Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 16, 2013 05:13PM |

Registered: 12 years ago Posts: 177 |

Nophead

Yep the whole situation is a little bit murky to me. You point out the most obvious flaw in my theory - the constraint of the not-quite-fluid filament in the XY plane due to the tube walls - this should eliminate "springiness"? There is also the question of filament above the expanded "plug" becoming more flexible and springy if it is warmer but not yet part of the plug itself.

However I think the answer might actually lie in the movement of filament in the Z direction, or at least the accumulation of it in the tube at varying lengths due to speed of extrusion and heat creeping up the barrel.

Thomas Sanladerer did some really nice sketches that line up with my thinking on the situation:

[plus.google.com]

By "locking" the position of the transition I think you are inducing some stability and removing some variables. With the long-transition hotends there exists situations where pushing in 10mm of filament at one time will result in more extrudate than pushing in 10mm of filament at another point in time. Chiefly after a period of slow or no extrusion there could be a tall column of filament in the barrel heated and filling the whole tube. Due to the clearance of the diameter of the tube (eg 2mm diameter tube for 1.75mm filament) this filament will have a higher cross sectional area - so pushing in 10mm of filament will result in more extrudate than expected.

I am tired and realise I am starting to explain my ideas poorly so I will stop writing!

Yep the whole situation is a little bit murky to me. You point out the most obvious flaw in my theory - the constraint of the not-quite-fluid filament in the XY plane due to the tube walls - this should eliminate "springiness"? There is also the question of filament above the expanded "plug" becoming more flexible and springy if it is warmer but not yet part of the plug itself.

However I think the answer might actually lie in the movement of filament in the Z direction, or at least the accumulation of it in the tube at varying lengths due to speed of extrusion and heat creeping up the barrel.

Thomas Sanladerer did some really nice sketches that line up with my thinking on the situation:

[plus.google.com]

By "locking" the position of the transition I think you are inducing some stability and removing some variables. With the long-transition hotends there exists situations where pushing in 10mm of filament at one time will result in more extrudate than pushing in 10mm of filament at another point in time. Chiefly after a period of slow or no extrusion there could be a tall column of filament in the barrel heated and filling the whole tube. Due to the clearance of the diameter of the tube (eg 2mm diameter tube for 1.75mm filament) this filament will have a higher cross sectional area - so pushing in 10mm of filament will result in more extrudate than expected.

I am tired and realise I am starting to explain my ideas poorly so I will stop writing!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 16, 2013 05:48PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes I am not disagreeing that a short transition is desirable for accurate flow rate, just questioning whether springiness of the plug is an issue. The fact its length changes with flow rate will create some volumetric errors, how much depends on how close fitting the bore is.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 16, 2013 10:06PM |

Registered: 11 years ago Posts: 482 |

nophead Wrote:

-------------------------------------------------------

> Yes I am not disagreeing that a short transition

> is desirable for accurate flow rate, just

> questioning whether springiness of the plug is an

> issue. The fact its length changes with flow rate

> will create some volumetric errors, how much

> depends on how close fitting the bore is.

Hi Nophead, and Sanjay,

I'm really honored to talk to some of the great"doers" for reprap nozzle technologies, and this area seems really lacking in expertise (or documentation on fundamentals otherwise).

What I am trying to do is achieve a fan-free all metal heater nozzle, because I don't like the noise and extra cost /fan management. Its just one more thing that can break to me.

Without any question at all, there is a gumminess in the transition region. This happens around 100C-160C for PLA. What happens is the filament softens. Then when you push on it, it shrinks in the Z direction, and pancakes sideways in the XY as you have explained. For whatever reason (conformity against the sideways, pure pressure enhancing friction, vanderwaals forces, etc) this generates and incredible amount of resistance. This IS the reason for all hot end jams that don't include filaments being stripped, and motors running out of torque.

To make it worse, the more you push, the worse it gets, because you increase the force sideways, and this is why the taper idea worked so well. It would also explain why a smooth polish wall would help.

"I am not sure how springy the gummy section is when it is constrained by a tube."

