Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 29, 2013 12:49AM |

Registered: 11 years ago Posts: 137 |

SanjayM Wrote:

-------------------------------------------------------

> Hendo420 and PolygonHell

> I believe your stuff has gone out already, I will

> have to double check this because I don't actually

> perform the shipping. You guys were at the top of

> the priorities list when it came to getting stuff

> out. Hope to have you guys up and rolling very

> soon!

Still nothing.

-------------------------------------------------------

> Hendo420 and PolygonHell

> I believe your stuff has gone out already, I will

> have to double check this because I don't actually

> perform the shipping. You guys were at the top of

> the priorities list when it came to getting stuff

> out. Hope to have you guys up and rolling very

> soon!

Still nothing.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] May 29, 2013 01:35AM |

Registered: 11 years ago Posts: 939 |

Yes I haven't seen my replacement parts yet either. People do seem to be receiving hotends from the second order now, so I was going to give it a week or so given mine has to make it to the west coast of the US.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 01, 2013 06:48AM |

Registered: 10 years ago Posts: 5 |

Did some more testing. My problems are not caused by retractions, although they might contribute to the issue.

That is the propellor vase thing 85218, printed with continuous z-lift. 50 mm/s, supply3dpla.com silver PLA @ 210 °C. Again, after the hotend jammed, I could pull the filament out quite easily and extrude the same filament by hand after snipping the melted part away..

Oh, I did make a new heaterblock that's roughly the same size (all I have to work with is a pre WWII lathe that has been serviced perhaps in the '60s and almost as old drill press. Also I'm no machinist.. > < ) so the problem still might be bad alignment in the heaterblock. Guess I'll run a 2 mm reamer though the assembled hotend.

< ) so the problem still might be bad alignment in the heaterblock. Guess I'll run a 2 mm reamer though the assembled hotend.

That is the propellor vase thing 85218, printed with continuous z-lift. 50 mm/s, supply3dpla.com silver PLA @ 210 °C. Again, after the hotend jammed, I could pull the filament out quite easily and extrude the same filament by hand after snipping the melted part away..

Oh, I did make a new heaterblock that's roughly the same size (all I have to work with is a pre WWII lathe that has been serviced perhaps in the '60s and almost as old drill press. Also I'm no machinist.. >

< ) so the problem still might be bad alignment in the heaterblock. Guess I'll run a 2 mm reamer though the assembled hotend.

< ) so the problem still might be bad alignment in the heaterblock. Guess I'll run a 2 mm reamer though the assembled hotend.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 01, 2013 07:07AM |

Registered: 11 years ago Posts: 973 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 01, 2013 09:05AM |

Registered: 10 years ago Posts: 75 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 03, 2013 02:59PM |

Registered: 12 years ago Posts: 177 |

Mickman

Yep we really should get some sample print images up. For now you can look back through this thread - richrap has some particularly nice examples of good prints off well calibrated printers.

Chris33

3.70mm is the actual measurement on currently shipping parts.

Hendo, PolygonHell, Extin

Still nothing arrived in the post yet?! Something may have gone wrong in my communications with getting your spares shipped by the guy that does the shipping. I am terribly sorry you guys have been without new stuff - I was so sure I arranged for your stuff to go out at the start of last month! If you haven't got anything let me know and I will chase this up with avengeance.

I really want to knock the last nails in this jamming issues coffin, and getting you parts should clear things up.

thejollygrimreaper

Muffler putty for what exactly? Thermistor bonding?

In general

All other systems are go! All the parts for the next batch are here apart from the machined metal parts, which the machinist is cranking out as fast as possible - all looking good for delivery as promised/expected. This batch is really quite large, and should be big enough to get rid of pre-orders and move to 24 order>dispatch turnaround.

The jamming issue is something I am quite sure was caused by a bad drill bit in the lathe that did the 1.75mm nozzles, causing dodgy internal surface finish on the heatbreak. When the replacements get to those affected we will know for sure. To put things into perspective, the rate at which people have been experiencing issues with jamming to date are just below 1% of orders that we know have arrived with people to date. All from the first batch, all on 1.75mm filament.

