head MKV - It can deal with a little less extruder reversal for PLA and ABS - I'm still tuning it for Nylon.

I have ran it as 15mm/sec to 80mm/sec with PLA, and with 0.5mm to 2.5mm retraction no issues at all.

I'm using exactly the same Temperature settings as the J-head, but it does seem to give sharp and crisp results with about +5 Degrees C more heat.

For me it performs really well for PLA and ABS - I'll be trying PC later this week.

But I have tried all week, and have not yet found a goon combination of settings for Nylon 618 or 645 - It's not performing like a J-head for Nylon - Anyone got any tips? or is anyone printing well with Nylon - The prints below are straight off the printer in PLA - I can get similar results to this in Nylon using a J-head, but not quite yet with the E3D.

I'm also going to say this hot-end is giving the sharpest prints and definition I have ever seen my worn out MendelMax Black print - Ever.

25% line infill - Bi Cube model 100% size

0.25mm Layers

65mm/sec infill speed

60mm/sec perimeter

2.5mm extruder retraction - Purposely using a long retraction on this model - normally 1.5mm is fine.

15 seconds minimum layer time - (needs to be a bit longer really - some curling)

Using the E3D Nozzle - 0.4mm / Stainless Steel

Gold PLA 1.75mm - 190 Degrees C

Small fan cooling the print - single object printed.

Two perimeters.

All images straight off the printer, not touched at all - (as they are for the competition going on Here)

Heated (64 Deg C) Mirror-Glass bed with Hairspray layer

Brim to aid sticking to Heated Bed.

Some very fine hairs and curling up on the side that was not cooled - only using one small fan - really must print and mount a nozzle ducted fan guide for PLA printing at some point soon. - Really liking this Ultimaker one from Owen - Anyone using anything similar on a RepRap?

[richrap.blogspot.com]

I'm basically running it in exactly the same way as a J-head MKV - It can deal with a little less extruder reversal for PLA and ABS - I'm still tuning it for Nylon.

I have ran it as 15mm/sec to 80mm/sec with PLA, and with 0.5mm to 2.5mm retraction no issues at all.

I'm using exactly the same Temperature settings as the J-head, but it does seem to give sharp and crisp results with about +5 Degrees C more heat.

For me it performs really well for PLA and ABS - I'll be trying PC later this week.

But I have tried all week, and have not yet found a goon combination of settings for Nylon 618 or 645 - It's not performing like a J-head for Nylon - Anyone got any tips? or is anyone printing well with Nylon - The prints below are straight off the printer in PLA - I can get similar results to this in Nylon using a J-head, but not quite yet with the E3D.

I'm also going to say this hot-end is giving the sharpest prints and definition I have ever seen my worn out MendelMax Black print - Ever.

25% line infill - Bi Cube model 100% size

0.25mm Layers

65mm/sec infill speed

60mm/sec perimeter

2.5mm extruder retraction - Purposely using a long retraction on this model - normally 1.5mm is fine.

15 seconds minimum layer time - (needs to be a bit longer really - some curling)

Using the E3D Nozzle - 0.4mm / Stainless Steel

Gold PLA 1.75mm - 190 Degrees C

Small fan cooling the print - single object printed.

Two perimeters.

All images straight off the printer, not touched at all - (as they are for the competition going on Here)

Heated (64 Deg C) Mirror-Glass bed with Hairspray layer

Brim to aid sticking to Heated Bed.

Some very fine hairs and curling up on the side that was not cooled - only using one small fan - really must print and mount a nozzle ducted fan guide for PLA printing at some point soon. - Really liking this Ultimaker one from Owen - Anyone using anything similar on a RepRap?

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 11:09AM |

Registered: 11 years ago Posts: 11 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 11:21AM |

Registered: 13 years ago Posts: 818 |

cambo3d Wrote:

-------------------------------------------------------

> but you guys aren't using a bowden setup like

> polygonhell and some others.

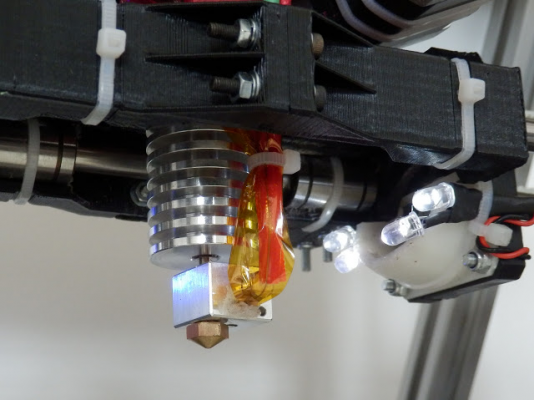

Yes, using both Bowden on a Rostock and Greg's Geared on a MendelMax

Main difference is that I'm not using the E3D fan and mount - just a normal 40mm carriage fan mounted on my Quick-Fir X carriage - use that for all extruders.

And on Rostock a similar arangement with a 40mm fan pointing 30 degrees up across the fins.

[richrap.blogspot.com]

-------------------------------------------------------

> but you guys aren't using a bowden setup like

> polygonhell and some others.

