Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 05:21PM |

Registered: 11 years ago Posts: 137 |

Polygonhell Wrote:

-------------------------------------------------------

> Just wanted to say I just received my replacement

> parts from E3D, the package was sent airmail, I'm

> going to put it together and test it this weekend,

> I'll follow up then.

sweet! That means mine should be in any day.

Let me know how it goes.

-------------------------------------------------------

> Just wanted to say I just received my replacement

> parts from E3D, the package was sent airmail, I'm

> going to put it together and test it this weekend,

> I'll follow up then.

sweet! That means mine should be in any day.

Let me know how it goes.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 06:06PM |

Registered: 12 years ago Posts: 177 |

Hey all.

Sorry i'm not being massively active right now. My wisdom teeth are erupting and it's bloody awful. It feels like an animal digging out of my face.

The ferrules are indeed to replace the need for soldering - put them around the thermistor legs and a stripped end of the green high-temp cabling and crush the crimp as hard as possible with needle nosed pliers or similar. (Or indeed a crimping tool if you have one) This is meant to replace the solder joint because it is quicker and easier. Like nophead says, solder is fine too - heat really isnt going to creep up the wires. It's just a way for us to make assembly easier for the user.

We have also ditched the PTFE heatshrink. It's really not needed when you have Kapton tape that does exactly the same thing, but is much better at higher temperatures, and also doesn't require a separate heating step for the user.

The manual will be updated as soon as it stops feeling like a honey badger is clawing its way out of my jaw.

Extin and PolygonHell

Glad to hear your stuff came in, hope you get running soon. Do let me know how you get on.

MRC

Daft as it may sound, we don't actually have true drawings for the latest parts - last minute back and forth phone calls with the machinists along the lines of "Can you add a 0.5mm on here and change the angle you do that at" is the reality of the situation. Drawings will go up soon on the downloads section of the site. I also need to reorganise the downloads section to make things more understandable/coherent.

SmartRoad

As it stands we are not really in a position to be customising each and every box that leaves for shipping. In order to keep up with orders in the amount of time we have in a day we have to consolidate - this means we can pack 500 boxed units in a weekend or so, and then ship them out as appropriate. Adding accessories on top as needed. Individually picking out nozzles and doing things in a pick and mix fashion just isn't logistically possible. If you want more than 5 then get in touch via email and we can do you a deal.

Maddox

Just to be clear - the water cooled and the multi-nozzle are the same product. The prototype is on my desk, and I am really planning on going fast to market with this one, time to beta units on sale 4-6 weeks.

It's got a nice simple way of levelling nozzles in seconds, super compact arrangement of heater blocks etc. You should be able to mount using the standard 50mm spaced M4 holes in a "normal" reprap carriage that usually accommodate the wades extruder screws. To fit 3 nozzles you might need a quite large hole in your carriage to permit the bowdens etc to pass through though.

My current dilemma is that my RAMPS boards only have 2 extruder motor driver positions. Any smart ideas for getting a third extruder on there? My current thinking is just to use some of the broken out AUX pins to take some I/O off to a breadboard and place the stepstick board on that and write in some new pin assignments in marlin. Anyone done this before? See any reason it won't work?

Sanjay

Sorry i'm not being massively active right now. My wisdom teeth are erupting and it's bloody awful. It feels like an animal digging out of my face.

The ferrules are indeed to replace the need for soldering - put them around the thermistor legs and a stripped end of the green high-temp cabling and crush the crimp as hard as possible with needle nosed pliers or similar. (Or indeed a crimping tool if you have one) This is meant to replace the solder joint because it is quicker and easier. Like nophead says, solder is fine too - heat really isnt going to creep up the wires. It's just a way for us to make assembly easier for the user.

We have also ditched the PTFE heatshrink. It's really not needed when you have Kapton tape that does exactly the same thing, but is much better at higher temperatures, and also doesn't require a separate heating step for the user.

The manual will be updated as soon as it stops feeling like a honey badger is clawing its way out of my jaw.

Extin and PolygonHell

Glad to hear your stuff came in, hope you get running soon. Do let me know how you get on.

MRC

Daft as it may sound, we don't actually have true drawings for the latest parts - last minute back and forth phone calls with the machinists along the lines of "Can you add a 0.5mm on here and change the angle you do that at" is the reality of the situation. Drawings will go up soon on the downloads section of the site. I also need to reorganise the downloads section to make things more understandable/coherent.

SmartRoad

As it stands we are not really in a position to be customising each and every box that leaves for shipping. In order to keep up with orders in the amount of time we have in a day we have to consolidate - this means we can pack 500 boxed units in a weekend or so, and then ship them out as appropriate. Adding accessories on top as needed. Individually picking out nozzles and doing things in a pick and mix fashion just isn't logistically possible. If you want more than 5 then get in touch via email and we can do you a deal.

Maddox

Just to be clear - the water cooled and the multi-nozzle are the same product. The prototype is on my desk, and I am really planning on going fast to market with this one, time to beta units on sale 4-6 weeks.

