Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 10:10AM |

Registered: 10 years ago Posts: 790 |

The hotend has no possible electrical connection to anything but the port, and I know it's the heater port because the thermistor reads properly on both the bed and extruder. I've got the crap acrylic "Jigsaw" extruder that for whatever stupid reason I still haven't replaced. I've tried having everything plugged up besides the heater, all is normal, temps read and everything. I plug the heater in [and I've tried this using two different pole orientations even though I know it makes no difference] and it instantly starts heating. Unplug and plug in old heater, having changed nothing else, no warmth from original. I've used the heater for testing on my Megatronics V3 with Repetier firmware and it does what it's supposed to when it's supposed to do it. Heat up only when I tell it to and hold temp well.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 10:12AM |

Registered: 10 years ago Posts: 790 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 10:25AM |

Registered: 10 years ago Posts: 474 |

no it's the ground of the thermister port their talking about in other words one wire from the heater and one from the thermister. Try what I said plug it in but not attached to the machine or touching it make sure you didn't mix the wires between the heater and a thermister one of each in other words they have to stay as pairsQuote

cnc dick

Just check that the heater cartridge is not shorted to the metal on the cartridge. If I remember right solid doodle is all metal the original hot end was probably insulated from the machine with peak barrier. Try plugging it in and not attaching it to machine or touching it to the machine and see if it does the same thing. It is definitely something to think about for all of us who have all metal machines could be quite dangerous

Edited 2 time(s). Last edit at 05/01/2014 10:29AM by cnc dick.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 10:32AM |

Registered: 10 years ago Posts: 790 |

Aaaahhh, I see what you're saying now. Connections between thermistor and heator shorted through the hotend. I'll check that out today, even though I hate to have to remove my clean looking togetherness of my hotend..

Could I test that by disconnecting my thermistor and feeling for heat? That would give the same result as your test, right?

Could I test that by disconnecting my thermistor and feeling for heat? That would give the same result as your test, right?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 02:59PM |

Registered: 10 years ago Posts: 474 |

Yes as long as it's not touching any thing and if it doesn't heat up check your thermistor wires in the hot end make sure none of them are touching ground. You might have to go all the way back to the board make sure you don't have a bad wire going to ground. But check for any continuity on the heater leads to the metal of the heater they should be none. If you do cartridge is no good

Edited 1 time(s). Last edit at 05/01/2014 03:01PM by cnc dick.

Edited 1 time(s). Last edit at 05/01/2014 03:01PM by cnc dick.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 01, 2014 03:16PM |

Registered: 10 years ago Posts: 790 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 08:45AM |

Registered: 11 years ago Posts: 71 |

(Sorry, if this has been asked before.)

How are you guys handling changing filament types with this extruder? Do you have a different nozzle for each one? Do you just over heat the existing material and extrude it out with the new material? Anyway, just trying to figure out if I should order multiple nozzles if I want to print PLA, ABS, and anything else....

How are you guys handling changing filament types with this extruder? Do you have a different nozzle for each one? Do you just over heat the existing material and extrude it out with the new material? Anyway, just trying to figure out if I should order multiple nozzles if I want to print PLA, ABS, and anything else....

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 09:05AM |

Registered: 10 years ago Posts: 790 |

I unplugged the thermistor and it still heated. But I also thought of something that would have disproved that from the start: it worked just like it should on my Megatronics V3, only heated when told to. So I know it's physically fine. Something that my board does that automatically heats the different heater. Which just flabbergasts me even more. Why would a board put power to something when not told to when it only does it with that specific heater? When I unplugged the thermistor and connected it forced dry run mode [different wording, but I assume it's the same] and wouldn't let me heat anything through the host. But it would still heat up on it's own. I just don't know. Hot end's fine. It's my board.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 09:19AM |

Registered: 12 years ago Posts: 2,470 |

I do the same thing with every kind of hotend. I heat it up to roughly 80% or less of the normal extrusion temperature, then i pull out the remaining filament. This way you sometimes get the hotend completely clear or only very small remains. Afterwards i just feed in the new material.Quote

lions3

(Sorry, if this has been asked before.)

How are you guys handling changing filament types with this extruder? Do you have a different nozzle for each one? Do you just over heat the existing material and extrude it out with the new material? Anyway, just trying to figure out if I should order multiple nozzles if I want to print PLA, ABS, and anything else....

