Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 19, 2013 09:41PM |

Registered: 13 years ago Posts: 118 |

Looking at the Kapton tape and how it turned black and knowing I've taken my hot end to 310C (overshoot for the toque procedure) and both thermistor and tape are fine...I would say you went well above 300C

Quote

tjb1

So...anyone printing with an E3D should probably know the limit is 300c or the thermistor dies.

Here are a few SS of Repetier when the thermistor died. This happened while attempting to print polycarbonate at 300-310c.

Maybe update the product page to say that? The datasheet has a 300c limit on the thermistor so maybe it isn't wise to have an assembly step run it to 300c where it can easily overshoot if this is the first use.

The purple line is the set temperature, the fat orange one is the average and the red is what the thermistor is recording. The green graph at the bottom is the PID power to the hotend. As you can see, the red line started bouncing around and reporting temps as low as 170C and then you can see at the same time this caused it to dump full power into the cartridge.

Here is a picture of the hotend on the printer, no damage that I can see.

[www.dropbox.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 19, 2013 11:50PM |

Registered: 10 years ago Posts: 553 |

Quote

jaydmdigital

Looking at the Kapton tape and how it turned black and knowing I've taken my hot end to 310C (overshoot for the toque procedure) and both thermistor and tape are fine...I would say you went well above 300C

Quote

tjb1

So...anyone printing with an E3D should probably know the limit is 300c or the thermistor dies.

Here are a few SS of Repetier when the thermistor died. This happened while attempting to print polycarbonate at 300-310c.

Maybe update the product page to say that? The datasheet has a 300c limit on the thermistor so maybe it isn't wise to have an assembly step run it to 300c where it can easily overshoot if this is the first use.

The purple line is the set temperature, the fat orange one is the average and the red is what the thermistor is recording. The green graph at the bottom is the PID power to the hotend. As you can see, the red line started bouncing around and reporting temps as low as 170C and then you can see at the same time this caused it to dump full power into the cartridge.

Here is a picture of the hotend on the printer, no damage that I can see.

[www.dropbox.com]

It was at 300-310c until it died

and judging from the PID to the hotend it was pumping for a while before I shut it off.

and judging from the PID to the hotend it was pumping for a while before I shut it off.It was at the 300-310 and continued at full power for 2 minutes before I caught it.

Edited 1 time(s). Last edit at 12/19/2013 11:53PM by tjb1.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 20, 2013 05:05PM |

Registered: 11 years ago Posts: 544 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 20, 2013 06:37PM |

Registered: 10 years ago Posts: 53 |

I figured out the issue related to "pulsing" extrusion width...

I'm using a RUMBA powered by 24V... and my motors are 2.5V... I guess the step drivers are having a hard time powering low voltage motor from a high voltage power supply.

I tried powering with 12V and the print went fine with Direct Drive and 95 steps/mm.

Living and learning!!

Cheers.

Alex.

I'm using a RUMBA powered by 24V... and my motors are 2.5V... I guess the step drivers are having a hard time powering low voltage motor from a high voltage power supply.

I tried powering with 12V and the print went fine with Direct Drive and 95 steps/mm.

Living and learning!!

Cheers.

Alex.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 22, 2013 04:43PM |

Registered: 11 years ago Posts: 374 |

Another happy E3D customer here. I've got a few hours (10-15 maybe) on my E3D printing PLA from a couple of different sources. I've had zero problems with jams or any other kind of issue. I've printed fast, slow, and everything in between. Since I run a bowden I retract roughly 5mm and this hasn't caused any issues. Filament flow is precise and stops on a dime when it retracts. I've printed a few objects that had a lot of sequential retractions and low flow rates, which should be situation where it's most inclined to jam.

Overall very impressed with the quality of the hotend and how easy it is to use.

