Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 05, 2013 12:02PM |

Admin Registered: 11 years ago Posts: 3,096 |

From what I've seen so far from others is that the tubes that are used in normal water-cooled systems are not flexible enough.

I think a water-cooled system with two flexible in- and output tubes connected on the backside of the X-carriage will make for a very flexible solution, also, when using a bowden system the tubes can also be guided along the bowden tube. Best would be a closed system (the ones I've seen were open and pull water from a big open reservoir) with de-mineralized water to make sure there will be no sediment in the system, or maybe even cooling liquid for small motor-vehicles.

Very curious to see what you have come up with!

SanjayM Wrote:

-------------------------------------------------------

> Ohmarius

> I really do think water cooling is very promising

> for a heated chamber system. I have a design being

> finalised and going to manufacture sometime today

> or tomorrow for a prototype run. It's quite

> specialist so I might kickstart it to gauge

> interest before I go buying way too few/too many.

I think a water-cooled system with two flexible in- and output tubes connected on the backside of the X-carriage will make for a very flexible solution, also, when using a bowden system the tubes can also be guided along the bowden tube. Best would be a closed system (the ones I've seen were open and pull water from a big open reservoir) with de-mineralized water to make sure there will be no sediment in the system, or maybe even cooling liquid for small motor-vehicles.

Very curious to see what you have come up with!

SanjayM Wrote:

-------------------------------------------------------

> Ohmarius

> I really do think water cooling is very promising

> for a heated chamber system. I have a design being

> finalised and going to manufacture sometime today

> or tomorrow for a prototype run. It's quite

> specialist so I might kickstart it to gauge

> interest before I go buying way too few/too many.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 06, 2013 05:28AM |

Registered: 11 years ago Posts: 67 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 06, 2013 11:16AM |

Registered: 11 years ago Posts: 246 |

Yeah, I have definitely considered using a snorkel to improve cooling within my heated chamber. I have heard that the Stratasys machines have AC units that cool the electronics and/or motor and are also used to cool the hot ends. I have an AC in a window close to my printer so would really want to test this out. This could probably be achieved without too much difficulty using a 2in vacuum hose.

Also, regarding water cooled hot ends: I always wondered why people make such a big deal about the hoses working themselves loose If you were to use silicone hoses with the correct size of coupler and strap the hoses to the carriage, you shouldn't have a problem. This is what we do with the thermistor wires to make sure the thermistor is not accidentally pulled out of the heater block, and the same principal would work for silicone hoses. BTW my laser cutter uses silicone hoses to connect the water pump to the laser tube, and the hoses are VERY hard to work loose at the connection between the hose and the coupler.

If you were to use silicone hoses with the correct size of coupler and strap the hoses to the carriage, you shouldn't have a problem. This is what we do with the thermistor wires to make sure the thermistor is not accidentally pulled out of the heater block, and the same principal would work for silicone hoses. BTW my laser cutter uses silicone hoses to connect the water pump to the laser tube, and the hoses are VERY hard to work loose at the connection between the hose and the coupler.

Eric

Also, regarding water cooled hot ends: I always wondered why people make such a big deal about the hoses working themselves loose

If you were to use silicone hoses with the correct size of coupler and strap the hoses to the carriage, you shouldn't have a problem. This is what we do with the thermistor wires to make sure the thermistor is not accidentally pulled out of the heater block, and the same principal would work for silicone hoses. BTW my laser cutter uses silicone hoses to connect the water pump to the laser tube, and the hoses are VERY hard to work loose at the connection between the hose and the coupler.

If you were to use silicone hoses with the correct size of coupler and strap the hoses to the carriage, you shouldn't have a problem. This is what we do with the thermistor wires to make sure the thermistor is not accidentally pulled out of the heater block, and the same principal would work for silicone hoses. BTW my laser cutter uses silicone hoses to connect the water pump to the laser tube, and the hoses are VERY hard to work loose at the connection between the hose and the coupler.Eric

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 06, 2013 09:11PM |

Registered: 11 years ago Posts: 67 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 10, 2013 08:41PM |

Registered: 10 years ago Posts: 1 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 18, 2013 04:47PM |

Admin Registered: 15 years ago Posts: 1,470 |

Any news on the new hotends? I would love to experiment with them. I've currently got dual-extrusion working with two e3d hotends (see [www.thingiverse.com] ).

