Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 13, 2013 11:56AM |

Registered: 11 years ago Posts: 118 |

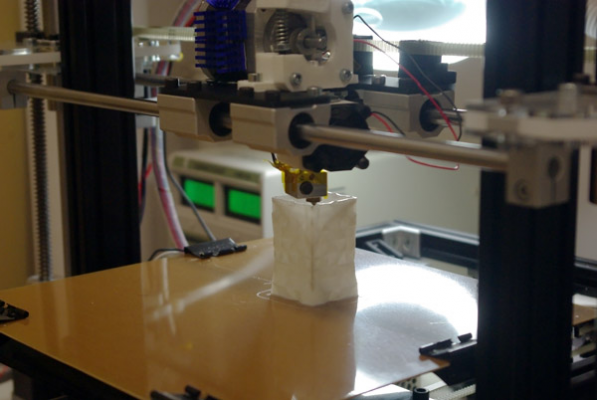

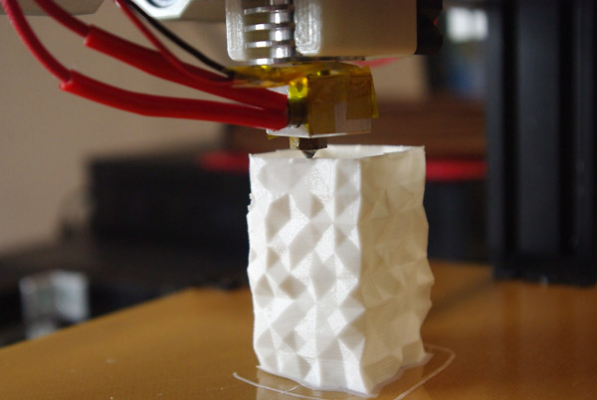

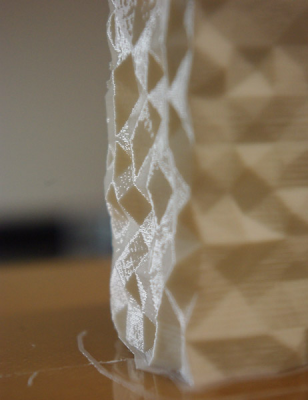

I finally got mine assembled,

the first few prints came out beatiful!

very even extrusion the whole time,

best Hotend so far (I had the QU-BD and Chess hotend)

ps: i Think you could shorten the Cooler to 20mm, or even 15mm heigh.

The Second ripple on my e3d was already cool...

like that:

Edited 3 time(s). Last edit at 06/13/2013 12:01PM by mrc.

the first few prints came out beatiful!

very even extrusion the whole time,

best Hotend so far (I had the QU-BD and Chess hotend)

ps: i Think you could shorten the Cooler to 20mm, or even 15mm heigh.

The Second ripple on my e3d was already cool...

like that:

Edited 3 time(s). Last edit at 06/13/2013 12:01PM by mrc.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 13, 2013 06:26PM |

Registered: 12 years ago Posts: 177 |

liweitianux and others with off heaters

We posted hundreds of new heaters today. Anybody who has had any chance at all of having a bad heater has been shipped a new heater - first class airmail. Should be with you in a few days - no need to ask.

I am really sorry to anyone who has had issues relating to this, we have been as proactive as possible in getting this sorted and have taken a bit of a financial hit in doing so. We don't even know if the supplier is going to refund us. It's important to us that everyone gets proper parts, and this is the only really fair way to sort this mess out that we can see.

It's important to us that everyone gets proper parts, and this is the only really fair way to sort this mess out that we can see.

In general I think people need to be aware that there are bad heater cartridges out in the reprap arena, and these will be among many suppliers

Symptoms:

Inconsistent size/shape - not round, bulged, over 6mm in diameter.

Low power output (High resistance) Around 7.5-8.5 Ohms for 18W of power. Poor heat up times, inability to maintain or obtain high temperatures.

They are labelled as 40w and 12v - but I have a suspicion that they are perhaps 24v units that have ended up mislabelled. But this doesn't account for the poor dimensional accuracy/inconsistency.

mrc

Really nice looking prints! Thanks for the feedback. The second fin may be cool, but that doesn't mean that it doesn't need to exist - if you look at the internal shaft of the hotend you will see that it is carefully contoured to conduct heat up and away from the lower fins so heat is being drawn up and dissipated higher up. We also have to consider that this hotend is designed and sold as a super-high temp capable part, that allows printing polycarbonate at 300+C, as well as hopefully being able to extrude more exotic polymers such as PEEK. Printing at very high temps with the hotend shown might not be great on a printed carriage, I think some other all-metal hotends might struggle to keep heat away from whatever they are attached to when hitting super-hot.

It seems to be clear now that whatever all metal hotend you use, you are going to want a fan on it cooling it 100% of the time. If we know we must use a fan, then it makes sense to design around the most compact fan readily available (30mm) - the height of our wide finned heatsinking portion is 30mm because of this fact. If we go shorter then we would end up with air everywhere, over the nozzle, on the print. We have learned from experience that you really need separate airflow control for the print. But at this length we can tightly confine the airflow to the heatsink with the duct.

In general

We are still waiting on parts from the machinists for the batch that is currently waiting to ship. They've had a guy sick which has been killing the deadline on getting the next batch of machined parts in, and thus kits out the door. It's lame, but we really can't blame them. We really tried to account for problems, and added extra time to our lead time after lessons from missing prior deadlines, but once again Murphys Law intervenes. I think we are looking at a week to 10 days to ship. Argh. If packages leave late then we always try and put something extra in the box for free, like exotic polymer filaments.

