Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 03:20AM |

Admin Registered: 11 years ago Posts: 1,063 |

how long is the thermal barrier?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Anonymous User

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 03:50AM |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 04:26AM |

Admin Registered: 11 years ago Posts: 1,063 |

ohioplastics Wrote:

-------------------------------------------------------

> There isn't any. I don't use thermal barriers. You

> only need a thermal barrier if your x-carriage is

> made out of plastic.

have you got any pictures?

-------------------------------------------------------

> There isn't any. I don't use thermal barriers. You

> only need a thermal barrier if your x-carriage is

> made out of plastic.

have you got any pictures?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 04:44AM |

Registered: 11 years ago Posts: 791 |

I am also using aluminium carriage and mounting base for the extruder.

Hotend in the photos below are used for PLA and ABS and have a PEEK section.

Can run the hotend at 250C and can put fingers on aluminium base and hardy feel any heat.

Will be trying out an all metal hotend later this week and testing on nylon at 280C.

Extruder image 1

Extruder image 2

Extruder image 3

I will post test results and further photos that show the new hotend

Hotend in the photos below are used for PLA and ABS and have a PEEK section.

Can run the hotend at 250C and can put fingers on aluminium base and hardy feel any heat.

Will be trying out an all metal hotend later this week and testing on nylon at 280C.

Extruder image 1

Extruder image 2

Extruder image 3

I will post test results and further photos that show the new hotend

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 04:47AM |

Admin Registered: 17 years ago Posts: 7,879 |

The only way a heat pump will make the cold end cooler is my making your carriage hotter so that it dissipates heat faster. Semiconductor ones also generate heat as they are very inefficient, so that would make your carriage even hotter. A fan is a lot more efficient in this application.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 23, 2013 06:10AM |

Registered: 12 years ago Posts: 1,450 |

For some reason I hadn't looked at this thread previously, but now i find a huge amount of good info here. Perhaps I can return the favour by putting the results of some of my attempts on here. Having used ca 1.5M of stainless steel rod on hot ends which are typically 50mm long, I can claim to have been through lots of variants and iterations. My hot ends now work (mostly) very well.

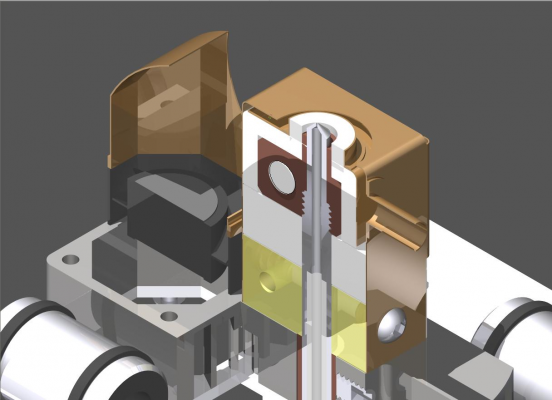

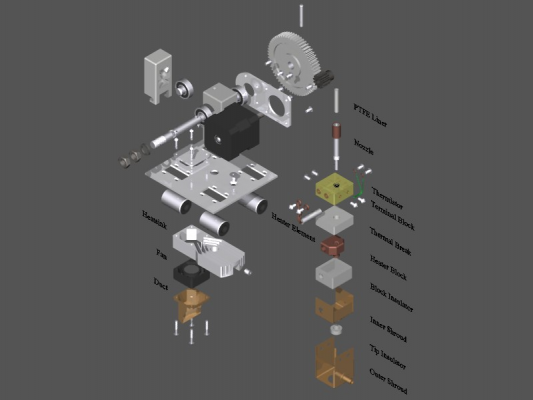

My typical nozzle is machined from a single piece of stainless steel and screws into a copper heater block on one end and a very lightweight heatsink on the other. The chamber is parallel and bored to 2.0mm dia with a PTFE sleeve extending down the top 26mm of the length. I have attached a sectioned view which shows the general layout of a new version which is in construction at the moment (I have recently used these pictures on other threads in this forum.)

Results of my trials:

3mm version is pants and will not be retried.

