Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2013 06:36PM |

Registered: 11 years ago Posts: 11 |

NewPerfection Wrote:

-------------------------------------------------------

> cambo3d Wrote:

> --------------------------------------------------

> -----

> > and just becuase i have 4 messages on this

> > forum,,,your point is? and oh this makes it

> 5,

> > does that help at all?

> >

> > i dont believe these or any of my comments are

> > for you.....so whose policing who here?

>

> The number of posts you have doesn't matter. The

> point is that this forum is supposed to be for

> constructive comments and discussion, not personal

> attacks.

your right cameron it doesn't matter, was being scarcastic. I'm sure you knew that but if you guys need more posts on forums I can point you to other forums where im an active member of also. would that help post count.??

this is an open forum for which im a member of and I can pretty much say what I choose to say, is it not?

but if you guys dont feel my honest opinions are'nt inline with yours, dont comment.

If this guy handled his business offline. I wouldn't be here posting any of this.

but anyway can we get back to the topic at hand here which is the ED3 all metal hotend.

edit: all the sudden i have a shipping notice in my email that's about 3 weeks late,,,, coincidence???? I think not.

Edited 9 time(s). Last edit at 05/02/2013 05:22AM by cambo3d.

-------------------------------------------------------

> cambo3d Wrote:

> --------------------------------------------------

> -----

> > and just becuase i have 4 messages on this

> > forum,,,your point is? and oh this makes it

> 5,

> > does that help at all?

> >

> > i dont believe these or any of my comments are

> > for you.....so whose policing who here?

>

> The number of posts you have doesn't matter. The

> point is that this forum is supposed to be for

> constructive comments and discussion, not personal

> attacks.

your right cameron it doesn't matter, was being scarcastic. I'm sure you knew that but if you guys need more posts on forums I can point you to other forums where im an active member of also. would that help post count.??

this is an open forum for which im a member of and I can pretty much say what I choose to say, is it not?

but if you guys dont feel my honest opinions are'nt inline with yours, dont comment.

If this guy handled his business offline. I wouldn't be here posting any of this.

but anyway can we get back to the topic at hand here which is the ED3 all metal hotend.

edit: all the sudden i have a shipping notice in my email that's about 3 weeks late,,,, coincidence???? I think not.

Edited 9 time(s). Last edit at 05/02/2013 05:22AM by cambo3d.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 03:14AM |

Registered: 12 years ago Posts: 147 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 04:24AM |

Registered: 11 years ago Posts: 661 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 04:57AM |

Registered: 11 years ago Posts: 11 |

yydoctt Wrote:

-------------------------------------------------------

> 'coincidence????'

>

> Yes, stop trolling.

[www.urbandictionary.com] [curezone.com] by these definitions I dont consider myself a troller. maybe you need to understand what these terms mean before you use them.

[www.urbandictionary.com] [curezone.com] by these definitions I dont consider myself a troller. maybe you need to understand what these terms mean before you use them.

so has the issue with the ED3 retract been worked out or was that just a fluke hot end.

or is there something I need to do to it when I recieve it?

Edited 5 time(s). Last edit at 05/02/2013 05:13AM by cambo3d.

-------------------------------------------------------

> 'coincidence????'

>

> Yes, stop trolling.

[www.urbandictionary.com] [curezone.com] by these definitions I dont consider myself a troller. maybe you need to understand what these terms mean before you use them.

[www.urbandictionary.com] [curezone.com] by these definitions I dont consider myself a troller. maybe you need to understand what these terms mean before you use them.so has the issue with the ED3 retract been worked out or was that just a fluke hot end.

or is there something I need to do to it when I recieve it?

Edited 5 time(s). Last edit at 05/02/2013 05:13AM by cambo3d.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 05:11AM |

Registered: 13 years ago Posts: 818 |

cambo3d Wrote:

-------------------------------------------------------

> and just becuase i have 4 messages on this

> forum,,,your point is? and oh this makes it 5,

> does that help at all?

>

> i dont believe these or any of my comments are

> for you.....so whose policing who here?