It's got a nice simple way of levelling nozzles in seconds, super compact arrangement of heater blocks etc. You should be able to mount using the standard 50mm spaced M4 holes in a "normal" reprap carriage that usually accommodate the wades extruder screws. To fit 3 nozzles you might need a quite large hole in your carriage to permit the bowdens etc to pass through though.

My current dilemma is that my RAMPS boards only have 2 extruder motor driver positions. Any smart ideas for getting a third extruder on there? My current thinking is just to use some of the broken out AUX pins to take some I/O off to a breadboard and place the stepstick board on that and write in some new pin assignments in marlin. Anyone done this before? See any reason it won't work?

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 06:25PM |

Admin Registered: 17 years ago Posts: 7,879 |

Note the holes changed to M3 on Prusa, but I still use M4 on Mendel90.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 06:55PM |

Registered: 12 years ago Posts: 1,236 |

SanjayM Wrote:

-------------------------------------------------------

> My current dilemma is that my RAMPS boards only

> have 2 extruder motor driver positions. Any smart

> ideas for getting a third extruder on there? My

> current thinking is just to use some of the broken

> out AUX pins to take some I/O off to a breadboard

> and place the stepstick board on that and write in

> some new pin assignments in marlin. Anyone done

> this before? See any reason it won't work?

I think that is quickest and simplest way to get going.

I am working on a 6 stepper RAMPS board, and also thinking about a 4 stepper extension board. Won't be ready for a while yet. There are some other hardware options but probably require more hacking of firmware or hardware.

-------------------------------------------------------

> My current dilemma is that my RAMPS boards only

> have 2 extruder motor driver positions. Any smart

> ideas for getting a third extruder on there? My

> current thinking is just to use some of the broken

> out AUX pins to take some I/O off to a breadboard

> and place the stepstick board on that and write in

> some new pin assignments in marlin. Anyone done

> this before? See any reason it won't work?

I think that is quickest and simplest way to get going.

I am working on a 6 stepper RAMPS board, and also thinking about a 4 stepper extension board. Won't be ready for a while yet. There are some other hardware options but probably require more hacking of firmware or hardware.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 07:44PM |

Registered: 11 years ago Posts: 490 |

Seeing your shop come together from the start when there were still a lot of dead links to now is somewhat enjoyable. I have finally placed my order some days ago after hesitating for like as long as the announcement for your hot end was out and can't wait to extrude some PET with it.

Hope you guys don't get into it over your heads like some others promising projects. Cheers!

By the way: Did you omit the second smaller hole in the heater block in the latest iterations? Would be useful for calibrating the thermistor with a thermocouple for the majority who don't want to use thermocouples directly.

Hope you guys don't get into it over your heads like some others promising projects. Cheers!

By the way: Did you omit the second smaller hole in the heater block in the latest iterations? Would be useful for calibrating the thermistor with a thermocouple for the majority who don't want to use thermocouples directly.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 10:07PM |

Registered: 11 years ago Posts: 67 |

I look forward for the feedback from the people who formerly had clogging issues. I hope the new batches cure any previous issues.

SanjayM Wrote:

-------------------------------------------------------

> Maddox

> Just to be clear - the water cooled and the

> multi-nozzle are the same product.

That's actually better for me, as any unified heatsink on more than one nozzle would potentially cause issues with my intended design. So your watercooled is my multi-nozzle (hopefully)

(hopefully)

BTW Sanjay, I appreciate your professionalism and tone throughout the thread. I understand that the reprap community and reprap companies are largely non-business-professionals who have found an interest and are branching out, and it does sound/look like for the most part you are avoiding some of the business growth, failure resolution, etc that often plague the startups in this community. There's always snags to be had, but it looks like you're doing all right

SanjayM Wrote:

-------------------------------------------------------

> Maddox

> Just to be clear - the water cooled and the

> multi-nozzle are the same product.

That's actually better for me, as any unified heatsink on more than one nozzle would potentially cause issues with my intended design. So your watercooled is my multi-nozzle

(hopefully)

(hopefully)BTW Sanjay, I appreciate your professionalism and tone throughout the thread. I understand that the reprap community and reprap companies are largely non-business-professionals who have found an interest and are branching out, and it does sound/look like for the most part you are avoiding some of the business growth, failure resolution, etc that often plague the startups in this community. There's always snags to be had, but it looks like you're doing all right

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 07, 2013 06:16PM |

Registered: 11 years ago Posts: 137 |

My replacement parts came in today. It was actually a full kit. I expected just metal parts.

Idk if you intended it or not but I got 2x heater cartridges in the kit. Ty if you did.

The fan you sent in the kit is actually weaker than the one I bought IMO but I will run the fan that you sent anyway.

I have done a few small ABS prints and they turned out well. I will move to PLA next and let you know how it goes.

So far so good.

Edited 1 time(s). Last edit at 06/07/2013 06:17PM by hendo420.