1.75mm works well with 0.45 mm nozzle and 0.35mm nozzle, somewhat tempermental with 0.25mm nozzle which needed the melt chamber length shortened. (PTFE liner extended to 35mm) 0.2mm very tempermental but gives short runs of really good print before blocking. 0.3mm and 0.15mm exist but haven't been tried.

Mike

Future trials on nozzle:

Replace PTFE with Tekapeek (RS stock no 297-0147) and shorten the melt chamber as much as possible. Increase angle of tip to 90 degrees from present 135 degrees.

My typical nozzle is machined from a single piece of stainless steel and screws into a copper heater block on one end and a very lightweight heatsink on the other. The chamber is parallel and bored to 2.0mm dia with a PTFE sleeve extending down the top 26mm of the length. I have attached a sectioned view which shows the general layout of a new version which is in construction at the moment (I have recently used these pictures on other threads in this forum.)

Results of my trials:

3mm version is pants and will not be retried.

1.75mm works well with 0.45 mm nozzle and 0.35mm nozzle, somewhat tempermental with 0.25mm nozzle which needed the melt chamber length shortened. (PTFE liner extended to 35mm) 0.2mm very tempermental but gives short runs of really good print before blocking. 0.3mm and 0.15mm exist but haven't been tried.

Mike

Future trials on nozzle:

Replace PTFE with Tekapeek (RS stock no 297-0147) and shorten the melt chamber as much as possible. Increase angle of tip to 90 degrees from present 135 degrees.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 25, 2013 05:58AM |

Registered: 13 years ago Posts: 81 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 25, 2013 04:48PM |

Registered: 11 years ago Posts: 329 |

what extruders are people using? as iv tried a few now with J-Head mount and iv found the hot end ends up at a slight angle. also its not very tight in the extruder. so far iv tried missans i3 gregs and also sgrabbers compact i3 extruder.

Currently im running with an alu groove mount form hotends.com the hotend spins so iv had to pack it in tight using M8 washers.

hotend is a E3D V4 guessing 1st batch as i ordered as soon as it was annouced via these forms

Currently im running with an alu groove mount form hotends.com the hotend spins so iv had to pack it in tight using M8 washers.

hotend is a E3D V4 guessing 1st batch as i ordered as soon as it was annouced via these forms

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 26, 2013 03:33AM |

Registered: 10 years ago Posts: 1 |

Enlightx Wrote:

-------------------------------------------------------

> what extruders are people using? as iv tried a few

> now with J-Head mount and iv found the hot end

> ends up at a slight angle. also its not very tight

> in the extruder. so far iv tried missans i3 gregs

> and also sgrabbers compact i3 extruder.

>

> Currently im running with an alu groove mount form

> hotends.com the hotend spins so iv had to pack it

> in tight using M8 washers.

I had the same problem so I made this: [www.thingiverse.com]

-------------------------------------------------------

> what extruders are people using? as iv tried a few

> now with J-Head mount and iv found the hot end

> ends up at a slight angle. also its not very tight

> in the extruder. so far iv tried missans i3 gregs

> and also sgrabbers compact i3 extruder.

>

> Currently im running with an alu groove mount form

> hotends.com the hotend spins so iv had to pack it

> in tight using M8 washers.

I had the same problem so I made this: [www.thingiverse.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 26, 2013 03:49AM |

Registered: 11 years ago Posts: 791 |

I re-designed a Wades type extruder to suit my machines a little better. Not many changes were made, and the mounting was made to an aluminium plate that also attaches to the aluminium X carriage. Both act as a heat-sink as well. The M6 thread is used to do the mounting with an M6 nut that holds the plate in place, the nut fitting inside the extruder body where the PEEK section would normally go.

Photos below of how I did it.

Photo1

Photo2

Photo3

Photo4

Photos below of how I did it.

Photo1

Photo2

Photo3

Photo4

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 26, 2013 07:59AM |

Registered: 11 years ago Posts: 67 |

Enlightx Wrote:

-------------------------------------------------------

> what extruders are people using? as iv tried a few

> now with J-Head mount and iv found the hot end

> ends up at a slight angle. also its not very tight

> in the extruder. so far iv tried missans i3 gregs

> and also sgrabbers compact i3 extruder.