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 10:14AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

Why would a board put power to something when not told to when it only does it with that specific heater?

I don't think it can. What you describe seems impossible.

Do you have a multimeter? If so measure the voltage accross the heater terminals before connecting the heater and after. If it reads zero with nothing connected and then goes to 12V with just the heater connected across the same two terminals then it breaks the laws of physics.

What happens if you connect both heaters in parallel?

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 10:28AM |

Registered: 10 years ago Posts: 790 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 11:51AM |

Registered: 10 years ago Posts: 474 |

you are right makes no sense the only thing I can think of is if he had a J head or something that was insulated electrically before and there is a chafed wire to the frame it would work okay. And if the new heater cartridge as a short two the metal part of the cartridge and because it is all metal is grounded would be the only possible thing that could be wrong. So sounds like two things are wrong it would have to be a shorted heater cartridge plus something else going to the frame. It's The only thing I can think of because he says he can plug-in is old hot end and it works. Unless there's a way for Mofset to go bad that I've never heard of with a certain amount of load to short out there either open or closed constantly when badQuote

nophead

Quote

Why would a board put power to something when not told to when it only does it with that specific heater?

I don't think it can. What you describe seems impossible.

Do you have a multimeter? If so measure the voltage accross the heater terminals before connecting the heater and after. If it reads zero with nothing connected and then goes to 12V with just the heater connected across the same two terminals then it breaks the laws of physics.

What happens if you connect both heaters in parallel?

Edited 5 time(s). Last edit at 05/02/2014 12:10PM by cnc dick.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 05:57PM |

Registered: 10 years ago Posts: 790 |

So whilst making the video showing what was going on I finally figured what was going on.. and I feel like RepRap's least intelligent person, hah. That wasn't the extruder heater port, that was the extruder fan port......

It works as it should now. And so does my fan that I paid no attention to.

It works as it should now. And so does my fan that I paid no attention to.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2014 06:19PM |

Registered: 10 years ago Posts: 790 |

I never knew a hotend could be so sexy..

EVERY solid layer it is laying down it is laying down like a sheet of glass. This has renewed my hope in printing clear objects, I truly think with enough tuning I could make a near-solid clear object that looks good.

I have to turn up all of my temps, as the Solidoodle original is off [I used to print at 162, I'm now at 185 and I think it needs to go higher still]

I've only had experience with two now, but still, this hotend is like going from my old Palm T|X to my current Galaxy S4 in one jump.

EVERY solid layer it is laying down it is laying down like a sheet of glass. This has renewed my hope in printing clear objects, I truly think with enough tuning I could make a near-solid clear object that looks good.

I have to turn up all of my temps, as the Solidoodle original is off [I used to print at 162, I'm now at 185 and I think it needs to go higher still]

I've only had experience with two now, but still, this hotend is like going from my old Palm T|X to my current Galaxy S4 in one jump.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 05, 2014 12:17PM |

Registered: 10 years ago Posts: 35 |

Is there any fudge room on the temperature to do the final tightening? I got my hot end together and wired up but my 3DStuffMaker has a max temp limit of 275 set. The directions say 290. At 275 I could not tighten it any more than was already hand tight. Is there a torque spec available for how tight the nozzle should be? I have a tendancy to tighten things WAAAY too much from working on cars all my life. But I do have nice torque wrenches because of this!

I've got an AVR programmer on the way. This brand of printer doesn't have a bootloader for making changes to the firmware. I'm so anxious to put some plastic through but don't want to jump the gun and have to clean the threads from a poor seal.

I've got an AVR programmer on the way. This brand of printer doesn't have a bootloader for making changes to the firmware. I'm so anxious to put some plastic through but don't want to jump the gun and have to clean the threads from a poor seal.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 05, 2014 12:29PM |

Registered: 12 years ago Posts: 48 |

I managed to wang off the first nozzle I did up. I used a small socket wrench and it did not take much pressure at all to snap it off.

When new nozzle arrived I used small spanner and putting light pressure on the spanner just gently pushed it up tight, so it was just past thumb tight.

I would say between thumb tight before you take the heat up and then tightening it off was less than 1/4 of a turn.

The thermistor only seemed to read up to 255 on my external temp monitor, so I did it up when it hit that.