Idk if you intended it or not but I got 2x heater cartridges in the kit. Ty if you did.

The fan you sent in the kit is actually weaker than the one I bought IMO but I will run the fan that you sent anyway.

I have done a few small ABS prints and they turned out well. I will move to PLA next and let you know how it goes.

So far so good.

Edited 1 time(s). Last edit at 06/07/2013 06:17PM by hendo420.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 07, 2013 08:59PM |

Registered: 12 years ago Posts: 177 |

nophead

Yeah, I am thinking of dropping the "fits on normal 50mm spaced carriage mountings" because really people are going to need a custom carriage for this multi-hotend anyway, you just can't fit 3x nozzles and blocks through the hole in the middle of a normal carriage. If people are going to have to use a new carriage, I may as well go to 60-65mm which makes the entire design much nicer to layout and the wiring of the heaters less cramped.

bobc

I think I might just plonk down for a RUMBA board from reprapdiscount, that board looks amazing, everything i could ever want on an atmega based board, including stepper sockets for XYZEEE and lots more FETs and thermistors, so I wouldn't need to ditch my heated bed and fan just to heat 3X extruders.

I do however think there would be a market for an add-on/expansion board for RAMPS that adds some fets, thermistor inputs, and stepper sockets. There are tonnes of ramps in the wild, and when I release my hotend loads of people are going to need extra stepper sockets! (I hope)

(I hope)

uGen

I really appreciate that. It's been a crazy road, and we've made a lot of mistakes no doubt. But I think the one thing that has always worked for us is being honest and transparent with the community. Having all these posts about jamming hotends really troubled me, but I was really happy to see people coming along and chipping in advice and helping out. The customers experiencing problems really helped by collaborating with us to find the problem. It looks like now, we should be arriving at a place where the whole situation is ironed out.

A lot of engineers make terrible business people. I know I would be terrible at running a business! However I am blessed with my awesome co-director of E3D David, who doesn't post or even read the forums, but behind the scenes he is the guy accounting, shipping, taking stock, budgeting and scheduling orders. It means I can stick to making cool stuff.

I'd be super interested in seeing how you get on with PET. Where did you get the filament? We have been looking, as we would like to put it on our "tried and tested list" (Currently ABS, PLA, PC, Nylon 618 & 645, B&Q green nylon strimmer line, 2mm acrylic rod)

I intended to knock the extra hole off the block, but I have been ill, so not been able to create new drawings for the machinists, so I think the ones being milled right now should be the same as the previous ones.

Maddox

Yup me too!

I am really going to try and get this multi-nozzle-water-cooled out of the door as soon as possible. Lessons learned from previous experience however mean I am going to do a limited Beta production run (depends on demand) of units to get to experienced people who aren't expecting an out of the box experience and are willing to do some development around the part. In exchange for their input the beta units will be cheaper than production units.

Beta units in 4-6 weeks I reckon.

I really appreciate your compliments, I try my best, we do foul up here and there, but I think as long as we are transparent about things and keep communication open people are understanding of the fact that we are just getting up and running. In general though, things are looking great and I hope E3D can become my full time job soon enough.

Hendo420

Good to hear! I asked Dave to throw whatever he could spare in the box for you guys for your trouble. I think there should be some taulman618 in there too. Hope to hear back from you soon!

Yeah, I am thinking of dropping the "fits on normal 50mm spaced carriage mountings" because really people are going to need a custom carriage for this multi-hotend anyway, you just can't fit 3x nozzles and blocks through the hole in the middle of a normal carriage. If people are going to have to use a new carriage, I may as well go to 60-65mm which makes the entire design much nicer to layout and the wiring of the heaters less cramped.

bobc

I think I might just plonk down for a RUMBA board from reprapdiscount, that board looks amazing, everything i could ever want on an atmega based board, including stepper sockets for XYZEEE and lots more FETs and thermistors, so I wouldn't need to ditch my heated bed and fan just to heat 3X extruders.

I do however think there would be a market for an add-on/expansion board for RAMPS that adds some fets, thermistor inputs, and stepper sockets. There are tonnes of ramps in the wild, and when I release my hotend loads of people are going to need extra stepper sockets!

(I hope)

(I hope)uGen

I really appreciate that. It's been a crazy road, and we've made a lot of mistakes no doubt. But I think the one thing that has always worked for us is being honest and transparent with the community. Having all these posts about jamming hotends really troubled me, but I was really happy to see people coming along and chipping in advice and helping out. The customers experiencing problems really helped by collaborating with us to find the problem. It looks like now, we should be arriving at a place where the whole situation is ironed out.

A lot of engineers make terrible business people. I know I would be terrible at running a business! However I am blessed with my awesome co-director of E3D David, who doesn't post or even read the forums, but behind the scenes he is the guy accounting, shipping, taking stock, budgeting and scheduling orders. It means I can stick to making cool stuff.