>>>

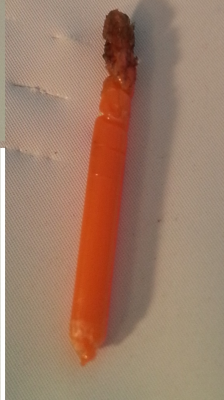

It is extremely springy! If you push, you can reach a steady steady of what has already been pushed past the spring (viscoelastic like) but if you retract you are doomed. The molten region flows better than honey, there is no springiness there. I know because I tried 10 different geometries, and removed the filaments and found a ...naturally formed spring in the transition region! See the attached . It deforms so much that the bigger the inner diameter, the more loops of "springcoil" will be made inside. And yes, fixing this will make huge differences in accuracy (especially if retract is ever used) as the user MRC showed.

By the way, this "sticking" or jamming is reversible if you pull up, further supporting these theories.

So my question to you experts - is an all metal (non fan) cooled hot end possible?

FYI Stainless is used because it has a low thermal conductivity k=17, vs 300 for alum and brass. Interestingly enough, in certain situations high k leads to better cooling (like heat fins). In this case, you want a heat break, so low k is best.

Edited 2 time(s). Last edit at 07/16/2013 10:09PM by Simba.

-------------------------------------------------------

> Yes I am not disagreeing that a short transition

> is desirable for accurate flow rate, just

> questioning whether springiness of the plug is an

> issue. The fact its length changes with flow rate

> will create some volumetric errors, how much

> depends on how close fitting the bore is.

Hi Nophead, and Sanjay,

I'm really honored to talk to some of the great"doers" for reprap nozzle technologies, and this area seems really lacking in expertise (or documentation on fundamentals otherwise).

What I am trying to do is achieve a fan-free all metal heater nozzle, because I don't like the noise and extra cost /fan management. Its just one more thing that can break to me.

Without any question at all, there is a gumminess in the transition region. This happens around 100C-160C for PLA. What happens is the filament softens. Then when you push on it, it shrinks in the Z direction, and pancakes sideways in the XY as you have explained. For whatever reason (conformity against the sideways, pure pressure enhancing friction, vanderwaals forces, etc) this generates and incredible amount of resistance. This IS the reason for all hot end jams that don't include filaments being stripped, and motors running out of torque.

To make it worse, the more you push, the worse it gets, because you increase the force sideways, and this is why the taper idea worked so well. It would also explain why a smooth polish wall would help.

"I am not sure how springy the gummy section is when it is constrained by a tube."

>>>

It is extremely springy! If you push, you can reach a steady steady of what has already been pushed past the spring (viscoelastic like) but if you retract you are doomed. The molten region flows better than honey, there is no springiness there. I know because I tried 10 different geometries, and removed the filaments and found a ...naturally formed spring in the transition region! See the attached . It deforms so much that the bigger the inner diameter, the more loops of "springcoil" will be made inside. And yes, fixing this will make huge differences in accuracy (especially if retract is ever used) as the user MRC showed.

By the way, this "sticking" or jamming is reversible if you pull up, further supporting these theories.

So my question to you experts - is an all metal (non fan) cooled hot end possible?

FYI Stainless is used because it has a low thermal conductivity k=17, vs 300 for alum and brass. Interestingly enough, in certain situations high k leads to better cooling (like heat fins). In this case, you want a heat break, so low k is best.

Edited 2 time(s). Last edit at 07/16/2013 10:09PM by Simba.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 17, 2013 03:22AM |

Registered: 10 years ago Posts: 9 |

I thought the gummy section was the main source of friction in the hot end, except maybe for the nozzle. During operation the gummy section varies in size, thereby causing varying friction, leading to inconsistent extrusion. Edit: Guess I missed a couple of posts...

Edited 1 time(s). Last edit at 07/17/2013 04:12AM by Sal.

Edited 1 time(s). Last edit at 07/17/2013 04:12AM by Sal.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 17, 2013 06:32AM |

Admin Registered: 17 years ago Posts: 7,879 |

Simba Wrote:

-------------------------------------------------------

>

> Hi Nophead, and Sanjay,

>

> I'm really honored to talk to some of the

> great"doers" for reprap nozzle technologies, and

> this area seems really lacking in expertise (or

> documentation on fundamentals otherwise).

>

> What I am trying to do is achieve a fan-free all

> metal heater nozzle, because I don't like the

> noise and extra cost /fan management. Its just

> one more thing that can break to me.

>

> Without any question at all, there is a gumminess

> in the transition region. This happens around

> 100C-160C for PLA. What happens is the filament

> softens. Then when you push on it, it shrinks in

> the Z direction, and pancakes sideways in the XY

> as you have explained. For whatever reason

> (conformity against the sideways, pure pressure

> enhancing friction, vanderwaals forces, etc) this

> generates and incredible amount of resistance.