Overall very impressed with the quality of the hotend and how easy it is to use.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 23, 2013 02:56AM |

Registered: 11 years ago Posts: 544 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 23, 2013 09:31AM |

Registered: 11 years ago Posts: 374 |

Quote

I pre-ordered the kraken hot end, and Im very excited, I already have a water cooled hot end so I should be able to provide some useful feedback on it.

The thing that's scaring me away from the Kraken is the water cooling. Well, I also don't need 4 hotends, but mostly the water cooling.

As far as I can tell he's using PC water cooling parts. PC water cooling systems are static - they get installed and then basically never move again. The water cooling system on Kraken is going to get slung around at fairly high speeds and accelerations for many many hours. To me, this looks like a use case that's outside of the original design envelop of those fittings, tubing, etc. Eventually one of them is going to come loose and it's going to make a huge mess. Water + electronics + high heat doesn't sound like a good combination.

Maybe this will be less of a problem than I think it will be. Maybe those fittings are designed to hold onto hoses that are flexing and moving around for thousands of hours. This is still what I would call a science project: lots of potential and some cool ideas, but also very unproven. There's nothing wrong with science projects as long as everyone realizes that's what it is.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] December 23, 2013 04:48PM |

Registered: 11 years ago Posts: 544 |

Ive had my hot end water cooled for over a year, I had it leak once when i was taking the hoses off, the hoses fit over barbs and there is usually a clamp over the barb, originally it used metal clamps then I put on zipties instead. as long as the silicon tubing is rated for high temperature exposure it should be fine. my only concern is how thick the tubes are, they only need to be about 4mm thick anything above that is a waste.

Edited 1 time(s). Last edit at 12/23/2013 04:49PM by aduy.

Edited 1 time(s). Last edit at 12/23/2013 04:49PM by aduy.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 02, 2014 05:03PM |

Registered: 12 years ago Posts: 44 |

Got back from vacation and found my new E3D hotend waiting for me. Assembly was pretty easy, but I did hit a couple of snags.

1. The Epcos thermistor was replaced in October with one from Semitec with different specs. The documentation still refers to the Epcos model, though, so when I followed them my thermistor table values were all wrong. This could be dangerous, but I think it biases downwards. That is, I think using the Epcos values on the Semitech thermistor causes it to read higher than it really is. I thought I torqued the head on at 300C, but it was really only about 240C; but I haven't double-checked that.

2. I reassembled my extruder backwards on the X-carriage and now the 30mm fan is about 5mm too low because it's hitting a screw under my carriage. I want to rotate the fan to the other side but I can't without disassembling the whole head again. This would be easier if the fan+shroud could be removed from the hotend sideways instead of sliding up or down. But it seems like it will break if I do that, so I'll leave it low (worryingly near to the heat chamber). Yeah, I see in the documentation where it warns about this, but I forgot all about it by the time I got to putting my carriage back together. I was more worried about routing wires.

I am very impressed with the hotend itself. I heated it up to 300C for the seating procedure, and the cool end did not seem to even get warm. I held it in my hand just as easily as I did my plastic J-Head.

The hotend heats up quickly and cools off slowly. My PSU turns off when idle and this kills the cooling fan. Since the hotend is still well over 220C when this happens, I was worried that heat would travel up to my head and cause damage or later jams. I felt the cool end during cool-down without the fan running and it still did not get very warm. I'm wondering if the cooling fan is even necessary! I suppose it is for long prints and high-temp materials. Don't worry -- I'm not going to remove it.

I suppose it is for long prints and high-temp materials. Don't worry -- I'm not going to remove it.

The melt-chamber seems smaller on this nozzle than on the J-head, but not by much. It doesn't seem to matter, although I haven't tried to crank up the print speed yet.

I added some "Arctic Silver" heat transfer compound to the thermistor hole since I had some nearby for stepper driver heat sinks. I expect it should make the temp reading more responsive and accurate, but I'm sure it would also work fine without it. I didn't add any to the heater core hole since I'm not sure it can take the stress. But it's a thought.