Yes, using both Bowden on a Rostock and Greg's Geared on a MendelMax

Main difference is that I'm not using the E3D fan and mount - just a normal 40mm carriage fan mounted on my Quick-Fir X carriage - use that for all extruders.

And on Rostock a similar arangement with a 40mm fan pointing 30 degrees up across the fins.

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 11:26AM |

Admin Registered: 15 years ago Posts: 1,470 |

I've printed the Bi-Cube in nylon with my E3D hot end. It turned out quite nice other than the first few layers - which was because my nylon print surface wasn't flat. See: [forums.reprap.org]

I used 4mm of retraction without issue.

I used 4mm of retraction without issue.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 12:02PM |

Registered: 13 years ago Posts: 818 |

Nice Print Cameron, Thanks - I'll try a few more and slow down with settings similar to yours, I was going about 2x that speed, maybe that's the issue.

[richrap.blogspot.com]

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 12:09PM |

Registered: 11 years ago Posts: 67 |

richrap Wrote:>

> [2.bp.blogspot.com]

> AAAAAAAACz0/CiWi9xPHvHk/s640/E3D_Hotend_and_PRUSA_

> nozzle.jpg

>

With you having experience with both the E3 and the Prusa stainless hotends, any quick words on how they compare?

> [2.bp.blogspot.com]

> AAAAAAAACz0/CiWi9xPHvHk/s640/E3D_Hotend_and_PRUSA_

> nozzle.jpg

>

With you having experience with both the E3 and the Prusa stainless hotends, any quick words on how they compare?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 12:26PM |

Registered: 11 years ago Posts: 973 |

maddox Wrote:

-------------------------------------------------------

> richrap Wrote:>

> >

> [2.bp.blogspot.com]

>

> >

> AAAAAAAACz0/CiWi9xPHvHk/s640/E3D_Hotend_and_PRUSA_

>

> > nozzle.jpg

> >

>

> With you having experience with both the E3 and

> the Prusa stainless hotends, any quick words on

> how they compare?

I second that.

-------------------------------------------------------

> richrap Wrote:>

> >

> [2.bp.blogspot.com]

>

> >

> AAAAAAAACz0/CiWi9xPHvHk/s640/E3D_Hotend_and_PRUSA_

>

> > nozzle.jpg

> >

>

> With you having experience with both the E3 and

> the Prusa stainless hotends, any quick words on

> how they compare?

I second that.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 03:30PM |

Registered: 13 years ago Posts: 818 |

maddox Wrote:

-------------------------------------------------------

> With you having experience with both the E3 and

> the Prusa stainless hotends, any quick words on

> how they compare?

I'm going to be doing a full review for Issue 3 of the RepRap Magazine, so watch out for that (after we all get Issue 2 finished that is!)

But since you asked and I did post that photo...

Prusa Nozzle -

Josef is still tweaking the Prusa Nozzle so it's not totally finished yet, but it's the Hot end with the fastest print capability at the moment, in fact it likes to go fast and hot, not quite as easy to use it going very slowly at the moment, but Josef's modifications will make this aspect better.

E3D -

It's the most accurate and controlled nozzle I have ever used (so far) - for PLA and ABS - I'm still working out how best to use it with Nylon, but It's getting there - as I type this the E3D nozzle is producing a 'good' Nylon print, much better slowing down.

In short I really like them both, but for different reasons (and also my Trusty bank of J-heads) that's why I have them all on Quick-fit Extruder mounts so I can swap them easily

I have more Hot-ends to test and more seem to be released each day, and I would really like to test the MetalMagma out for size.

Cheers,

Rich.

[richrap.blogspot.com]

-------------------------------------------------------

> With you having experience with both the E3 and

> the Prusa stainless hotends, any quick words on

> how they compare?

I'm going to be doing a full review for Issue 3 of the RepRap Magazine, so watch out for that (after we all get Issue 2 finished that is!)

But since you asked and I did post that photo...

Prusa Nozzle -

Josef is still tweaking the Prusa Nozzle so it's not totally finished yet, but it's the Hot end with the fastest print capability at the moment, in fact it likes to go fast and hot, not quite as easy to use it going very slowly at the moment, but Josef's modifications will make this aspect better.

E3D -

It's the most accurate and controlled nozzle I have ever used (so far) - for PLA and ABS - I'm still working out how best to use it with Nylon, but It's getting there - as I type this the E3D nozzle is producing a 'good' Nylon print, much better slowing down.

In short I really like them both, but for different reasons (and also my Trusty bank of J-heads) that's why I have them all on Quick-fit Extruder mounts so I can swap them easily

I have more Hot-ends to test and more seem to be released each day, and I would really like to test the MetalMagma out for size.

Cheers,

Rich.

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 29, 2013 08:45PM |

Registered: 11 years ago Posts: 67 |

richrap Wrote:

-------------------------------------------------------

> maddox Wrote:

> --------------------------------------------------

> -----

> > With you having experience with both the E3 and

> > the Prusa stainless hotends, any quick words on

> > how they compare?

>

> I'm going to be doing a full review for Issue 3 of

> the RepRap Magazine, so watch out for that (after

> we all get Issue 2 finished that is!)