I'd be super interested in seeing how you get on with PET. Where did you get the filament? We have been looking, as we would like to put it on our "tried and tested list" (Currently ABS, PLA, PC, Nylon 618 & 645, B&Q green nylon strimmer line, 2mm acrylic rod)

I intended to knock the extra hole off the block, but I have been ill, so not been able to create new drawings for the machinists, so I think the ones being milled right now should be the same as the previous ones.

Maddox

Yup me too!

I am really going to try and get this multi-nozzle-water-cooled out of the door as soon as possible. Lessons learned from previous experience however mean I am going to do a limited Beta production run (depends on demand) of units to get to experienced people who aren't expecting an out of the box experience and are willing to do some development around the part. In exchange for their input the beta units will be cheaper than production units.

Beta units in 4-6 weeks I reckon.

I really appreciate your compliments, I try my best, we do foul up here and there, but I think as long as we are transparent about things and keep communication open people are understanding of the fact that we are just getting up and running. In general though, things are looking great and I hope E3D can become my full time job soon enough.

Hendo420

Good to hear! I asked Dave to throw whatever he could spare in the box for you guys for your trouble. I think there should be some taulman618 in there too. Hope to hear back from you soon!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 08, 2013 08:56AM |

Registered: 11 years ago Posts: 490 |

@SanjayM: You posting in the forum and generally actively communicating with the community was one of the major reasons why I finally decided to buy your hot end (although I am normally very impatient about lead times). Customer service and transparency really matter to me.

I got the PET filament from plastic2print: Direct Link

Seems like they carried some a long time ago when the wiki page about printing material suppliers was written, ditched it or ran out of stock for quite a while and reintroduced it recently. Some plastic welding rod manufacturers also make PET welding rod in 3mm, but I have yet to find one with a web shop (guess as company, it might be easier for you to get your hands on some).

Polypropylene and HDPE might also be interesting. PP for example is used in plastic hinges as it resists wear from continuous bending. Here is a link the list of plastic welding rods of a German supplier. There are other interesting materials like ECTFE and PVDF, but unfortunately, the PDF is in German only.

I even saw a supplier of POM welding rods, but due to health concerns, this might not be interesting for home use.

I got the PET filament from plastic2print: Direct Link

Seems like they carried some a long time ago when the wiki page about printing material suppliers was written, ditched it or ran out of stock for quite a while and reintroduced it recently. Some plastic welding rod manufacturers also make PET welding rod in 3mm, but I have yet to find one with a web shop (guess as company, it might be easier for you to get your hands on some).

Polypropylene and HDPE might also be interesting. PP for example is used in plastic hinges as it resists wear from continuous bending. Here is a link the list of plastic welding rods of a German supplier. There are other interesting materials like ECTFE and PVDF, but unfortunately, the PDF is in German only.

I even saw a supplier of POM welding rods, but due to health concerns, this might not be interesting for home use.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 08, 2013 09:49AM |

Registered: 11 years ago Posts: 67 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 05:49AM |

Registered: 10 years ago Posts: 5 |

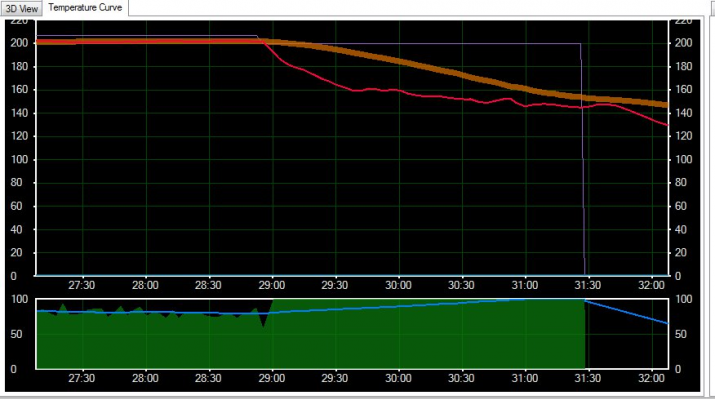

SanjayM: I got two heater cartridges and some 618 too, thanks. But you should check your heater cartridge supplier, both of the new heater cartridges were 20 W instead of 40 W, measured resistance around 8.3-8.5 ohms and ~4.0 in the old. The new heater cartridge has trouble getting to anything above 200 °C, can't keep up with printing fan on and it's stuck in the heaterblock so I can't use the old (which is stuck in the old heaterblock,).. You might want to add to the assembly instructions that if it needs force to insert the cartridge to the block, you need to sand the cartridge a bit?

Anyone got an idea how I can get the cartridge out of the block without destroying the block? I don't mind destroying the cartridge though. I've tried to get it moving with pump pliers but it won't budge even a mm.

Extrusion seems to be a lot easier with the new hotend, will report back when I get this working properly.

Edited 1 time(s). Last edit at 06/09/2013 05:51AM by extin.

Anyone got an idea how I can get the cartridge out of the block without destroying the block? I don't mind destroying the cartridge though. I've tried to get it moving with pump pliers but it won't budge even a mm.