Bowden systems and spare nozzles are coming in the next batch too - we weren't able to go for drilling/tapping everything and using a delrin plug in the end - the cost was just too high to make it feasible. Instead we have two separate versions, bowden and non-bowden.

Have some interesting developments in the pipes regarding water cooling and multi-nozzle, with some interesting stuff going on with direct-extrusion drive systems too!

Regards,

Sanjay

Yep we really should get some sample print images up. For now you can look back through this thread - richrap has some particularly nice examples of good prints off well calibrated printers.

Chris33

3.70mm is the actual measurement on currently shipping parts.

Hendo, PolygonHell, Extin

Still nothing arrived in the post yet?! Something may have gone wrong in my communications with getting your spares shipped by the guy that does the shipping. I am terribly sorry you guys have been without new stuff - I was so sure I arranged for your stuff to go out at the start of last month! If you haven't got anything let me know and I will chase this up with avengeance.

I really want to knock the last nails in this jamming issues coffin, and getting you parts should clear things up.

thejollygrimreaper

Muffler putty for what exactly? Thermistor bonding?

In general

All other systems are go! All the parts for the next batch are here apart from the machined metal parts, which the machinist is cranking out as fast as possible - all looking good for delivery as promised/expected. This batch is really quite large, and should be big enough to get rid of pre-orders and move to 24 order>dispatch turnaround.

The jamming issue is something I am quite sure was caused by a bad drill bit in the lathe that did the 1.75mm nozzles, causing dodgy internal surface finish on the heatbreak. When the replacements get to those affected we will know for sure. To put things into perspective, the rate at which people have been experiencing issues with jamming to date are just below 1% of orders that we know have arrived with people to date. All from the first batch, all on 1.75mm filament.

Bowden systems and spare nozzles are coming in the next batch too - we weren't able to go for drilling/tapping everything and using a delrin plug in the end - the cost was just too high to make it feasible. Instead we have two separate versions, bowden and non-bowden.

Have some interesting developments in the pipes regarding water cooling and multi-nozzle, with some interesting stuff going on with direct-extrusion drive systems too!

Regards,

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 03, 2013 03:17PM |

Registered: 13 years ago Posts: 81 |

Liking this design. Couple of questions though, hope you don't mind!

Are you planning on making other extrusion sizes? I would love to have a 0.3mm nozzle.

The machine I am designing/building has two extruders close together. With the active cooling that this system uses I wouldn't have space to have both fans on each extruder. My current design would have the hotends centers 28.5mm apart (the total width of the two hotends would be 53.5mm), could I use a bigger fan, say a deeper 40mm or 60mm fan to cool both at the same time?

-edit-

Noticed on your site that you are selling upgraded nozzles. Will these be available in the kits? Rather then buy the hotend to only 'throw out' (read - store hehe) the nozzle it came with lol

Edited 2 time(s). Last edit at 06/03/2013 05:30PM by smartroad.

Are you planning on making other extrusion sizes? I would love to have a 0.3mm nozzle.

The machine I am designing/building has two extruders close together. With the active cooling that this system uses I wouldn't have space to have both fans on each extruder. My current design would have the hotends centers 28.5mm apart (the total width of the two hotends would be 53.5mm), could I use a bigger fan, say a deeper 40mm or 60mm fan to cool both at the same time?

-edit-

Noticed on your site that you are selling upgraded nozzles. Will these be available in the kits? Rather then buy the hotend to only 'throw out' (read - store hehe) the nozzle it came with lol

Edited 2 time(s). Last edit at 06/03/2013 05:30PM by smartroad.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 03, 2013 05:29PM |

Registered: 11 years ago Posts: 939 |

Quote

Still nothing arrived in the post yet?! Something may have gone wrong in my communications with getting your spares shipped by the guy that does the shipping.

I just checked my mail box, and I've still received nothing,

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 03, 2013 05:45PM |

Registered: 11 years ago Posts: 21 |

Polygonhell Wrote:

-------------------------------------------------------

> Still nothing arrived in the post yet?! Something

> may have gone wrong in my communications with

> getting your spares shipped by the guy that does

> the shipping.