However you want to live your life, my point was that 50% of your comments so far were attacking another member when the post by that member was not directed to you, you just come across as aggressive and that's not cool. - I'm more than happy to stay away from you in you have no interest in what I'm saying, I was simply trying to help get across how this forum seems to work for people, it's a nice community.

[richrap.blogspot.com]

-------------------------------------------------------

> and just becuase i have 4 messages on this

> forum,,,your point is? and oh this makes it 5,

> does that help at all?

>

> i dont believe these or any of my comments are

> for you.....so whose policing who here?

However you want to live your life, my point was that 50% of your comments so far were attacking another member when the post by that member was not directed to you, you just come across as aggressive and that's not cool. - I'm more than happy to stay away from you in you have no interest in what I'm saying, I was simply trying to help get across how this forum seems to work for people, it's a nice community.

[richrap.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 05:38AM |

Admin Registered: 11 years ago Posts: 1,063 |

cambo3d Wrote:

-------------------------------------------------------

> yydoctt Wrote:

> --------------------------------------------------

> -----

> > 'coincidence????'

> >

> > Yes, stop trolling.

>

>

> [www.urbandictionary.com]

> um+troll [curezone.com]

> by these definitions I dont consider myself a

> troller. maybe you need to understand what these

> terms mean before you use them.

>

>

> so has the issue with the ED3 retract been worked

> out or was that just a fluke hot end.

>

> or is there something I need to do to it when I

> recieve it?

i won't say it's so much as issue with the E3D the design is very sound, i would put it down more to a combination of filament brand color and attempted printing speed,

-------------------------------------------------------

> yydoctt Wrote:

> --------------------------------------------------

> -----

> > 'coincidence????'

> >

> > Yes, stop trolling.

>

>

> [www.urbandictionary.com]

> um+troll [curezone.com]

> by these definitions I dont consider myself a

> troller. maybe you need to understand what these

> terms mean before you use them.

>

>

> so has the issue with the ED3 retract been worked

> out or was that just a fluke hot end.

>

> or is there something I need to do to it when I

> recieve it?

i won't say it's so much as issue with the E3D the design is very sound, i would put it down more to a combination of filament brand color and attempted printing speed,

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 05:39AM |

Admin Registered: 16 years ago Posts: 13,884 |

... all here, calm down please!

This discussion was reported/flagged from different users as trolling/ranting -- if this will heat up, we have to close this thread

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

This discussion was reported/flagged from different users as trolling/ranting -- if this will heat up, we have to close this thread

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 05:46AM |

Admin Registered: 11 years ago Posts: 1,063 |

VDX Wrote:

-------------------------------------------------------

> ... all here, calm down please!

>

> This discussion was reported/flagged from

> different users as trolling/ranting -- if this

> will heat up, we have to close this thread

if it comes to that can it just be locked and the offending posts removed, there' s bit of information in this one people might find usefull

-------------------------------------------------------

> ... all here, calm down please!

>

> This discussion was reported/flagged from

> different users as trolling/ranting -- if this

> will heat up, we have to close this thread

if it comes to that can it just be locked and the offending posts removed, there' s bit of information in this one people might find usefull

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 05:51AM |

Registered: 11 years ago Posts: 11 |

richrap Wrote:

-------------------------------------------------------

>

> However you want to live your life, my point was

> that 50% of your comments so far were attacking

> another member when the post by that member was

> not directed to you, you just come across as

> aggressive and that's not cool. - I'm more than

> happy to stay away from you in you have no

> interest in what I'm saying, I was simply trying

> to help get across how this forum seems to work

> for people, it's a nice community.

well think about this.

If I had as many posts as yourself in this forum and I made that comment would it have made a difference? absolutely not. Maybe I did come off aggressive and I have my reasons for doing so. bye the way, I wasn't the only one thinking it.

but really can we get back to the topic of this thread.. which is the ED3 Hotend.

-------------------------------------------------------

>

> However you want to live your life, my point was

> that 50% of your comments so far were attacking

> another member when the post by that member was

> not directed to you, you just come across as

> aggressive and that's not cool. - I'm more than

> happy to stay away from you in you have no

> interest in what I'm saying, I was simply trying

> to help get across how this forum seems to work

> for people, it's a nice community.

well think about this.