I have a J-Head groove mount plate from Brian @ hotends.com, but it's an early version and always a little bit tight/narrow. The E3D hotend fit on it, but it's a tight fit and I had to work it into place with pliers. But this is why I can't easily rotate my hotend in-place without disassembling the extruder. :-(

I had some trouble extruding through the default 0.4mm nozzle, but that could be caused by mechanical problems elsewhere in the head since I just rebuilt it in the process of swapping heads. I switched to the 0.6mm nozzle and all my extruder problems vanished. I mean, all of them. Like, all the extruder problems I have ever had. 0.6mm seems huge compared to 0.35mm that I'm used to, but wow, it extruded like warm butter! It was so smooth and accurate, and bridges appeared like magic without any sag at all. Jeez-Louise, have I been torturing myself with 0.35mm all this time? It does make me want to try 0.5, now, but that doesn't appear to be available yet from E3D (web site says it is, but it is not listed for sale as a product). And sure, this is less precise than 0.35, but it should be much faster. I do have a nice new 0.25mm nozzle from E3D. Maybe someday I'll even try it.

There's an "extra" hole bored through the heater block. What's that for? Not the extra thermistor hole. I get that. But parallel to the heater element hole there is a small hole bored all the way through. Not sure what that is to be used for. Is that for a nichrome option?

1. The Epcos thermistor was replaced in October with one from Semitec with different specs. The documentation still refers to the Epcos model, though, so when I followed them my thermistor table values were all wrong. This could be dangerous, but I think it biases downwards. That is, I think using the Epcos values on the Semitech thermistor causes it to read higher than it really is. I thought I torqued the head on at 300C, but it was really only about 240C; but I haven't double-checked that.

2. I reassembled my extruder backwards on the X-carriage and now the 30mm fan is about 5mm too low because it's hitting a screw under my carriage. I want to rotate the fan to the other side but I can't without disassembling the whole head again. This would be easier if the fan+shroud could be removed from the hotend sideways instead of sliding up or down. But it seems like it will break if I do that, so I'll leave it low (worryingly near to the heat chamber). Yeah, I see in the documentation where it warns about this, but I forgot all about it by the time I got to putting my carriage back together. I was more worried about routing wires.

I am very impressed with the hotend itself. I heated it up to 300C for the seating procedure, and the cool end did not seem to even get warm. I held it in my hand just as easily as I did my plastic J-Head.

The hotend heats up quickly and cools off slowly. My PSU turns off when idle and this kills the cooling fan. Since the hotend is still well over 220C when this happens, I was worried that heat would travel up to my head and cause damage or later jams. I felt the cool end during cool-down without the fan running and it still did not get very warm. I'm wondering if the cooling fan is even necessary!

I suppose it is for long prints and high-temp materials. Don't worry -- I'm not going to remove it.

I suppose it is for long prints and high-temp materials. Don't worry -- I'm not going to remove it. The melt-chamber seems smaller on this nozzle than on the J-head, but not by much. It doesn't seem to matter, although I haven't tried to crank up the print speed yet.

I added some "Arctic Silver" heat transfer compound to the thermistor hole since I had some nearby for stepper driver heat sinks. I expect it should make the temp reading more responsive and accurate, but I'm sure it would also work fine without it. I didn't add any to the heater core hole since I'm not sure it can take the stress. But it's a thought.