>

> I just checked my mail box, and I've still

> received nothing,

Did you get a tracking number? I got one and I can see that I should have it by the end of the week. It shipped last Tuesday and I'm in Canada

-------------------------------------------------------

> Still nothing arrived in the post yet?! Something

> may have gone wrong in my communications with

> getting your spares shipped by the guy that does

> the shipping.

>

> I just checked my mail box, and I've still

> received nothing,

Did you get a tracking number? I got one and I can see that I should have it by the end of the week. It shipped last Tuesday and I'm in Canada

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 03, 2013 06:05PM |

Registered: 11 years ago Posts: 939 |

matty2013 Wrote:

\> Did you get a tracking number? I got one and I can

> see that I should have it by the end of the week.

> It shipped last Tuesday and I'm in Canada

No tracking number, and no communication since Sanjay contacted me to get my name and address.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

\> Did you get a tracking number? I got one and I can

> see that I should have it by the end of the week.

> It shipped last Tuesday and I'm in Canada

No tracking number, and no communication since Sanjay contacted me to get my name and address.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 03, 2013 06:22PM |

Registered: 11 years ago Posts: 118 |

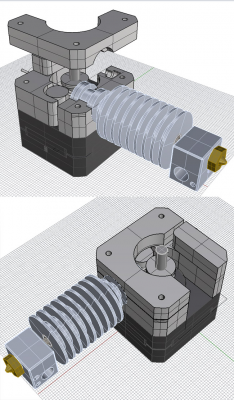

I got my E3D today, earlier than expected.

Tomorrow i will cnc mill this Directdrive Extruder:

and test it a few days...

ps: the parts are very nice, but the printed Fan

mount is crap i hope you didn´t print it with your own hotend....

Edited 1 time(s). Last edit at 06/03/2013 06:23PM by mrc.

Tomorrow i will cnc mill this Directdrive Extruder:

and test it a few days...

ps: the parts are very nice, but the printed Fan

mount is crap i hope you didn´t print it with your own hotend....

Edited 1 time(s). Last edit at 06/03/2013 06:23PM by mrc.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 03, 2013 07:43PM |

Registered: 12 years ago Posts: 177 |

SmartRoad

Yup nozzles are up for preorder now on the site.

Your proposed arrangement for having two extruders and a larger 40mm fan would almost certainly work just fine. Be sure that you get enough air hitting those bottom fins near the hot end of the nozzle.

Hope to be coming out with a dual/triple/quad/hex modular upgradeable nozzle version in the next few months. Probably bowden only to begin with.

Have some sneaky tricks for getting multi filament direct drive packed tightly on top of 6 tightly packed nozzles. Soon.

PolygonHell

Emailed you. Will make sure this is made right. Pinky promise.

I genuinely think/thought your parts were shipped at the start of last month. Possible balls-up occurred in communications between me (Engineering/Tech Support) and my colleague David (Sales, Delivery, Payments).

MRC

That looks AWESOME. Really like how the filament path leads directly into the inlet of the top of the hotend. Did you use the STEP/IGES files from the site? I think they may be slightly out of date and not mm-perfect with some shipped versions around the mounting area. Cracking work all round on the design. Cannot wait to see the results.

Sanjay

Edited 2 time(s). Last edit at 06/03/2013 08:01PM by SanjayM.

Yup nozzles are up for preorder now on the site.

Your proposed arrangement for having two extruders and a larger 40mm fan would almost certainly work just fine. Be sure that you get enough air hitting those bottom fins near the hot end of the nozzle.

Hope to be coming out with a dual/triple/quad/hex modular upgradeable nozzle version in the next few months. Probably bowden only to begin with.

Have some sneaky tricks for getting multi filament direct drive packed tightly on top of 6 tightly packed nozzles. Soon.

PolygonHell

Emailed you. Will make sure this is made right. Pinky promise.

I genuinely think/thought your parts were shipped at the start of last month. Possible balls-up occurred in communications between me (Engineering/Tech Support) and my colleague David (Sales, Delivery, Payments).