Extrusion seems to be a lot easier with the new hotend, will report back when I get this working properly.

Edited 1 time(s). Last edit at 06/09/2013 05:51AM by extin.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 06:12AM |

Registered: 10 years ago Posts: 180 |

Maybe you could wrap the heater block with a couple layers of kapton tape for insulation like this j-head. I think it would be worth a try.

Edited 1 time(s). Last edit at 06/09/2013 06:13AM by lajos.

Edited 1 time(s). Last edit at 06/09/2013 06:13AM by lajos.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 07:28AM |

Registered: 11 years ago Posts: 205 |

extin Wrote:

>

> Anyone got an idea how I can get the cartridge out

> of the block without destroying the block? I don't

> mind destroying the cartridge though. I've tried

> to get it moving with pump pliers but it won't

> budge even a mm.

you should able to drill to 4.2 on the opposite side of wires and tap it to M5. That should give you enough purchase to remove it i think

>

> Anyone got an idea how I can get the cartridge out

> of the block without destroying the block? I don't

> mind destroying the cartridge though. I've tried

> to get it moving with pump pliers but it won't

> budge even a mm.

you should able to drill to 4.2 on the opposite side of wires and tap it to M5. That should give you enough purchase to remove it i think

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 07:56AM |

Admin Registered: 17 years ago Posts: 7,879 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 10:13AM |

Registered: 12 years ago Posts: 177 |

Gone through the cartridges of various batches with a multimeter. Extin is correct. There are some bogus cartridges in the mix. Despite being ordered as 40w, and labelled as 40w a small number of the cartridges from a particular shipment are more like 18W, with resistances between 7.5-8.5 Ohms. ARGH. I really appreciate the heads up. I would try drifting it out with a 5.5mm/6mm punch, or even the shank end of an old drill bit. A vice would probably help. If you can't get it out without killing the block I will get you a new block. I will make one by hand if needs be so you don't have to wait.

I have sent Dave over to the place where we keep the rest of the stock to go through them with a multimeter.

I am so angry right now.

I am very sorry to anyone who is having heating issues. You will receive a free replacement heater if you have a bad one.

I have sent Dave over to the place where we keep the rest of the stock to go through them with a multimeter.

I am so angry right now.

I am very sorry to anyone who is having heating issues. You will receive a free replacement heater if you have a bad one.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 10:24AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes supply chain screwups are my main headache selling Mendel90 kits and it seems the simpler the product the less likely it comes in correct.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 10:26AM |

Registered: 10 years ago Posts: 25 |

why is the 4.1 version so much more expensive than the 4.0? it says it has less parts and better cooling (and of course bowden system) but does it worth it? i am building a delta robot so bowden is important for me. will version 5.0 bring important features? if so i will wait for it since i have some time.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 11:12AM |

Registered: 11 years ago Posts: 248 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 09, 2013 11:59AM |

Registered: 12 years ago Posts: 177 |

Nophead

Here here! so far the simplest parts have been the most awful pain. Simple off the shelf fan? You can have that in 6 days...... Actually I haven't even made them yet, and we're all on holiday. Wait 2 months for fans! Specifically specified 6mm heater @ 40Watts? We'll change it to a 6.2mm heater @18W halfway though the batch. But we won't tell you, and we will label and package them as exactly the same product.

Want a complex multi-axis machined part from a specific grade of metal, made to a drawing that has a few errors on it that you correct over the phone? Not a problem sir, in fact your parts are going in the post early, and here are some thoughts I had about improving your designs. - Love our UK based machinists, awesome guys.

Turutk

We only sell the V4.1 right now. The difference between the bowden and non-bowden versions is to cover the cost of machining in the threads for the coupler in the top, the cost of the couplers, and the cost of the tubing.

V5 will be only an incremental improvement, with small tweaks, but no major changes in function, features or performance.

woo

Yup three weeks is the lead time. If you ordered now, it's likely that your part might ship earlier. But the promised time of 3 weeks still holds.

Those wondering about their heater cartridge

Just had confirmation that most of the heaters are fine, coming in at correct resistances etc. We have figured out exactly which shipment of heaters has the problem. We are in the process of figuring out who may have duff heaters. We are going to ship everyone whos heater came from that shipment a new heater, 1st class airmail, dispatch ASAP. You don't need to get in touch, we will ship them out proactively to all those who have had even a slight chance of having been affected. But if you are having problems don't hesitate to get in touch.

Edited 1 time(s). Last edit at 06/09/2013 12:01PM by SanjayM.

Here here! so far the simplest parts have been the most awful pain. Simple off the shelf fan? You can have that in 6 days...... Actually I haven't even made them yet, and we're all on holiday. Wait 2 months for fans! Specifically specified 6mm heater @ 40Watts? We'll change it to a 6.2mm heater @18W halfway though the batch. But we won't tell you, and we will label and package them as exactly the same product.