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 19, 2013 06:11AM |

Registered: 11 years ago Posts: 248 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 19, 2013 06:32AM |

Registered: 11 years ago Posts: 528 |

now that I worked the gremlins out off my printer, this hotend is brilliant preforms better than my expectations

and thanks to Smartroad & sanjay for pointing out the cooling issue,, there's no turning back> <

<

Edited 3 time(s). Last edit at 08/19/2013 06:47AM by jinx.

and thanks to Smartroad & sanjay for pointing out the cooling issue,, there's no turning back>

<

<Edited 3 time(s). Last edit at 08/19/2013 06:47AM by jinx.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 21, 2013 07:08AM |

Registered: 10 years ago Posts: 474 |

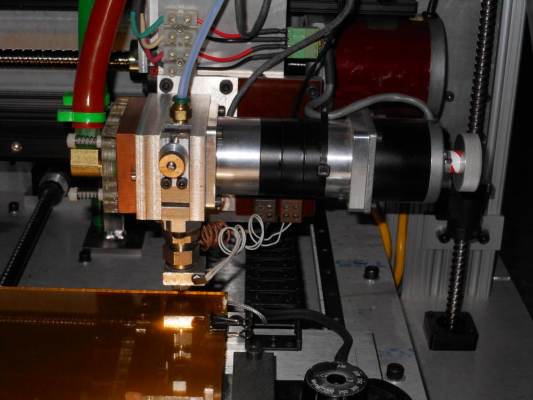

Here is a picture of my extruder and hot end way too heavy for any standard reprap but is very reliable it utilizes water cooling and outside air using an aquarium air pump to push air through filament tube with a tight fitting Teflon bushing at the beginning where filament enters the tube and loosefitting where it goes into the extruder so air from down low outside blows around filament and down onto drive wheel I did this because I plan on enclosure but never did quite get there

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 22, 2013 08:50AM |

Registered: 11 years ago Posts: 490 |

I have been running my printer inside a heat retention chamber with the E3D hotend without any problems. The chamber reaches up to 45°C, but then again, the fan is permanently wired to the 12V power supply, so that might affect how well the hotend works in the chamber.

The snorkel idea is rather intriguing, though. I wonder if the added mass of ducts and associated springiness will in some way affect print speeds and quality.

One could use some tubing as combination cable and filament guide/enclosure and air duct, but then air flow might be less than ideal...

The snorkel idea is rather intriguing, though. I wonder if the added mass of ducts and associated springiness will in some way affect print speeds and quality.

One could use some tubing as combination cable and filament guide/enclosure and air duct, but then air flow might be less than ideal...

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 25, 2013 05:54PM |

Registered: 10 years ago Posts: 16 |

So I have my 3mm E3D hotend running pretty well. I have some of the newest Taulman PETT on pre order and now their order page has been changed to say this: "NOTE: 3mm t-glase size will actually be the new Industry Standard of 2.8mm-3mm Max rather than 3mm +/-".  Didn't say that when I placed the order. My Taulman 645 and 618 runs about 3.05 mm. Any idea if this 2.8-3 will work in the E3D?

Didn't say that when I placed the order. My Taulman 645 and 618 runs about 3.05 mm. Any idea if this 2.8-3 will work in the E3D?

ETA: And where does this 'new industry standard' come from anyway?

Edited 1 time(s). Last edit at 08/25/2013 05:55PM by drawcut.

Didn't say that when I placed the order. My Taulman 645 and 618 runs about 3.05 mm. Any idea if this 2.8-3 will work in the E3D?

Didn't say that when I placed the order. My Taulman 645 and 618 runs about 3.05 mm. Any idea if this 2.8-3 will work in the E3D?ETA: And where does this 'new industry standard' come from anyway?