>

Nice, thanks for the comparison. When can we expect Issue 3 with the comparison? Also, in the comparison, is the SG2 (or the watercooled Europa) in the group?

-------------------------------------------------------

> maddox Wrote:

> --------------------------------------------------

> -----

> > With you having experience with both the E3 and

> > the Prusa stainless hotends, any quick words on

> > how they compare?

>

> I'm going to be doing a full review for Issue 3 of

> the RepRap Magazine, so watch out for that (after

> we all get Issue 2 finished that is!)

>

Nice, thanks for the comparison. When can we expect Issue 3 with the comparison? Also, in the comparison, is the SG2 (or the watercooled Europa) in the group?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 30, 2013 03:05AM |

Admin Registered: 11 years ago Posts: 1,063 |

richrap: bear in mind there will be a difference between 3mm and 1.75mm hotend performances, are you planning on reviewing both sizes?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 30, 2013 04:42AM |

Registered: 13 years ago Posts: 818 |

thejollygrimreaper Wrote:

-------------------------------------------------------

> richrap: bear in mind there will be a difference

> between 3mm and 1.75mm hotend performances, are

> you planning on reviewing both sizes?

Where available and possible to get hold of (for example the Prusa nozzle is only 3mm), I can't look at every single type as it would cost me a fortune, but I'm doing my best to cover as many aspects as possible with the ones I can get, I'm sure people will have many comments but it's a starting point for discussion about different hot-ends for different uses and what people want to do with them.

[richrap.blogspot.com]

-------------------------------------------------------

> richrap: bear in mind there will be a difference

> between 3mm and 1.75mm hotend performances, are

> you planning on reviewing both sizes?

Where available and possible to get hold of (for example the Prusa nozzle is only 3mm), I can't look at every single type as it would cost me a fortune, but I'm doing my best to cover as many aspects as possible with the ones I can get, I'm sure people will have many comments but it's a starting point for discussion about different hot-ends for different uses and what people want to do with them.

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 30, 2013 11:58AM |

Registered: 12 years ago Posts: 177 |

So!

Apologies for my recent lack of replies and so on, I have been working completely flat out trying to work out what these issues that PolygonHell and Hendo420 are finding.

My current conclusion/thinking is:

There is some sort of defect at the break, around the constriction. This may be a bend or poor internal surface finish. Printing jams as the sticky filament in the small thermal transition jams on the bend, or poor internal surface finish.

Increasing temperature appears to alleviate the issue somewhat, because you are raising the position at which the filament is liquid to a higher position - above the bend/rough patch. With the thermal transition now away from the problem area printing resumes, however temperature is much too high now, and too much heat transfer is occurring. What should be the cold side of the heatbreak gradually gets hot enough until a large amount of filament is gummy, and jamming occurs part way through the print.

Either that or some freak filament that I am unfamiliar with.

Hendo420/PolygonHell

You will be recieving replacement parts as soon as possible. We will test these parts before getting them over to you to be absolutely sure they are good. It would be awesome if we could get parts sent back to us for inspection - we would of course pay all shipping costs. Polygonhell - you mentioned trying to drill things out to see if that fixes it - go for it, we are sending you new parts anyway so nothing to lose. Do report back if it works out for you.

Thank-you so much for your really detailed feedback and photographs describing the issue - it has been incredibly helpful. Also many thanks to those who have chimed in to say that theirs is working correctly even in the aggravated conditions such as slow hot printing - this has narrowed it down to some sort of manufacturing defect.

Sal

We agree with you on the nozzle end shape, and you are absolutely right about the updated drawings being to further optimise this.

RichRap

Thanks for the awesome feedback! Glad you like it, precision really was priority number one all the way through with this design, going through the effort of getting this sharp thermal transition even though it needs some good thermal management, as well as really being careful about the nozzle orifice length/diameter ratios is quite key. A lot of people purchase a hotend, looking at specs like weight, max temp, overall length, speed of extrusion, but the actual precision of the extrusion itself is something that isn't thought about much, and it makes a difference!

On the Nylon front, I think that what might be happening is that in hotends with longer transitions and less aggressive heat-management you are getting the filament quite hot along quite a length, for quite some time. (Compared to ours at least) What I think might be happening is that in long thermal transitions a hydroscopic filament like Nylon will heat up and cook-off - just like in Prusa's heated PTFE tubing filament dryer. In our hotend, you go from ambient temp to molten very sharply, no time for filament to cook off and dry out. This means even if your filament is "quite dry" you could get some off-gassing in the melt area, which is going to cause dodgy variability in pressure, and therefore extrude rate - even if your prints don't look "bubbly". This is just a theory - but I am getting clean prints in 618 from filament I have completely dried at 60C for 24 hours. (Left it in a plastics oven for a day, because a day was a convenient amount of time).

What exactly are the symptoms of your unpleasant prints in Nylon? What do they look like?

I see you mention going slower is improving things, this might be again due to "cook-off" - slower means more time for the filament to dry in the quite tiny warm-zone of our hotend.