If I had as many posts as yourself in this forum and I made that comment would it have made a difference? absolutely not. Maybe I did come off aggressive and I have my reasons for doing so. bye the way, I wasn't the only one thinking it.

but really can we get back to the topic of this thread.. which is the ED3 Hotend.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 05:56AM |

Registered: 11 years ago Posts: 11 |

thejollygrimreaper Wrote:

-------------------------------------------------------

>

> i won't say it's so much as issue with the E3D the

> design is very sound, i would put it down more to

> a combination of filament brand color and

> attempted printing speed,

thanks jolly, by the way i wasn't putting down your hotend either, I did have one on order from trinity labs.

VDX Wrote:

-------------------------------------------------------

> ... all here, calm down please!

>

> This discussion was reported/flagged from

> different users as trolling/ranting -- if this

> will heat up, we have to close this thread

well apparently my definition of trolling doesn't match the members of this forum or members are overly sensitive. the only people that are "heating up" are the other members of this forum. If this thread gets locked you guys are to blame. I get called a troll and other things but you don't see me hitting the report button. seriously..? or am i being too opinionated here also. whatever happened to free speech. I don't think it stops at the internet but feel free to delete these post or lock or close this thread as you wish. That'll keep these other guys from calling me a troll and what not.

and maybe we get back to the topic that this thread was originally about.

Edited 2 time(s). Last edit at 05/02/2013 06:33AM by cambo3d.

-------------------------------------------------------

>

> i won't say it's so much as issue with the E3D the

> design is very sound, i would put it down more to

> a combination of filament brand color and

> attempted printing speed,

thanks jolly, by the way i wasn't putting down your hotend either, I did have one on order from trinity labs.

VDX Wrote:

-------------------------------------------------------

> ... all here, calm down please!

>

> This discussion was reported/flagged from

> different users as trolling/ranting -- if this

> will heat up, we have to close this thread

well apparently my definition of trolling doesn't match the members of this forum or members are overly sensitive. the only people that are "heating up" are the other members of this forum. If this thread gets locked you guys are to blame. I get called a troll and other things but you don't see me hitting the report button. seriously..? or am i being too opinionated here also. whatever happened to free speech. I don't think it stops at the internet but feel free to delete these post or lock or close this thread as you wish. That'll keep these other guys from calling me a troll and what not.

and maybe we get back to the topic that this thread was originally about.

Edited 2 time(s). Last edit at 05/02/2013 06:33AM by cambo3d.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 01:31PM |

Registered: 10 years ago Posts: 9 |

Regarding problems with jamming possibly related to difficult filament. I am right now printing with a red/orange filament from Supply3dPLA that was more or less impossible to use with old hot end due to jamming every few layers. Tried all temp and speed combinations.

With e3d hot end I have seen no problems at all. Just standard temp and go. These are just my observations, not sure if it helps.

With e3d hot end I have seen no problems at all. Just standard temp and go. These are just my observations, not sure if it helps.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 02:46PM |

Registered: 12 years ago Posts: 177 |

Oh dear...

I am quite happy that companies like TL and E3D can post and collaborate in forums such as these. I think Ezra and I actually bumped into each other on IRC the day we both launched our parts for sale. (Big coincidence.)

This isn't a sales thread, it's about discussing engineering aspects of my design, helping people out, and furthering 3D printing in general. That Ezra is here admitting he had some issues, and openly discussing how he solved them is a big positive in my eyes. I also quite like his design, it differs from mine quite a lot, and addresses different goals. I expect my design to be a little more precise on extrusion and I expect his will have a higher maximum feedrate. Choices are good! We can all coexist here.

I don't there actually was ever a design issue intrinsically, I have had overwhelmingly positive feedback in almost all cases, and these are the only cases of jamming I know of. I cannot replicate the issue myself, no matter how much I exacerbate the conditions - and I really have tried for hours/days. It's a damaged or mis-machined part I'm quite sure. Replacing the parts with parts I have checked/tested will put the final nail in this coffin.

Freak filament is also a small possibility. Hendo420 and Polygonhell - what filament are you guys using?

Just follow the instruction manual and enjoy.