Edited 1 time(s). Last edit at 08/25/2013 05:55PM by drawcut.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 25, 2013 06:01PM |

Registered: 11 years ago Posts: 246 |

I am not sure about the "new industry standard" as there have always been 2 definitions of 3mm filament (3mm +/-, and 2.85 +/-). I presume that they are trying to establish 3mm filament as strictly "less than 3mm".

I have used 2.85mm ABS with my 3mm version of the E3D hot end and it works just fine. However, you should anticipate greater backpressure due to the reduced nominal filament diameter.

Eric

I have used 2.85mm ABS with my 3mm version of the E3D hot end and it works just fine. However, you should anticipate greater backpressure due to the reduced nominal filament diameter.

Eric

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 25, 2013 07:22PM |

Admin Registered: 15 years ago Posts: 1,470 |

I exclusively use 2.85mm PLA and ABS in my E3D hot ends. Works just fine other than the rare plug up. AFAIK, 2.85mm has always been more popular than 3mm.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 25, 2013 08:33PM |

Registered: 10 years ago Posts: 16 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 26, 2013 10:19PM |

Registered: 10 years ago Posts: 22 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 26, 2013 10:27PM |

Registered: 11 years ago Posts: 246 |

I also have a kuehling carriage and I had trouble mounting the fan duct. I managed to fit it underneath the 8mm smooth rods pointing to the front of the printer, but it was a few mm lower than it should have been. I had to hack away a few bits from the plastic duct but it works fine now

If you do this make sure that the fan does not blow on the 2mm shaved portion of the ss insulator as this will further shorten the transitions zone. If the transition zone is too short you may get more frequent jams during retractions.

Eric

If you do this make sure that the fan does not blow on the 2mm shaved portion of the ss insulator as this will further shorten the transitions zone. If the transition zone is too short you may get more frequent jams during retractions.

Eric

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 26, 2013 10:44PM |

Registered: 10 years ago Posts: 22 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 27, 2013 06:16AM |

Registered: 13 years ago Posts: 81 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 27, 2013 05:04PM |

Registered: 13 years ago Posts: 1,918 |

Well, this is a long thread, so please excuse me, if I lost track a little.

As far as I've learned the E3D can manage 3 mm PLA without jams. That was achieved with version 4.1

Does the 1.75 mm version reliably run without jams, too (PLA)?

What I like about the E3D is that the design is still kept all-metal (no PTFE workarounds) and that the PLA isn't blamed for the jams in case of them. Instead the design of the hotend is improved until it can handle the stuff. That's a good habit.

Detlef

As far as I've learned the E3D can manage 3 mm PLA without jams. That was achieved with version 4.1

Does the 1.75 mm version reliably run without jams, too (PLA)?

What I like about the E3D is that the design is still kept all-metal (no PTFE workarounds) and that the PLA isn't blamed for the jams in case of them. Instead the design of the hotend is improved until it can handle the stuff. That's a good habit.

Detlef

| Excalibur Hotend |

reprapzone.blogspot.de |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 27, 2013 05:28PM |

Registered: 10 years ago Posts: 9 |

theodleif Wrote:

> Does the 1.75 mm version reliably run without

> jams, too (PLA)?

No problems whatsoever, and I have an early version of the E3D. For example, I recently printed all parts (PLA) for my delta, maybe 15 hours of printing without an issue. The delta is also getting an E3D hotend, did not think twice before ordering. It will be interesting to try out bowden and the new nozzle geometry.

Edited 1 time(s). Last edit at 08/27/2013 05:29PM by Sal.

> Does the 1.75 mm version reliably run without

> jams, too (PLA)?

No problems whatsoever, and I have an early version of the E3D. For example, I recently printed all parts (PLA) for my delta, maybe 15 hours of printing without an issue. The delta is also getting an E3D hotend, did not think twice before ordering. It will be interesting to try out bowden and the new nozzle geometry.