JollyGrimReaper / Nophead

I'm quite sure that the whole affair isn't related to temperature. I have spent all weekend trying to replicate and test conditions for jamming, and unless you go well below the processing temp of the plastic you are running it really doesn't affect things beyond max-extrude rate. Nonetheless I agree that thermistor placement is key, and having it as close to the nozzle, and away from the heater is the optimum situation. We have amended our blocks to this end - future versions will have the placement detailed in the drawings on the website under downloads.

Whew! Mega post over...

Sanjay

Apologies for my recent lack of replies and so on, I have been working completely flat out trying to work out what these issues that PolygonHell and Hendo420 are finding.

My current conclusion/thinking is:

There is some sort of defect at the break, around the constriction. This may be a bend or poor internal surface finish. Printing jams as the sticky filament in the small thermal transition jams on the bend, or poor internal surface finish.

Increasing temperature appears to alleviate the issue somewhat, because you are raising the position at which the filament is liquid to a higher position - above the bend/rough patch. With the thermal transition now away from the problem area printing resumes, however temperature is much too high now, and too much heat transfer is occurring. What should be the cold side of the heatbreak gradually gets hot enough until a large amount of filament is gummy, and jamming occurs part way through the print.

Either that or some freak filament that I am unfamiliar with.

Hendo420/PolygonHell

You will be recieving replacement parts as soon as possible. We will test these parts before getting them over to you to be absolutely sure they are good. It would be awesome if we could get parts sent back to us for inspection - we would of course pay all shipping costs. Polygonhell - you mentioned trying to drill things out to see if that fixes it - go for it, we are sending you new parts anyway so nothing to lose. Do report back if it works out for you.

Thank-you so much for your really detailed feedback and photographs describing the issue - it has been incredibly helpful. Also many thanks to those who have chimed in to say that theirs is working correctly even in the aggravated conditions such as slow hot printing - this has narrowed it down to some sort of manufacturing defect.

Sal

We agree with you on the nozzle end shape, and you are absolutely right about the updated drawings being to further optimise this.

RichRap

Thanks for the awesome feedback! Glad you like it, precision really was priority number one all the way through with this design, going through the effort of getting this sharp thermal transition even though it needs some good thermal management, as well as really being careful about the nozzle orifice length/diameter ratios is quite key. A lot of people purchase a hotend, looking at specs like weight, max temp, overall length, speed of extrusion, but the actual precision of the extrusion itself is something that isn't thought about much, and it makes a difference!

On the Nylon front, I think that what might be happening is that in hotends with longer transitions and less aggressive heat-management you are getting the filament quite hot along quite a length, for quite some time. (Compared to ours at least) What I think might be happening is that in long thermal transitions a hydroscopic filament like Nylon will heat up and cook-off - just like in Prusa's heated PTFE tubing filament dryer. In our hotend, you go from ambient temp to molten very sharply, no time for filament to cook off and dry out. This means even if your filament is "quite dry" you could get some off-gassing in the melt area, which is going to cause dodgy variability in pressure, and therefore extrude rate - even if your prints don't look "bubbly". This is just a theory - but I am getting clean prints in 618 from filament I have completely dried at 60C for 24 hours. (Left it in a plastics oven for a day, because a day was a convenient amount of time).

What exactly are the symptoms of your unpleasant prints in Nylon? What do they look like?

I see you mention going slower is improving things, this might be again due to "cook-off" - slower means more time for the filament to dry in the quite tiny warm-zone of our hotend.

I really agree with this approach - and I think going forward in the reprap world, comparisons about hotends (and other components) are going to have to be less about "product X is better than product Y" and more towards "if you want to do A, then hotend X is best for you, but if you need B then you want Y". This is a good thing in my mind, and a symptom of a maturing ecosystem.Quote

it's a starting point for discussion about different hot-ends for different uses and what people want to do with them.

JollyGrimReaper / Nophead

I'm quite sure that the whole affair isn't related to temperature. I have spent all weekend trying to replicate and test conditions for jamming, and unless you go well below the processing temp of the plastic you are running it really doesn't affect things beyond max-extrude rate. Nonetheless I agree that thermistor placement is key, and having it as close to the nozzle, and away from the heater is the optimum situation. We have amended our blocks to this end - future versions will have the placement detailed in the drawings on the website under downloads.

Whew! Mega post over...

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 07:19AM |

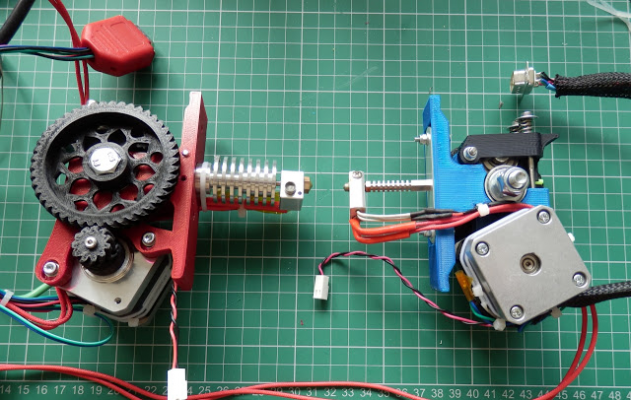

@rickrap- shoot me your address at ez@trinitylabs.com and I will toss a sample Magma hot end in the post for you to try if you just give me some honest feedback good bad and ugly

I held back shipping on 500 of these hot ends after I got them back from my machinist because of two issues that annoyed me enough to hold back shipping until I could figure out what needed done to fix these two issues.