> This IS the reason for all hot end jams that don't

> include filaments being stripped, and motors

> running out of torque.

> To make it worse, the more you push, the worse it

> gets, because you increase the force sideways, and

> this is why the taper idea worked so well. It

> would also explain why a smooth polish wall would

> help.

Yes I explained all this with a diagram here: [hydraraptor.blogspot.co.uk]

There is a critical value for the length of the plug, determined by the coefficient of friction, beyond which it will jam solid not matter how hard you push it. When you add a taper it can't jam as long as the plug isn't longer than the taper.

PLA is very sticky when molten, like glue. I think it is due to it being polymerised acid, so very polar. Also past Tg is is rubber like and rubber must have one of the highest coefficients of friction there is, hence tyres are made from it.

I am surprised that the Prusa nozzle works at all with PLA, even when highly polished. I think stainless steel has a coefficient of friction an order of magnitude higher than PTFE, which is the only material that has been shown to work with a long transition zone.

>

> "I am not sure how springy the gummy section is

> when it is constrained by a tube."

> >>>

> It is extremely springy! If you push, you can

> reach a steady steady of what has already been

> pushed past the spring (viscoelastic like) but if

> you retract you are doomed.

I think it is only springy until it swells to hit the wall, once constrained it isn't. Funny you say you are doomed when retracting. I pioneered retracting to stop ooze and it was with PLA and my all metal hot end. [hydraraptor.blogspot.co.uk]

>The molten region

> flows better than honey, there is no springiness

> there. I know because I tried 10 different

> geometries, and removed the filaments and found a

> ...naturally formed spring in the transition

> region! See the attached . It deforms so much

> that the bigger the inner diameter, the more loops

> of "springcoil" will be made inside. And yes,

> fixing this will make huge differences in accuracy

> (especially if retract is ever used) as the user

> MRC showed.

If it is not springy when molten and all the springiness is in the transition, as you assert, then we could have a much larger melt chamber without any loss of precision. That would allow faster feeds and also make the exit temperature more stable. All the pictures I have seen of Stratasys hot ends look like they have a long melt chamber after a short transition. I also made one like that [hydraraptor.blogspot.co.uk]. The motor I used couldn't reverse fast and had a lot of backlash in the gearbox so it was a bit blobby. I should try it with better motor drive.

>

> By the way, this "sticking" or jamming is

> reversible if you pull up, further supporting

> these theories.

Yes when you pull on the plug it stretches lengthways and so pulls away from the wall.

>

> So my question to you experts - is an all metal

> (non fan) cooled hot end possible?

Well mine is all metal and without a fan but it has a massive heatsink. So yes it is possible, but only suitable for moving table machines. To get a short transition with metal you need to get rid of a significant amount of heat some how. You can reduce that by making the wall thinner but then it becomes too fragile.

[www.hydraraptor.blogspot.com]

-------------------------------------------------------

>

> Hi Nophead, and Sanjay,

>

> I'm really honored to talk to some of the

> great"doers" for reprap nozzle technologies, and

> this area seems really lacking in expertise (or

> documentation on fundamentals otherwise).

>

> What I am trying to do is achieve a fan-free all

> metal heater nozzle, because I don't like the

> noise and extra cost /fan management. Its just

> one more thing that can break to me.

>

> Without any question at all, there is a gumminess

> in the transition region. This happens around

> 100C-160C for PLA. What happens is the filament

> softens. Then when you push on it, it shrinks in

> the Z direction, and pancakes sideways in the XY

> as you have explained. For whatever reason

> (conformity against the sideways, pure pressure

> enhancing friction, vanderwaals forces, etc) this

> generates and incredible amount of resistance.

> This IS the reason for all hot end jams that don't

> include filaments being stripped, and motors

> running out of torque.

> To make it worse, the more you push, the worse it

> gets, because you increase the force sideways, and

> this is why the taper idea worked so well. It

> would also explain why a smooth polish wall would

> help.

Yes I explained all this with a diagram here: [hydraraptor.blogspot.co.uk]

There is a critical value for the length of the plug, determined by the coefficient of friction, beyond which it will jam solid not matter how hard you push it. When you add a taper it can't jam as long as the plug isn't longer than the taper.