>

> Currently im running with an alu groove mount form

> hotends.com the hotend spins so iv had to pack it

> in tight using M8 washers.

>

> hotend is a E3D V4 guessing 1st batch as i ordered

> as soon as it was annouced via these forms

Hello,

I am also using the jhead metal mount from hotends.com and mine is very tight in the mount ounce pushed in all the way which takes a bit of force. I wonder why such a difference?

-------------------------------------------------------

> what extruders are people using? as iv tried a few

> now with J-Head mount and iv found the hot end

> ends up at a slight angle. also its not very tight

> in the extruder. so far iv tried missans i3 gregs

> and also sgrabbers compact i3 extruder.

>

> Currently im running with an alu groove mount form

> hotends.com the hotend spins so iv had to pack it

> in tight using M8 washers.

>

> hotend is a E3D V4 guessing 1st batch as i ordered

> as soon as it was annouced via these forms

Hello,

I am also using the jhead metal mount from hotends.com and mine is very tight in the mount ounce pushed in all the way which takes a bit of force. I wonder why such a difference?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 26, 2013 08:05AM |

Registered: 11 years ago Posts: 67 |

Can anyone let me know how much retraction you are able to use sucessfully without any jamming. I can get up to .7mm and any more than that it jams some where around/in the nozzle. When this happens I am able to heat it up to a higher than printing temperature and unjam the nozzle so I do not know exactly where the jam is occurring but it is definitly in the melt zone somewhere.

I was thinking that my print temp might be to low but I'm printing at 220C, verified with a thermocouple. I'm sure it is PLA as it will not dissolve in acetone and it gives off that sweet smell when printing. Thanks a lot,

Bob

I was thinking that my print temp might be to low but I'm printing at 220C, verified with a thermocouple. I'm sure it is PLA as it will not dissolve in acetone and it gives off that sweet smell when printing. Thanks a lot,

Bob

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 27, 2013 09:18AM |

Registered: 10 years ago Posts: 25 |

before i make my order i need to ask you 2 questions:

-where are you located?

-which postage service do you use? (i can only order if you use governmental postage service. i mean royal mail for the uk, usps for the usa etc.. certainly no ups,fedex,dhl)

Edited 1 time(s). Last edit at 07/27/2013 02:11PM by turutk.

-where are you located?

-which postage service do you use? (i can only order if you use governmental postage service. i mean royal mail for the uk, usps for the usa etc.. certainly no ups,fedex,dhl)

Edited 1 time(s). Last edit at 07/27/2013 02:11PM by turutk.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 27, 2013 10:14AM |

Registered: 10 years ago Posts: 16 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 27, 2013 04:44PM |

Registered: 12 years ago Posts: 10 |

[lcamtuf.coredump.cx]

"This guide (or book?) couldn't be upvoted enough. With his comprehensive work I believe Michal has done more for home manufacturing and high quality hobbyist robotics than all us and "disruptive" companies combined."

pvarangot

"Some people make you wonder if they're not like Shakespeare is rumored to have been; so phenomenally productive that they might be a myth, an amalgamation of the work of several brilliant people, piled up behind one convenient name.

Michal Zalewski is that kind of guy."

lifeisstillgood

"This guide (or book?) couldn't be upvoted enough. With his comprehensive work I believe Michal has done more for home manufacturing and high quality hobbyist robotics than all us and "disruptive" companies combined."

pvarangot

"Some people make you wonder if they're not like Shakespeare is rumored to have been; so phenomenally productive that they might be a myth, an amalgamation of the work of several brilliant people, piled up behind one convenient name.

Michal Zalewski is that kind of guy."

lifeisstillgood

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 27, 2013 06:44PM |

Registered: 11 years ago Posts: 2 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 29, 2013 03:05AM |

Registered: 11 years ago Posts: 248 |

so, let me say a few words.

i have v 4.1 and i am very satisfied with it. i have printed 10-15 prints till now... i have printer for about one week, prusa i3 with full modified electronic.

so i suggest to everyone, buy good stuff, it wil pay itself(hot end, printer is crap..).

i think the best side of this hotend is, it cant be broken

il buy another one soon for second printer

one weird stuff, when i print pla, with 180, or 200 deggrees celsius, prints are the same, no difference. same thing with abs, it isnt matter if its 235 or 260, prints are identical. is that normal?

this is printed @60 mm/sec, 2 layers, 190 celsius, 0.288 mm layer heignt., no fan..