I have some really awesome stuff that is about to go to the manufacturers for a short run of prototypes. To avoid teething problems the release of my "next big thing" (Still a hotend) will involve a beta program of sorts. Watch this space!

We posted hundreds of new heaters today. Anybody who has had any chance at all of having a bad heater has been shipped a new heater - first class airmail. Should be with you in a few days - no need to ask.

I am really sorry to anyone who has had issues relating to this, we have been as proactive as possible in getting this sorted and have taken a bit of a financial hit in doing so. We don't even know if the supplier is going to refund us.

It's important to us that everyone gets proper parts, and this is the only really fair way to sort this mess out that we can see.

It's important to us that everyone gets proper parts, and this is the only really fair way to sort this mess out that we can see.In general I think people need to be aware that there are bad heater cartridges out in the reprap arena, and these will be among many suppliers

Symptoms:

Inconsistent size/shape - not round, bulged, over 6mm in diameter.

Low power output (High resistance) Around 7.5-8.5 Ohms for 18W of power. Poor heat up times, inability to maintain or obtain high temperatures.

They are labelled as 40w and 12v - but I have a suspicion that they are perhaps 24v units that have ended up mislabelled. But this doesn't account for the poor dimensional accuracy/inconsistency.

mrc

Really nice looking prints! Thanks for the feedback. The second fin may be cool, but that doesn't mean that it doesn't need to exist - if you look at the internal shaft of the hotend you will see that it is carefully contoured to conduct heat up and away from the lower fins so heat is being drawn up and dissipated higher up. We also have to consider that this hotend is designed and sold as a super-high temp capable part, that allows printing polycarbonate at 300+C, as well as hopefully being able to extrude more exotic polymers such as PEEK. Printing at very high temps with the hotend shown might not be great on a printed carriage, I think some other all-metal hotends might struggle to keep heat away from whatever they are attached to when hitting super-hot.

It seems to be clear now that whatever all metal hotend you use, you are going to want a fan on it cooling it 100% of the time. If we know we must use a fan, then it makes sense to design around the most compact fan readily available (30mm) - the height of our wide finned heatsinking portion is 30mm because of this fact. If we go shorter then we would end up with air everywhere, over the nozzle, on the print. We have learned from experience that you really need separate airflow control for the print. But at this length we can tightly confine the airflow to the heatsink with the duct.

In general

We are still waiting on parts from the machinists for the batch that is currently waiting to ship. They've had a guy sick which has been killing the deadline on getting the next batch of machined parts in, and thus kits out the door. It's lame, but we really can't blame them. We really tried to account for problems, and added extra time to our lead time after lessons from missing prior deadlines, but once again Murphys Law intervenes. I think we are looking at a week to 10 days to ship. Argh. If packages leave late then we always try and put something extra in the box for free, like exotic polymer filaments.

I have some really awesome stuff that is about to go to the manufacturers for a short run of prototypes. To avoid teething problems the release of my "next big thing" (Still a hotend) will involve a beta program of sorts. Watch this space!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 14, 2013 12:34AM |

Registered: 10 years ago Posts: 3 |

SanjayM Wrote:

-------------------------------------------------------

> liweitianux and others with off heaters

> We posted hundreds of new heaters today. Anybody

> who has had any chance at all of having a bad

> heater has been shipped a new heater - first class

> airmail. Should be with you in a few days - no

> need to ask.

>

> I am really sorry to anyone who has had issues

> relating to this, we have been as proactive as

> possible in getting this sorted and have taken a

> bit of a financial hit in doing so. We don't even

> know if the supplier is going to refund us.

> It's important to us that everyone gets proper

> parts, and this is the only really fair way to

> sort this mess out that we can see.

I'm also very sorry that our Chinese sellers provide counterfeit or poor quality products.

And I insist that the honesty should be the most important for a seller.

Thank you very much for the replacement. In addition, I'd like to buy another cartridge

from the local online sellers, considering that it will take serveral weeks to received the

replacement posted from the UK. Many thanks to E3D.

-------------------------------------------------------

> liweitianux and others with off heaters

> We posted hundreds of new heaters today. Anybody

> who has had any chance at all of having a bad

> heater has been shipped a new heater - first class

> airmail. Should be with you in a few days - no

> need to ask.

>

> I am really sorry to anyone who has had issues

> relating to this, we have been as proactive as

> possible in getting this sorted and have taken a

> bit of a financial hit in doing so. We don't even

> know if the supplier is going to refund us.

> It's important to us that everyone gets proper

> parts, and this is the only really fair way to

> sort this mess out that we can see.

I'm also very sorry that our Chinese sellers provide counterfeit or poor quality products.

And I insist that the honesty should be the most important for a seller.