Edited 1 time(s). Last edit at 08/27/2013 05:29PM by Sal.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 27, 2013 05:28PM |

Registered: 13 years ago Posts: 81 |

theodleif Wrote:

-------------------------------------------------------

> Does the 1.75 mm version reliably run without

> jams, too (PLA)?

I've been printing with 1.75mm pla filament with no issues. I have set a 0.5mm retract and make sure that the hot end is fully cooled before shutting down the fan.

-------------------------------------------------------

> Does the 1.75 mm version reliably run without

> jams, too (PLA)?

I've been printing with 1.75mm pla filament with no issues. I have set a 0.5mm retract and make sure that the hot end is fully cooled before shutting down the fan.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 31, 2013 03:19PM |

I just wonder yesterday when I have same problem that no one hasn't say anything that fan wont fit under x-carriage.

I don't know what carriage I have, but i'ts not origina. Otherwise I would just mill fan&fanmount or carriage for some millimeter and it would fit tight but I had to put extruder little sideways that motor would'nt touch belt.

So I make little mount for fan that hangs from x-carriage, close to hotend and make "wind tunnel" from kapton tape.

Let see if I replace it with something else later when I get my prusa running.

I don't know what carriage I have, but i'ts not origina. Otherwise I would just mill fan&fanmount or carriage for some millimeter and it would fit tight but I had to put extruder little sideways that motor would'nt touch belt.

So I make little mount for fan that hangs from x-carriage, close to hotend and make "wind tunnel" from kapton tape.

Let see if I replace it with something else later when I get my prusa running.

|

| Lähettäjä Elektroniikkaa ja tietotekniikkaa |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 31, 2013 06:55PM |

Registered: 11 years ago Posts: 490 |

I am also printing 1.75mm PLA without problems here. The hot end design I used before tended to jam horribly when switching from ABS to PLA even after a full purge, but I can freely swap around different materials without problem here. It's just great - works without fail so far and the nozzle also stays cleaner than the one of my old hot end.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] September 01, 2013 12:24PM |

Registered: 11 years ago Posts: 40 |

Sanjay,

Thinking aloud, and decided to run this by you. My hotend kit arrived on Friday, many thanks, and I like the quality a lot, even before I start to use it.

My plan is to use it in a Delta Pi, so there are bed position and calibration issues, so I am going to throw a thought your way to see if it's possible or desirable.

All sorts of fancy probes are being used to sense the bed position in relation to the hot end, my thought is that as long as the bed, (or a plate mounted on it) is metallic, how feasible and expensive would it be to make up a partial hot end that would be the cold end, (no fan or mount needed, and no significant machining at the filament end. other than a thread for a cable connection screw, the heater interface, a joiner with the same thread as the heater block, but no other machining, so a piece of round bar threaded through, and a nozzle without a hole in it, or if we want to get really fancy, a nozzle the same depth as the standard nozzle, but machined to have a point on it so that it makes a good clean contact with the bed metal material. That said, a piece of bar the same length as the interface tube and the nozzle would peform the same function, with a lower part count and machining cost, or an alternative would be a pointed piece of bar that is locked into the cold end without threading using an Allen set screw, similar to that used for the heater block. That option would mean that the hot end could be used to establish a known height from the bed plate, and then the alignment setter could be put in it's place, and also set to be the right height, which would allow the calibration to be completed..

If the bed is then connected to one side of a switch pair, and the "nozzle", (via the other pieces) is connected to the other side, the bed height and accuracy can be calibrated across as much or as little of the bed area as is needed, if the bed is out of level it can be adjusted and checked, iteratively if needed, until accurate, at which point the Delta "fudge factors" can be checked to ensure that it operates accurately over the entire printing area.

Then the calibration hot end is removed, the "live" hot end installed in it's place, and then the machine is in theory ready to extrude plastic, the only change to make is to put in the Z offset required for the heated bed and it's cover, which in theory should be a constant across the entire bed area, and any possible difference between the calibrator and the live hot end.

Is this a valid concept, is it worth going to this degree of accuracy, and it it something that you could offer as an extra product for the printers that require calibration of their Z height?