1. with the thermistor in the heaterblock I had to run my temperatures 20-40C hotter then I would run the same filament in my trusty jhead. I don't like this at all as it just feels hackish and everyone is pretty used to their little temperatures they use with their filament so using the same temps as I use on a jhead mov-b was one release blocker.

In the end the fix for this ended up being a strategically placed cubby hole for mounting the thermistor that is in the brass nozzle itself rather then the aluminum heater block so as to place the thermistor as close to the actual melt zone and nozzle orifice extrusion exit as possible and measure temps based on what the plastic is at right before it is extruded. This was a great fix as it not only allow3ed me to use 185C on my magma if I used 185C for the same filament on my jhead but it also made the temperature swings almost imperceptable as the temp nails it at what you set and fluctuates barely +-1C.

I also discovered the importance of exacting tolerance specifications in CAD models you pass of to someone else, As the nozzles were within the drawings speced out tolerance but still had way too much brass material in the tip where the orifice was. In the end we removed 2.9mm of inner brass from the nozzle with a 2.9mm drill bit and then another 0.8mm with a 1.2mm drill bit to give it that reservoir tip style that allows for such nice retractrion as long as you do not retract too much and suck an air bubble up past the smaller diameter into the 2.8mm part.

2. I want this hot end to be consistently able to print PLA, ABS, Polycarbonate, Nylon and Lay Wood for now and anything else that comes along that we can extruder under 400C or so at slow, medium and high speeds. Fresh from the machine shop the Magma's passed all of these tests except for the PLA slow and medium slow speed tests.

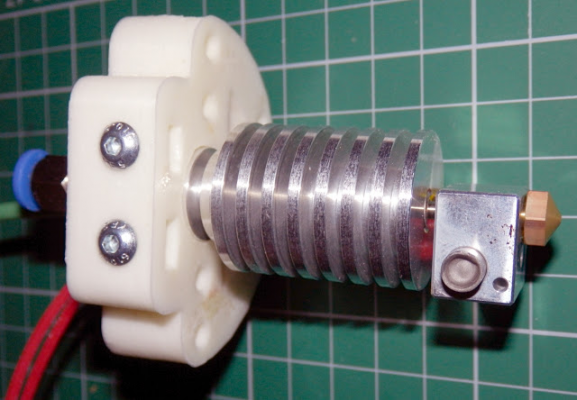

The Magma is a 4 piece hot end with an upper aluminum heat sink barrel , an inner thin wall stainless polished inside barrel and an aluminukm heater block with a brass nozzle.

The principle behind this hot end is that stainless is a poor conductor of heat, especially thin wall tubing and especially when the heat is coming from a different type of metal crossing a barier into the stainless. So our nozzle is brass and screws into the bottom of the heater block, the heater block is aluminum and the stainless tube screws into the top of the heater block and the nozzle and stainless tube mate in the middle of the threads forming a nice tight seal with no lip or catch for the plastic to snag on at the joint.

Measuring the temperare with 4 thermistors placed on the nozzle I was reading extrusion temp on the heater block of 185C, about 3mm up the stainless tube above the heater block I was reading 125C alkready and where the stainless entered the upper aluminum heat sink/groovemount barrel it was already down to 80C. The upper aluminum barrel remains room temperature throughout prints that last hours even when printing polycarbonate at 290C.

But when I tried to print PLA at a rate slower then around 40mm/sec it would inevitably clog up within a few layers or so. This was frustrating and made me spend a few weeks staring at my unimat and hacking different ideas to try and figure out how to fix this >>

After 40+ failed attemps of different voodoo incantations and sacrificing chickens(3d porinted ones to be PC), I finally figured out what was happening. Even though the stainless barrel and aluminum upper barrel were doing their jobs wonderfully and were well under the PLA glassine temp of 60C, during slow printing the heat was traveling up the PLA *itself* and had nothing to do with the metal bits! When PLA gets over 60C it starts to get gloopy and tacky and will expand in the barrel and start sticking to the walls and generally become harder and harder to push until you get a clog.

Investigating the newly machined hot ends I discovered a small difference between the new ones and the prototypes thast worked without flaws. The threaded part on the ends of the small stainless barrel were only 5mm long, while on the prototype the thrfeasds were 8mm long and therefor had more surface contact with the outside of the stainless barrel anbd the inside of the aluminum upper barrel and so the heat sink aluminum barrel was not wicking heat away from the stainless core fast enough so the heat was able to travel up the barrel through the PLA plastic itself.

So what is a reprapper to do when faced with an issue like this? Break out the tin foil! I realized that more surface area contact between the stainless barrel and the aluminum heat sink could only be a good thing™ and it turned out to be the final straw that cracked the nut and allowed the Magma to pass all of my tests and to start shipping as of last friday.