After doing it tight, I turned off the power and let it all cool down first so the metal would shrink down and make a nice tight fit. Then took it up to 180+ and started extruding.

No leaks so far

Cheers

Sean.

Edited 1 time(s). Last edit at 05/05/2014 12:30PM by CLaNZeR.

******************************

[www.cncdudez.co.uk]

******************************

When new nozzle arrived I used small spanner and putting light pressure on the spanner just gently pushed it up tight, so it was just past thumb tight.

I would say between thumb tight before you take the heat up and then tightening it off was less than 1/4 of a turn.

The thermistor only seemed to read up to 255 on my external temp monitor, so I did it up when it hit that.

After doing it tight, I turned off the power and let it all cool down first so the metal would shrink down and make a nice tight fit. Then took it up to 180+ and started extruding.

No leaks so far

Cheers

Sean.

Edited 1 time(s). Last edit at 05/05/2014 12:30PM by CLaNZeR.

******************************

[www.cncdudez.co.uk]

******************************

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 06, 2014 05:36AM |

Registered: 12 years ago Posts: 177 |

Very busy with getting our "next big thing out the door" - but thought I'd just chime in with clarification on tightening.

As long as you tighten the nozzle at a temperature that is above the temperatures you are going to print at you're golden. The amount of torque you need is in the order of 3Nm as measured by our little torque wrench - aka not very much.

As long as you tighten the nozzle at a temperature that is above the temperatures you are going to print at you're golden. The amount of torque you need is in the order of 3Nm as measured by our little torque wrench - aka not very much.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 20, 2014 09:56AM |

Registered: 10 years ago Posts: 35 |

Hi guys, I'm hoping someone out there can lend me some advice on how to fix my installation.

I started out with a 3DStuffMaker Evolution. I swapped in the E3D and used the stock carriage and wiring. Now my thermistor is reading strange and I cant find the reason why.

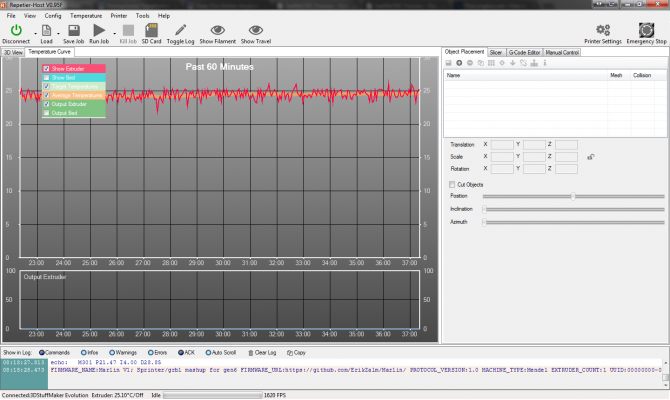

Here is my temp gauge from Repetier Host when I simply turn on the machine and open the program. I let it sit a few minutes without running anything to see how spiky the graph was at idle.

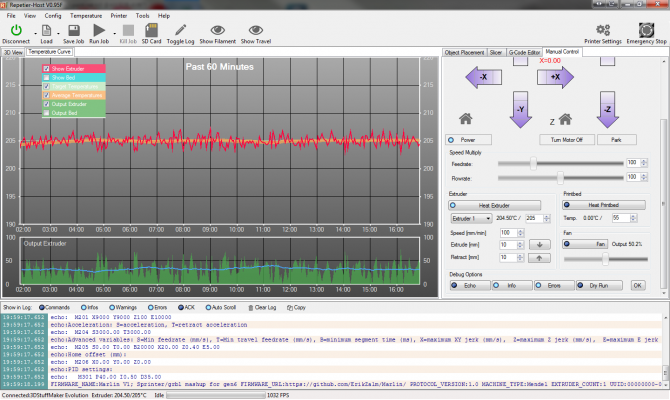

Then I set the temp to 205 and let that simmer for awhile.

Details:

Gen6 electronics

correct thermistor setting in firmware (#5)

Thermistor was originally seated with kapton tape.

After results above, I thought there was a contact problem so I sealed the hole with sodium silicate paste.(NO CHANGE)

Wires not routed with motor wires.

Soldered all connections

Wiring for hot end/thermistor is a shared 4 wire ribbon.

Tried 2 different power supplies.

