Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 12, 2014 08:58AM |

Registered: 10 years ago Posts: 239 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 17, 2014 04:20PM |

Registered: 12 years ago Posts: 48 |

Well at last a hot end/nozzle that does what it claims !

I have been through most models of hot ends over the last couple of years as we run our prototype 3D printer at high speeds non stop some weeks, printing covers for the motors on our machines.

We started out using the Mendel parts hot ends and to be honest they were great as never jammed and the heat separation using a simple peek barrier, combined with the brass nozzle worked great.

But if your thermistor went or you hit over heat, they soon fell apart as the peek gave in at higher temperature's.

Got a couple of these E3D ones the other week, one normal and the other Bowden style and they work great.

Be a little careful when doing the initial heat up to 290 degrees and tighten off nozzle, as we broke the first one very quickly. But next time we did the recommended thumb pressure and works great without leaks.

After printing for hours upon hours this week, at rapid rates, the hot end and nozzle has been great, with much better results than previous hot ends.

We found the J-Head MKV hot ends print quality very good, but the aluminium nozzle lasted about 30 hours of print time and soon lost shape and extrusion became very uneven. This started to turn out expensive, having to replace them each week.

Others we have tried have lasted a couple of days and then just become useless.

We are due to release our production machine in the next few weeks into the market that uses commercial bearings/ballscrews etc etc and will be seriously looking at using the E3D nozzle on the production model.

Cheers

Sean.

******************************

[www.cncdudez.co.uk]

******************************

I have been through most models of hot ends over the last couple of years as we run our prototype 3D printer at high speeds non stop some weeks, printing covers for the motors on our machines.

We started out using the Mendel parts hot ends and to be honest they were great as never jammed and the heat separation using a simple peek barrier, combined with the brass nozzle worked great.

But if your thermistor went or you hit over heat, they soon fell apart as the peek gave in at higher temperature's.

Got a couple of these E3D ones the other week, one normal and the other Bowden style and they work great.

Be a little careful when doing the initial heat up to 290 degrees and tighten off nozzle, as we broke the first one very quickly. But next time we did the recommended thumb pressure and works great without leaks.

After printing for hours upon hours this week, at rapid rates, the hot end and nozzle has been great, with much better results than previous hot ends.

We found the J-Head MKV hot ends print quality very good, but the aluminium nozzle lasted about 30 hours of print time and soon lost shape and extrusion became very uneven. This started to turn out expensive, having to replace them each week.

Others we have tried have lasted a couple of days and then just become useless.

We are due to release our production machine in the next few weeks into the market that uses commercial bearings/ballscrews etc etc and will be seriously looking at using the E3D nozzle on the production model.

Cheers

Sean.

******************************

[www.cncdudez.co.uk]

******************************

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 22, 2014 02:04PM |

Registered: 10 years ago Posts: 35 |

I have my heart set on an E3D hot end but have a few questions about how it will work on my current printer. I have a 3DStuffMaker Evolution (I know, I know, it was a gift) and it looks like the carriage is ready to mount it in. Will I need to do anything to the firmware? This particular printer does not have a bootloader. So to flash anything I would need some additional hardware and possibly a copy of 3DStuffMaker's firmware and/or configuration. I have not had any luck dealing with this company's support system but others have claimed to received a compiled version of the firmware via e-mail with the upper temp limit raised.

I'm hoping I can just plug it in and get good enough results. One of my main problems with the current setup I have is the wild temp swings. At any set temp I see +/- 10 degrees in either direction. It never stays stable, even at idle. This is the 2nd fully assembled hot end they have sent me. I'm worried the PID settings are terrible from the start.

I'm hoping I can just plug it in and get good enough results. One of my main problems with the current setup I have is the wild temp swings. At any set temp I see +/- 10 degrees in either direction. It never stays stable, even at idle. This is the 2nd fully assembled hot end they have sent me. I'm worried the PID settings are terrible from the start.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 22, 2014 04:17PM |

Registered: 14 years ago Posts: 142 |

I have no experience of this printer, but I can't imagine that it would be that big a deal to replace the current electronics with generic RepRap electronics, then you don't have to be limited by their firmware lock down.