MRC

That looks AWESOME. Really like how the filament path leads directly into the inlet of the top of the hotend. Did you use the STEP/IGES files from the site? I think they may be slightly out of date and not mm-perfect with some shipped versions around the mounting area. Cracking work all round on the design. Cannot wait to see the results.

Sanjay

Edited 2 time(s). Last edit at 06/03/2013 08:01PM by SanjayM.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 04, 2013 12:31AM |

Registered: 11 years ago Posts: 137 |

SanjayM Wrote:

-------------------------------------------------------

> Hendo, PolygonHell, Extin

> Still nothing arrived in the post yet?! Something

> may have gone wrong in my communications with

> getting your spares shipped by the guy that does

> the shipping. I am terribly sorry you guys have

> been without new stuff - I was so sure I arranged

> for your stuff to go out at the start of last

> month! If you haven't got anything let me know and

> I will chase this up with avengeance.

>

> I really want to knock the last nails in this

> jamming issues coffin, and getting you parts

> should clear things up.

>

> Regards,

> Sanjay

Nothing yet, got a tracking number for it?

-------------------------------------------------------

> Hendo, PolygonHell, Extin

> Still nothing arrived in the post yet?! Something

> may have gone wrong in my communications with

> getting your spares shipped by the guy that does

> the shipping. I am terribly sorry you guys have

> been without new stuff - I was so sure I arranged

> for your stuff to go out at the start of last

> month! If you haven't got anything let me know and

> I will chase this up with avengeance.

>

> I really want to knock the last nails in this

> jamming issues coffin, and getting you parts

> should clear things up.

>

> Regards,

> Sanjay

Nothing yet, got a tracking number for it?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 04, 2013 09:59AM |

Registered: 10 years ago Posts: 5 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 04, 2013 11:24AM |

Registered: 11 years ago Posts: 118 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 04, 2013 04:42PM |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 05, 2013 01:02AM |

Registered: 11 years ago Posts: 67 |

RickZehr Wrote:

-------------------------------------------------------

> Ezra, I bought one of these from you three weeks

> ago, after my first magma head on my A1 clogged,

> and it promptly clogged solid too.

>

> Both of them have been back at TL since then.

>

> Can I PLEASE get them back from you in working

> condition?

I don't see Trinity Labs posting in this thread lately.

Edited 1 time(s). Last edit at 06/05/2013 01:03AM by maddox.

-------------------------------------------------------

> Ezra, I bought one of these from you three weeks

> ago, after my first magma head on my A1 clogged,

> and it promptly clogged solid too.

>

> Both of them have been back at TL since then.

>

> Can I PLEASE get them back from you in working

> condition?

I don't see Trinity Labs posting in this thread lately.

Edited 1 time(s). Last edit at 06/05/2013 01:03AM by maddox.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 05, 2013 08:13AM |

Registered: 13 years ago Posts: 81 |

Looking forward to the multi extruder!! Just to clarify at the moment to buy a complete hot end you only have a choice of 0.4mm will the system be updated to allow for a hot end to be ordered with the other sizes? I ask simple as I don't like waste by having a nozzle that will never be used.

Cheers

PS Any discounts for ordering more than one?! hehe gotta ask!

SanjayM Wrote:

-------------------------------------------------------

> SmartRoad

> Yup nozzles are up for preorder now on the site.

>

> Your proposed arrangement for having two extruders

> and a larger 40mm fan would almost certainly work

> just fine. Be sure that you get enough air hitting

> those bottom fins near the hot end of the nozzle.

>

> Hope to be coming out with a dual/triple/quad/hex

> modular upgradeable nozzle version in the next few

> months. Probably bowden only to begin with.

> Have some sneaky tricks for getting multi filament

> direct drive packed tightly on top of 6 tightly

> packed nozzles. Soon.

>

Cheers

PS Any discounts for ordering more than one?! hehe gotta ask!

SanjayM Wrote:

-------------------------------------------------------

> SmartRoad

> Yup nozzles are up for preorder now on the site.

>

> Your proposed arrangement for having two extruders

> and a larger 40mm fan would almost certainly work

> just fine. Be sure that you get enough air hitting

> those bottom fins near the hot end of the nozzle.