Thank you very much for the replacement. In addition, I'd like to buy another cartridge

from the local online sellers, considering that it will take serveral weeks to received the

replacement posted from the UK. Many thanks to E3D.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 15, 2013 04:53PM |

Registered: 11 years ago Posts: 118 |

SanjayM Wrote:

-------------------------------------------------------

> mrc

> Really nice looking prints! Thanks for the

> feedback. The second fin may be cool, but that

> doesn't mean that it doesn't need to exist - if

> you look at the internal shaft of the hotend you

> will see that it is carefully contoured to conduct

> heat up and away from the lower fins so heat is

> being drawn up and dissipated higher up. We also

> have to consider that this hotend is designed and

> sold as a super-high temp capable part, that

> allows printing polycarbonate at 300+C, as well as

> hopefully being able to extrude more exotic

> polymers such as PEEK. Printing at very high temps

> with the hotend shown might not be great on a

> printed carriage, I think some other all-metal

> hotends might struggle to keep heat away from

> whatever they are attached to when hitting

> super-hot.

>

> It seems to be clear now that whatever all metal

> hotend you use, you are going to want a fan on it

> cooling it 100% of the time. If we know we must

> use a fan, then it makes sense to design around

> the most compact fan readily available (30mm) -

> the height of our wide finned heatsinking portion

> is 30mm because of this fact. If we go shorter

> then we would end up with air everywhere, over the

> nozzle, on the print. We have learned from

> experience that you really need separate airflow

> control for the print. But at this length we can

> tightly confine the airflow to the heatsink with

> the duct.

On high Temps it might be useful to have such a big cooler,

especially if you want to be 120% sure that it is cool in the Cold end, like you want it i think.

But i have some ideas for dual extrusion in my head with a shorter cooler and one 50mm fan for

both Extruder + MK5 drive gear and Motorcooling. I think about Lathíng a shorter cooler for further tests.

And i got nice 20mm and 25mm fans making 13000RPM but they are a bit pricey.

ps: Im running on 190°C with no Jams at all, 1.5mm retraction, temperature fluctuates around -+ 0.2° without! calibrating,

but still experimenting.

Edited 4 time(s). Last edit at 06/15/2013 05:03PM by mrc.

-------------------------------------------------------

> mrc

> Really nice looking prints! Thanks for the

> feedback. The second fin may be cool, but that

> doesn't mean that it doesn't need to exist - if

> you look at the internal shaft of the hotend you

> will see that it is carefully contoured to conduct

> heat up and away from the lower fins so heat is

> being drawn up and dissipated higher up. We also

> have to consider that this hotend is designed and

> sold as a super-high temp capable part, that

> allows printing polycarbonate at 300+C, as well as

> hopefully being able to extrude more exotic

> polymers such as PEEK. Printing at very high temps

> with the hotend shown might not be great on a

> printed carriage, I think some other all-metal

> hotends might struggle to keep heat away from

> whatever they are attached to when hitting

> super-hot.

>

> It seems to be clear now that whatever all metal

> hotend you use, you are going to want a fan on it

> cooling it 100% of the time. If we know we must

> use a fan, then it makes sense to design around

> the most compact fan readily available (30mm) -

> the height of our wide finned heatsinking portion

> is 30mm because of this fact. If we go shorter

> then we would end up with air everywhere, over the

> nozzle, on the print. We have learned from

> experience that you really need separate airflow

> control for the print. But at this length we can

> tightly confine the airflow to the heatsink with

> the duct.

On high Temps it might be useful to have such a big cooler,

especially if you want to be 120% sure that it is cool in the Cold end, like you want it i think.

But i have some ideas for dual extrusion in my head with a shorter cooler and one 50mm fan for

both Extruder + MK5 drive gear and Motorcooling. I think about Lathíng a shorter cooler for further tests.

And i got nice 20mm and 25mm fans making 13000RPM but they are a bit pricey.

ps: Im running on 190°C with no Jams at all, 1.5mm retraction, temperature fluctuates around -+ 0.2° without! calibrating,

but still experimenting.

Edited 4 time(s). Last edit at 06/15/2013 05:03PM by mrc.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 15, 2013 06:16PM |

Registered: 11 years ago Posts: 973 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 15, 2013 06:53PM |

Registered: 12 years ago Posts: 177 |

chris33

Almost all of the revision-1 hotends seemed to print without issue. RichRap has one of the first off the production line and is getting excellent prints. Along with many others. So far only 3-4 hotends from the first batch have had the jamming issue. Those all seem to have been sorted out and are now up and printing with replacement parts. (Although I am still to hear from Hendo420?)

I don't understand why you specifically want a revision-1 hotend though? The newer versions are fully compatible mounting wise and also have an array of tweaks for better cooling and smoother passage of filament.

mrc

Glad to hear you are getting good prints, and with those settings too. Would be cool to see what you come up with when your hotend is all done. We did look at 20-25mm fans, but there just isn't a decent supply chain in place - getting 30mm fans is hard enough! Multi-nozzle is definitely something we are very interested in.

Sanjay

Almost all of the revision-1 hotends seemed to print without issue. RichRap has one of the first off the production line and is getting excellent prints. Along with many others. So far only 3-4 hotends from the first batch have had the jamming issue. Those all seem to have been sorted out and are now up and printing with replacement parts. (Although I am still to hear from Hendo420?)

I don't understand why you specifically want a revision-1 hotend though? The newer versions are fully compatible mounting wise and also have an array of tweaks for better cooling and smoother passage of filament.

mrc

Glad to hear you are getting good prints, and with those settings too. Would be cool to see what you come up with when your hotend is all done. We did look at 20-25mm fans, but there just isn't a decent supply chain in place - getting 30mm fans is hard enough! Multi-nozzle is definitely something we are very interested in.