Just my 2p worth.

I am running an E3D on my homebuilt Mendel90 and it's a dream.

Craig

----------------------------------------------------------------------------------------------------

[blogger.kritzinger.net]

Just my 2p worth.

I am running an E3D on my homebuilt Mendel90 and it's a dream.

Craig

----------------------------------------------------------------------------------------------------

[blogger.kritzinger.net]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 22, 2014 06:57PM |

Registered: 10 years ago Posts: 35 |

I think before I do an electronics upgrade I would just get a whole new printer. For what I have now, my goal is to get is to print consistently without spending a dime more than I have to. For about $20 I could buy a USB programmer. That's not a big deal, really. But I would then need to find a valid (pre-existing) config file for it, or start from scratch and flash my own.

I'm hoping it works correctly by just hooking it up, even if the temperature is way off. As long as its consistent I can adjust.

I'm hoping it works correctly by just hooking it up, even if the temperature is way off. As long as its consistent I can adjust.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 23, 2014 03:45AM |

Registered: 14 years ago Posts: 142 |

Got you on that.

I was inquisitive, so I went to look at those printers, and I couldn't see anything about what the electronics were based on, and only 1 or 2 obscure pictures. Seems very "closed" for something based quite blatantly on an "open" project.

Anything, going off topic, so let's stop there.

Good luck getting an E3D working!!!

----------------------------------------------------------------------------------------------------

[blogger.kritzinger.net]

I was inquisitive, so I went to look at those printers, and I couldn't see anything about what the electronics were based on, and only 1 or 2 obscure pictures. Seems very "closed" for something based quite blatantly on an "open" project.

Anything, going off topic, so let's stop there.

Good luck getting an E3D working!!!

----------------------------------------------------------------------------------------------------

[blogger.kritzinger.net]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 23, 2014 08:06AM |

Registered: 10 years ago Posts: 35 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 23, 2014 02:25PM |

Registered: 14 years ago Posts: 142 |

Quote

s10blazed

The electronics are GEN6 with a fairly recent Marlin firmware.

Great, I wonder why they don't simply say that openly. Admittedly I didn't dig very deep in the site.

----------------------------------------------------------------------------------------------------

[blogger.kritzinger.net]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 08:42AM |

Registered: 10 years ago Posts: 770 |

Cant remember if its been covered yet but yesterday I got my E3D hot end and it looks great but....

On a Makerfarm printer that came with a Magma hot end the aluminum adapter plate WILL NOT work with the E3D heatsink!

Luckily I have access to a Stratus printer at work and im printing an adapter that I made yesterday in Solidworks.

**Also a little FYI for those with the Makerfarm unit** File down the two nuts that sit slightly above the X carriage plate. If you dont then your adapter plate wont be sitting level and by relation your tip will not be 90* to the heated bed.

On a Makerfarm printer that came with a Magma hot end the aluminum adapter plate WILL NOT work with the E3D heatsink!

Luckily I have access to a Stratus printer at work and im printing an adapter that I made yesterday in Solidworks.

**Also a little FYI for those with the Makerfarm unit** File down the two nuts that sit slightly above the X carriage plate. If you dont then your adapter plate wont be sitting level and by relation your tip will not be 90* to the heated bed.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 04:28PM |

Registered: 11 years ago Posts: 334 |

I got my e3d mounted and printing PLA the other day but it get it to print I need to keep the temp at 240-260C to prevent clogs. It prints fine at that temp but it gives my print a very glossy finish. Is anyone else experiencing anything like this?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 04:35PM |

Registered: 10 years ago Posts: 770 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 05:06PM |

Registered: 11 years ago Posts: 939 |

Quote

jzatopa

I got my e3d mounted and printing PLA the other day but it get it to print I need to keep the temp at 240-260C to prevent clogs. It prints fine at that temp but it gives my print a very glossy finish. Is anyone else experiencing anything like this?