>

> Hope to be coming out with a dual/triple/quad/hex

> modular upgradeable nozzle version in the next few

> months. Probably bowden only to begin with.

> Have some sneaky tricks for getting multi filament

> direct drive packed tightly on top of 6 tightly

> packed nozzles. Soon.

>

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 05, 2013 11:55AM |

Registered: 11 years ago Posts: 21 |

I just received mine today, I didn't get any PTFE heat shrink as per the instructions, but I did receive these two small aluminum tubes that are flared at one end.

Anyone know what they are for?

Anyone know what they are for?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 05, 2013 12:23PM |

Admin Registered: 17 years ago Posts: 7,879 |

The look like ferrules for joining the thermistor wires. Shouldn't be aluminium though.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 05, 2013 02:47PM |

Registered: 11 years ago Posts: 67 |

SanjayM Wrote:

-------------------------------------------------------

> Have some interesting developments in the pipes

> regarding water cooling and multi-nozzle, with

> some interesting stuff going on with

> direct-extrusion drive systems too!

>

> Regards,

> Sanjay

SanjayM Wrote:

-------------------------------------------------------

> Hope to be coming out with a dual/triple/quad/hex

> modular upgradeable nozzle version in the next few

> months. Probably bowden only to begin with.

> Have some sneaky tricks for getting multi filament

> direct drive packed tightly on top of 6 tightly

> packed nozzles. Soon.

Just some thoughts on the watercooling and multihead stuff:

1. Since one of the benefits of watercooling is a lower weight, I assume you are trimming all of the unnecessary material out of the standard air-cooled heatsink part for the watercooled versions? Maybe the watercooled could be shorter than the air cooled versions as well, considering they shouldn't need all of that heatsink height to achieve the same heat wicking with active water cooling?

2. With the multi-nozzle setup, being able to adjust the nozzle height on the carriage is going to be a critical feature. Have you given much thought to how you might go about this? (I'm sure you have.) Reprappro has a pretty elegant/simple height adjustment on their tri-color nozzles, as can be seen here:

[reprappro.com]

3. From matty's picture 2 posts above, the part of the hot heatsink where the nozzle screws into is offset far to one side of the heater block, which will be good for accommodating multiple nozzles placed closely together without the heater blocks interfering with each other. Maybe you could do something similar with the watercooled heatsink as well, in an effort to allow the compact placement of the multiple nozzles?

4. You have mentioned in the past about potentially doing a single heatsink for the multiple nozzle setup. While this could be an efficient way to do it, it also would pose technical issues to being able to individually adjust the height of the separate nozzles (or, for example, make it difficult if someone were to want to implement a system where the nozzles can retract individually when not in use). Thoughts?

Anywho, I'm sure you've likely thought of these issues (and many more), but since I'm not part of your development with this, I thought I'd throw these thoughts out there. I'd love to eventually use your watercooled multihead bowden setup, if it turns out to be compatible with the goals of my machine. I'd love to hear more about the development in that arena, if you're willing/able to share.

Edited 1 time(s). Last edit at 06/05/2013 09:07PM by maddox.

-------------------------------------------------------

> Have some interesting developments in the pipes

> regarding water cooling and multi-nozzle, with

> some interesting stuff going on with

> direct-extrusion drive systems too!

>

> Regards,

> Sanjay

SanjayM Wrote:

-------------------------------------------------------

> Hope to be coming out with a dual/triple/quad/hex

> modular upgradeable nozzle version in the next few

> months. Probably bowden only to begin with.

> Have some sneaky tricks for getting multi filament

> direct drive packed tightly on top of 6 tightly

> packed nozzles. Soon.

Just some thoughts on the watercooling and multihead stuff:

1. Since one of the benefits of watercooling is a lower weight, I assume you are trimming all of the unnecessary material out of the standard air-cooled heatsink part for the watercooled versions? Maybe the watercooled could be shorter than the air cooled versions as well, considering they shouldn't need all of that heatsink height to achieve the same heat wicking with active water cooling?