The issue of heat conduction up the filament is interesting, but I really don't think it is pertinent in the case of the E3D - the aggressive active cooling will not permit filament above the break to go above it's glass transition. Looking at Hendo420's very helpful photos of withdrawn jammed filament there is also no buckling or deformation, just a very rapid transition towards a melt-plug.

I agree with Ezra that thermal coupling to the nozzle should be as close as possible, and having the thermistor away from the heater is also a positive but having it on the nozzle really makes nozzle changes a pain. Same for J-Head style one-piece 'blocknozzle'. It's a choice, a tradeoff. Again - choice is good!

I have actually updated the block design to relocate the thermistor somewhat - but really I have never seen any temperature issues. Furthermore, without using a feed-forward value in our firmware PID equation we are not really going to be able to solve the problem of filament flow cooling the nozzle. Marlin allegedly can do this.

I am quite happy that companies like TL and E3D can post and collaborate in forums such as these. I think Ezra and I actually bumped into each other on IRC the day we both launched our parts for sale. (Big coincidence.)

This isn't a sales thread, it's about discussing engineering aspects of my design, helping people out, and furthering 3D printing in general. That Ezra is here admitting he had some issues, and openly discussing how he solved them is a big positive in my eyes. I also quite like his design, it differs from mine quite a lot, and addresses different goals. I expect my design to be a little more precise on extrusion and I expect his will have a higher maximum feedrate. Choices are good! We can all coexist here.

Quote

Cambo3D

so has the issue with the ED3 retract been worked out or was that just a fluke hot end.

or is there something I need to do to it when I recieve it?

I don't there actually was ever a design issue intrinsically, I have had overwhelmingly positive feedback in almost all cases, and these are the only cases of jamming I know of. I cannot replicate the issue myself, no matter how much I exacerbate the conditions - and I really have tried for hours/days. It's a damaged or mis-machined part I'm quite sure. Replacing the parts with parts I have checked/tested will put the final nail in this coffin.

Freak filament is also a small possibility. Hendo420 and Polygonhell - what filament are you guys using?

Just follow the instruction manual and enjoy.

The issue of heat conduction up the filament is interesting, but I really don't think it is pertinent in the case of the E3D - the aggressive active cooling will not permit filament above the break to go above it's glass transition. Looking at Hendo420's very helpful photos of withdrawn jammed filament there is also no buckling or deformation, just a very rapid transition towards a melt-plug.

I agree with Ezra that thermal coupling to the nozzle should be as close as possible, and having the thermistor away from the heater is also a positive but having it on the nozzle really makes nozzle changes a pain. Same for J-Head style one-piece 'blocknozzle'. It's a choice, a tradeoff. Again - choice is good!

I have actually updated the block design to relocate the thermistor somewhat - but really I have never seen any temperature issues. Furthermore, without using a feed-forward value in our firmware PID equation we are not really going to be able to solve the problem of filament flow cooling the nozzle. Marlin allegedly can do this.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 02:56PM |

Registered: 11 years ago Posts: 137 |

the green and blue filament is from justpla.com

red and black from a manufacture that's about an hour away who claims its all virgin filament, not recycled. I would buy all of my filament from him but he only has 4 colors.

I have natural that I don't know where it comes from.

My ABS is color change from ebay, no idea of its origins.

red and black from a manufacture that's about an hour away who claims its all virgin filament, not recycled. I would buy all of my filament from him but he only has 4 colors.

I have natural that I don't know where it comes from.

My ABS is color change from ebay, no idea of its origins.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 03:09PM |

Registered: 12 years ago Posts: 177 |

Cheers, for the info Hendo.

I suppose the other thing to try is to take a leaf from Ezras book and try a bit of heatsink compound around the threads on the cold side of the break. That or foil like he suggests. It's worth a shot. Feel free to play around, nothing to lose as you will be getting replacements.

I suppose the other thing to try is to take a leaf from Ezras book and try a bit of heatsink compound around the threads on the cold side of the break. That or foil like he suggests. It's worth a shot. Feel free to play around, nothing to lose as you will be getting replacements.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 03:12PM |

Registered: 11 years ago Posts: 11 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 03:16PM |

Registered: 10 years ago Posts: 1 |

No jamming here either, and running from very slow up to 80 mm/s at 190-195C. Did the Owl statue yesterday with a very nice result.