Does anyone have any suggestions other than trying a different thermistor? I have a feeling I will need to do that in the future. I just am not looking forward to chipping out that paste and perhaps ruining the thermistor entirely.

I started out with a 3DStuffMaker Evolution. I swapped in the E3D and used the stock carriage and wiring. Now my thermistor is reading strange and I cant find the reason why.

Here is my temp gauge from Repetier Host when I simply turn on the machine and open the program. I let it sit a few minutes without running anything to see how spiky the graph was at idle.

Then I set the temp to 205 and let that simmer for awhile.

Details:

Gen6 electronics

correct thermistor setting in firmware (#5)

Thermistor was originally seated with kapton tape.

After results above, I thought there was a contact problem so I sealed the hole with sodium silicate paste.(NO CHANGE)

Wires not routed with motor wires.

Soldered all connections

Wiring for hot end/thermistor is a shared 4 wire ribbon.

Tried 2 different power supplies.

Does anyone have any suggestions other than trying a different thermistor? I have a feeling I will need to do that in the future. I just am not looking forward to chipping out that paste and perhaps ruining the thermistor entirely.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 20, 2014 10:43AM |

Registered: 10 years ago Posts: 553 |

Quote

s10blazed

Hi guys, I'm hoping someone out there can lend me some advice on how to fix my installation.

I started out with a 3DStuffMaker Evolution. I swapped in the E3D and used the stock carriage and wiring. Now my thermistor is reading strange and I cant find the reason why.

Here is my temp gauge from Repetier Host when I simply turn on the machine and open the program. I let it sit a few minutes without running anything to see how spiky the graph was at idle.

[attachment 33215 TempGraph-Idle.png]

Then I set the temp to 205 and let that simmer for awhile.

[attachment 33216 TempGraph-205.png]

Details:

Gen6 electronics

correct thermistor setting in firmware (#5)

Thermistor was originally seated with kapton tape.

After results above, I thought there was a contact problem so I sealed the hole with sodium silicate paste.(NO CHANGE)

Wires not routed with motor wires.

Soldered all connections

Wiring for hot end/thermistor is a shared 4 wire ribbon.

Tried 2 different power supplies.

Does anyone have any suggestions other than trying a different thermistor? I have a feeling I will need to do that in the future. I just am not looking forward to chipping out that paste and perhaps ruining the thermistor entirely.

The spikes seem to match the hotend PID turning off/on. When the thermistor spikes up, the hotend is going down and when the thermistor goes down, the hotend is going up. Try separating those wires.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 20, 2014 10:50AM |

Registered: 10 years ago Posts: 35 |

I'll pull them apart along the length of the ribbon and see if it makes any difference. Would it still cause interference even if the heater is not active?

EDIT: Also, isn't that's what supposed to happen (at temp)? The thermistor goes down, the hot end goes up. But why it would do that with the heater turned off is confusing to me.

Edited 1 time(s). Last edit at 05/20/2014 11:06AM by s10blazed.

EDIT: Also, isn't that's what supposed to happen (at temp)? The thermistor goes down, the hot end goes up. But why it would do that with the heater turned off is confusing to me.

Edited 1 time(s). Last edit at 05/20/2014 11:06AM by s10blazed.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 21, 2014 10:58AM |

Registered: 10 years ago Posts: 35 |

Quote

s10blazed

I'll pull them apart along the length of the ribbon and see if it makes any difference. Would it still cause interference even if the heater is not active?

Well I pulled all of the wires apart and disconnected the heater and fan that were running along side the thermistor wiring in the loom. That still made no difference. I checked for a short in dozens of different positions with my multimeter. Everything is isolated in that reguard. I even re-did my connections to be sure.

My next step is going to be to put a 100k resistor on the thermistor pins of my board and see if that is stable. I've had enough suggestions that it could be the board that I need to know if thats the case.

If its fine I will try hooking the thermistor legs directly to my pins and see how it reads.

Should I be able to measure any resistance between the legs of the thermistor?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 26, 2014 04:23PM |

Registered: 11 years ago Posts: 46 |

Has anyone with a v5 tried a v6? I use v5 and want to know if its worth the $100 to upgrade the relevant parts/nozzles to v6? (I am guessing not, but would like to know) specifically I am looking for data on print quality v5 vs v6. thanks!