I have a J-Head groove mount plate from Brian @ hotends.com, but it's an early version and always a little bit tight/narrow. The E3D hotend fit on it, but it's a tight fit and I had to work it into place with pliers. But this is why I can't easily rotate my hotend in-place without disassembling the extruder. :-(

I had some trouble extruding through the default 0.4mm nozzle, but that could be caused by mechanical problems elsewhere in the head since I just rebuilt it in the process of swapping heads. I switched to the 0.6mm nozzle and all my extruder problems vanished. I mean, all of them. Like, all the extruder problems I have ever had. 0.6mm seems huge compared to 0.35mm that I'm used to, but wow, it extruded like warm butter! It was so smooth and accurate, and bridges appeared like magic without any sag at all. Jeez-Louise, have I been torturing myself with 0.35mm all this time? It does make me want to try 0.5, now, but that doesn't appear to be available yet from E3D (web site says it is, but it is not listed for sale as a product). And sure, this is less precise than 0.35, but it should be much faster. I do have a nice new 0.25mm nozzle from E3D. Maybe someday I'll even try it.

There's an "extra" hole bored through the heater block. What's that for? Not the extra thermistor hole. I get that. But parallel to the heater element hole there is a small hole bored all the way through. Not sure what that is to be used for. Is that for a nichrome option?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 02, 2014 06:00PM |

Registered: 13 years ago Posts: 118 |

Found a photo [www.3dprintedsculpture.com] - that guy used it as a strain relief. I just use Kapton tape to secure mine and a wire tie to strin relieve using the thicker heater wires.

Edited 1 time(s). Last edit at 01/02/2014 06:03PM by jaydmdigital.

Quote

phord

There's an "extra" hole bored through the heater block. What's that for? Not the extra thermistor hole. I get that. But parallel to the heater element hole there is a small hole bored all the way through. Not sure what that is to be used for. Is that for a nichrome option?

Edited 1 time(s). Last edit at 01/02/2014 06:03PM by jaydmdigital.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 02, 2014 10:01PM |

Registered: 11 years ago Posts: 374 |

Quote

Found a photo [www.3dprintedsculpture.com] - that guy used it as a strain relief.

The seems really clever, but remember those ptfe tubes will melt at much above 245C. If that happens the thermistor is going to short to the heater block. Might work better if you replace the ptfe tubing with kapton tape as shown in the E3D build instructions - kapton's melting temperature is much higher.

Quote

I added some "Arctic Silver" heat transfer compound to the thermistor hole

Bad idea - it's not rated for the temperatures it will see in the hotend, unless you get some extra special high temp formulation.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 12:10AM |

Registered: 10 years ago Posts: 1,381 |

Quote

phord

I added some "Arctic Silver" heat transfer compound to the thermistor hole since I had some nearby for stepper driver heat sinks. I expect it should make the temp reading more responsive and accurate, but I'm sure it would also work fine without it. I didn't add any to the heater core hole since I'm not sure it can take the stress. But it's a thought.

Always add thermal compound to the bore and body of the heater cartridge before assembly.

This ensures that the heat is transferred, and it acts as an antiseize (i.e. it will be easier to disassemble it).

Same with the thermisitor, the glass end needs to be encased in thermal compound.

Air acts as an insulator, your readings will not be true or could vary if/when the thermistor shifts.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 07:19AM |

Registered: 10 years ago Posts: 553 |

Quote

phord

Got back from vacation and found my new E3D hotend waiting for me. Assembly was pretty easy, but I did hit a couple of snags.

1. The Epcos thermistor was replaced in October with one from Semitec with different specs. The documentation still refers to the Epcos model, though, so when I followed them my thermistor table values were all wrong. This could be dangerous, but I think it biases downwards. That is, I think using the Epcos values on the Semitech thermistor causes it to read higher than it really is. I thought I torqued the head on at 300C, but it was really only about 240C; but I haven't double-checked that.

There's an "extra" hole bored through the heater block. What's that for? Not the extra thermistor hole. I get that. But parallel to the heater element hole there is a small hole bored all the way through. Not sure what that is to be used for. Is that for a nichrome option?