Quality has definitely improved compared to my Mendel-parts v9/v10 hotend (with same issues as described by Sal).

And I've never even been close to getting this kind of bridging before, so I'm very satisfied.

Edited 1 time(s). Last edit at 05/02/2013 03:23PM by hakalan.

Quality has definitely improved compared to my Mendel-parts v9/v10 hotend (with same issues as described by Sal).

And I've never even been close to getting this kind of bridging before, so I'm very satisfied.

Edited 1 time(s). Last edit at 05/02/2013 03:23PM by hakalan.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 03:17PM |

Registered: 11 years ago Posts: 939 |

Quote

Hendo420 and Polygonhell - what filament are you guys using?

I'm using some PLA I got from SeeMeCNC, it seems to be consistent diameter wise, requires slightly more temperature than the Ultimachine PLA I was using, but was printing fine in my existing hotend. I have 3 other rolls I can try here, I will after I get a chance to reassemble.

The ABS was Ultimachine natural, I think I have some Yellow somewhere I can also try.

I also have some Ultimachine PLA samples here, and I did successfully print the small amount of black I had without retraction. Unfortunately I don't have enough Ultimachine filament currently to run a long print with it., I'll order some and let you know.

I wanted to say that Sanjay just contacted me for details to send out a replacement, IMO you measure the quality of a company not when everything works but when something doesn't, there will invariably be problems and sometimes you just get unlucky, it's how a vendor deals with that.

I'm going to run a drill bit through the one I have (been very busy at work this week so I haven't had a chance) and try it after reassembling and I will report back on that and the results with the replacement hotend when it arrives.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 05:43PM |

Admin Registered: 17 years ago Posts: 7,879 |

Regarding heat conducting up the filament:

The filament in the cold section will only be cooled if it is in good contact with it, but that won't be the case because the filament is smaller than the bore (so can only have tangential contact at best) until it gets past its glass transition and expands outwards. It will then meet the wall and be cooled. So I can see why it might be a problem because you could get a plug formed in the cold section.

Whether the plug jams depends on the coefficient of friction between rubbery PLA and the wall and the length of the plug. I think there is a critical value where the more you push the more outwards pressure you get and so more friction to resist the force. That might be very dependent on the plastic, its thermal conductivity, glass transition temp and friction coefficient.

My own design never jammed when going slowly, but it didn't work well until I added the taper in the transition section, which I don't see in any of the recent designs. It made the force required to extrude three times less.

The only time it ever jammed was with filament that was undersized. I designed it for 3mm +/- 0.1 and it did not like 2.85 +/-.0.1 because at 2.75 the gap allows more back flow and a bigger plug to form. It probably gets above the tapered section. The inside of the stainless steel tube wasn't particularly smooth. Seems from Joseph Prusa's work that polishing it makes big difference.

I can't get the 3mm filament any more and have been running on 2.85mm ABS for a few weeks. Today I have had three extruders fail. Two J-heads and one of my own design PEEK / PTFE hybrids. Not sure what's going on until I conduct post mortems. I think the force needed to extrude is higher due to the smaller filament forming a bigger plug. I suspect that has damaged the PTFE liner, that is about they only thing that can fail.

[www.hydraraptor.blogspot.com]

The filament in the cold section will only be cooled if it is in good contact with it, but that won't be the case because the filament is smaller than the bore (so can only have tangential contact at best) until it gets past its glass transition and expands outwards. It will then meet the wall and be cooled. So I can see why it might be a problem because you could get a plug formed in the cold section.

Whether the plug jams depends on the coefficient of friction between rubbery PLA and the wall and the length of the plug. I think there is a critical value where the more you push the more outwards pressure you get and so more friction to resist the force. That might be very dependent on the plastic, its thermal conductivity, glass transition temp and friction coefficient.

My own design never jammed when going slowly, but it didn't work well until I added the taper in the transition section, which I don't see in any of the recent designs. It made the force required to extrude three times less.