PLA is very sticky when molten, like glue. I think it is due to it being polymerised acid, so very polar. Also past Tg is is rubber like and rubber must have one of the highest coefficients of friction there is, hence tyres are made from it.

I am surprised that the Prusa nozzle works at all with PLA, even when highly polished. I think stainless steel has a coefficient of friction an order of magnitude higher than PTFE, which is the only material that has been shown to work with a long transition zone.

>

> "I am not sure how springy the gummy section is

> when it is constrained by a tube."

> >>>

> It is extremely springy! If you push, you can

> reach a steady steady of what has already been

> pushed past the spring (viscoelastic like) but if

> you retract you are doomed.

I think it is only springy until it swells to hit the wall, once constrained it isn't. Funny you say you are doomed when retracting. I pioneered retracting to stop ooze and it was with PLA and my all metal hot end. [hydraraptor.blogspot.co.uk]

>The molten region

> flows better than honey, there is no springiness

> there. I know because I tried 10 different

> geometries, and removed the filaments and found a

> ...naturally formed spring in the transition

> region! See the attached . It deforms so much

> that the bigger the inner diameter, the more loops

> of "springcoil" will be made inside. And yes,

> fixing this will make huge differences in accuracy

> (especially if retract is ever used) as the user

> MRC showed.

If it is not springy when molten and all the springiness is in the transition, as you assert, then we could have a much larger melt chamber without any loss of precision. That would allow faster feeds and also make the exit temperature more stable. All the pictures I have seen of Stratasys hot ends look like they have a long melt chamber after a short transition. I also made one like that [hydraraptor.blogspot.co.uk]. The motor I used couldn't reverse fast and had a lot of backlash in the gearbox so it was a bit blobby. I should try it with better motor drive.

>

> By the way, this "sticking" or jamming is

> reversible if you pull up, further supporting

> these theories.

Yes when you pull on the plug it stretches lengthways and so pulls away from the wall.

>

> So my question to you experts - is an all metal

> (non fan) cooled hot end possible?

Well mine is all metal and without a fan but it has a massive heatsink. So yes it is possible, but only suitable for moving table machines. To get a short transition with metal you need to get rid of a significant amount of heat some how. You can reduce that by making the wall thinner but then it becomes too fragile.

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 17, 2013 12:57PM |

Registered: 11 years ago Posts: 482 |

Wow, sorry i missed that diagram before. I totally reinvented the wheel! Funny thing is, i landed at the top of that page several times for the navier-stokes equations

Someday, these will be a textbooks sir.

Can you point me to your design specs for the fan-free all metal hot end? Or was that the picture earlier in the thread that looks like a scifi laser gun head with many baffles?

Someday, these will be a textbooks sir.

Can you point me to your design specs for the fan-free all metal hot end? Or was that the picture earlier in the thread that looks like a scifi laser gun head with many baffles?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 17, 2013 06:44PM |

Registered: 11 years ago Posts: 41 |

Hello,

I was wondering how accurate everyone's temperatures are when printing with the e3d hotend. With auto PID settings set and my hotend's temperature set to 255C it will go any where from 253.9C - 256.5C. Is this normal? Is there any way to get a more steady reading?

Thank you,

Cameron

Edited 2 time(s). Last edit at 07/17/2013 06:46PM by cameronm.

I was wondering how accurate everyone's temperatures are when printing with the e3d hotend. With auto PID settings set and my hotend's temperature set to 255C it will go any where from 253.9C - 256.5C. Is this normal? Is there any way to get a more steady reading?

Thank you,

Cameron

Edited 2 time(s). Last edit at 07/17/2013 06:46PM by cameronm.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 17, 2013 10:40PM |

Registered: 11 years ago Posts: 482 |

Sounds to me like you have an ideal system.

Thermistors differ from actual filament temperature easily by 10's of degrees. This wouldn't worry me, unless you are asking about analog input conversion accuracy issues (that is also within the equivalent of 1-2 degC). And accuracy gets worse with increasing temperature for NTC thermistors, I think.

Thermistors differ from actual filament temperature easily by 10's of degrees. This wouldn't worry me, unless you are asking about analog input conversion accuracy issues (that is also within the equivalent of 1-2 degC). And accuracy gets worse with increasing temperature for NTC thermistors, I think.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 17, 2013 10:56PM |

Registered: 11 years ago Posts: 41 |

Thank you Simba for answering. That makes sense about the "accuracy gets worse with increasing temperature for NTC thermistors" When I ran a standard Auto PID that gets up to 150C pronterface was reading either dead on or +- .1.