Cheers

Steve

Shore, if twas easy, we'd all be doin it

Irish Steve

Thinking aloud, and decided to run this by you. My hotend kit arrived on Friday, many thanks, and I like the quality a lot, even before I start to use it.

My plan is to use it in a Delta Pi, so there are bed position and calibration issues, so I am going to throw a thought your way to see if it's possible or desirable.

All sorts of fancy probes are being used to sense the bed position in relation to the hot end, my thought is that as long as the bed, (or a plate mounted on it) is metallic, how feasible and expensive would it be to make up a partial hot end that would be the cold end, (no fan or mount needed, and no significant machining at the filament end. other than a thread for a cable connection screw, the heater interface, a joiner with the same thread as the heater block, but no other machining, so a piece of round bar threaded through, and a nozzle without a hole in it, or if we want to get really fancy, a nozzle the same depth as the standard nozzle, but machined to have a point on it so that it makes a good clean contact with the bed metal material. That said, a piece of bar the same length as the interface tube and the nozzle would peform the same function, with a lower part count and machining cost, or an alternative would be a pointed piece of bar that is locked into the cold end without threading using an Allen set screw, similar to that used for the heater block. That option would mean that the hot end could be used to establish a known height from the bed plate, and then the alignment setter could be put in it's place, and also set to be the right height, which would allow the calibration to be completed..

If the bed is then connected to one side of a switch pair, and the "nozzle", (via the other pieces) is connected to the other side, the bed height and accuracy can be calibrated across as much or as little of the bed area as is needed, if the bed is out of level it can be adjusted and checked, iteratively if needed, until accurate, at which point the Delta "fudge factors" can be checked to ensure that it operates accurately over the entire printing area.

Then the calibration hot end is removed, the "live" hot end installed in it's place, and then the machine is in theory ready to extrude plastic, the only change to make is to put in the Z offset required for the heated bed and it's cover, which in theory should be a constant across the entire bed area, and any possible difference between the calibrator and the live hot end.

Is this a valid concept, is it worth going to this degree of accuracy, and it it something that you could offer as an extra product for the printers that require calibration of their Z height?

Cheers

Steve

Shore, if twas easy, we'd all be doin it

Irish Steve

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] September 02, 2013 12:53AM |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] September 02, 2013 03:33AM |

Registered: 11 years ago Posts: 528 |

Hi millerii,

Forgive my humour, the nozzle looks like it not in propley,redo that part till it flush with the heater block.

I did an experiment the other month using a fan duct for the hot end ,because like you I couldn't get it to fit at first, the heat crept up the barrel caused the filament to

Swell and jam. Think it something to be aware off.

Forgive my humour, the nozzle looks like it not in propley,redo that part till it flush with the heater block.

I did an experiment the other month using a fan duct for the hot end ,because like you I couldn't get it to fit at first, the heat crept up the barrel caused the filament to

Swell and jam. Think it something to be aware off.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] September 02, 2013 12:18PM |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] September 02, 2013 12:34PM |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] September 02, 2013 03:29PM |

Admin Registered: 15 years ago Posts: 1,470 |

jinx Wrote:

-------------------------------------------------------

> Hi millerii,

> Forgive my humour, the nozzle looks like

> it not in propley,redo that part till it flush

> with the heater block.

According to E3D's own instructions, there should be a small gap between the nozzle and heater block.

-------------------------------------------------------

> Hi millerii,

> Forgive my humour, the nozzle looks like

> it not in propley,redo that part till it flush

> with the heater block.

According to E3D's own instructions, there should be a small gap between the nozzle and heater block.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] September 02, 2013 04:04PM |

Registered: 13 years ago Posts: 1,918 |

NewPerfection Wrote:

-------------------------------------------------------

> According to E3D's own instructions, there should

> be a small gap between the nozzle and heater

> block.

Do you know the reason?

Detlef

-------------------------------------------------------

> According to E3D's own instructions, there should

> be a small gap between the nozzle and heater

> block.

Do you know the reason?

Detlef

| Excalibur Hotend |

reprapzone.blogspot.de |

Sorry, only registered users may post in this forum.