The only time it ever jammed was with filament that was undersized. I designed it for 3mm +/- 0.1 and it did not like 2.85 +/-.0.1 because at 2.75 the gap allows more back flow and a bigger plug to form. It probably gets above the tapered section. The inside of the stainless steel tube wasn't particularly smooth. Seems from Joseph Prusa's work that polishing it makes big difference.

I can't get the 3mm filament any more and have been running on 2.85mm ABS for a few weeks. Today I have had three extruders fail. Two J-heads and one of my own design PEEK / PTFE hybrids. Not sure what's going on until I conduct post mortems. I think the force needed to extrude is higher due to the smaller filament forming a bigger plug. I suspect that has damaged the PTFE liner, that is about they only thing that can fail.

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 06:12PM |

Registered: 12 years ago Posts: 177 |

Cambo3d

Should be, yep!

Hakalan

Always appreciate the positive feedback! Glad you are liking it, those bridges are TIGHT and your owl looks stunning!

Polygonhell

Cheers for the additional info, all helps! Any idea what the diameters are? (See nopheads post)

Nophead

Interesting theory indeed. Our stainless break is drilled/reamed to 2mm ID. I have tried a really wide range of filaments in it, from 1.65mm PLA that is from a reseller of cheap chinese stuff to 1.88 PLA, from the same vendor as the 1.65mm stuff, but a different batch. Despite the batch to batch variation the diameter on a spool is quite consistent (+/-25microns) . Both printed well, with no problems spotted. I'll go back to the 1.65 stuff and try and induce a failure on undersized filament.

I have also printed some Nylon trimmer line that was listed at 2mm, and measures just a hair under at around 1.95mm - extruded fine, printed terribly.

Should be, yep!

Hakalan

Always appreciate the positive feedback! Glad you are liking it, those bridges are TIGHT and your owl looks stunning!

Polygonhell

Cheers for the additional info, all helps! Any idea what the diameters are? (See nopheads post)

Nophead

Interesting theory indeed. Our stainless break is drilled/reamed to 2mm ID. I have tried a really wide range of filaments in it, from 1.65mm PLA that is from a reseller of cheap chinese stuff to 1.88 PLA, from the same vendor as the 1.65mm stuff, but a different batch. Despite the batch to batch variation the diameter on a spool is quite consistent (+/-25microns) . Both printed well, with no problems spotted. I'll go back to the 1.65 stuff and try and induce a failure on undersized filament.

I have also printed some Nylon trimmer line that was listed at 2mm, and measures just a hair under at around 1.95mm - extruded fine, printed terribly.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 06:55PM |

Admin Registered: 11 years ago Posts: 1,063 |

Nophead:

what you'll find is that there is a speed band these things need to operate within to low and your plug will creep into the cold section and the friction will overcome the pushing power of the drive system, - it's where we've really been spoilt by the jhead design and that ptfe tube down the middle,

on the prusa nozzle i believe you can actually let the whole thing cool right down and because of the polished surface then pull the filament out completely,

this is where you'll have a huge difference in performance between 1.75mm and 3mm because the 1.75mm goes through a lot quicker so the speed band sits a lot lower,

the tendancy for a lot of people when something jams up is to slow down, which is obviously quite the opposite to what needs to happen as it will only make the situation worse

your idea with the coned section in the end was a brilliant one, and one i've done myself as well with a custom made drill bit (well i gound it to a taper on a bench grinder) and worked brilliantly, it's something I'm looking at down the track in mine, getting a machine shop to do it is another kettle of fish,

the big problem i think all of us have now is that there is no feedback from the extruder as to how much back pressure/resistance there is until it's too late, so at the moment we cannot measure and test for upper and lower limits of this speed band,

what you'll find is that there is a speed band these things need to operate within to low and your plug will creep into the cold section and the friction will overcome the pushing power of the drive system, - it's where we've really been spoilt by the jhead design and that ptfe tube down the middle,

on the prusa nozzle i believe you can actually let the whole thing cool right down and because of the polished surface then pull the filament out completely,

this is where you'll have a huge difference in performance between 1.75mm and 3mm because the 1.75mm goes through a lot quicker so the speed band sits a lot lower,

the tendancy for a lot of people when something jams up is to slow down, which is obviously quite the opposite to what needs to happen as it will only make the situation worse

your idea with the coned section in the end was a brilliant one, and one i've done myself as well with a custom made drill bit (well i gound it to a taper on a bench grinder) and worked brilliantly, it's something I'm looking at down the track in mine, getting a machine shop to do it is another kettle of fish,

the big problem i think all of us have now is that there is no feedback from the extruder as to how much back pressure/resistance there is until it's too late, so at the moment we cannot measure and test for upper and lower limits of this speed band,

