Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 16, 2013 06:41PM |

Registered: 11 years ago Posts: 25 |

I wonder what the optimal speed is for steppers to get high throughput on a hotend like the E3D that can generate a lot of heat quickly. I'm thinking about very fast print speeds or high rates of material extrusion.

Running stepper motors at high speeds decreases their torque, until at some point they stall on their own or under very small loads. For that reason, a direct drive extruder would be attractive because at lower motor speeds you get more extruded material. On the other hand, direct drive extruders require more input torque from the motor at a given rate of extrusion, so the geared extruders are attractive for pushing material as well.

It's probably just a matter of looking at the torque vs. pulse rate curves of the motors, the desired extrusion rate, and the reduction ratio of a direct drive vs. geared extruder to determine when each is more optimal. Has anyone seen or done that type of analysis?

I would be interested in knowing specifically for the E3D hotends where the sweet spot is, since I'm building a new machine that uses these hotends. (Currently I have Wade's Geared Extruders planned for this machine build, mainly because of price and my familiarity with them.)

Daniel

Running stepper motors at high speeds decreases their torque, until at some point they stall on their own or under very small loads. For that reason, a direct drive extruder would be attractive because at lower motor speeds you get more extruded material. On the other hand, direct drive extruders require more input torque from the motor at a given rate of extrusion, so the geared extruders are attractive for pushing material as well.

It's probably just a matter of looking at the torque vs. pulse rate curves of the motors, the desired extrusion rate, and the reduction ratio of a direct drive vs. geared extruder to determine when each is more optimal. Has anyone seen or done that type of analysis?

I would be interested in knowing specifically for the E3D hotends where the sweet spot is, since I'm building a new machine that uses these hotends. (Currently I have Wade's Geared Extruders planned for this machine build, mainly because of price and my familiarity with them.)

Daniel

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 16, 2013 08:43PM |

Registered: 10 years ago Posts: 52 |

Quote

dtmille2

I wonder what the optimal speed is for steppers to get high throughput on a hotend like the E3D that can generate a lot of heat quickly. I'm thinking about very fast print speeds or high rates of material extrusion.

If you want speed i think you need better control over the extruder's pressure on the hotend. One way i've seen this done is by fixing an extruder on a load cell. There is a good example of this at [airtripper.com] . But i've yet to see a single video of even a picture of the potential benefit that this could give. In theory you could use the load cell's data to better control the steppers, but i dont know if the arduino is fast enough. I would test it myself if i could, but i'm still lacking a 3d printer...

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 05:43AM |

Registered: 11 years ago Posts: 544 |

not sure if this relates but on my personal hot end ive noticed that I can extrude about 7mm/s of 1.75mm filament continiously, i can extrude upwards of 25mm/s in short bursts of about 15mm long, if i try to extrude faster than 7mm/s continously the hot end cannot heat the plastic fast enough for it to be extrueable. does anyone else have any data like this about the e3d hot end?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 05:46AM |

Registered: 10 years ago Posts: 53 |

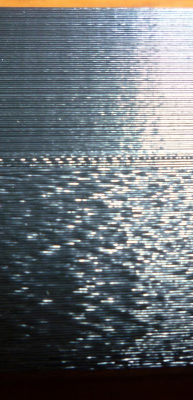

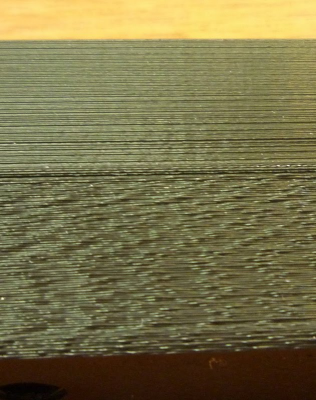

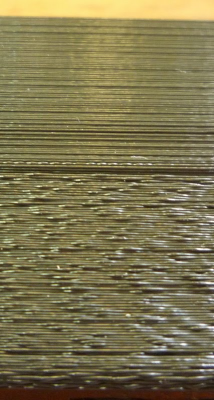

An update on my issue...