1. The new thermistor information has been on E3D-online documentation for a while.. First on this page ( [e3d-online.com] ) it says "We are in the process of updating our documentation to show how to assemble the hot-end with our new thermistors. In the mean time, please see this blog post for more information." and the blog post here describes everything you need to know ( [e3d-online.com] ). You can also find the datasheet for the Semitec on the product page(it should be in the blog post also and the documentation...hint hint Sanjay) which is here ( [e3d-online.com] ) and the datasheet is here ( [www.mouser.com] )

2. The extra hole bored through the body is for an axial thermistor. The one sold by E3D - ( [e3d-online.com] )

As crispy1 already said...

Extended Temperature Limits:

Peak: –50°C to >180°C

Long-Term: –50°C to 130°C

( [www.arcticsilver.com] )

Nothing that Arctic Silver sells is rated for even continuous use at PLA temps.

I found this which may work at PLA temps but useless for this hotend pretty much ( [www.mcmaster.com] )

Edited 5 time(s). Last edit at 01/03/2014 07:52AM by tjb1.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 07:48AM |

Admin Registered: 11 years ago Posts: 3,096 |

No matter how much I like my J-head, I am still doubting to buy this one hotend some day... Oh, and also switching to 1.75mm PLA filament since I think it's the future and I expect 3mm to become less and less popular because of the requirements it puts on an extruder and is harder to calibrate.

I want to give Direct Drive extrusion a try. But first I have to save some money

I want to give Direct Drive extrusion a try. But first I have to save some money

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 09:51AM |

Registered: 10 years ago Posts: 3 |

Just wanted to give a shoutout to Sanjay, josh and the rest of the team. I had a problem with my order that was 100% my fault. E3d didnt need to do anything but they helped correct my mistake and extremely quickly too. So kudos on the excellent service and you have earned a very happy and future customer.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 11:55AM |

Registered: 11 years ago Posts: 490 |

@Ohmarinus: I am using a 1.75mm E3D v4 hotend. PLA and everything else I throw at it work like a charm (except of PC-ABS and PC at the moment, which still need some calibration). Not a single jam, although I frequently change filament with the most varying properties possible. However, I think I might use the 3mm system for my next printer as some materials like PP, PE, PVDF and PA6 are available as plastic welding rod in 3mm. Conversely, PC-ABS isn't readily available in 3mm for me. So it might be a good idea to support both filament sizes for now.

@Sanjay: Nice to see that you are now offering thermocouples, too. As someone else pointed out already, the PTFE insulation of this specific model is a limitation. Is there any chance that you will start to offer other types e.g. with glass fiber insulation in the future? Or for even better thermal contact something like the model Ultimaker is using? This kind of thermocouple might be a little bit more expensive, but I suspect some markup going on as their other parts are similarly expensive.

@Sanjay: Nice to see that you are now offering thermocouples, too. As someone else pointed out already, the PTFE insulation of this specific model is a limitation. Is there any chance that you will start to offer other types e.g. with glass fiber insulation in the future? Or for even better thermal contact something like the model Ultimaker is using? This kind of thermocouple might be a little bit more expensive, but I suspect some markup going on as their other parts are similarly expensive.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 01:15PM |

Registered: 10 years ago Posts: 553 |

Quote

uGen

@Ohmarinus: I am using a 1.75mm E3D v4 hotend. PLA and everything else I throw at it work like a charm (except of PC-ABS and PC at the moment, which still need some calibration). Not a single jam, although I frequently change filament with the most varying properties possible. However, I think I might use the 3mm system for my next printer as some materials like PP, PE, PVDF and PA6 are available as plastic welding rod in 3mm. Conversely, PC-ABS isn't readily available in 3mm for me. So it might be a good idea to support both filament sizes for now.

@Sanjay: Nice to see that you are now offering thermocouples, too. As someone else pointed out already, the PTFE insulation of this specific model is a limitation. Is there any chance that you will start to offer other types e.g. with glass fiber insulation in the future? Or for even better thermal contact something like the model Ultimaker is using? This kind of thermocouple might be a little bit more expensive, but I suspect some markup going on as their other parts are similarly expensive.