Check the actual vs reported temperature of the hotend with a thermocouple, one of the semitec thermistors I got with an E3D was 35C off (reading high) and required a radically different beta value to get a decent reading out of it.

BUT my first two did something like this, to get PLA to print at all they required very high temperatures, and even then there were issues with reliability.

One thing that's been raised recently is there seems to be some variation in nozzle orifice length, you might want to try and measure it, you can do it with a 2mm drill bit and a caliper, though it's not overly accurate. It's supposed to be just over 1mm, my original E3D V4 which was virtually impossible to print PLA with measured at 3mm, and the early V5 that I had issues with was 2mm, the last V5 I got didn't have issues with PLA and was right around 1mm long.

Sanjay is aware of this, and has done some measurements on his stock, they all appear to be in spec. This could just be me and a few others measuring poorly, or could be an infrequent manufacturing issue.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 05:08PM |

Registered: 12 years ago Posts: 48 |

I would check your thermistor and the settings you have set in firmware as I actually had to turn it down to 190C to stop too much melt.

We use an external temperature controller for the heated bed and extruder as found the built in firmware routines could give us issue on fast printing.

I always whack it up to 220C for the first layer to get a good grip and then trim it back to 190 ish so we do not get too many loose strands building up between bridges.

Pop a meter on the thermistor legs and see what K reading you are getting on the meter when you are at this temp.

Cheers

Sean.

We use an external temperature controller for the heated bed and extruder as found the built in firmware routines could give us issue on fast printing.

I always whack it up to 220C for the first layer to get a good grip and then trim it back to 190 ish so we do not get too many loose strands building up between bridges.

Pop a meter on the thermistor legs and see what K reading you are getting on the meter when you are at this temp.

Cheers

Sean.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 05:28PM |

Registered: 11 years ago Posts: 334 |

The temps are right, I double checked with my thermo couple. The difference between the two is 1.8c.

Here is order of events that led me to cranking up the temp.

1. heat up hotend to 190c

2. Once hotend reaches ~190 I can extrude without problems for a few minutes.

3. After a period of time the filament starts to jam. Barrel is cool to the touch due to fan.

4. Finally the hot end jams.

At first I thought the problem was cooling so I tried all sorts of different fan setups, none of it changed anything and now I am pretty sure it was never a source of the problems. Out of exasperation I started to bring the temps up way beyond where I would normally print. When I hit ~ 240-260 it started to flow again. I tried printing @ 260 and I didn't have a problem. Now I can print @ 260 but printing that hot with PLA gives me an undesirable finish and the feeling that something isn't working correctly.

@polygonhell Where exactly am I measuring? From the threads of the nozzle to where the orifice starts? Could my problem really just be the nozzle?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

Here is order of events that led me to cranking up the temp.

1. heat up hotend to 190c

2. Once hotend reaches ~190 I can extrude without problems for a few minutes.

3. After a period of time the filament starts to jam. Barrel is cool to the touch due to fan.

4. Finally the hot end jams.

At first I thought the problem was cooling so I tried all sorts of different fan setups, none of it changed anything and now I am pretty sure it was never a source of the problems. Out of exasperation I started to bring the temps up way beyond where I would normally print. When I hit ~ 240-260 it started to flow again. I tried printing @ 260 and I didn't have a problem. Now I can print @ 260 but printing that hot with PLA gives me an undesirable finish and the feeling that something isn't working correctly.

@polygonhell Where exactly am I measuring? From the threads of the nozzle to where the orifice starts? Could my problem really just be the nozzle?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 05:43PM |

Registered: 10 years ago Posts: 15 |

Quote

jzatopa

The temps are right, I double checked with my thermo couple. The difference between the two is 1.8c.

Here is order of events that led me to cranking up the temp.

1. heat up hotend to 190c

2. Once hotend reaches ~190 I can extrude without problems for a few minutes.

3. After a period of time the filament starts to jam. Barrel is cool to the touch due to fan.

4. Finally the hot end jams.

At first I thought the problem was cooling so I tried all sorts of different fan setups, none of it changed anything and now I am pretty sure it was never a source of the problems. Out of exasperation I started to bring the temps up way beyond where I would normally print. When I hit ~ 240-260 it started to flow again. I tried printing @ 260 and I didn't have a problem. Now I can print @ 260 but printing that hot with PLA gives me an undesirable finish and the feeling that something isn't working correctly.?