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 18, 2013 04:32AM |

Registered: 10 years ago Posts: 5 |

What are the specifications of the PTFE Tubing and push-fit couplers for the bowden-style hot end? I am looking to see if it will be compatible with SeeMeCNC's EZStruder, which I believe is 4mm ID, 6mm OD tubing.

Thanks!

P.S.

I really enjoy following this thread. It's great to see that a lot of the problems people were having have been taken care of. Great work!

Thanks!

P.S.

I really enjoy following this thread. It's great to see that a lot of the problems people were having have been taken care of. Great work!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 18, 2013 12:04PM |

Registered: 10 years ago Posts: 25 |

Drawings of the stainless stell doesn't contain info about the threads. in the finished product i see that the threads start some distance from the top of the barrel. can you give more information about that please? if the total length of the top part of the barrel is 10mm then do the threads in the heatsink not go all the way in that 6mm diameter 10mm long place?

edit: are the drawings for v4.0 and photos for v4.1?

Edited 1 time(s). Last edit at 06/18/2013 12:13PM by turutk.

edit: are the drawings for v4.0 and photos for v4.1?

Edited 1 time(s). Last edit at 06/18/2013 12:13PM by turutk.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 18, 2013 12:25PM |

Registered: 12 years ago Posts: 177 |

Coin3

The tubing is 3.175mmID 6.35mmOD (Which is 1/8th Inch ID and 1/4 Inch OD).

The couplers are 1/8th BSPP theaded couplers designed to accept 6mm or 1/4 Inch tubing.

Whether you use your existing 4mm SMCNC tubing or our tighter tubing is up to you - but either will plug into our hotend coupler. I expect the SMCNC coupler will accept our tubing too. So it's likely that there are multiple configurations that will work and you will just need to decide which best suits you.

turutk

I know it's a bit odd, but we don't actually have drawings for that little end of the heatbreak - the machinist suggested a little modification that improved smooth filament passage at the junctions and sent us some parts to see what we think. Ever since we have just been saying "do the same thing on top please and thankyou" because it works fantastically well.

I can tell you that the cold side of the heat-break has 10mm of threads and the "stubby bit" is in addition to the threads as drawn on the downloads page.

I will give him a ring and ask him for a sketch of the "little stubby bit" and try and get the drawings updated on the site. We have also done a few other tiny changes that need open-sourcing properly. Once all these little tweaks have been drawn up and we get the latest (huge) batch in stock we will be shipping next day with no pre-order nonsense. We will probably then refer to the hotend with all the little tweaks from the start of the v4 saga incorporated as "E3D v5 Hotend - Direct" and "E3D v5 Hotend - Bowden"

Hope that helps!

The tubing is 3.175mmID 6.35mmOD (Which is 1/8th Inch ID and 1/4 Inch OD).

The couplers are 1/8th BSPP theaded couplers designed to accept 6mm or 1/4 Inch tubing.

Whether you use your existing 4mm SMCNC tubing or our tighter tubing is up to you - but either will plug into our hotend coupler. I expect the SMCNC coupler will accept our tubing too. So it's likely that there are multiple configurations that will work and you will just need to decide which best suits you.

turutk

I know it's a bit odd, but we don't actually have drawings for that little end of the heatbreak - the machinist suggested a little modification that improved smooth filament passage at the junctions and sent us some parts to see what we think. Ever since we have just been saying "do the same thing on top please and thankyou" because it works fantastically well.

I can tell you that the cold side of the heat-break has 10mm of threads and the "stubby bit" is in addition to the threads as drawn on the downloads page.

I will give him a ring and ask him for a sketch of the "little stubby bit" and try and get the drawings updated on the site. We have also done a few other tiny changes that need open-sourcing properly. Once all these little tweaks have been drawn up and we get the latest (huge) batch in stock we will be shipping next day with no pre-order nonsense. We will probably then refer to the hotend with all the little tweaks from the start of the v4 saga incorporated as "E3D v5 Hotend - Direct" and "E3D v5 Hotend - Bowden"

Hope that helps!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 18, 2013 12:54PM |

Registered: 10 years ago Posts: 25 |

thanks for replying. i was waiting for v5 to buy but my hotend broke down yesterday and i need a hotend somewhat urgently so i am trying to build a v4.1 of yours with a lathe just to use until you get new ones ready. that stubby part seems to be 4 or 5mm long and its diameter seems to be a little bit less than 6mm (guessing 5mm) so i am thinking to leave a 4mm long part with 5mm diameter on top of the cold side and also drill a hole of the same size in the aluminum. would that be close enough? otherwise i am just going to go with your drawings as i need a working hotend quickly for a limited time (which may not be perfect).

Edited 2 time(s). Last edit at 06/18/2013 01:07PM by turutk.

Edited 2 time(s). Last edit at 06/18/2013 01:07PM by turutk.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 18, 2013 01:45PM |

Registered: 11 years ago Posts: 973 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 18, 2013 02:29PM |

Registered: 12 years ago Posts: 177 |

turutk

The idea behind the "stubby bit" is that if you drill a hole you will end up with the 59 degree drill point. If you tap that all the way to the bottom with a bottoming tap and then screw in a heatbreak you are going to end up with a tiny bit of free space, where the filament can wander catch or jam on it's way down.

Using a bottoming tap and a heatbreak that is well countersunk on the entrance eliminates the issue pretty much entirely. But in a large batch of CNC parts it is not economical to do multistage tapping with a starting tap, second tap, bottoming tap etc. So thus the "stubby bit" is born. The stub protrudes up from the entrance to the break and clears any area where there are unfinished threads from using just a normal starting tap. The top of the stub has matched chamfers to the drill tip cone so it seats right up into the hole. It also has it's own small top countersink to ensure there is no catching of filament at the junction.