For the heater cartridge, in firmware should I change PID_Max to a different value? Or should it be left alone? Does a higher PID_Max have anything to do with a more accurate reading?

Thank you,

Cameron

For the heater cartridge, in firmware should I change PID_Max to a different value? Or should it be left alone? Does a higher PID_Max have anything to do with a more accurate reading?

Thank you,

Cameron

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 18, 2013 05:34PM |

Registered: 11 years ago Posts: 490 |

@SanjayM: Just wondering, how many iterations did you go through until you were satisfied with the nozzle? I mean the top layers look so perfect, at a glance, you can't discern them from a loosely printed bottom layer and what is maybe even more amazing to me is that the nozzle stays clean - no charred plastic creeping up the cone.

My old hot end while not bad in general needed cleaning from time to time because the plastic tended to stick to the brass tip, but so far, this hot end looks clean as new.

Have you considered using a larger aluminium block that completely encases the heater cartridge by the way? This should be more efficient or did I miss something like slower reaction time due to increased mass?

My old hot end while not bad in general needed cleaning from time to time because the plastic tended to stick to the brass tip, but so far, this hot end looks clean as new.

Have you considered using a larger aluminium block that completely encases the heater cartridge by the way? This should be more efficient or did I miss something like slower reaction time due to increased mass?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 18, 2013 05:50PM |

Registered: 11 years ago Posts: 246 |

@uGen

I am sure that Sanjay can give you a better answer to this question, but one reason could be that the "heated length" of heater cartridges is shorter than the "overall length". Basically, there is a "cold zone" at each end of the cartridge so a 23mm heater cartridge may only have a "heated length" of 16mm. Also, increasing the size/mass of the aluminium heater block could increase the area of the bottom of the block and therefore increase the amount of heat that is radiated at the part.

Just my 2 cents

Eric

I am sure that Sanjay can give you a better answer to this question, but one reason could be that the "heated length" of heater cartridges is shorter than the "overall length". Basically, there is a "cold zone" at each end of the cartridge so a 23mm heater cartridge may only have a "heated length" of 16mm. Also, increasing the size/mass of the aluminium heater block could increase the area of the bottom of the block and therefore increase the amount of heat that is radiated at the part.

Just my 2 cents

Eric

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 18, 2013 07:19PM |

Admin Registered: 11 years ago Posts: 1,063 |

i've really got to ask the question.. whats the obsession with fan-less hotend operation? most people have one on the carriage anyway blowing on the print.

cost and weight savings don't exactly sound like much of a motivation, especially when you're talking maybe $2 and 5 to 10 grams. even a lack of mosfet outputs on whatever electronics board to drive it isn't really an issue since they can be wired directly up to the power supply, a pyhsical lack of space i can understand but seriously ..... i'd rather drop the use of two end stops before i consider loosing the fan ..

cost and weight savings don't exactly sound like much of a motivation, especially when you're talking maybe $2 and 5 to 10 grams. even a lack of mosfet outputs on whatever electronics board to drive it isn't really an issue since they can be wired directly up to the power supply, a pyhsical lack of space i can understand but seriously ..... i'd rather drop the use of two end stops before i consider loosing the fan ..

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 19, 2013 09:08AM |

Registered: 11 years ago Posts: 374 |

Quote

whats the obsession with fan-less hotend operation?

I think with a good thermal design it's not necessary. In my case it's less about weight and cost (but those are factors), and more about space available on the print head. At the extreme positions of my print head I have less than 6mm to spare between the head and the frame of the machine. Another factor is noise - more fans = more noise.

Quote

most people have one on the carriage anyway blowing on the print.

This fan doesn't run all the time, and its speed varies over the print as well. I think this would be worse than no fan at all, because it would cause the transition zone to vary wildly in location inside the hotend. Not to mention ducting this air from the fan, past the hotend, and THEN down to the print would need a very sophisticated duct system.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 19, 2013 10:41AM |

Admin Registered: 11 years ago Posts: 1,063 |

crispy1 Wrote:

-------------------------------------------------------

>

> I think with a good thermal design it's not

> necessary. In my case it's less about weight and

> cost (but those are factors), and more about space

> available on the print head. At the extreme

> positions of my print head I have less than 6mm to

> spare between the head and the frame of the

> machine. Another factor is noise - more fans =

> more noise.