The problem with the thermocouples are is that you aren't even sure the temps that the one sold by Ultimaker is good for, it may only be good until 300c. I see Makerbot sells one that is reasonably priced(but same issue, no information at all), I have one waiting for me at home right now from McMaster that I will begin testing by using it as extruder 2 temp monitor to compare to my thermistor.

Edited 1 time(s). Last edit at 01/03/2014 01:16PM by tjb1.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 02:10PM |

Registered: 11 years ago Posts: 490 |

@tjb1: yes, I am aware that Ultimaker provides minimal information about their parts in their shop. However, their BOM on github reveals more (still, no operating temperatures. A search for the part number didn't return useful results.).

What I intended to say, though, is that E3D could look into selling thermocouples similar to the Ultimaker one as the form factor is better for thermal transfer between heater block and sensor. Also, it would be easier to fit without having to use Kapton or high temperature silicone, making the whole heater block assembly much neater and even more reliable (not that I had any problems with Kapton tape not holding the thermistor in place).

What I intended to say, though, is that E3D could look into selling thermocouples similar to the Ultimaker one as the form factor is better for thermal transfer between heater block and sensor. Also, it would be easier to fit without having to use Kapton or high temperature silicone, making the whole heater block assembly much neater and even more reliable (not that I had any problems with Kapton tape not holding the thermistor in place).

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 03, 2014 06:32PM |

Registered: 10 years ago Posts: 553 |

Quote

uGen

@tjb1: yes, I am aware that Ultimaker provides minimal information about their parts in their shop. However, their BOM on github reveals more (still, no operating temperatures. A search for the part number didn't return useful results.).

What I intended to say, though, is that E3D could look into selling thermocouples similar to the Ultimaker one as the form factor is better for thermal transfer between heater block and sensor. Also, it would be easier to fit without having to use Kapton or high temperature silicone, making the whole heater block assembly much neater and even more reliable (not that I had any problems with Kapton tape not holding the thermistor in place).

I just started playing with this tonight ( [www.mcmaster.com] ), I ground the weld down on the wires to reduce the thermal mass and the response time is now significantly faster and should work quite well. I am using the thermocouple board from E3D and once I get some time I am going to mount this on my i3 and do some prints with it.

Specs on the McMaster thermocouple

Temperature Range 32° to 900° F

After being ground down on the end, I can now fit this into even the axial hole.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 05, 2014 05:05AM |

Registered: 10 years ago Posts: 6 |

Has anybody ever tried one of these hot ends on a Velleman K8200 ? (think not, search returned nothing...)

I ordered a hotend to replace the one from my printer that I broke during re-assembly....

The only real (small) challenge I see, is mounting it to the extruder driver. It is about the same length as the stock extruder, but the original mounting plate will probably not fit...

Looking forward to receiving it and testing it out

Ordered on Saturday, shipped on Monday. Couldn't ask for quicker service

Planning to run a hybrid setup, re-using the original heater element from the Velleman kit so as not to need to modify the firmware. Also easier, since I only have 15 volt available and running the 12 volt heater at 15 might make it become too hot too fast...

See how that turns out...

Edited 1 time(s). Last edit at 01/06/2014 02:06PM by anixie.

I ordered a hotend to replace the one from my printer that I broke during re-assembly....

The only real (small) challenge I see, is mounting it to the extruder driver. It is about the same length as the stock extruder, but the original mounting plate will probably not fit...

Looking forward to receiving it and testing it out

Ordered on Saturday, shipped on Monday. Couldn't ask for quicker service

Planning to run a hybrid setup, re-using the original heater element from the Velleman kit so as not to need to modify the firmware. Also easier, since I only have 15 volt available and running the 12 volt heater at 15 might make it become too hot too fast...

See how that turns out...