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 07:22PM |

Admin Registered: 17 years ago Posts: 7,879 |

I don't think there was a speed band problem with mine because my own software slows down to almost zero speed when the size of a layer gets small so it always takes at least 20 seconds. Also my frequency limit software means infill is done at a whole variety of speeds, some very slow. My first layer outline is also a quarter of the infill speed so every build exercised a wide variety of speeds. It also didn't mind sitting hot for a long time.

I have never tried 1.75mm filament. I have the filament, I have a hot end, but no time.

[www.hydraraptor.blogspot.com]

I have never tried 1.75mm filament. I have the filament, I have a hot end, but no time.

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 07:47PM |

Admin Registered: 11 years ago Posts: 1,063 |

nophead Wrote:

-------------------------------------------------------

> I don't think there was a speed band problem with

> mine because my own software slows down to almost

> zero speed when the size of a layer gets small so

> it always takes at least 20 seconds. Also my

> frequency limit software means infill is done at a

> whole variety of speeds, some very slow. My first

> layer outline is also a quarter of the infill

> speed so every build exercised a wide variety of

> speeds. It also didn't mind sitting hot for a long

> time.

>

> I have never tried 1.75mm filament. I have the

> filament, I have a hot end, but no time.

haven't tried 1.75mm , you're missing out on all the fun,

-------------------------------------------------------

> I don't think there was a speed band problem with

> mine because my own software slows down to almost

> zero speed when the size of a layer gets small so

> it always takes at least 20 seconds. Also my

> frequency limit software means infill is done at a

> whole variety of speeds, some very slow. My first

> layer outline is also a quarter of the infill

> speed so every build exercised a wide variety of

> speeds. It also didn't mind sitting hot for a long

> time.

>

> I have never tried 1.75mm filament. I have the

> filament, I have a hot end, but no time.

haven't tried 1.75mm , you're missing out on all the fun,

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2013 09:14PM |

Registered: 11 years ago Posts: 939 |

According to my micrometer it's pretty much 1.70 plus or minus 0.01Quote

Cheers for the additional info, all helps! Any idea what the diameters are? (See nopheads post)

The Ultimachine stuff is pretty much spot on 1.75 with about the same variance.

Edited 1 time(s). Last edit at 05/03/2013 12:53AM by Polygonhell.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 03, 2013 12:25AM |

Registered: 13 years ago Posts: 301 |

To add another PLA hotend anecdote.. My hotend design does not plug at slow speed or long periods of idle and I think it entirely has to do with the very sharp transition zone and PTFE bridging of the entire top to bottom cold to hot path. The hotend block and fan cooled coldend block are separated by a 0.5mm to 1mm air gap and a thin stainless strap around the blocks prevents the blocks from separating. The gap makes for a nice sharp thermal break, but it's small enough to well constrain the drilled 5/16" PTFE rod. The aluminum coldend block is less than 1mm from the aluminum hotend block and I can keep my finger on it hours into a print. In the next month or so I am going to look into a high temperature capable variant of the design and my first plan is to just swap out the PTFE for as thin walled stainless hypodermic tube I can find. I think the transition could possibly end up even sharper because in my latest builds my new fan mount guides the fan flow between the hot and cold blocks which might actually add a cooling factor to a thin stainless tube that likely is insignificant with the thick PTFE.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 08, 2013 02:43PM |

Registered: 11 years ago Posts: 137 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 08, 2013 02:54PM |

Registered: 10 years ago Posts: 9 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 08, 2013 05:33PM |

Registered: 12 years ago Posts: 177 |

Hendo420

Second batch of metal just arrived today.

Parts in post for Hendo and PolygonHell tomorrow I expect!

Sal

Really wouldn't be too scared about breaking it, its really quite strong, I can't break one with my fingers as much as I try (I'm no superman however).