The prints get pretty much better with 4.7:1 reduction on extruder.

Check pictures bellow:

I guess there is no need for labels.

The results is not perfect, but far better than before.

I'm running the extruder with 635 steps/mm. I'm planing increasing to about 1000 steps/mm...

Then I ask again: Am I the only one realizing such issue??? Nobody else with 1.75 and direct drive have the issue??

I tried to swap all components except the hotend and filament.

Cheers,

Alex.

Edited 1 time(s). Last edit at 12/18/2013 05:48AM by AlexBorro.

The prints get pretty much better with 4.7:1 reduction on extruder.

Check pictures bellow:

I guess there is no need for labels.

The results is not perfect, but far better than before.

I'm running the extruder with 635 steps/mm. I'm planing increasing to about 1000 steps/mm...

Then I ask again: Am I the only one realizing such issue??? Nobody else with 1.75 and direct drive have the issue??

I tried to swap all components except the hotend and filament.

Cheers,

Alex.

Edited 1 time(s). Last edit at 12/18/2013 05:48AM by AlexBorro.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 07:31AM |

Registered: 10 years ago Posts: 45 |

I'm using 1.75mm and a direct drive extruder and have not seen the same problem you are having. I'll have to go home and look at what the steps are set to but I'm using this Extruder with a MK7 drive gear. My filament comes from Toybuilderlabs.com. I did have to turn up the driver to get the extruder to operate smoothly but other than that, no issues.

I just got done printing the parts for the Auto-bed-leveling mod last night so I'll be in the firmware making changes tonight and I'll check what my steps are set to.

I just got done printing the parts for the Auto-bed-leveling mod last night so I'll be in the firmware making changes tonight and I'll check what my steps are set to.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 08:16AM |

Admin Registered: 17 years ago Posts: 7,879 |

The higher the current is, the more accurate the microsteps become, so the issue might have been the current set too low.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 08:31AM |

Registered: 10 years ago Posts: 53 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 10:06AM |

Admin Registered: 17 years ago Posts: 7,879 |

As I said earlier, I don't think DR8825 is a suitable driver for RepRap. It doesn't have the low current microstepping mode that the later Allegro drivers have.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 10:08AM |

Registered: 12 years ago Posts: 44 |

Quote

SanjayM

Just moved house, quit my job, gone full E3D, its been a crazy time. Thank you all for your patience, and I'm sorry if some people have been waiting for customer service a little longer than usual. It's been hard!

Congrats, Sanjay. I don't need a new hotend, but I want to experiment with higher temps someday. I'm sold on your customer service so far in this forum, your new refocusing, and your current sale. Just ordered me a new hotend from your store. Thanks.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 11:47AM |

Registered: 10 years ago Posts: 553 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 03:13PM |

Registered: 11 years ago Posts: 490 |

@mrPrik: I have a black PLA fan duct sitting right next to the heater block of an E3D hot end running at 300°C without problems. The fan isn't even running most of the time.

How I get away with it: I wrapped the fan duct in aluminium adhesive tape to reflect the infrared radiation (aluminium is really good at doing that), so the only heat that the fan duct gets is through convection. As the carriage moves a lot, this doesn't seem to be a problem. Of course, the aluminium tape also helps with structural integrity, but after trying to bend the duct when the hot end is heating, I doubt that this actually plays a role.