Have a look at the geometry of your taps and your drill bits and you should be able to derive the appropriate geometry for your own stub.

For what it's worth the part you will receive is a "v5 " - everyone who is waiting on a hotend to ship will recieve a v5. It's just the culmination of a bunch of tweaks, an incremental improvement as opposed to a large change reallly. Once we have all the parts in, boxes packed, and are ready to ship any order in a day or two without delay we will do a sort of re-launch, with a rundown of what has changed and why in detail, as well as release full drawings. And we will start actually calling it "v5"!

chris33

I think we are going to go with NC BY SA for a bit, and as we iterate forward onto newer versions the older versions designs will become plain SA. I'm not yet decided quite yet though. Either way you are still fine to go make one for yourself! We already have one guy who has made one from the drawings online and has it running on an ultimaker successfully. I would be interested to know how you get on with your self build, if you have any problems or want any advice on your clone then please just ask.

I still don't get why you want a v4 revision 1 though?!

The idea behind the "stubby bit" is that if you drill a hole you will end up with the 59 degree drill point. If you tap that all the way to the bottom with a bottoming tap and then screw in a heatbreak you are going to end up with a tiny bit of free space, where the filament can wander catch or jam on it's way down.

Using a bottoming tap and a heatbreak that is well countersunk on the entrance eliminates the issue pretty much entirely. But in a large batch of CNC parts it is not economical to do multistage tapping with a starting tap, second tap, bottoming tap etc. So thus the "stubby bit" is born. The stub protrudes up from the entrance to the break and clears any area where there are unfinished threads from using just a normal starting tap. The top of the stub has matched chamfers to the drill tip cone so it seats right up into the hole. It also has it's own small top countersink to ensure there is no catching of filament at the junction.

Have a look at the geometry of your taps and your drill bits and you should be able to derive the appropriate geometry for your own stub.

For what it's worth the part you will receive is a "v5 " - everyone who is waiting on a hotend to ship will recieve a v5. It's just the culmination of a bunch of tweaks, an incremental improvement as opposed to a large change reallly. Once we have all the parts in, boxes packed, and are ready to ship any order in a day or two without delay we will do a sort of re-launch, with a rundown of what has changed and why in detail, as well as release full drawings. And we will start actually calling it "v5"!

chris33

I think we are going to go with NC BY SA for a bit, and as we iterate forward onto newer versions the older versions designs will become plain SA. I'm not yet decided quite yet though. Either way you are still fine to go make one for yourself! We already have one guy who has made one from the drawings online and has it running on an ultimaker successfully. I would be interested to know how you get on with your self build, if you have any problems or want any advice on your clone then please just ask.

I still don't get why you want a v4 revision 1 though?!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 18, 2013 02:50PM |

Registered: 11 years ago Posts: 973 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 19, 2013 09:21AM |

Registered: 10 years ago Posts: 3 |

Hey Sanjay, I got delivery of my E3D today and first thing i did was check the resistance of the heater cartridge, i have 5.7 ohms which work out as a 25W @ 12V. Would that be enough to heat up to 300deg for the assembly? Or did i receive one of the bad heaters?

Then i checked the bowden kit, the push to fit connector isn't aligned with the hotend. It seems that the top wasn't properly tapped and that slight angle prevents the filament from entering the hotend. I tried both sides of the bowden push to fit connectors and they have the same issue. The picture attached explains it better.

Otherwise everything else seems good, i have to say machining quality is a beauty. Keep up the good work Sanjay & David.

Then i checked the bowden kit, the push to fit connector isn't aligned with the hotend. It seems that the top wasn't properly tapped and that slight angle prevents the filament from entering the hotend. I tried both sides of the bowden push to fit connectors and they have the same issue. The picture attached explains it better.

Otherwise everything else seems good, i have to say machining quality is a beauty. Keep up the good work Sanjay & David.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 20, 2013 09:22AM |

Registered: 11 years ago Posts: 21 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 20, 2013 06:47PM |

Registered: 10 years ago Posts: 3 |

matty2013 Wrote:

-------------------------------------------------------

> How do I go about checking if I have the correct

Get your multimeter and measure the Resistance (Ohms) across the heater cartridge. Ideally for a 40W @ 12v heater it should have 3.6 Ohms resistance.

P=(V*V)/R

Sanjay

Thanks for emailing me and all other customers who are receiving replacement heaters, you guys are awesome, can't wait to get my e3d up and running. I would like to know if there is a fix to the miss aligned bowden setup. I also just noticed that i didn't get a M3 set screw in my e3D, i have some M3 SHCS but the head is too big and gets in the way of the nozzle

-------------------------------------------------------

> How do I go about checking if I have the correct

Get your multimeter and measure the Resistance (Ohms) across the heater cartridge. Ideally for a 40W @ 12v heater it should have 3.6 Ohms resistance.