Morale of the story is that there is zero science in hot end development and perfection., It is all voodoo and alchemy and jig dancing as well as sleepless nights and angry wives.

Along trhe way though when I had not so high hopes for the first design of heater block and brass nozzle working to my standards we quickly designed a female "innie" jhead style nozzle with the internal geometry that I had come to discover via trial and error to be the best for meeting all the stated goals of this hot end. So here are some pics of the j-magma nozzle which I really like and which we will be offering as an option in the near fuiture.

And here are some nice cutaways of the nozzlew geometry that ended up worknig best as I think this helps visualize what is going on inside these hot ends. The reason this j-magma one piece heater block/nozzle works extremely well is that the resistor is a tiny fraction of a miollimeter away from the melt zone side of the filamernt path and the nozzle internal gheopmetry never gets larger then the stainless tube that feeds it after the join, it only gets narrower until it ends in the small ID reservoir tip that hlps retraction so very much.

Anyway these are finally working well enough to pass the smell test and ship out to the world so there are hundreds in the mail as we speak. The main lessons learned about all metal hot ends and their differences from PTFE lined jheads(my old faithful) is a few main points.

1. You can and should get the thermistor as close to the real melt zone as possible so you can use the same temperature readings that you use with a jhead.

2. Even if you are cooling the metal of your hot end perfectly the PLA itself can still tranfer heat up the barrel though the plastic itself.

3. All metal hot ends seem to prefer as little as half the retraction as their teflon lined bretheren. For example with PLA I retract 0.86mmm in slicer. Whiule with the magma I retracted 0.45mm instead to get similar retraction effects.

4. Forget science if you want to make a well rounded hot end and study up on voodoo and sacrificing.

5. If you try real hard and eat your wheaties you canb make something you are extremely proud of that works extremely well

I held back shipping on 500 of these hot ends after I got them back from my machinist because of two issues that annoyed me enough to hold back shipping until I could figure out what needed done to fix these two issues.

1. with the thermistor in the heaterblock I had to run my temperatures 20-40C hotter then I would run the same filament in my trusty jhead. I don't like this at all as it just feels hackish and everyone is pretty used to their little temperatures they use with their filament so using the same temps as I use on a jhead mov-b was one release blocker.

In the end the fix for this ended up being a strategically placed cubby hole for mounting the thermistor that is in the brass nozzle itself rather then the aluminum heater block so as to place the thermistor as close to the actual melt zone and nozzle orifice extrusion exit as possible and measure temps based on what the plastic is at right before it is extruded. This was a great fix as it not only allow3ed me to use 185C on my magma if I used 185C for the same filament on my jhead but it also made the temperature swings almost imperceptable as the temp nails it at what you set and fluctuates barely +-1C.

I also discovered the importance of exacting tolerance specifications in CAD models you pass of to someone else, As the nozzles were within the drawings speced out tolerance but still had way too much brass material in the tip where the orifice was. In the end we removed 2.9mm of inner brass from the nozzle with a 2.9mm drill bit and then another 0.8mm with a 1.2mm drill bit to give it that reservoir tip style that allows for such nice retractrion as long as you do not retract too much and suck an air bubble up past the smaller diameter into the 2.8mm part.

2. I want this hot end to be consistently able to print PLA, ABS, Polycarbonate, Nylon and Lay Wood for now and anything else that comes along that we can extruder under 400C or so at slow, medium and high speeds. Fresh from the machine shop the Magma's passed all of these tests except for the PLA slow and medium slow speed tests.

The Magma is a 4 piece hot end with an upper aluminum heat sink barrel , an inner thin wall stainless polished inside barrel and an aluminukm heater block with a brass nozzle.

The principle behind this hot end is that stainless is a poor conductor of heat, especially thin wall tubing and especially when the heat is coming from a different type of metal crossing a barier into the stainless. So our nozzle is brass and screws into the bottom of the heater block, the heater block is aluminum and the stainless tube screws into the top of the heater block and the nozzle and stainless tube mate in the middle of the threads forming a nice tight seal with no lip or catch for the plastic to snag on at the joint.

Measuring the temperare with 4 thermistors placed on the nozzle I was reading extrusion temp on the heater block of 185C, about 3mm up the stainless tube above the heater block I was reading 125C alkready and where the stainless entered the upper aluminum heat sink/groovemount barrel it was already down to 80C. The upper aluminum barrel remains room temperature throughout prints that last hours even when printing polycarbonate at 290C.

But when I tried to print PLA at a rate slower then around 40mm/sec it would inevitably clog up within a few layers or so. This was frustrating and made me spend a few weeks staring at my unimat and hacking different ideas to try and figure out how to fix this >>

After 40+ failed attemps of different voodoo incantations and sacrificing chickens(3d porinted ones to be PC), I finally figured out what was happening. Even though the stainless barrel and aluminum upper barrel were doing their jobs wonderfully and were well under the PLA glassine temp of 60C, during slow printing the heat was traveling up the PLA *itself* and had nothing to do with the metal bits! When PLA gets over 60C it starts to get gloopy and tacky and will expand in the barrel and start sticking to the walls and generally become harder and harder to push until you get a clog.