I'm watching closely as I've had the same sequence of events. My nozzle is about 3 weeks old and when I built it, it would extrude nicely at 200c...

After about 10-12 prints over a few evenings my extruder started skiipping. Turned up the voltage a tad but after a bit it simply stopped hard. Turning by hand could be done but with a lot of resistance.

I fired it up last weekend, not changing anything but temp and it extrudes at 250c, but the prints are bad...looking like I need to recalibrate. Added a little olive oil to a foot of the filament and can extrude down to 240c. Much lower than that it starts tightening up again.

I did that moustache ring thingy very nicely with an hour after I put the thing together. Repeating it last night, the nozzle was dragging through the top layers like the Z step was off, though I suspect it's actually just extruding faster with the higher heat. I'll report on what I find after I recalibrate...probably Sunday...

I get an hour or two every several days to work with it, so troubleshooting is going slowly....

Oh..this is a wade extruder on a Prusa I3 using Blue PLA....

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 05:47PM |

Registered: 11 years ago Posts: 939 |

Quote

@polygonhell Where exactly am I measuring? From the threads of the nozzle to where the orifice starts? Could my problem really just be the nozzle?

You need to measure the orifice length, general idea is, with the nozzle separate from the hotend, and cleaned out of all plastic, take a 2mm drill bit insert it into the nozzle, measure the length from drill bit start to nozzle end, remove drill bit, measure drill bit length and subtract from the first value. Now you have the approximate length of the orifice.

The reason it can contribute to difficulties like this is the longer the orifice, the more pressure required to extrude plastic through it and the more likely you'll get a PLA jam, as you increase the temperature you're printing PLA at, it becomes less and less viscous, reducing the pressure required. The spec from E3d is approximately 1mm, the Jhead by comparison is about 0.5 mm (though older Jheads were about 1.2 mm), Buddaschnozzle closer to 0.25mm, if your measuring something significantly over 1mm you should talk to Sanjay.

Several people over at the SeeMeCNC forums (myself included) have been drilling out the nozzles to reduce the orifice length to around 0.5mm with very positive results. It's unclear if it's THE issue with the E3D hotend that have a hard time with PLA, but it seems to be a part of the answer.

Edited 1 time(s). Last edit at 04/25/2014 05:49PM by Polygonhell.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 05:48PM |

Registered: 12 years ago Posts: 48 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 25, 2014 07:53PM |

Registered: 10 years ago Posts: 1,381 |

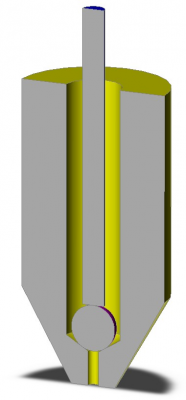

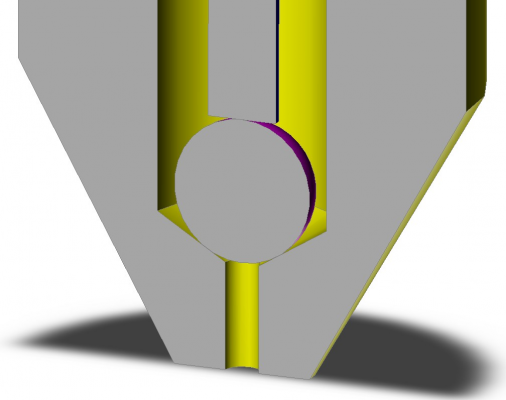

To measure the orifice land length you need to determine where a frustum described by a sphere is located on the taper using calipers, a small ball bearing, and a pin.

Measure the orifice diameter, and the ball diameter, and note the lead in angle to the orifice, (e.g. 118 degrees, 60 degrees, etc.).

Using a CAD program draw the internal geometry with the sphere tangent to the taper. Where the sphere contacts the taper (tangent) is the frustum.