>

>

> This fan doesn't run all the time, and its speed

> varies over the print as well. I think this would

> be worse than no fan at all, because it would

> cause the transition zone to vary wildly in

> location inside the hotend. Not to mention

> ducting this air from the fan, past the hotend,

> and THEN down to the print would need a very

> sophisticated duct system.

to a point i agree, building a hotend that runs fan-less isn't particularly difficult, it's just the end result that isn't popular

-------------------------------------------------------

>

>Quote

whats the obsession with fan-less hotend

> operation?

> I think with a good thermal design it's not

> necessary. In my case it's less about weight and

> cost (but those are factors), and more about space

> available on the print head. At the extreme

> positions of my print head I have less than 6mm to

> spare between the head and the frame of the

> machine. Another factor is noise - more fans =

> more noise.

>

>

>Quote

most people have one on the carriage anyway

> blowing on the print.

> This fan doesn't run all the time, and its speed

> varies over the print as well. I think this would

> be worse than no fan at all, because it would

> cause the transition zone to vary wildly in

> location inside the hotend. Not to mention

> ducting this air from the fan, past the hotend,

> and THEN down to the print would need a very

> sophisticated duct system.

to a point i agree, building a hotend that runs fan-less isn't particularly difficult, it's just the end result that isn't popular

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 19, 2013 10:45AM |

Registered: 12 years ago Posts: 177 |

uGen

Honestly I'm not sure, I have made a tonne myself on manual lathes. Well over 20 iterations, a lot of dumb ideas too before I found my way. After that there were about 5 iterations made by professional machinists.

Surface-finish of the machined nozzle plays a large part in stopping stuff sticking. Angle of chamfer helps too. Oddly I think that the angle of chamfer helps keep things clean, because it reduces radiated heat towards the part, and this in turn reduces overhang curling. A reduction in curling means that edges of overhangs are less likely to drag over the nozzle cone and foul it. Additionally the steeper angle keeps the most-part of the cone out of the way of things.

As Eric pointed out, the heater doesn't actually distribute heat evenly along its length. So adding material to try and grab the last bits of heat from the ends is a bit of a false economy.

Honestly I'm not sure, I have made a tonne myself on manual lathes. Well over 20 iterations, a lot of dumb ideas too before I found my way. After that there were about 5 iterations made by professional machinists.

Surface-finish of the machined nozzle plays a large part in stopping stuff sticking. Angle of chamfer helps too. Oddly I think that the angle of chamfer helps keep things clean, because it reduces radiated heat towards the part, and this in turn reduces overhang curling. A reduction in curling means that edges of overhangs are less likely to drag over the nozzle cone and foul it. Additionally the steeper angle keeps the most-part of the cone out of the way of things.

As Eric pointed out, the heater doesn't actually distribute heat evenly along its length. So adding material to try and grab the last bits of heat from the ends is a bit of a false economy.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 20, 2013 08:12PM |

Registered: 11 years ago Posts: 67 |

Hello,

I have been trying to get my E3D hotend to print PLA without jamming with little success. I have managed to get a couple of short prints to complete but nothing longer than a half hour or so. My hot end is jamming toward the top of the hotend near the upper cooling fins. I'm not sure why since nothing past the bottom 3 or 4 fins is hot. The only way I can unjam it is by melting the filament out the top hole using a lighter. If anyone has any suggestions on what I might be doing wrong I would appreciate it. Thanks in advance.

I'm using the 1.75mm version of the hotend.

Bob

I have been trying to get my E3D hotend to print PLA without jamming with little success. I have managed to get a couple of short prints to complete but nothing longer than a half hour or so. My hot end is jamming toward the top of the hotend near the upper cooling fins. I'm not sure why since nothing past the bottom 3 or 4 fins is hot. The only way I can unjam it is by melting the filament out the top hole using a lighter. If anyone has any suggestions on what I might be doing wrong I would appreciate it. Thanks in advance.

I'm using the 1.75mm version of the hotend.

Bob

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 21, 2013 09:45AM |

Registered: 11 years ago Posts: 490 |

@Bob: Have you measured the filament diameter? I have had jamming problems with 3mm FormFutura filament - the diameter and roundness varied greatly from somewhere about 2.6 to 3.2mm! Needless to say, the filament became stuck in the extruder (a Wade's derivate) itself and didn't even reach the hot end with the clog. Their 1.75mm filament also exhibits similar loose tolerances, but luckily, it hasn't become stuck yet in my printer.

