Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 28, 2014 02:48AM |

Registered: 9 years ago Posts: 45 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 28, 2014 10:04AM |

Registered: 10 years ago Posts: 790 |

I'm just going to throw it out there that the jamming on the v6 has actually gotten worse for me on my 1.75mm MatterHacker Pro PLA filament. It was the dirty boy of the v5 and I got the v6 to hopefully leave that problem behind. To no avail. Jams even more.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] August 28, 2014 02:35PM |

Registered: 9 years ago Posts: 83 |

I've narrowed my v6 issues down to specific filaments-- two of my PLA filaments have a "rough" texture ("Fern Green" from filamentoutlet and a translucent blue from g-bargain (no, really!)), and I have many, many issues with them.

The rest of my filaments, PLA, ABS, 618, and T-Glase, all have a reasonably smooth texture, and I have no problems with them.

Otherwise, the E3D has been pretty reliable for me.

The rest of my filaments, PLA, ABS, 618, and T-Glase, all have a reasonably smooth texture, and I have no problems with them.

Otherwise, the E3D has been pretty reliable for me.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] October 17, 2014 02:15PM |

Registered: 10 years ago Posts: 363 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] October 17, 2014 02:25PM |

Registered: 11 years ago Posts: 195 |

Last time I got a RD3010B12H, which is 4CFM (http://www.alibaba.com/product-detail/FILN-China-factory-12-volt-dc_1272306273.html). The photos on E3D website show a different manufacturer and model though.

Edited 1 time(s). Last edit at 10/17/2014 02:26PM by MPower.

http://www.i3d.ro

Edited 1 time(s). Last edit at 10/17/2014 02:26PM by MPower.

http://www.i3d.ro

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] October 19, 2014 01:29AM |

Registered: 10 years ago Posts: 363 |

Quote

MPower

Last time I got a RD3010B12H, which is 4CFM (http://www.alibaba.com/product-detail/FILN-China-factory-12-volt-dc_1272306273.html). The photos on E3D website show a different manufacturer and model though.

Thank you. It seems these 30mm fans all make about 4CFM. I am designing a different fan shroud which aims for cooling the heatbreak to within ~1 to 0.5mm of the heater block in addition to cooling the heatsink fins. It uses a blower fan. I will consider 4CFM as the lowest airflow fan I choose.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 07, 2015 04:40PM |

Registered: 15 years ago Posts: 242 |

Quote

bobc

Basically, Stratasys have patented heated tubes. (The "thin-wall" qualifier is meaningless, all tubes have thin walls).

It is a totally bogus patent, and I expect it to be ruled invalid in the Afinia case.

Instead of working around bogus patents, we should be getting rid of this stupid patent system.

Absolutely agree. Very few patents actually meet the "novelty" requirements and most are indeed obvious to anyone working in the field.

More than 99% of patents these days are made by companies/corporations and serve more to block technology usage than to support it. It really is hard for me to accept that we are still stuck on this when prior art is highly active in things like spark plugs, heat pipes, heat pumps, Peltier effect devices and so on.

I consider it obvious that we should be using state of the art Peltier effect devices with washer stack orientation and thick film tubular or washer design resistors to make up the difference of what's not currently achievable with a peltier heat differential. A "thermal break" is what a Peltier device achieves.

Ignorance of relavent technologies should not be admissable in these days of pervasive educational scientific media for claiming natural technological progressions as being non obvious.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] January 08, 2015 12:33AM |

Registered: 9 years ago Posts: 351 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 02, 2015 12:26PM |

Registered: 11 years ago Posts: 137 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 27, 2015 02:24PM |

Registered: 8 years ago Posts: 82 |

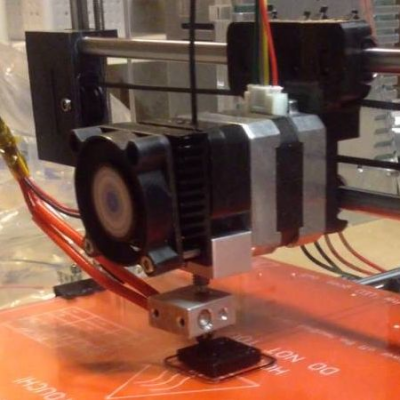

I'm wondering if there's a way to put this on my Prusa I3 from Folgertech. I can't tell from the pictures of the V6 how this would work.

I've attached a picture of the whole extruder assembly. 2 screws go through the fan bottom holes, heatsink, and heatbreak, into the motor. The direct drive extruder is sandwiched between the heatsink and motor.

I'm not at the stage yet where I can print parts to do this, and I don't have the expertise (or shop) to do custom stuff.

One idea may be to replace the extruder with something this hotend will fit into. This one is already giving me problems with very little use.

Any ideas?

I've attached a picture of the whole extruder assembly. 2 screws go through the fan bottom holes, heatsink, and heatbreak, into the motor. The direct drive extruder is sandwiched between the heatsink and motor.

I'm not at the stage yet where I can print parts to do this, and I don't have the expertise (or shop) to do custom stuff.

One idea may be to replace the extruder with something this hotend will fit into. This one is already giving me problems with very little use.

Any ideas?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 27, 2015 03:13PM |

Registered: 8 years ago Posts: 18 |

I dont think it is possible without printing a new mount. I just upgraded my FolgerTech to a Lite6. Initally I printed this which works with the original extruder and was simple to print. Next, I printed this full replacement including a new extruder which works a whole lot better than the original one.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 28, 2015 03:18AM |

Registered: 8 years ago Posts: 82 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 28, 2015 10:15PM |

Registered: 8 years ago Posts: 18 |

Sorry, only registered users may post in this forum.