Then measure the distance from the intersection of the orifice land, and taper to the top of the sphere, name this dimension (dim1).

Measure the length of the pin, and add it to dim1, and name this dimension (dim2).

Measure the over all length from the outside of the nozzle to the top of the pin, and name this dimension (dim3).

Subtract dim2 from dim3 to reveal the orifice land length.

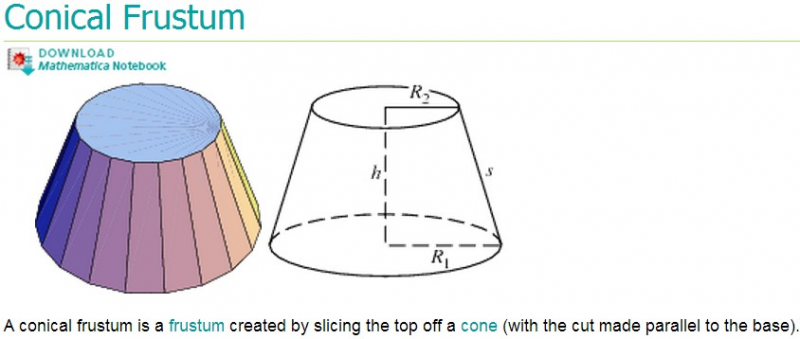

Frustum

The part of a conical solid left after cutting off a top portion with a plane parallel to the base.

[dictionary.reference.com]

Conical Frustum

[mathworld.wolfram.com]

Edited 9 time(s). Last edit at 04/26/2014 08:46AM by A2.

Measure the orifice diameter, and the ball diameter, and note the lead in angle to the orifice, (e.g. 118 degrees, 60 degrees, etc.).

Using a CAD program draw the internal geometry with the sphere tangent to the taper. Where the sphere contacts the taper (tangent) is the frustum.

Then measure the distance from the intersection of the orifice land, and taper to the top of the sphere, name this dimension (dim1).

Measure the length of the pin, and add it to dim1, and name this dimension (dim2).

Measure the over all length from the outside of the nozzle to the top of the pin, and name this dimension (dim3).

Subtract dim2 from dim3 to reveal the orifice land length.

Frustum

The part of a conical solid left after cutting off a top portion with a plane parallel to the base.

[dictionary.reference.com]

Conical Frustum

[mathworld.wolfram.com]

Edited 9 time(s). Last edit at 04/26/2014 08:46AM by A2.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 26, 2014 07:19PM |

Registered: 11 years ago Posts: 53 |

i took a 1mm drill bit measured with caliper and set it to zero at length of bit. then put drill bit inside nozzle and measure end of bit to nozzle tip. no math just read caliper. i also used a toothpick it was close to the same.

for what is worth i solved my pla problem with vegetable oil and sponge on filament. did a 1 drop or 2 a week or so. it stopped my jams i have not used any oil for about a month but it still has not jammed even with dual hotends where 1 nozzle sits hot for a while not printing.

for what is worth i solved my pla problem with vegetable oil and sponge on filament. did a 1 drop or 2 a week or so. it stopped my jams i have not used any oil for about a month but it still has not jammed even with dual hotends where 1 nozzle sits hot for a while not printing.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 28, 2014 07:55AM |

Registered: 10 years ago Posts: 553 |

Quote

jzatopa

The temps are right, I double checked with my thermo couple. The difference between the two is 1.8c.

Here is order of events that led me to cranking up the temp.

1. heat up hotend to 190c

2. Once hotend reaches ~190 I can extrude without problems for a few minutes.

3. After a period of time the filament starts to jam. Barrel is cool to the touch due to fan.

4. Finally the hot end jams.

At first I thought the problem was cooling so I tried all sorts of different fan setups, none of it changed anything and now I am pretty sure it was never a source of the problems. Out of exasperation I started to bring the temps up way beyond where I would normally print. When I hit ~ 240-260 it started to flow again. I tried printing @ 260 and I didn't have a problem. Now I can print @ 260 but printing that hot with PLA gives me an undesirable finish and the feeling that something isn't working correctly.