@SanjayM: Whoa, that's a lot of iterations! Nice to see that every design also has a process involved that is normally hidden from the end-user.

I haven't tried much with overhangs yet, but I tend to think that the flat bottom also contributes to how the filament comes out of the nozzle. The exit bore I suppose is much more exact than on a conical end design that promotes the filament curling back as it exits the nozzle (at least that is my experience) just like how running water follows the contour of the back side of a spoon when dripping from it.

Ah, I see. Didn't know that the heater cartridges weren't homogenous inside.

@SanjayM: Whoa, that's a lot of iterations! Nice to see that every design also has a process involved that is normally hidden from the end-user.

I haven't tried much with overhangs yet, but I tend to think that the flat bottom also contributes to how the filament comes out of the nozzle. The exit bore I suppose is much more exact than on a conical end design that promotes the filament curling back as it exits the nozzle (at least that is my experience) just like how running water follows the contour of the back side of a spoon when dripping from it.

Ah, I see. Didn't know that the heater cartridges weren't homogenous inside.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 21, 2013 10:30AM |

Registered: 11 years ago Posts: 67 |

I did measure it. It was measuring between 1.7 and 1.76, obviously not that good but I wouldn't have thought it would get stuck. It tried pulling in it hard enough that the filament was breaking that's why I had to melt it out. I really would have liked to see what the filament looked like if I was able to get it out without melting it.

Do you think that if the filament was out of round or too thick that it would get far enough in that it couldn't be pulled out? I do hope this is the case, I would really like to make this hotend work.

I am going to have to take a really close look at the roundness of the filament. Thanks.

Bob

Do you think that if the filament was out of round or too thick that it would get far enough in that it couldn't be pulled out? I do hope this is the case, I would really like to make this hotend work.

I am going to have to take a really close look at the roundness of the filament. Thanks.

Bob

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 21, 2013 04:01PM |

Registered: 11 years ago Posts: 67 |

new to3Dbob Wrote:

-------------------------------------------------------

> Hello,

> I have been trying to get my E3D hotend to

> print PLA without jamming with little success. I

> have managed to get a couple of short prints to

> complete but nothing longer than a half hour or

> so. My hot end is jamming toward the top of the

> hotend near the upper cooling fins. I'm not sure

> why since nothing past the bottom 3 or 4 fins is

> hot. The only way I can unjam it is by melting the

> filament out the top hole using a lighter. If

> anyone has any suggestions on what I might be

> doing wrong I would appreciate it. Thanks in

> advance.

>

> I'm using the 1.75mm version of the hotend.

>

> Bob

I think I figured out what my problem was. I was printing way to slowly, 15mm. I doubled the speed and was able to finish the print that I failed on many times prior to the speed increase. I was able to complete a 5 hour print of the Mendel 90 X motor mount. Thanks for all the suggestions.

Bob

Edited 1 time(s). Last edit at 07/22/2013 07:52AM by new to3Dbob.

-------------------------------------------------------

> Hello,

> I have been trying to get my E3D hotend to

> print PLA without jamming with little success. I

> have managed to get a couple of short prints to

> complete but nothing longer than a half hour or

> so. My hot end is jamming toward the top of the

> hotend near the upper cooling fins. I'm not sure

> why since nothing past the bottom 3 or 4 fins is

> hot. The only way I can unjam it is by melting the

> filament out the top hole using a lighter. If

> anyone has any suggestions on what I might be

> doing wrong I would appreciate it. Thanks in

> advance.

>

> I'm using the 1.75mm version of the hotend.

>

> Bob

I think I figured out what my problem was. I was printing way to slowly, 15mm. I doubled the speed and was able to finish the print that I failed on many times prior to the speed increase. I was able to complete a 5 hour print of the Mendel 90 X motor mount. Thanks for all the suggestions.

Bob

Edited 1 time(s). Last edit at 07/22/2013 07:52AM by new to3Dbob.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 07:55AM |

Registered: 11 years ago Posts: 528 |

hi,

well am not an happy chap got the 1.75 installed

extruded at little last night this morning the whole thing jammed up

gonna require me stripping it the whole carriage too get at this hotend

ok striped the carriage down this is what I believe happened: once I turned the printer off straight after extruding some filament for the night heat crept up the heat sink expanded the filament inside causing it to jam

don't know still seem too take a lot effect to push some pla though 200c.