Edited 2 time(s). Last edit at 07/29/2013 03:08AM by woo.

i have v 4.1 and i am very satisfied with it. i have printed 10-15 prints till now... i have printer for about one week, prusa i3 with full modified electronic.

so i suggest to everyone, buy good stuff, it wil pay itself(hot end, printer is crap..).

i think the best side of this hotend is, it cant be broken

il buy another one soon for second printer

one weird stuff, when i print pla, with 180, or 200 deggrees celsius, prints are the same, no difference. same thing with abs, it isnt matter if its 235 or 260, prints are identical. is that normal?

this is printed @60 mm/sec, 2 layers, 190 celsius, 0.288 mm layer heignt., no fan..

Edited 2 time(s). Last edit at 07/29/2013 03:08AM by woo.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 29, 2013 03:57PM |

Registered: 11 years ago Posts: 137 |

new to3Dbob Wrote:

-------------------------------------------------------

> Can anyone let me know how much retraction you are

> able to use sucessfully without any jamming. I

> can get up to .7mm and any more than that it jams

> some where around/in the nozzle. When this

> happens I am able to heat it up to a higher than

> printing temperature and unjam the nozzle so I do

> not know exactly where the jam is occurring but it

> is definitly in the melt zone somewhere.

>

> I was thinking that my print temp might be to low

> but I'm printing at 220C, verified with a

> thermocouple. I'm sure it is PLA as it will not

> dissolve in acetone and it gives off that sweet

> smell when printing. Thanks a lot,

>

> Bob

try higher temp. I'm printing most pla at about 250-260c

ABS at 270c

This prevents all but the most stubborn jams from happening to me.

I try to dial in every roll of filament I get in.

Edited 2 time(s). Last edit at 07/29/2013 04:14PM by hendo420.

-------------------------------------------------------

> Can anyone let me know how much retraction you are

> able to use sucessfully without any jamming. I

> can get up to .7mm and any more than that it jams

> some where around/in the nozzle. When this

> happens I am able to heat it up to a higher than

> printing temperature and unjam the nozzle so I do

> not know exactly where the jam is occurring but it

> is definitly in the melt zone somewhere.

>

> I was thinking that my print temp might be to low

> but I'm printing at 220C, verified with a

> thermocouple. I'm sure it is PLA as it will not

> dissolve in acetone and it gives off that sweet

> smell when printing. Thanks a lot,

>

> Bob

try higher temp. I'm printing most pla at about 250-260c

ABS at 270c

This prevents all but the most stubborn jams from happening to me.

I try to dial in every roll of filament I get in.

Edited 2 time(s). Last edit at 07/29/2013 04:14PM by hendo420.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 29, 2013 04:52PM |

Registered: 10 years ago Posts: 1 |

trsaunders Wrote:

-------------------------------------------------------

> Enlightx Wrote:

> --------------------------------------------------

> -----

> > what extruders are people using? as iv tried a

> few

> > now with J-Head mount and iv found the hot end

> > ends up at a slight angle. also its not very

> tight

> > in the extruder. so far iv tried missans i3

> gregs

> > and also sgrabbers compact i3 extruder.

> >

> > Currently im running with an alu groove mount

> form

> > hotends.com the hotend spins so iv had to pack

> it

> > in tight using M8 washers.