Spare parts should be getting on the site in about 2 weeks I expect.

We are still waiting on some other bits, such as fans AGAIN. But everyone should be getting their stuff within the lead times stated on the site at the time of ordering. We should be able to be turning around parts with no lead times in 15 days. We have gone full throttle and committed some serious cash to buying a large amount of stock - after that we should never be in this lead-time mess again. Hopefully!

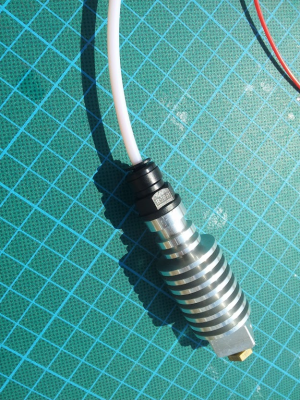

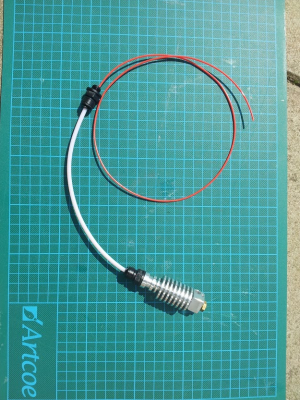

Here is the fully integrated Bowden system that we are now going to be able to ship in the next week or so - if you have already ordered and would like your order amended include one of these you can just ping us an email.

Will come with two couplers (one for each end - so you can attach easily to your extruder as well as the hotend) and 750mm of PTFE or PFA tubing. Would people prefer PTFE or PFA? Ultimaker use PFA and allege it is superior. I have tried and tested both here with samples of each tubing. The PFA has noticeably more friction, and is not noticeably mechanically stronger or less elastic. Youngs Modulus of PFA is about 40% better than PTFE though apparently, but I'm not sure this translates into significantly better properties for bowden applications.

We are also selling spare nozzles (only 0.4mm right now) but newer sizes (0.25 and 0.6) are on the way.

Sanjay

Second batch of metal just arrived today.

Parts in post for Hendo and PolygonHell tomorrow I expect!

Sal

Really wouldn't be too scared about breaking it, its really quite strong, I can't break one with my fingers as much as I try (I'm no superman however).

Spare parts should be getting on the site in about 2 weeks I expect.

We are still waiting on some other bits, such as fans AGAIN. But everyone should be getting their stuff within the lead times stated on the site at the time of ordering. We should be able to be turning around parts with no lead times in 15 days. We have gone full throttle and committed some serious cash to buying a large amount of stock - after that we should never be in this lead-time mess again. Hopefully!

Here is the fully integrated Bowden system that we are now going to be able to ship in the next week or so - if you have already ordered and would like your order amended include one of these you can just ping us an email.

Will come with two couplers (one for each end - so you can attach easily to your extruder as well as the hotend) and 750mm of PTFE or PFA tubing. Would people prefer PTFE or PFA? Ultimaker use PFA and allege it is superior. I have tried and tested both here with samples of each tubing. The PFA has noticeably more friction, and is not noticeably mechanically stronger or less elastic. Youngs Modulus of PFA is about 40% better than PTFE though apparently, but I'm not sure this translates into significantly better properties for bowden applications.

We are also selling spare nozzles (only 0.4mm right now) but newer sizes (0.25 and 0.6) are on the way.

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 08, 2013 05:40PM |

Registered: 11 years ago Posts: 205 |

problem of teflon (PTFE) in bowden systems is plastic memory. When you bend a teflon part, the place that bended become a little less elastic as deformation are not 100% in the elastic domain. Not much a problem as we have very little load, but it means that fatigue failures can occur.

Never used PFA so dont know if better.

Never used PFA so dont know if better.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 08, 2013 05:56PM |

Registered: 12 years ago Posts: 177 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 08, 2013 06:28PM |

Admin Registered: 11 years ago Posts: 1,063 |

i don't know who did it but i remember somone covering the ptfe tube in several layers of heatshrink while it's held straight and that kept it acting a little like a spingy thing and had a nice curve to it

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Sorry, only registered users may post in this forum.