[www.printrbottalk.com] Printrbot Forum and Wiki

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 26, 2014 06:00PM |

Registered: 11 years ago Posts: 210 |

Quote

plexus

Has anyone with a v5 tried a v6? I use v5 and want to know if its worth the $100 to upgrade the relevant parts/nozzles to v6? (I am guessing not, but would like to know) specifically I am looking for data on print quality v5 vs v6. thanks!

The upgrade would be much closer to $60, since you can reuse the fan, heater, and thermistor. $61.46 from Filastruder, in fact.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 26, 2014 06:07PM |

Registered: 11 years ago Posts: 195 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 26, 2014 06:43PM |

Registered: 11 years ago Posts: 46 |

Quote

greenman100

Quote

plexus

Has anyone with a v5 tried a v6? I use v5 and want to know if its worth the $100 to upgrade the relevant parts/nozzles to v6? (I am guessing not, but would like to know) specifically I am looking for data on print quality v5 vs v6. thanks!

The upgrade would be much closer to $60, since you can reuse the fan, heater, and thermistor. $61.46 from Filastruder, in fact.

I was planning to order only the parts I need to upgrade v5 to v6 including 4 v6 nozzles and a couple of the injection moulded fan shrouds. when priced out with e3d-online this comes to £58 which is about $98.75USD or taking into consideration an extra 2% for CC transactions $100US. this actually includes the "metal only" bundle which also includes the newly designed heat block

From filastruder, the same items comes to $112US. so its better to get it from e3d-online because its cheaper. also believe it or not shipping is faster to me in Toronto, Canada from the UK than from the US (and cheaper).

Edited 1 time(s). Last edit at 06/26/2014 06:46PM by plexus.

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 30, 2014 09:37AM |

Registered: 10 years ago Posts: 474 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 30, 2014 12:05PM |

Registered: 10 years ago Posts: 790 |

I think he's due for a ban, other posts lead to spam pages placed oddly throughout his posts. Nothing subtle about it. But I'm no admin, nor do I claim real knowledge of things. Just what I see and what I think should be done.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 30, 2014 02:05PM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

MrDoctorDIV

I think he's due for a ban, other posts lead to spam pages placed oddly throughout his posts. Nothing subtle about it. But I'm no admin, nor do I claim real knowledge of things. Just what I see and what I think should be done.

Yep, he's been banned. Looked like some sort of spam-bot.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] July 01, 2014 01:16AM |

Registered: 9 years ago Posts: 330 |

Hi.

I'd like to ask a question about the length of the hot end. Is there a way to adjust it? I don't have access to my printer right now but it seems that my hot end might be longer than E3D and I am not able to mount a shorter one because the bearings are nearly at the ground level. I'd have to raise the heated bed and this would require longer bolts and springs. The reason for the height difference is a metal tube between the heater block and heatsink. I don't see this on E3D images (well there seems to be a similar tube on certain images but not on the final construction)

Thanks

Edited 1 time(s). Last edit at 07/01/2014 01:17AM by drmaestro.

I'd like to ask a question about the length of the hot end. Is there a way to adjust it? I don't have access to my printer right now but it seems that my hot end might be longer than E3D and I am not able to mount a shorter one because the bearings are nearly at the ground level. I'd have to raise the heated bed and this would require longer bolts and springs. The reason for the height difference is a metal tube between the heater block and heatsink. I don't see this on E3D images (well there seems to be a similar tube on certain images but not on the final construction)

Thanks

Edited 1 time(s). Last edit at 07/01/2014 01:17AM by drmaestro.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 28, 2014 12:31AM |

Registered: 10 years ago Posts: 9 |

Quote

drmaestro

Hi.

I'd like to ask a question about the length of the hot end. Is there a way to adjust it? I don't have access to my printer right now but it seems that my hot end might be longer than E3D and I am not able to mount a shorter one because the bearings are nearly at the ground level. I'd have to raise the heated bed and this would require longer bolts and springs. The reason for the height difference is a metal tube between the heater block and heatsink. I don't see this on E3D images (well there seems to be a similar tube on certain images but not on the final construction)

Thanks

There is technical drawings available in [e3d-online.com]

Based on drawings, if I read right, it's from top to nozzle about ~60mm.

Sorry, only registered users may post in this forum.