2. With the multi-nozzle setup, being able to adjust the nozzle height on the carriage is going to be a critical feature. Have you given much thought to how you might go about this? (I'm sure you have.) Reprappro has a pretty elegant/simple height adjustment on their tri-color nozzles, as can be seen here:

[reprappro.com]

3. From matty's picture 2 posts above, the part of the hot heatsink where the nozzle screws into is offset far to one side of the heater block, which will be good for accommodating multiple nozzles placed closely together without the heater blocks interfering with each other. Maybe you could do something similar with the watercooled heatsink as well, in an effort to allow the compact placement of the multiple nozzles?

4. You have mentioned in the past about potentially doing a single heatsink for the multiple nozzle setup. While this could be an efficient way to do it, it also would pose technical issues to being able to individually adjust the height of the separate nozzles (or, for example, make it difficult if someone were to want to implement a system where the nozzles can retract individually when not in use). Thoughts?

Anywho, I'm sure you've likely thought of these issues (and many more), but since I'm not part of your development with this, I thought I'd throw these thoughts out there. I'd love to eventually use your watercooled multihead bowden setup, if it turns out to be compatible with the goals of my machine. I'd love to hear more about the development in that arena, if you're willing/able to share.

Edited 1 time(s). Last edit at 06/05/2013 09:07PM by maddox.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 05, 2013 05:09PM |

Registered: 11 years ago Posts: 203 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 05, 2013 06:35PM |

Registered: 11 years ago Posts: 21 |

plexer Wrote:

-------------------------------------------------------

> They are boot lace ferrules for joining wires to

> the heater cartridge.

>

> Ben

The E3d instructions say to solder the thermistor leads to the silicone wrapped wires.

I imagine this ferrule is meant to work sort of like a butt connector? Or is it meant to go on the end of the power wires for the heater where they plug into the ramps board?

-------------------------------------------------------

> They are boot lace ferrules for joining wires to

> the heater cartridge.

>

> Ben

The E3d instructions say to solder the thermistor leads to the silicone wrapped wires.

I imagine this ferrule is meant to work sort of like a butt connector? Or is it meant to go on the end of the power wires for the heater where they plug into the ramps board?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 01:47AM |

Registered: 12 years ago Posts: 72 |

Those ferrules are meant to be crimped to the wire that leads away from the hotend and the wires coming from the thermistor. From what I've experienced in electronics they seem to be suggesting that you solder the wires whilst the ferrules are around the thermistor wires so you can bring them over the soldered connection and crimp/squeeze them over. Personally I would crimp them (as I have access to the appropriate crimpers) or even squeeze them tight with good needle nose pliers, and forget soldering entirely.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 01:58AM |

Admin Registered: 16 years ago Posts: 13,884 |

... with problematic joints I'm twisting the ends, crimping such a ferrule around i and only at last solder it - with some (not solderable) materials this is the easiest practicable solid connection ... the other methode is brazing - either with a flame-torch or better an IR-laser with enough power to melt the brazing alloy ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 04:36AM |

Admin Registered: 17 years ago Posts: 7,879 |

I simply solder thermistor wires because they have low conductivity dumet wires and are sufficiently long that the joints don't get too hot.

I use lead free solder which has a higher melting point than leaded, about 212C versus 188C.

[www.hydraraptor.blogspot.com]

I use lead free solder which has a higher melting point than leaded, about 212C versus 188C.

[www.hydraraptor.blogspot.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 04:52AM |

Admin Registered: 11 years ago Posts: 1,063 |

has anyone tried that ptfe heatshrink that has popped up on aliexpress?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 05:20AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I have some silikone-heatshrink, that is rated for temps up to 260 degC for isolating ... or use 'exhaust-putty' rated for up to 800 degC or own ceramic+waterglass mixtures for applications with even higher temps ...

Edited 1 time(s). Last edit at 06/06/2013 05:21AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Edited 1 time(s). Last edit at 06/06/2013 05:21AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 02:47PM |

Registered: 11 years ago Posts: 661 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] June 06, 2013 02:52PM |

Registered: 11 years ago Posts: 939 |

Just wanted to say I just received my replacement parts from E3D, the package was sent airmail, I'm going to put it together and test it this weekend, I'll follow up then.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

Sorry, only registered users may post in this forum.