How I get away with it: I wrapped the fan duct in aluminium adhesive tape to reflect the infrared radiation (aluminium is really good at doing that), so the only heat that the fan duct gets is through convection. As the carriage moves a lot, this doesn't seem to be a problem. Of course, the aluminium tape also helps with structural integrity, but after trying to bend the duct when the hot end is heating, I doubt that this actually plays a role.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 03:28PM |

Registered: 10 years ago Posts: 439 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 03:37PM |

Registered: 11 years ago Posts: 374 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 04:04PM |

Registered: 10 years ago Posts: 439 |

I don't have a lack of space to fit a 4cm fan and the 3cm fan supplied was noisy. I cannot fathom the logic of considering it a waste of space to use space that is unused anyway. The bottom fin of the heatsink is barely warm for me. Mounting a fan on the carriage seemed better as the snap fit wasn't very good.

I just find the 4cm fan attached to the carriage better. Some have said that there are problems with PLA and the E3D. I have none. Its a great product that I am really happy with. Zero leakage is wonderful compared to the occasional blobs of dark goo from a leaky jhead. I have seen other designs for all metal hotends and they seem poorly designed in comparison.

I just find the 4cm fan attached to the carriage better. Some have said that there are problems with PLA and the E3D. I have none. Its a great product that I am really happy with. Zero leakage is wonderful compared to the occasional blobs of dark goo from a leaky jhead. I have seen other designs for all metal hotends and they seem poorly designed in comparison.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 04:08PM |

Registered: 11 years ago Posts: 374 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 04:12PM |

Admin Registered: 17 years ago Posts: 7,879 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 04:47PM |

Registered: 10 years ago Posts: 439 |

Chris - your supplied jhead was fine until I took it apart after a jam after several months of use. The 2 I got from another source leaked even after repair attempts with teflon tape.

The E3D doesn't leak so I'm happy. The jhead is an immature design in comparison to the E3D from my limited experience :-)

Crispy - the E3d is a lot longer than the jhead so I see lots of space. I lost 2cm+ of Z space but I don't personally need it for my prints. There are lots of x-carriage designs around so perhaps some don't have the space for a 4cm fan mounted to the x-carriage. They will just have to apply their ingenuity to solve their problems themselves or post their problem in order to receive multiple responses from all the good people here to help them resolve it.

The E3D doesn't leak so I'm happy. The jhead is an immature design in comparison to the E3D from my limited experience :-)

Crispy - the E3d is a lot longer than the jhead so I see lots of space. I lost 2cm+ of Z space but I don't personally need it for my prints. There are lots of x-carriage designs around so perhaps some don't have the space for a 4cm fan mounted to the x-carriage. They will just have to apply their ingenuity to solve their problems themselves or post their problem in order to receive multiple responses from all the good people here to help them resolve it.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 05:14PM |

Registered: 11 years ago Posts: 374 |

Quote

J-Heads don't leak unless they are faulty.

I have had some leak PLA from in between the mate between the brass and PEEK, if the brass is not adequately torqued down. If it's not fully torqued, after a few heating and cooling cycles it will loosen up enough to leak some PLA down the side of the brass block and onto the bottom face. I wouldn't really call this faulty, since all you need to do is heat it up to about 170C and torque the heater block down until it's fully seated.

What I do now is heat cycle them twice, then torque the brass down before any plastic is run through them. This nips the problem in the bud nicely, and it's similar to the "heat to 300C and torque down" step in the E3D instructions.

Quote

The jhead is an immature design in comparison to the E3D from my limited experience :-)

You do know Brian (reifsnyderb) has been at this for longer than 99% of people have been involved in 3D printing, right? The jhead is a very mature design that continues to improve with each iteration. I think you're blaming the tool for operator shortcomings.

Quote

the E3d is a lot longer than the jhead so I see lots of space.

I wasn't referring to vertical space. Many people are using side-by-side E3Ds for dual extrusion, and a 40mm fan would force them to position the hotends further apart, which would reduce the build envelope correspondingly.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 05:47PM |

Registered: 10 years ago Posts: 439 |

Quote

crispy1

Quote

J-Heads don't leak unless they are faulty.