Want a complex multi-axis machined part from a specific grade of metal, made to a drawing that has a few errors on it that you correct over the phone? Not a problem sir, in fact your parts are going in the post early, and here are some thoughts I had about improving your designs. - Love our UK based machinists, awesome guys.

Turutk

We only sell the V4.1 right now. The difference between the bowden and non-bowden versions is to cover the cost of machining in the threads for the coupler in the top, the cost of the couplers, and the cost of the tubing.

V5 will be only an incremental improvement, with small tweaks, but no major changes in function, features or performance.

woo

Yup three weeks is the lead time. If you ordered now, it's likely that your part might ship earlier. But the promised time of 3 weeks still holds.

Those wondering about their heater cartridge

Just had confirmation that most of the heaters are fine, coming in at correct resistances etc. We have figured out exactly which shipment of heaters has the problem. We are in the process of figuring out who may have duff heaters. We are going to ship everyone whos heater came from that shipment a new heater, 1st class airmail, dispatch ASAP. You don't need to get in touch, we will ship them out proactively to all those who have had even a slight chance of having been affected. But if you are having problems don't hesitate to get in touch.

Edited 1 time(s). Last edit at 06/09/2013 12:01PM by SanjayM.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 10, 2013 07:33AM |

Registered: 11 years ago Posts: 248 |

one hotend ordered from Croatia

just one question, if i got it right, hotend is prepaired also for bowden pneumatic push-fit?

because, my plan is start with hotend directly attached to Greg's Wade extruder, but if necessary swap to bowden style

Edited 1 time(s). Last edit at 06/10/2013 08:53AM by woo.

just one question, if i got it right, hotend is prepaired also for bowden pneumatic push-fit?

because, my plan is start with hotend directly attached to Greg's Wade extruder, but if necessary swap to bowden style

Edited 1 time(s). Last edit at 06/10/2013 08:53AM by woo.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 10, 2013 11:53AM |

Registered: 11 years ago Posts: 939 |

And a follow up.

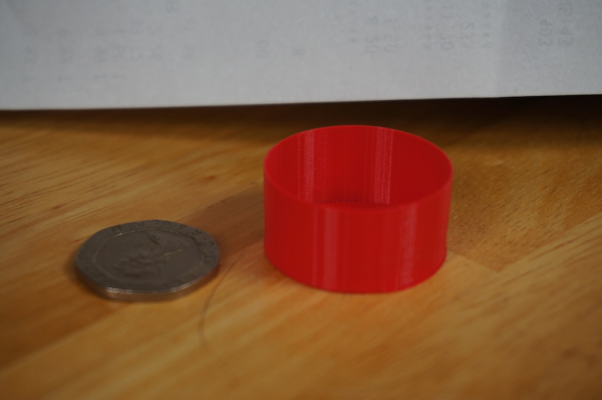

If you're not printing PLA I have to say this hotend is REALLY nice, and I wouldn't hesitate to recommend it, it produced one of the nicest ABS prints I've seen off my printer.

The replacement will print PLA reliably I ran about 9 50% sized buddha models (in 2 different PLAs) through it yesterday, I still have some issues with PLA, notably I see a small gap at the start of each layer which I think is it taking time for the pressure to normalize after a retract, and a secondary issue where extrusion becomes inconsistent as the head slows down when it's respecting the minimum layer time of 20s I have set.

I want to run some more tests today, it occurred to me part of the issue might be my vert aggressive retract settings, (I retract 5mm at 100mm/s) and I wanted to do some experiments with some test models to understand what's happening and see if I can dial out the issues I'm seeing.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

If you're not printing PLA I have to say this hotend is REALLY nice, and I wouldn't hesitate to recommend it, it produced one of the nicest ABS prints I've seen off my printer.

The replacement will print PLA reliably I ran about 9 50% sized buddha models (in 2 different PLAs) through it yesterday, I still have some issues with PLA, notably I see a small gap at the start of each layer which I think is it taking time for the pressure to normalize after a retract, and a secondary issue where extrusion becomes inconsistent as the head slows down when it's respecting the minimum layer time of 20s I have set.

I want to run some more tests today, it occurred to me part of the issue might be my vert aggressive retract settings, (I retract 5mm at 100mm/s) and I wanted to do some experiments with some test models to understand what's happening and see if I can dial out the issues I'm seeing.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 10, 2013 01:04PM |

Registered: 11 years ago Posts: 739 |

greetings to all

I write from Italy

I'm new in this community

I wanted to show my version V4 'received after about 30 days of waiting

why be 10 layers instead of 8 that I see in the pictures on the forum

seem to be too thin layers

SanjayM essere un nuovo modello?

Edited 4 time(s). Last edit at 06/10/2013 02:00PM by maralb.

I write from Italy

I'm new in this community

I wanted to show my version V4 'received after about 30 days of waiting

why be 10 layers instead of 8 that I see in the pictures on the forum

seem to be too thin layers

SanjayM essere un nuovo modello?