Edited 4 time(s). Last edit at 07/22/2013 09:57AM by jinx.

well am not an happy chap got the 1.75 installed

extruded at little last night this morning the whole thing jammed up

gonna require me stripping it the whole carriage too get at this hotend

ok striped the carriage down this is what I believe happened: once I turned the printer off straight after extruding some filament for the night heat crept up the heat sink expanded the filament inside causing it to jam

don't know still seem too take a lot effect to push some pla though 200c.

Edited 4 time(s). Last edit at 07/22/2013 09:57AM by jinx.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 12:29PM |

Registered: 11 years ago Posts: 490 |

@ new to 3Dbob: that is strange. I have had much slower extrusions work with a hot end that conducts heat upwards way better without much trouble (although admittedly, I these slow feedrates only lasted for some minutes at the end of a print).

If we exclude the construction in heat conduction, this leaves hot air and the filament itself. If the filament has got good enough contact to the hot end at the walls, this should sink the heat away? The bore is 2mm IIRC...but I can't imagine this playing such a big role in jamming to be honest.

If we exclude the construction in heat conduction, this leaves hot air and the filament itself. If the filament has got good enough contact to the hot end at the walls, this should sink the heat away? The bore is 2mm IIRC...but I can't imagine this playing such a big role in jamming to be honest.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 12:34PM |

Registered: 13 years ago Posts: 81 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 01:39PM |

Registered: 11 years ago Posts: 67 |

@uGen: I was able to get the slower print rate to print without clogging for around 15 minutes pretty consistently. Since the only change I made was the print speed I was just assuming that the filament was the source of the heat. I could be totally wrong and would love to hear other possible theories why increasing the print speed eliminated my jams.

Bob

Bob

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 06:47PM |

Registered: 11 years ago Posts: 633 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 07:08PM |

Registered: 11 years ago Posts: 246 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 07:11PM |

Registered: 11 years ago Posts: 633 |

Eric, did that.

The thermistor was a little loose, so i wrapped it in tin foil, same thing,

RP Iron Man Wrote:

-------------------------------------------------------

> @ nic0laz

>

> Make sure you are running PID Autotune in the same

> conditions that you will be printing in. For

> example, if you have a fan on the carriage during

> the print, turn the fan on before you run

> autotune. This will make a huge difference.

>

> Eric

The thermistor was a little loose, so i wrapped it in tin foil, same thing,

RP Iron Man Wrote:

-------------------------------------------------------

> @ nic0laz

>

> Make sure you are running PID Autotune in the same

> conditions that you will be printing in. For

> example, if you have a fan on the carriage during

> the print, turn the fan on before you run

> autotune. This will make a huge difference.

>

> Eric

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 22, 2013 10:27PM |

Registered: 11 years ago Posts: 246 |

Ok, seems odd that the temp still fluctuates so much. I am honestly not sure what the problem could be. The heater cartridges are 40W so maybe turning down the PID power would help stabilize things. Then again, I am using a 40W heater cartridge with my J Head and its stable at 220C...

Good luck.

Eric

Good luck.

Eric

|

Anonymous User

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 12:52AM |

A bit off topic; has anybody used a thermoelectric cooler in conjunction with the JGR hot end?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 01:43AM |

Admin Registered: 11 years ago Posts: 1,063 |

to cool or heat it?

ohioplastics Wrote:

-------------------------------------------------------

> A bit off topic; has anybody used a thermoelectric

> cooler in conjunction with the JGR hot end?

>0E9s37F,nhBRwtKjOBkQ~~60_14.JPG)

ohioplastics Wrote:

-------------------------------------------------------

> A bit off topic; has anybody used a thermoelectric

> cooler in conjunction with the JGR hot end?

>

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Anonymous User

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 02:16AM |

Cooling. I've been messing with crazy short hot ends. Most have failed due to excess heat, but the ones that work have aluminum carriages. I work at a street sing shop, so there's plenty of .08" aluminum laying around. Basically I use the carriage as a heat sink. I'm gunning for an extruder w/ carriage that's 40mm wide (width of a nema 17 motor) by 78mm high (13mm nozzle + 25mm tube + 40mm motor). But smaller carriages mean less thermal dissipation, so I'm hoping these little guys will do the trick.

Sorry, only registered users may post in this forum.