P=(V*V)/R

Sanjay

Thanks for emailing me and all other customers who are receiving replacement heaters, you guys are awesome, can't wait to get my e3d up and running. I would like to know if there is a fix to the miss aligned bowden setup. I also just noticed that i didn't get a M3 set screw in my e3D, i have some M3 SHCS but the head is too big and gets in the way of the nozzle

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 21, 2013 08:09PM |

Registered: 11 years ago Posts: 205 |

kwetty Wrote:

-------------------------------------------------------

> Hey Sanjay, I got delivery of my E3D today and

> first thing i did was check the resistance of the

> heater cartridge, i have 5.7 ohms which work out

> as a 25W @ 12V. Would that be enough to heat up to

> 300deg for the assembly? Or did i receive one of

> the bad heaters?

I used a 30W I had lying aroung when I found mine was out of round, and it heats crazingly fast up to 300°C.

Sanjay, got my relacement today. Awesome aftersales service you guys have.

-------------------------------------------------------

> Hey Sanjay, I got delivery of my E3D today and

> first thing i did was check the resistance of the

> heater cartridge, i have 5.7 ohms which work out

> as a 25W @ 12V. Would that be enough to heat up to

> 300deg for the assembly? Or did i receive one of

> the bad heaters?

I used a 30W I had lying aroung when I found mine was out of round, and it heats crazingly fast up to 300°C.

Sanjay, got my relacement today. Awesome aftersales service you guys have.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 22, 2013 03:46AM |

Registered: 10 years ago Posts: 3 |

alj_rprp Wrote:

> I used a 30W I had lying aroung when I found mine

> was out of round, and it heats crazingly fast up

> to 300°C.

>

> Sanjay, got my relacement today. Awesome

> aftersales service you guys have.

Thanks alj_rprp, that sounds good, i had real bad cartridge heaters from ebay which had about 11Ohms of resistance (12W) they took forever to heatup. I just got some M3 set screws from my local hobby shop, will assemble the e3d soon. I also printed a part to avoid using e3d's bowden kit until i hear from sanjay.

> I used a 30W I had lying aroung when I found mine

> was out of round, and it heats crazingly fast up

> to 300°C.

>

> Sanjay, got my relacement today. Awesome

> aftersales service you guys have.

Thanks alj_rprp, that sounds good, i had real bad cartridge heaters from ebay which had about 11Ohms of resistance (12W) they took forever to heatup. I just got some M3 set screws from my local hobby shop, will assemble the e3d soon. I also printed a part to avoid using e3d's bowden kit until i hear from sanjay.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 22, 2013 12:49PM |

Registered: 10 years ago Posts: 22 |

I am not sure if this have been answer. Is there a reason why we want to leave a gap between the block and nozzle? Why couldn't I tighten the nozzle to the block first before installing the heater break. My heater break doesn't stop when it thread into the block without the nozzle.

Edited 1 time(s). Last edit at 06/22/2013 12:49PM by DanMoto.

Edited 1 time(s). Last edit at 06/22/2013 12:49PM by DanMoto.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 22, 2013 01:20PM |

Registered: 10 years ago Posts: 22 |

Ok, I just read the instruction over again and it seem that the idea is to "crush" the nozzle against the heat-break. Question now is how much "crush" is enough to form a seal? 1/4 turn? 1/2 turn? Any torque specification? That way I can try to get the nozzle exactly flat against the heatblock and at the same time properly seal the heatbreak and nozzle.

Edited 2 time(s). Last edit at 06/22/2013 01:25PM by DanMoto.

Edited 2 time(s). Last edit at 06/22/2013 01:25PM by DanMoto.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 23, 2013 09:56AM |

Registered: 12 years ago Posts: 177 |

Kwetty

That sure doesn't look right or proper. My apologies. There is I supposed a chance you have cross-threaded it, but it sounds like you have had a pretty good try at getting it right. Be careful not to damage the delrin coupler threads by trying to force the coupler straight in the harder aluminium heatsink threads.

If you get in touch via the website feedback form I will sort you out with a replacement - but I can't tell your real name/address just from the forums.

Matty2013

Best way would be to use a multimeter to check the resistance of the heater cartridge. It should be below 5 Ohms. But the bottom line is if it is working then it's working.

DanMoto

The reason for the gap is that the nozzle needs to tighten against the heat-break to form a seal. No crushing involved, and not much torque either. Most of the work is done by the metal contracting as it cools, you just have to take out a little slack. I don't have a torque wrench to give you real numbers - but as a guide you should be able to apply plenty of torque with just two fingers.

That sure doesn't look right or proper. My apologies. There is I supposed a chance you have cross-threaded it, but it sounds like you have had a pretty good try at getting it right. Be careful not to damage the delrin coupler threads by trying to force the coupler straight in the harder aluminium heatsink threads.

If you get in touch via the website feedback form I will sort you out with a replacement - but I can't tell your real name/address just from the forums.

Matty2013

Best way would be to use a multimeter to check the resistance of the heater cartridge. It should be below 5 Ohms. But the bottom line is if it is working then it's working.

DanMoto

The reason for the gap is that the nozzle needs to tighten against the heat-break to form a seal. No crushing involved, and not much torque either. Most of the work is done by the metal contracting as it cools, you just have to take out a little slack. I don't have a torque wrench to give you real numbers - but as a guide you should be able to apply plenty of torque with just two fingers.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 26, 2013 04:11PM |

Hi all,

Sanjay and Dave, looks like you guys are doing a great job, and if Mr Berry of Berrybot 3d fame gives it his blessing (in the early posts) it certainly must be something special! Also, after having a read through this post you've handled all the feedback etc. incredibly well, gives me faith in a purchase very soon.