Edited 4 time(s). Last edit at 06/10/2013 02:00PM by maralb.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 10, 2013 02:23PM |

Registered: 11 years ago Posts: 973 |

maralb Wrote:

-------------------------------------------------------

> greetings to all

> I write from Italy

> I'm new in this community

> I wanted to show my version V4 'received after

> about 30 days of waiting

> why be 10 layers instead of 8 that I see in the

> pictures on the forum

> seem to be too thin layers

> SanjayM essere un nuovo modello?

>

rev 3 model the pictures one first posts or rev 1

-------------------------------------------------------

> greetings to all

> I write from Italy

> I'm new in this community

> I wanted to show my version V4 'received after

> about 30 days of waiting

> why be 10 layers instead of 8 that I see in the

> pictures on the forum

> seem to be too thin layers

> SanjayM essere un nuovo modello?

>

rev 3 model the pictures one first posts or rev 1

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 10, 2013 02:24PM |

Registered: 12 years ago Posts: 177 |

PolygonHell

Good to hear that the replacement parts have fixed the jamming problem! Those symptoms really do sound quite bowden related, and I would indeed take a look at your retraction settings. Intermittent extrusion at low speed could be stiction induced stick-slip type motion induced by friction in the tubing or anywhere else in the filament path. I haven't a great deal of experience with bowden system, but I have tested these hotends exhaustively at low speeds after you guys bought up the issue. I honestly cannot replicate the problems at low speed. What does your inconsistent extrusion look like?

From a purely practical perspective, you may find yourself much better off with a fan on carriage pointing at the print and printing with a lower min layer time.

If anyone else out there is printing on a bowden system at low speeds and has any information for me (positive or negative) I would really appreciate it. In the meantime I will get myself a bowden rig sorted for my Mendel90 so I can try and replicate/offer advice.

MaralB

That's the v4.1 revision (the latest model). It's lighter weight, and cools more effectively. It also has a bunch of other tiny little tweaks like nozzle angle which helps prevent curling-up overhangs in PLA, and improved chamfers around places where the filament has to cross a junction in the filament path to make initial feeding easier.

Good to hear that the replacement parts have fixed the jamming problem! Those symptoms really do sound quite bowden related, and I would indeed take a look at your retraction settings. Intermittent extrusion at low speed could be stiction induced stick-slip type motion induced by friction in the tubing or anywhere else in the filament path. I haven't a great deal of experience with bowden system, but I have tested these hotends exhaustively at low speeds after you guys bought up the issue. I honestly cannot replicate the problems at low speed. What does your inconsistent extrusion look like?

From a purely practical perspective, you may find yourself much better off with a fan on carriage pointing at the print and printing with a lower min layer time.

If anyone else out there is printing on a bowden system at low speeds and has any information for me (positive or negative) I would really appreciate it. In the meantime I will get myself a bowden rig sorted for my Mendel90 so I can try and replicate/offer advice.

MaralB

That's the v4.1 revision (the latest model). It's lighter weight, and cools more effectively. It also has a bunch of other tiny little tweaks like nozzle angle which helps prevent curling-up overhangs in PLA, and improved chamfers around places where the filament has to cross a junction in the filament path to make initial feeding easier.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 10, 2013 06:27PM |

Registered: 11 years ago Posts: 939 |

Quote

Those symptoms really do sound quite bowden related, and I would indeed take a look at your retraction settings. Intermittent extrusion at low speed could be stiction induced stick-slip type motion induced by friction in the tubing or anywhere else in the filament path

OK I am now getting good PLA prints, actually very good PLA prints.

The stiction is in the hotend, I know this because it only happens with PLA.

The problem appears to be, if you have significant retraction, there is some delay in the pressure returning to it's original level, I'd speculate because of rubbery PLA having to be pushed back through the hotend.

On my hotend with my bowden cable anything over 2mm of retraction results in voids following the retract, often followed by too much flow further into the layer, again I speculate because the backed up filment finally clears the hotend.

Unfortunately 2mm is not quite sufficient to remove strings with my setup, however I can compensate with Kisslicers wipe, which is what I did.

As an aside I'm still printing hotter than I would expect for PLA, what Beta value are you using for the thermister?

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 11, 2013 09:31AM |

Registered: 12 years ago Posts: 177 |

Glad to hear you are up and getting nice prints! Any pictures?  Really appreciate your feedback and patience throught the whole saga. If you ever order from us again do get in touch and I will sort you out with something.

Really appreciate your feedback and patience throught the whole saga. If you ever order from us again do get in touch and I will sort you out with something.

The thermistor is an EPCOS - B57560G104F rated beta is 4036K - What temps are you printing at?

I'd wager that the increased force at the start of extrusion results in spring-like compression of the filament in the bowden, once force accumulates enough to begin flow then the sprung filament decompresses and you see the extra filament you "lost" at the start appear later on in the extrusion.

Really appreciate your feedback and patience throught the whole saga. If you ever order from us again do get in touch and I will sort you out with something.