@polygonhell Where exactly am I measuring? From the threads of the nozzle to where the orifice starts? Could my problem really just be the nozzle?

I encountered the same problem. I printed for months with PLA just fine and then all of the sudden (using the same filaments) I could not print more than 20-30 minutes before it would jam up. I tried everything from 180-240 and still could not finish a print. I eventually got tired of screwing with it and looking over to see it 2-3mm above the surface of the print doing nothing and went back and put the Buda on.

I've tried printing polycarbonate and am not fond of it so I don't really need the high temp hotends anymore but I will keep my one E3D for the occasional use. I did sell my bowden ones as I was not looking forward to dealing with those problems added to the bowden problems.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 28, 2014 08:36AM |

Registered: 10 years ago Posts: 1,381 |

Check to see if there is chard plastic in the threads of the nozzle, and heater block or on the inside surface of the nozzle, if it has chard it will be an efficient insulator.

No one has mentioned replacing the nozzle, you might give that a go.

How about providing some pics of the hot end disassembled.

No one has mentioned replacing the nozzle, you might give that a go.

How about providing some pics of the hot end disassembled.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 28, 2014 11:55AM |

Registered: 10 years ago Posts: 770 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 30, 2014 10:06PM |

Registered: 11 years ago Posts: 334 |

I haven't pulled mine apart to measure it yet but I have got it printing at 215C, anything below that and it stops printing. As long as it keeps printing that that temp I am not going to worry.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] April 30, 2014 10:11PM |

Registered: 10 years ago Posts: 790 |

Your hotend is heating by itself as soon as I put power to the board! I can just connect USB and connect with the host, all is well. But as soon as I plug in 12V power it quickly [gloriously quickly, but scary in the "current" situation] heats up, host with heater off and on, no change. I plugged it into the heated bed port and exactly the same thing. Heats up by itself and I assume it will never stop, but that's not something I'm going to try. I set the host to 20C and it still heats [went to 160C on that attempt] is that something that firmware update will fix? I doubt it, but I'm so flabbergasted at it that I wouldn't be surprised that the answer was different color Sharpie marking the plug..

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 05:59AM |

Registered: 10 years ago Posts: 32 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 09:36AM |

Registered: 10 years ago Posts: 790 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 09:39AM |

Registered: 10 years ago Posts: 553 |

Quote

MrDoctorDIV

Your hotend is heating by itself as soon as I put power to the board! I can just connect USB and connect with the host, all is well. But as soon as I plug in 12V power it quickly [gloriously quickly, but scary in the "current" situation] heats up, host with heater off and on, no change. I plugged it into the heated bed port and exactly the same thing. Heats up by itself and I assume it will never stop, but that's not something I'm going to try. I set the host to 20C and it still heats [went to 160C on that attempt] is that something that firmware update will fix? I doubt it, but I'm so flabbergasted at it that I wouldn't be surprised that the answer was different color Sharpie marking the plug..

This has nothing to do with the hotend, it's called user error. The hotend can't heat without power so you are still sending power to it. Without knowing your controller and firmware, no one can help you but I can guarantee you that it is not the hotend.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 09:45AM |

Registered: 10 years ago Posts: 790 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 09:47AM |

Admin Registered: 17 years ago Posts: 7,879 |

Is it possible you have mixed up the wires? For example if you connect the heater to the +12V and the 0V intended for the thermistor it would always be on.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 10:03AM |

Registered: 10 years ago Posts: 474 |

Just check that the heater cartridge is not shorted to the metal on the cartridge. If I remember right solid doodle is all metal the original hot end was probably insulated from the machine with peak barrier. Try plugging it in and not attaching it to machine or touching it to the machine and see if it does the same thing. It is definitely something to think about for all of us who have all metal machines could be quite dangerous

Edited 6 time(s). Last edit at 05/01/2014 10:19AM by cnc dick.

Edited 6 time(s). Last edit at 05/01/2014 10:19AM by cnc dick.

Sorry, only registered users may post in this forum.