> I had the same problem so I made this:

> [www.thingiverse.com]

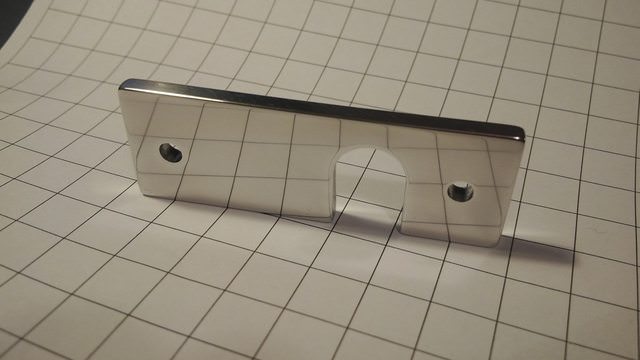

I decided to cut my own piece of aluminium

that's the result (it's for Yruds extruder):

more photos - [plus.google.com]

-------------------------------------------------------

> Enlightx Wrote:

> --------------------------------------------------

> -----

> > what extruders are people using? as iv tried a

> few

> > now with J-Head mount and iv found the hot end

> > ends up at a slight angle. also its not very

> tight

> > in the extruder. so far iv tried missans i3

> gregs

> > and also sgrabbers compact i3 extruder.

> >

> > Currently im running with an alu groove mount

> form

> > hotends.com the hotend spins so iv had to pack

> it

> > in tight using M8 washers.

> I had the same problem so I made this:

> [www.thingiverse.com]

I decided to cut my own piece of aluminium

that's the result (it's for Yruds extruder):

more photos - [plus.google.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 30, 2013 10:54AM |

Registered: 12 years ago Posts: 177 |

Hi All,

Sorry I haven't been as active here recently. We have just moved facilities to a new bigger unit where we can really set up shop. It's coming together nicely.

Once again we are out of stock, but really we are only waiting on heater cartridges. We have been through a few different suppliers, and the new poorly toleranced, lower power ones are shockingly prevalent. As soon as we get heaters in again we will be shipping - they should be arriving within the week. Everybody with pending orders etc will receive their stuff within the time frames promised. We are actually looking like we will ship most of the "4 week" orders well before schedule - as long as the heaters come in as proper quality and on time.

Jinx

It does seem likely that heat could have crept up after turning off the cooling when the nozzle is still hot. A 1 minute wait or so before killing cooling should prevent this from happening. If you need any more help or advice, just get in touch by email and I will be able to get back to you more quickly then on here.

Nic0laz

Are you taking the PID values from the tuning process and putting them into your firmware/reuploading the values?

Smartroad

Probably not going to be that long! (No promises though!)

EnlightX

The real root of this issue is that a large amount of groovemount extruders rely on screws biting into PEEK as they pass through the extruder from the side. Aluminium is obviously less compliant than PEEK and so we have to allow some room to let this still happen. It's a bit fudgy really. - Salvation comes in the shape of extruders designed for the E3D (Search thingiverse for E3D) or in extruders that use different (better?) mounting systems. I can highly reccomend nopheads derivative Wades extruder that uses 3x bolts with washers that come up from the bottom and push the collar of the hotend up into the extruder block. It's my favourite direct drive mounting system at the moment.

new to3Dbob

Reading back through your posts you mention that "nothing past the bottom 3-4 fins is hot" - implying that the bottom 3-4 are warm or even hot. If your bottom few fins are getting hot you may have a cooling problem - how is your fan mounted? Is it blowing the whole time? Are you using a heater chamber that might alter cooling?

Sorry I haven't been as active here recently. We have just moved facilities to a new bigger unit where we can really set up shop. It's coming together nicely.

Once again we are out of stock, but really we are only waiting on heater cartridges. We have been through a few different suppliers, and the new poorly toleranced, lower power ones are shockingly prevalent. As soon as we get heaters in again we will be shipping - they should be arriving within the week. Everybody with pending orders etc will receive their stuff within the time frames promised. We are actually looking like we will ship most of the "4 week" orders well before schedule - as long as the heaters come in as proper quality and on time.

Jinx

It does seem likely that heat could have crept up after turning off the cooling when the nozzle is still hot. A 1 minute wait or so before killing cooling should prevent this from happening. If you need any more help or advice, just get in touch by email and I will be able to get back to you more quickly then on here.

Nic0laz

Are you taking the PID values from the tuning process and putting them into your firmware/reuploading the values?

Smartroad

Probably not going to be that long! (No promises though!)