Really appreciate your feedback and patience throught the whole saga. If you ever order from us again do get in touch and I will sort you out with something.The thermistor is an EPCOS - B57560G104F rated beta is 4036K - What temps are you printing at?

I'd wager that the increased force at the start of extrusion results in spring-like compression of the filament in the bowden, once force accumulates enough to begin flow then the sprung filament decompresses and you see the extra filament you "lost" at the start appear later on in the extrusion.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 11, 2013 04:57PM |

Registered: 11 years ago Posts: 939 |

Quote

Glad to hear you are up and getting nice prints! Any pictures?

This is in ABS almost no messing with parameters, buddha at 50% scale

This is one of MANY PLA calibration objects

And a test print - pink panther woman at 50% scale

Excluding the single wall test all at 0.2mm layer height, 2 Perimeters (out to in) 20% infill, 60mm/s perimeters and 100mm/s infill, 10s Minimum layer time.

Edited 2 time(s). Last edit at 06/11/2013 05:19PM by Polygonhell.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 11, 2013 05:00PM |

Registered: 11 years ago Posts: 939 |

Quote

The thermistor is an EPCOS - B57560G104F rated beta is 4036K - What temps are you printing at?

I'm at 235, but I need to verify I get the same issues reducing the temperature (inconsistent extrusion) as I did before I changed the retract settings.

I've had Ultimachine PLA before that requires 230 to print consistently, and I haven't tried this color before, so it may just be par for the course.

I did check the block temperature with a thermocouple and it's not miles off.

EDIT - It appears to be printing fine at 200, so it's likely the issues I had were retraction related, which I probably compensated for with increased temperature.

EDIT - and it jammed as soon as the print got to the part where the minimum layer time had a significant effect.

EDIT - Print completes at 220 though, so it's not that much hotter than I'd expect

Edited 3 time(s). Last edit at 06/11/2013 06:49PM by Polygonhell.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 12, 2013 11:44PM |

Registered: 10 years ago Posts: 3 |

Hi,

Finally I've just received my hotend. It takes about 2 weeks to reach in Shanghai, China.

But I'm still waiting other parts to build my first printer. Hope this hotend can make a great

work

I measured the resistance of cartridge. it is exactly 8.5 ohm.

The cartridge is a bit elliptical, and can fit well with the heater block...

Finally I've just received my hotend. It takes about 2 weeks to reach in Shanghai, China.

But I'm still waiting other parts to build my first printer. Hope this hotend can make a great

work

I measured the resistance of cartridge. it is exactly 8.5 ohm.

The cartridge is a bit elliptical, and can fit well with the heater block...

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 13, 2013 03:48AM |

Registered: 10 years ago Posts: 5 |

liweitianux Wrote:

-------------------------------------------------------

> Hi,

>

> Finally I've just received my hotend. It takes

> about 2 weeks to reach in Shanghai, China.

>

> But I'm still waiting other parts to build my

> first printer. Hope this hotend can make a great

> work

>

> I measured the resistance of cartridge. it is

> exactly 8.5 ohm.

> The cartridge is a bit elliptical, and can fit

> well with the heater block...

Don't install that cartridge, at 8.5 ohms it's 16.9 W which is not nearly enough to keep the temperature stable during printing, even less so if you plan on installing a cooling fan to cool the print. Plus it bonds really easily to the aluminium heaterblock and is really pita to get off.

Wait until your replacement cartridge arrives.

SanjayM:

I managed to get the cartridge off without destroying the heaterblock. It did take quite a beating though Drilled most of the ceramic away with 4.5 mm drill and used a hammer to punch it off. Needed enough force to deform the block on one corner but it's only cosmetic. Thanks for everyone for the tips.

Drilled most of the ceramic away with 4.5 mm drill and used a hammer to punch it off. Needed enough force to deform the block on one corner but it's only cosmetic. Thanks for everyone for the tips.

-------------------------------------------------------

> Hi,

>

> Finally I've just received my hotend. It takes

> about 2 weeks to reach in Shanghai, China.

>

> But I'm still waiting other parts to build my

> first printer. Hope this hotend can make a great

> work

>

> I measured the resistance of cartridge. it is

> exactly 8.5 ohm.

> The cartridge is a bit elliptical, and can fit

> well with the heater block...

Don't install that cartridge, at 8.5 ohms it's 16.9 W which is not nearly enough to keep the temperature stable during printing, even less so if you plan on installing a cooling fan to cool the print. Plus it bonds really easily to the aluminium heaterblock and is really pita to get off.

Wait until your replacement cartridge arrives.

SanjayM:

I managed to get the cartridge off without destroying the heaterblock. It did take quite a beating though

Drilled most of the ceramic away with 4.5 mm drill and used a hammer to punch it off. Needed enough force to deform the block on one corner but it's only cosmetic. Thanks for everyone for the tips.

Drilled most of the ceramic away with 4.5 mm drill and used a hammer to punch it off. Needed enough force to deform the block on one corner but it's only cosmetic. Thanks for everyone for the tips.

Sorry, only registered users may post in this forum.