I have had some leak PLA from in between the mate between the brass and PEEK, if the brass is not adequately torqued down. If it's not fully torqued, after a few heating and cooling cycles it will loosen up enough to leak some PLA down the side of the brass block and onto the bottom face. I wouldn't really call this faulty, since all you need to do is heat it up to about 170C and torque the heater block down until it's fully seated.

What I do now is heat cycle them twice, then torque the brass down before any plastic is run through them. This nips the problem in the bud nicely, and it's similar to the "heat to 300C and torque down" step in the E3D instructions.

Unfortunately most kits don't come with such detailed instructions :-)

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 05:58PM |

Registered: 10 years ago Posts: 439 |

Sorry I'm a noob and missed that. E3D works better for noobs like me with operator shortcomings.Quote

crispy1

You do know Brian (reifsnyderb) has been at this for longer than 99% of people have been involved in 3D printing, right? The jhead is a very mature design that continues to improve with each iteration. I think you're blaming the tool for operator shortcomings.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 06:08PM |

Registered: 10 years ago Posts: 439 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 07:03PM |

Registered: 10 years ago Posts: 553 |

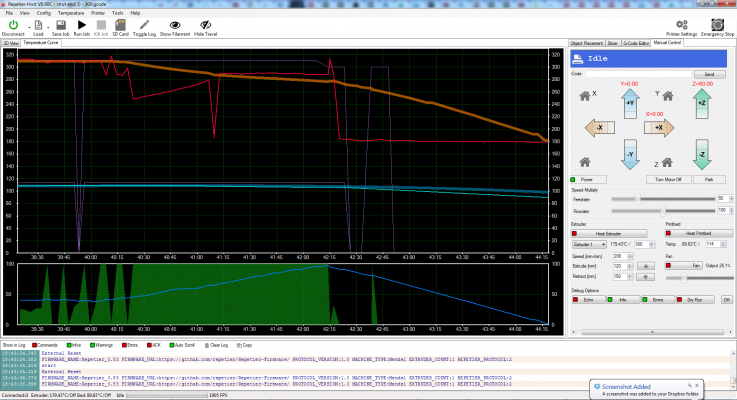

So...anyone printing with an E3D should probably know the limit is 300c or the thermistor dies.

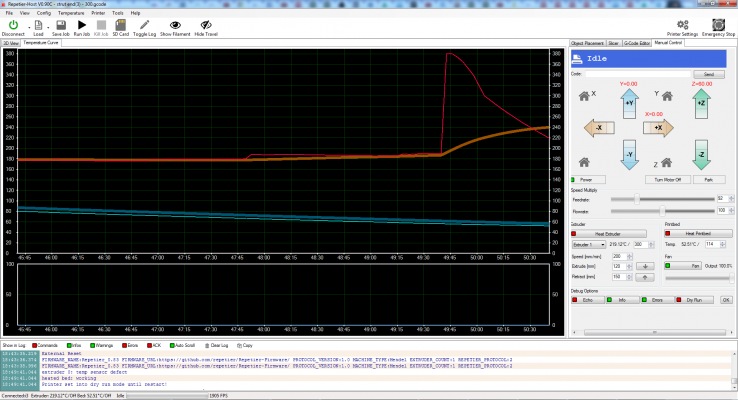

Here are a few SS of Repetier when the thermistor died. This happened while attempting to print polycarbonate at 300-310c.

Maybe update the product page to say that? The datasheet has a 300c limit on the thermistor so maybe it isn't wise to have an assembly step run it to 300c where it can easily overshoot if this is the first use.

The purple line is the set temperature, the fat orange one is the average and the red is what the thermistor is recording. The green graph at the bottom is the PID power to the hotend. As you can see, the red line started bouncing around and reporting temps as low as 170C and then you can see at the same time this caused it to dump full power into the cartridge.

The second picture is during cool down where you can see it spike with absolutely no power applied.

Here is a picture of the hotend on the printer, no damage that I can see.