EnlightX

The real root of this issue is that a large amount of groovemount extruders rely on screws biting into PEEK as they pass through the extruder from the side. Aluminium is obviously less compliant than PEEK and so we have to allow some room to let this still happen. It's a bit fudgy really. - Salvation comes in the shape of extruders designed for the E3D (Search thingiverse for E3D) or in extruders that use different (better?) mounting systems. I can highly reccomend nopheads derivative Wades extruder that uses 3x bolts with washers that come up from the bottom and push the collar of the hotend up into the extruder block. It's my favourite direct drive mounting system at the moment.

new to3Dbob

Reading back through your posts you mention that "nothing past the bottom 3-4 fins is hot" - implying that the bottom 3-4 are warm or even hot. If your bottom few fins are getting hot you may have a cooling problem - how is your fan mounted? Is it blowing the whole time? Are you using a heater chamber that might alter cooling?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 31, 2013 10:37AM |

Registered: 11 years ago Posts: 67 |

Hello,

My fan is mounted all the way at the bottom of the hotend, starting at the bottom cooling fin. I do not have a heated chamber. Perhaps hot was the incorrect word to use, it is by no means hot. What I should have said is, the bottom few fins are slightly warmer that the rest of the fins.

I have since noticed a I had a slight bit of slippage between the filament and the drive gear. I have corrected this and may try to increase the retraction again, but at .7 I am able to print great without minimal oozing. I may just leave well enough alone.

Thanks.

My fan is mounted all the way at the bottom of the hotend, starting at the bottom cooling fin. I do not have a heated chamber. Perhaps hot was the incorrect word to use, it is by no means hot. What I should have said is, the bottom few fins are slightly warmer that the rest of the fins.

I have since noticed a I had a slight bit of slippage between the filament and the drive gear. I have corrected this and may try to increase the retraction again, but at .7 I am able to print great without minimal oozing. I may just leave well enough alone.

Thanks.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 31, 2013 11:45AM |

Registered: 10 years ago Posts: 25 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 01, 2013 01:41PM |

Registered: 12 years ago Posts: 177 |

new to3Dbob

If it ain't broke... don't fix it! But if you do have any more issues do just email or post and I will do what I can.

turutk

Yup Royal Mail is all we use. God Save the Queen and all that....

In General

I would really like it if we could keep general sales enquires off the forum, it doesn't add to the discussion and I don't want to be seen as exploiting the forums as a sales platform. The thread is intended so we can discuss the engineering aspects etc of the E3D and other hotend types in an open way so the whole community can benefit and progress.

If you have a specific sales enquiry please use the web form on my site. http://e3d-online.com/contactus.html

We are getting large amounts of stock in fast, and earlier than expected. We hope to move away from pre-orders and to immediate dispatch by the end of next week. All orders placed with the "4 week" lead time will probably be shipped much much earlier than expected - but I am making no promises until I have tested parts in my hands!

If it ain't broke... don't fix it! But if you do have any more issues do just email or post and I will do what I can.

turutk

Yup Royal Mail is all we use. God Save the Queen and all that....

In General

I would really like it if we could keep general sales enquires off the forum, it doesn't add to the discussion and I don't want to be seen as exploiting the forums as a sales platform. The thread is intended so we can discuss the engineering aspects etc of the E3D and other hotend types in an open way so the whole community can benefit and progress.

If you have a specific sales enquiry please use the web form on my site. http://e3d-online.com/contactus.html

We are getting large amounts of stock in fast, and earlier than expected. We hope to move away from pre-orders and to immediate dispatch by the end of next week. All orders placed with the "4 week" lead time will probably be shipped much much earlier than expected - but I am making no promises until I have tested parts in my hands!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 01, 2013 03:39PM |

Registered: 10 years ago Posts: 25 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 04, 2013 08:26PM |

Registered: 10 years ago Posts: 65 |

Has anyone tried using the E3D nozzle in a printer enclosed to prevent ABS splitting? I tried it for the first time and had two jams as the print proceeded into the higher areas of the chamber. It even happened earlier on the second print when the chamber temp was a little higher. The chamber temp wasn't really that high: 95F at the top. I assume it was lower at the print area since the cover didn't extend all the way to the print bed.