Am interested to hear more about the forthcoming water-cooled model though before I take the plunge, and also doing some more research on nozzle and filament sizes if I go for the all in one option with Bowden tube.

Anybody have recommended setups that worked well for them (1.75mm or 3mm filament +nozzle size = ??) Plan to use this on a custom made Delta.

Keep up the good work and will get an order in soon!

Sanjay and Dave, looks like you guys are doing a great job, and if Mr Berry of Berrybot 3d fame gives it his blessing (in the early posts) it certainly must be something special! Also, after having a read through this post you've handled all the feedback etc. incredibly well, gives me faith in a purchase very soon.

Am interested to hear more about the forthcoming water-cooled model though before I take the plunge, and also doing some more research on nozzle and filament sizes if I go for the all in one option with Bowden tube.

Anybody have recommended setups that worked well for them (1.75mm or 3mm filament +nozzle size = ??) Plan to use this on a custom made Delta.

Keep up the good work and will get an order in soon!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 28, 2013 05:54PM |

Registered: 12 years ago Posts: 177 |

Hi All,

To everyone that has a pending order with us, and about shipping in general:

Everything is shipping!

All orders made before June 11th have shipped. Everything else is shipping over the weekend, possibly Monday for some of the very recent orders.

Everyone is receiving the most up-to date hotend, which is effectively the v5 now. Many performance and ease of use tweaks have been done, but the fundamentals such as mounting dimensions, overall length etc (the things that matter for making it fit your machine) have remained identical. You will just be receiving a hotend that is lighter in weight, and has a somewhat improved thermal performance.

We hope to move to a permanent state of "shipping within 1-2 days of purchase" by the end of the week.

Concerning water cooled and multi-nozzle hotends

Because there seems to be a bit of speculation/confusion surrounding this I am going to let the cat out of the bag.

We have on the way a small prototype run of a 4 nozzled, water cooled, bowden fed hotends.

We are calling this new hotend "Kraken" - A multi tentacled water borne monster!

The total footprint of the hotend is only 30*40mm in XY plane, the Z height from top to tip is under 40mm, and the 4 nozzles are arranged in a rectangle only 20mm*18mm apart. The weight without electronics looks to be around 110 grams, which is barely the weight of 2x E3Dv5 hotends. Each nozzle to have separate temperature control. Each nozzle can be individually levelled and adjusted in height to be planar with the bed in a very easy and quick way.

The small size and weight despite 4 nozzles is due mainly to the high efficiency of water cooling, even with only a tiny amount of water flow and a small cooling channel we still have a massive excess of cooling capacity. The second reason is a new way of mounting/gripping bowden tubes which has all the convenience and grip of pneumatic push-fit couplers, but with significantly less bulk and weight.

We intend to keep the price reasonable, and below the price for buying the equivalent number of E3Dv5.

But to be clear - Kraken is not a replacement for the normal v5 hotend, which will remain our main product that suits most users. The Kraken is designed purely for multi-nozzle bowden feed applications. Futhermore it is not finished! We will be shipping the majority of our beta prototyping run to trusted testers. I expect problems to occur and tweaks to be necessary. I will start a separate thread once things are ready, and the final version of Kraken will be developed in a public/interactive manner so the community can input what it wants/needs so that we can give you guys what you want.

Kraken will be open-source when sold publicly.

Cheers,

Sanjay

Edited 1 time(s). Last edit at 06/28/2013 06:02PM by SanjayM.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

To everyone that has a pending order with us, and about shipping in general:

Everything is shipping!

All orders made before June 11th have shipped. Everything else is shipping over the weekend, possibly Monday for some of the very recent orders.

Everyone is receiving the most up-to date hotend, which is effectively the v5 now. Many performance and ease of use tweaks have been done, but the fundamentals such as mounting dimensions, overall length etc (the things that matter for making it fit your machine) have remained identical. You will just be receiving a hotend that is lighter in weight, and has a somewhat improved thermal performance.

We hope to move to a permanent state of "shipping within 1-2 days of purchase" by the end of the week.

Concerning water cooled and multi-nozzle hotends

Because there seems to be a bit of speculation/confusion surrounding this I am going to let the cat out of the bag.

We have on the way a small prototype run of a 4 nozzled, water cooled, bowden fed hotends.

We are calling this new hotend "Kraken" - A multi tentacled water borne monster!

The total footprint of the hotend is only 30*40mm in XY plane, the Z height from top to tip is under 40mm, and the 4 nozzles are arranged in a rectangle only 20mm*18mm apart. The weight without electronics looks to be around 110 grams, which is barely the weight of 2x E3Dv5 hotends. Each nozzle to have separate temperature control. Each nozzle can be individually levelled and adjusted in height to be planar with the bed in a very easy and quick way.

The small size and weight despite 4 nozzles is due mainly to the high efficiency of water cooling, even with only a tiny amount of water flow and a small cooling channel we still have a massive excess of cooling capacity. The second reason is a new way of mounting/gripping bowden tubes which has all the convenience and grip of pneumatic push-fit couplers, but with significantly less bulk and weight.

We intend to keep the price reasonable, and below the price for buying the equivalent number of E3Dv5.

But to be clear - Kraken is not a replacement for the normal v5 hotend, which will remain our main product that suits most users. The Kraken is designed purely for multi-nozzle bowden feed applications. Futhermore it is not finished! We will be shipping the majority of our beta prototyping run to trusted testers. I expect problems to occur and tweaks to be necessary. I will start a separate thread once things are ready, and the final version of Kraken will be developed in a public/interactive manner so the community can input what it wants/needs so that we can give you guys what you want.