Edited 1 time(s). Last edit at 01/06/2014 02:06PM by anixie.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 06, 2014 04:37PM |

Registered: 10 years ago Posts: 160 |

Hi anixie,

actually, yes, I have one working in my K8200. But reports went to the Velleman forum on the one hand and the German section in the RepRap forums on the other hand; the latter one has a very lengthy thread on the K8200 ...

A printable adapter for the E3D is nearly finished and should be available on Thingiverse soon.

Cheers,

kuraasu

Quote

anixie

Has anybody ever tried one of these hot ends on a Velleman K8200 ? (think not, search returned nothing...)

actually, yes, I have one working in my K8200. But reports went to the Velleman forum on the one hand and the German section in the RepRap forums on the other hand; the latter one has a very lengthy thread on the K8200 ...

A printable adapter for the E3D is nearly finished and should be available on Thingiverse soon.

Cheers,

kuraasu

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 07, 2014 06:31AM |

Registered: 11 years ago Posts: 118 |

Did someone see that Makerbot

got a e3d styled Extruder in their new Printers?

//Edit

note that that the drive gear, ball screw (probably?) and hotend building one unit,

while the Motor and fan making another. The Axial fan blows through the hole on just four fins.

or short, more airpressure results in a shorter cooling bridge.

but its mysterous whats between the fins and the drive gear...

Edited 2 time(s). Last edit at 01/07/2014 07:21AM by mrc.

got a e3d styled Extruder in their new Printers?

//Edit

note that that the drive gear, ball screw (probably?) and hotend building one unit,

while the Motor and fan making another. The Axial fan blows through the hole on just four fins.

or short, more airpressure results in a shorter cooling bridge.

but its mysterous whats between the fins and the drive gear...

Edited 2 time(s). Last edit at 01/07/2014 07:21AM by mrc.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 07, 2014 07:40AM |

Registered: 10 years ago Posts: 6 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2014 01:24AM |

Registered: 14 years ago Posts: 18 |

I have a E3D but I have yet to install it. I haven't had the best of luck with finding a reliable filament drive design. Anyone have any recommendations for something that works well with the E3D? I would love to find something that works with a geared stepper motor, I have both geared NEMA17 and NEMA14 motors available. That or direct drive on a beefy NEMA17. I have lots of motors in different sizes/torque but haven't had the best of luck finding a reliable design for pushing the filament through. This is on a standard Mendel/Prusa Reprap.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2014 01:54AM |

Registered: 11 years ago Posts: 46 |

I got a 3mm and 1.75mm. I much prefer 3mm but since the world is moving towards 1.75 I had no choice but to get both. Assembly was straightforward, without instructions, and it installed on my Printrbot+ v1 with no issues. It... just... works. Its slightly shorter than the stock Ubis hotend but no adjustments were necessary. Great results with ABS and PLA. I am still working on polycarbonate - the Ubis works well with the wipe and suck parameters I have set in Kisslicer, but the E3D doesn't print well with those settings. I am working on getting good results with PC. I run PC at 290C. The hotend is reporting slightly lower temps than actual, but its not too bad, out about 10%. I have no idea what that included tiny glass thermistor is so I drilled out the hole for it to fit a Epcos 2.2mm which my firmware tables are set for. Its all working well so far and I have no issues to report.

[www.printrbottalk.com] Printrbot Forum and Wiki

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2014 06:37AM |

Registered: 10 years ago Posts: 53 |

@Krafter, check this extruder out:

[www.thingiverse.com]

There is a snap fit version for E3D.

Cheers.

[www.thingiverse.com]

There is a snap fit version for E3D.

Cheers.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2014 06:41AM |

Registered: 11 years ago Posts: 490 |

Looks like quite a bit of over-engineering on Makerbot's side for just printing the standard stuff. They are practically encouraging their customers to print PLA designed their filament spool holders in a way that it would be rather difficult to fit spools from any other supplier on to. So high temperature filaments seem more or less not (yet?) to be the intended purpose for this hot end. Maybe the lower extrusion temperature for PLA contributes to the reason why they get away with a shorter heatsink.