It took me retrying it to figure out what was happening. I'm running natural ABS, 1.0 mm retract (direct extruder), 215C (where this filament has worked very well to date), bed temp 110C on kapton.

I should try measuring the temp of the coolng fins. The fan has been making a noise on startup since shortly after I got the head. Maybe it isn't providing the proper cooling.

It took me retrying it to figure out what was happening. I'm running natural ABS, 1.0 mm retract (direct extruder), 215C (where this filament has worked very well to date), bed temp 110C on kapton.

I should try measuring the temp of the coolng fins. The fan has been making a noise on startup since shortly after I got the head. Maybe it isn't providing the proper cooling.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 04, 2013 11:20PM |

Registered: 11 years ago Posts: 246 |

I have been printing with a clear garbage bag over my prusa i2 and the chamber temp reaches about 40C. I have the 3mm version using a geared extruder and a good hobbed bolt and the print would jam with retracts greater than 0.6mm -__- I am printing quality ABS from Eckertech and printing at 220C with the bed at 110C on Kapton. That's the problem with air cooled hot ends: they don't work as well in heated chambers. I don't have a good fix for this problem yet...

Eric

Eric

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 05, 2013 12:04AM |

Registered: 12 years ago Posts: 198 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 05, 2013 06:40AM |

Registered: 12 years ago Posts: 177 |

To those using heated chambers:

I have heard of this sort of thing from users of other more enclosed printers. I think part or all of the issue is that the fans aren't happy at those temperatures, it seems to have some effect on the lubricant in the bearings. We've gone to higher spec two-ball-bearing fans recently to try and help with this, but there's only so much that can be done. Some low viscosity oil on the fan bearing (under the sticker) is reported to help.

Investigating Magnetic Levitation fans right now, which is promising for a few reasons beyond just the heat issue.

A snorkel arrangement would be interesting, you could even have the fan not on the hotend itself and have it on the entrance to the snorkel to reduce weight.

I have heard of this sort of thing from users of other more enclosed printers. I think part or all of the issue is that the fans aren't happy at those temperatures, it seems to have some effect on the lubricant in the bearings. We've gone to higher spec two-ball-bearing fans recently to try and help with this, but there's only so much that can be done. Some low viscosity oil on the fan bearing (under the sticker) is reported to help.

Investigating Magnetic Levitation fans right now, which is promising for a few reasons beyond just the heat issue.

A snorkel arrangement would be interesting, you could even have the fan not on the hotend itself and have it on the entrance to the snorkel to reduce weight.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 05, 2013 08:07AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi SanjayM, it's nice to see you think of snorkels, I am actually investigating a bit on this matter myself because I'm still working on a way to get 'cooler' air onto my PLA prints.

The only way I can get cooler air is from an area where the air is cooler, so from behind an enclosed box. For now I have only done tests with moving the air-duct away from the hotend more and towards the backside of the printer. First of all this is an area that I don't use much (I have arranged all my accessible parts on the front of the X-carriage), second of all, my enclosing is mostly on the front of the machine, so the cooler air would be towards the back and a bit up.

There are also people who have experimented with tubing and watercooled hotends.

The only way I can get cooler air is from an area where the air is cooler, so from behind an enclosed box. For now I have only done tests with moving the air-duct away from the hotend more and towards the backside of the printer. First of all this is an area that I don't use much (I have arranged all my accessible parts on the front of the X-carriage), second of all, my enclosing is mostly on the front of the machine, so the cooler air would be towards the back and a bit up.

There are also people who have experimented with tubing and watercooled hotends.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 05, 2013 09:12AM |

Registered: 12 years ago Posts: 177 |

Ohmarius

I really do think water cooling is very promising for a heated chamber system. I have a design being finalised and going to manufacture sometime today or tomorrow for a prototype run. It's quite specialist so I might kickstart it to gauge interest before I go buying way too few/too many.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

I really do think water cooling is very promising for a heated chamber system. I have a design being finalised and going to manufacture sometime today or tomorrow for a prototype run. It's quite specialist so I might kickstart it to gauge interest before I go buying way too few/too many.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

Sorry, only registered users may post in this forum.

Boo!

Boo!