[www.dropbox.com]

Also

[www.dropbox.com]

And

[www.dropbox.com]

Edited 7 time(s). Last edit at 12/19/2013 07:39AM by tjb1.

Here are a few SS of Repetier when the thermistor died. This happened while attempting to print polycarbonate at 300-310c.

Maybe update the product page to say that? The datasheet has a 300c limit on the thermistor so maybe it isn't wise to have an assembly step run it to 300c where it can easily overshoot if this is the first use.

The purple line is the set temperature, the fat orange one is the average and the red is what the thermistor is recording. The green graph at the bottom is the PID power to the hotend. As you can see, the red line started bouncing around and reporting temps as low as 170C and then you can see at the same time this caused it to dump full power into the cartridge.

The second picture is during cool down where you can see it spike with absolutely no power applied.

Here is a picture of the hotend on the printer, no damage that I can see.

[www.dropbox.com]

Also

[www.dropbox.com]

And

[www.dropbox.com]

Edited 7 time(s). Last edit at 12/19/2013 07:39AM by tjb1.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 07:48PM |

Registered: 10 years ago Posts: 553 |

Up and printing again, no damage from what I can see.

The insulation on one of the thermistor wires was melted. Not sure if the thermistor failed and let the temp run up and do it or if it shorted to the heater block causing the failure. Still doesn't change the fact that the resistor is only rated for 300c.

The insulation on one of the thermistor wires was melted. Not sure if the thermistor failed and let the temp run up and do it or if it shorted to the heater block causing the failure. Still doesn't change the fact that the resistor is only rated for 300c.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 07:53PM |

Registered: 11 years ago Posts: 246 |

Quote

tjb1

Up and printing again, no damage from what I can see.

The insulation on one of the thermistor wires was melted. Not sure if the thermistor failed and let the temp run up and do it or if it shorted to the heater block causing the failure. Still doesn't change the fact that the resistor is only rated for 300c.

Yeah, NTC thermistors get less accurate as the temp increases and nobody has been able to find one that is rated for higher than 300C. If they were available, everyone would be using them. On this note, the guys who are running the Pico Hot End kickstarter campaign claim that they have found a thermistor that is good for up to 500C. It is one of their stretch goals because they say they need to order large MOQ. I would be interested to see how it performs.

Eric

Edited 1 time(s). Last edit at 12/18/2013 07:54PM by RP Iron Man.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 18, 2013 09:17PM |

Registered: 10 years ago Posts: 52 |

Quote

tjb1

Up and printing again, no damage from what I can see.

The insulation on one of the thermistor wires was melted. Not sure if the thermistor failed and let the temp run up and do it or if it shorted to the heater block causing the failure. Still doesn't change the fact that the resistor is only rated for 300c.

The website says that the E3D as been tested for 400°C. Are you saying that the included thermistor is only rated for 300°C?? That would be a bit sad...

If that's the case, i'm gonna go and order thermocouple wires... I needed a thermistor for the heatbed anyway...

Using thermocouples instead of thermistors.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 19, 2013 04:50AM |

Registered: 11 years ago Posts: 490 |

They probably supplied a thermistor because most of the RepRappers out there don't have the setup to use thermocouples. Besides, most materials print fine below 300°C. Only with the PC-ABS from RepRapWorld and Polycarbonate from an Ebay seller I had to bump temperatures up to 300°C and those are still not printing fine, but that's more a material issue than anything else.

Checking the temperatures on my hotend with a multimeter, I found the thermistor to be spot-on, though. So the default thermistor-table in Marlin is pretty usable for me. If you find yours to be inaccurate at higher temperatures, though, you can still easily calibrate everything within 30-60 mins (pessimistic estimation) or so.

Edited 1 time(s). Last edit at 12/19/2013 07:43AM by uGen.

Checking the temperatures on my hotend with a multimeter, I found the thermistor to be spot-on, though. So the default thermistor-table in Marlin is pretty usable for me. If you find yours to be inaccurate at higher temperatures, though, you can still easily calibrate everything within 30-60 mins (pessimistic estimation) or so.