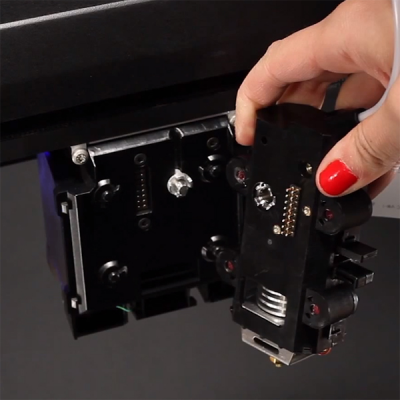

I like the detachable design, though - some RepRap user already did that on his Prusa X carriage, so I wonder why we are not seeing more of this. No demand maybe?

I like the detachable design, though - some RepRap user already did that on his Prusa X carriage, so I wonder why we are not seeing more of this. No demand maybe?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2014 06:49AM |

Admin Registered: 11 years ago Posts: 1,063 |

Quote

uGen

Looks like quite a bit of over-engineering on Makerbot's side for just printing the standard stuff. They are practically encouraging their customers to print PLA designed their filament spool holders in a way that it would be rather difficult to fit spools from any other supplier on to. So high temperature filaments seem more or less not (yet?) to be the intended purpose for this hot end. Maybe the lower extrusion temperature for PLA contributes to the reason why they get away with a shorter heatsink.

I like the detachable design, though - some RepRap user already did that on his Prusa X carriage, so I wonder why we are not seeing more of this. No demand maybe?

hopefully whatever they start putting on their printers is more reliable than the extruders they have built in the past , not that i'm complaining though, building ptfe lined thermal barriers to fix their extruders has been a semi profitable activity,

the whole spool thing isn't suprising ,i'm waiting for them to start using cartridges of some description and start chipping them to try and force people to use their filament, just like stratasys does and just like rest will when they join the 3d printing market,

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2014 08:14AM |

Registered: 11 years ago Posts: 118 |

Quote

uGen

Looks like quite a bit of over-engineering on Makerbot's side for just printing the standard stuff. They are practically encouraging their customers to print PLA designed their filament spool holders in a way that it would be rather difficult to fit spools from any other supplier on to. So high temperature filaments seem more or less not (yet?) to be the intended purpose for this hot end. Maybe the lower extrusion temperature for PLA contributes to the reason why they get away with a shorter heatsink.

I like the detachable design, though - some RepRap user already did that on his Prusa X carriage, so I wonder why we are not seeing more of this. No demand maybe?

I bet one of the reasons is the only PLA thing, heating up to 185°C is different from going up to 300°.

Another one is sure the Airpressure of a radial fan.

Detachable parts are nice, but not necessary in my opinion as long as you can clean the nozzle easily.

On this Printer it makes total sense since the hotend is on the backside and very hard to reach (maybe to avoid accidents?)

however im wondering why they just offer single extrusion,

i don´t know if they invented support structure completely new

but i had problems to print very complex geometrys with support structure made out of the same material.

Edited 1 time(s). Last edit at 01/08/2014 08:15AM by mrc.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2014 02:41PM |

Registered: 10 years ago Posts: 106 |

Quote

SanjayM

We are also looking at a super compact mini water cooled hotend, for just one nozzle. Might name it after some fast sea fish/animal. Marlin is already taken though, suggestions welcomed!

Not sure if anyone gave any suggestions (I just scrolled back to see the side view image of the Kraken and noticed this)

W3D

Wahoo is the 3rd fastest fish in the world

(max. recorded speed of 78 kph)

this can also be a play off of Water Cooled E3D

maybe Wahoo sounds to silly and to close to yahoo, but it does give an aquatic breed theme to W3D

Note: Fastest fish is the Sailfish and 2nd fastest is the Marlin and those can't be used due to the firmwares, the link to 3 is cool too.

Sorry, only registered users may post in this forum.