Investigating the newly machined hot ends I discovered a small difference between the new ones and the prototypes thast worked without flaws. The threaded part on the ends of the small stainless barrel were only 5mm long, while on the prototype the thrfeasds were 8mm long and therefor had more surface contact with the outside of the stainless barrel anbd the inside of the aluminum upper barrel and so the heat sink aluminum barrel was not wicking heat away from the stainless core fast enough so the heat was able to travel up the barrel through the PLA plastic itself.

So what is a reprapper to do when faced with an issue like this? Break out the tin foil! I realized that more surface area contact between the stainless barrel and the aluminum heat sink could only be a good thing™ and it turned out to be the final straw that cracked the nut and allowed the Magma to pass all of my tests and to start shipping as of last friday.

Morale of the story is that there is zero science in hot end development and perfection., It is all voodoo and alchemy and jig dancing as well as sleepless nights and angry wives.

Along trhe way though when I had not so high hopes for the first design of heater block and brass nozzle working to my standards we quickly designed a female "innie" jhead style nozzle with the internal geometry that I had come to discover via trial and error to be the best for meeting all the stated goals of this hot end. So here are some pics of the j-magma nozzle which I really like and which we will be offering as an option in the near fuiture.

And here are some nice cutaways of the nozzlew geometry that ended up worknig best as I think this helps visualize what is going on inside these hot ends. The reason this j-magma one piece heater block/nozzle works extremely well is that the resistor is a tiny fraction of a miollimeter away from the melt zone side of the filamernt path and the nozzle internal gheopmetry never gets larger then the stainless tube that feeds it after the join, it only gets narrower until it ends in the small ID reservoir tip that hlps retraction so very much.

Anyway these are finally working well enough to pass the smell test and ship out to the world so there are hundreds in the mail as we speak. The main lessons learned about all metal hot ends and their differences from PTFE lined jheads(my old faithful) is a few main points.

1. You can and should get the thermistor as close to the real melt zone as possible so you can use the same temperature readings that you use with a jhead.

2. Even if you are cooling the metal of your hot end perfectly the PLA itself can still tranfer heat up the barrel though the plastic itself.

3. All metal hot ends seem to prefer as little as half the retraction as their teflon lined bretheren. For example with PLA I retract 0.86mmm in slicer. Whiule with the magma I retracted 0.45mm instead to get similar retraction effects.

4. Forget science if you want to make a well rounded hot end and study up on voodoo and sacrificing.

5. If you try real hard and eat your wheaties you canb make something you are extremely proud of that works extremely well

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 07:33AM |

Registered: 11 years ago Posts: 11 |

i'll tell you what ezra, how about I buy now and pay later, since i can't seem to pay now and get anything shipped on time.

sound good to you.? I would love to see reviews of this so called great hotend of yours though.

also rather than hijack someone else's thread, maybe this should have been a post of your own. dont you think.?

seems every ed3 hotend post gets spammed by you.

Edited 3 time(s). Last edit at 05/01/2013 07:42AM by cambo3d.

sound good to you.? I would love to see reviews of this so called great hotend of yours though.

also rather than hijack someone else's thread, maybe this should have been a post of your own. dont you think.?

seems every ed3 hotend post gets spammed by you.

Edited 3 time(s). Last edit at 05/01/2013 07:42AM by cambo3d.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 09:29AM |

@cambo3d- do you have anything constructive to add at all? I did not even link to my site or mention it in that whole poist. I was simply trying to share information about what I have discovered while doing research on a very similarly built hot end to Sanjay's which seems to be what this thread is currently about no?

If shariing knowledge is a bad thing then sure I will stop posting but I am learning from watching the other all metal hot end designers face the same issues I face and am interested in how they solve them. I would welcome Sanjay or Prusa or whomever wanted to report on what they have figured out while hacking an all metal hot end in any thread I started about a magma hot end.

Sharing hardware design issues and solution is not something I consider spam. Anyone else offended or think I have spammed the topic? I will graciously delete my post if others feel as strongly and then we can go back to where knowledge sharing between open hardware designers doesn't happen when open knowledge exchange makes all of these hot ends better.

So when you spend months of your time working on a hot end and want to share what you have discovered please do speak up as i don't consider it spam and would be interested in what you ran into as issues and what workarounds you employed to solve them.

If shariing knowledge is a bad thing then sure I will stop posting but I am learning from watching the other all metal hot end designers face the same issues I face and am interested in how they solve them. I would welcome Sanjay or Prusa or whomever wanted to report on what they have figured out while hacking an all metal hot end in any thread I started about a magma hot end.

Sharing hardware design issues and solution is not something I consider spam. Anyone else offended or think I have spammed the topic? I will graciously delete my post if others feel as strongly and then we can go back to where knowledge sharing between open hardware designers doesn't happen when open knowledge exchange makes all of these hot ends better.

So when you spend months of your time working on a hot end and want to share what you have discovered please do speak up as i don't consider it spam and would be interested in what you ran into as issues and what workarounds you employed to solve them.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 09:39AM |

Registered: 11 years ago Posts: 374 |

Quote

also rather than hijack someone else's thread, maybe this should have been a post of your own. dont you think.?