Edited 1 time(s). Last edit at 12/19/2013 07:43AM by uGen.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 19, 2013 05:22AM |

Registered: 12 years ago Posts: 177 |

Very busy right now getting ready to shut up shop for Christmas - just chipping in to say that yes, the thermistor is rated to a max of 300C, and that the 400C figure on the site was done with a thermocouple. Going back and re-reading the description it reads as if the hotend should be able to run at 400 out of the box, which is not representative of reality. I'll get that clarified and changed ASAP. Sorry for any confusion caused.

tjb1 - if your thermistor is damaged from that heating cycle then please do get in touch via the website feedback form and I'll get you sorted out with a replacement/reimbursemnet. Thanks for bringing the whole issue to my attention.

Vishay makes some higher temperature thermistors - looking into it. But really I think thermocouples are the way forward at that point.

Cheers,

Sanjay

tjb1 - if your thermistor is damaged from that heating cycle then please do get in touch via the website feedback form and I'll get you sorted out with a replacement/reimbursemnet. Thanks for bringing the whole issue to my attention.

Vishay makes some higher temperature thermistors - looking into it. But really I think thermocouples are the way forward at that point.

Cheers,

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 19, 2013 07:39AM |

Registered: 10 years ago Posts: 553 |

Quote

SanjayM

Very busy right now getting ready to shut up shop for Christmas - just chipping in to say that yes, the thermistor is rated to a max of 300C, and that the 400C figure on the site was done with a thermocouple. Going back and re-reading the description it reads as if the hotend should be able to run at 400 out of the box, which is not representative of reality. I'll get that clarified and changed ASAP. Sorry for any confusion caused.

tjb1 - if your thermistor is damaged from that heating cycle then please do get in touch via the website feedback form and I'll get you sorted out with a replacement/reimbursemnet. Thanks for bringing the whole issue to my attention.

Vishay makes some higher temperature thermistors - looking into it. But really I think thermocouples are the way forward at that point.

Cheers,

Sanjay

This failed during attempting to print with polycarbonate, not during the assembly step but since most people may be doing the assembly step before any PID tuning maybe that should be called out. I know my PID was tuned much more agressive and ran it up to 330 the first time when set for 300. I am going to see if I can find anything thermocouple related for Ramps1.4.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 19, 2013 01:59PM |

Registered: 10 years ago Posts: 553 |

Sanjay, are the leads on the provided thermistor insulated with PTFE tubing? If so, the wiki claims that PTFE has a melting temp of 600k (326C) so maybe it was the thermistor that failed and the excess temperature caused the PTFE to melt.

I am currently investigating a way to use a thermocouple with Ramps1.4 to avoid this problem in the future.

Edited 2 time(s). Last edit at 12/19/2013 02:01PM by tjb1.

I am currently investigating a way to use a thermocouple with Ramps1.4 to avoid this problem in the future.

Edited 2 time(s). Last edit at 12/19/2013 02:01PM by tjb1.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 19, 2013 08:12PM |

Registered: 10 years ago Posts: 52 |

Sanjay, i think its nice that you have thermocouple in store, but, looking at the spec sheet of the ones you have. They can get a themperature reading of up to 1100°C, but if you look at the Operating Themperature, then they are rated only for -50 to 260°C. This is probably because they are insulated with PTFE, which melts between 260°C and 327°C.

Also, guys, carefull with the kapton tape, the cheap ones will also melt starting at 260°C.

Edited 1 time(s). Last edit at 12/19/2013 08:51PM by swe3tdave.

Also, guys, carefull with the kapton tape, the cheap ones will also melt starting at 260°C.

Edited 1 time(s). Last edit at 12/19/2013 08:51PM by swe3tdave.

Sorry, only registered users may post in this forum.