Kraken will be open-source when sold publicly.

Cheers,

Sanjay

Edited 1 time(s). Last edit at 06/28/2013 06:02PM by SanjayM.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 28, 2013 08:23PM |

Registered: 12 years ago Posts: 3 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 28, 2013 09:05PM |

Registered: 11 years ago Posts: 490 |

Finally!

I have been waiting impatiently over the last 3 weeks to finally be able to extrude more exotic stuff!

The Kraken sounds interesting, especially with the growing amount of materials with wildly varying properties. Water-cooling seems a little bit dangerous on a moving machine, though (well, Kühling&Kühling's machine is also water-cooled); I am excited about how you implement possible safeguard features to prevent leaks...

By the way: do you send a notice to the customers when their copy is being shipped?

Also, it is a little bit quirky to place the customer login only on the shop site, so I totally missed the account option when ordering. Maybe you could insert a global login button in the next website update?

I have been waiting impatiently over the last 3 weeks to finally be able to extrude more exotic stuff!

The Kraken sounds interesting, especially with the growing amount of materials with wildly varying properties. Water-cooling seems a little bit dangerous on a moving machine, though (well, Kühling&Kühling's machine is also water-cooled); I am excited about how you implement possible safeguard features to prevent leaks...

By the way: do you send a notice to the customers when their copy is being shipped?

Also, it is a little bit quirky to place the customer login only on the shop site, so I totally missed the account option when ordering. Maybe you could insert a global login button in the next website update?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 29, 2013 02:13AM |

Registered: 11 years ago Posts: 248 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 29, 2013 01:05PM |

Registered: 10 years ago Posts: 65 |

Has anyone seen this before?

My E3D hot end jammed and I had a heck of a time pulling the filament out. When I did get it out I discovered why. It appears there was a half-sleeve of ABS coming back up the filament through the hot end almost to the drive bolt. It looks like the retracts were driving it (you can see the folds) and it was a good 3" long by the time it jammed.

This is 3mm protoparadigm black ABS, diameter about 2.95 mm, extruded at 213-207C, wade reloaded direct extruder with 1.0mm retract. It printed fine up to the point it jammed.

The extrusion temp seems low for ABS, but I have little experience here. At higher temps the model obviously has insufficient chance to cool and harden and becomes a mushy mess. The only other ABS I have used is a no-name natural that was happy at ~220-215C.

Thanks

My E3D hot end jammed and I had a heck of a time pulling the filament out. When I did get it out I discovered why. It appears there was a half-sleeve of ABS coming back up the filament through the hot end almost to the drive bolt. It looks like the retracts were driving it (you can see the folds) and it was a good 3" long by the time it jammed.

This is 3mm protoparadigm black ABS, diameter about 2.95 mm, extruded at 213-207C, wade reloaded direct extruder with 1.0mm retract. It printed fine up to the point it jammed.

The extrusion temp seems low for ABS, but I have little experience here. At higher temps the model obviously has insufficient chance to cool and harden and becomes a mushy mess. The only other ABS I have used is a no-name natural that was happy at ~220-215C.

Thanks

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 29, 2013 02:43PM |

Admin Registered: 17 years ago Posts: 7,879 |

What is the thickness of the sleeve? Is it possible for that to fit in the barrel at the same time as the filament?

It is odd for ABS to become a mushy mess unless you are making a very small object, or building very quickly. That sounds more like PLA.

[www.hydraraptor.blogspot.com]

It is odd for ABS to become a mushy mess unless you are making a very small object, or building very quickly. That sounds more like PLA.

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 29, 2013 02:56PM |

Registered: 10 years ago Posts: 9 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 29, 2013 04:02PM |

Registered: 10 years ago Posts: 65 |

The filament plus sleeve is 3.16 to 3.18 all along it. The filament under the sleeve is 2.84.

The filament above the sleeve is 2.85 to 2.87 ish.

Either the dimension of the base filament has varied as I've used it or I am misremembering the dimension when I started the spool. I think it has varied along the spool because I remember measuring it to put the filament diameter in slic3r when i first started using it. I'l have to keep an eye on it.

My first thought was that it wasn't ABS as well, but it extrudes to the same matte finish as ABS and even more tellingly, dissolves in acetone. Definitely ABS.

I've got some blue PLA that extrudes at 195-187C, so I don't think the thermistor is reading low. That puts this weird filament in what seems like a very low range for ABS. It definitely gets mushy at a slightly higher temp.

I'm going to attribute this behavior to odd filament and use it as best I can. Does anyone have any tips?

The filament above the sleeve is 2.85 to 2.87 ish.

Either the dimension of the base filament has varied as I've used it or I am misremembering the dimension when I started the spool. I think it has varied along the spool because I remember measuring it to put the filament diameter in slic3r when i first started using it. I'l have to keep an eye on it.

My first thought was that it wasn't ABS as well, but it extrudes to the same matte finish as ABS and even more tellingly, dissolves in acetone. Definitely ABS.

I've got some blue PLA that extrudes at 195-187C, so I don't think the thermistor is reading low. That puts this weird filament in what seems like a very low range for ABS. It definitely gets mushy at a slightly higher temp.

I'm going to attribute this behavior to odd filament and use it as best I can. Does anyone have any tips?

Sorry, only registered users may post in this forum.