I was starting to think the same thing. But Ezra did include some key insights on why PLA might be jamming or printing less than optimally in the E3D nozzle at low speeds.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 10:55AM |

Registered: 13 years ago Posts: 818 |

We are all trying to collaborate here, so don't panic! - It actually makes a lot of sense to have different hot-end information in the same thread, it's all good knowledge for people to find and learn.

Hot-end designs are the most tricky areas for a 3DPrinter, anyone that has made their own or tried a design that was less than optimal will appreciate the sort of information Sanjay, Erza and Nophead have to say. Another Hot-end innovator - Brian at hot-ends.com has gone to a lot of trouble to explain how to make a good J-head, even pointing out how some Chinese copies don't work as well and how to fix the design, all in the interest of wanting good quality products made and people to use them and know why they work (or not).

So let's be a bit nicer to each other and remember people don't need to share this stuff if they don't want too. But we want a place where people can, and feel good about it.

[richrap.blogspot.com]

Hot-end designs are the most tricky areas for a 3DPrinter, anyone that has made their own or tried a design that was less than optimal will appreciate the sort of information Sanjay, Erza and Nophead have to say. Another Hot-end innovator - Brian at hot-ends.com has gone to a lot of trouble to explain how to make a good J-head, even pointing out how some Chinese copies don't work as well and how to fix the design, all in the interest of wanting good quality products made and people to use them and know why they work (or not).

So let's be a bit nicer to each other and remember people don't need to share this stuff if they don't want too. But we want a place where people can, and feel good about it.

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 01:32PM |

Registered: 11 years ago Posts: 11 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 02:31PM |

Registered: 11 years ago Posts: 265 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 02:49PM |

Registered: 13 years ago Posts: 818 |

@cambo3d - I'm glad you see a link, links are good, it's all good, development, sales, information, what's your problem? You have only posted 4 messages and two of them are badgering someone. - we don't need RepRap Police.

[richrap.blogspot.com]

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 02:56PM |

Registered: 11 years ago Posts: 374 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 05:57PM |

Registered: 11 years ago Posts: 11 |

richrap Wrote:

-------------------------------------------------------

> @cambo3d - I'm glad you see a link, links are

> good, it's all good, development, sales,

> information, what's your problem? You have only

> posted 4 messages and two of them are badgering

> someone. - we don't need RepRap Police.

and just becuase i have 4 messages on this forum,,,your point is? and oh this makes it 5, does that help at all?

i dont believe these or any of my comments are for you.....so whose policing who here?

Edited 5 time(s). Last edit at 05/01/2013 06:08PM by cambo3d.

-------------------------------------------------------

> @cambo3d - I'm glad you see a link, links are

> good, it's all good, development, sales,

> information, what's your problem? You have only

> posted 4 messages and two of them are badgering

> someone. - we don't need RepRap Police.

and just becuase i have 4 messages on this forum,,,your point is? and oh this makes it 5, does that help at all?

i dont believe these or any of my comments are for you.....so whose policing who here?

Edited 5 time(s). Last edit at 05/01/2013 06:08PM by cambo3d.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 06:20PM |

Admin Registered: 15 years ago Posts: 1,470 |

cambo3d Wrote:

-------------------------------------------------------

> and just becuase i have 4 messages on this

> forum,,,your point is? and oh this makes it 5,

> does that help at all?

>

> i dont believe these or any of my comments are

> for you.....so whose policing who here?

The number of posts you have doesn't matter. The point is that this forum is supposed to be for constructive comments and discussion, not personal attacks.

-------------------------------------------------------

> and just becuase i have 4 messages on this

> forum,,,your point is? and oh this makes it 5,

> does that help at all?

>

> i dont believe these or any of my comments are

> for you.....so whose policing who here?

The number of posts you have doesn't matter. The point is that this forum is supposed to be for constructive comments and discussion, not personal attacks.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 06:29PM |

Registered: 11 years ago Posts: 21 |

All you are doing is trolling, an open source community must not be the place for you.

cambo3d Wrote:

-------------------------------------------------------

> richrap Wrote:

> --------------------------------------------------

> -----

> > @cambo3d - I'm glad you see a link, links are

> > good, it's all good, development, sales,

> > information, what's your problem? You have only

> > posted 4 messages and two of them are badgering

> > someone. - we don't need RepRap Police.

>

>

> and just becuase i have 4 messages on this

> forum,,,your point is? and oh this makes it 5,

> does that help at all?

>

> i dont believe these or any of my comments are

> for you.....so whose policing who here?

cambo3d Wrote:

-------------------------------------------------------

> richrap Wrote:

> --------------------------------------------------

> -----

> > @cambo3d - I'm glad you see a link, links are

> > good, it's all good, development, sales,

> > information, what's your problem? You have only

> > posted 4 messages and two of them are badgering

> > someone. - we don't need RepRap Police.

>

>

> and just becuase i have 4 messages on this

> forum,,,your point is? and oh this makes it 5,

> does that help at all?

>

> i dont believe these or any of my comments are

> for you.....so whose policing who here?

Sorry, only registered users may post in this forum.