Reprappro tricolor mendel build!

Posted by PierreB

|

Reprappro tricolor mendel build! April 20, 2013 07:38PM |

Registered: 11 years ago Posts: 32 |

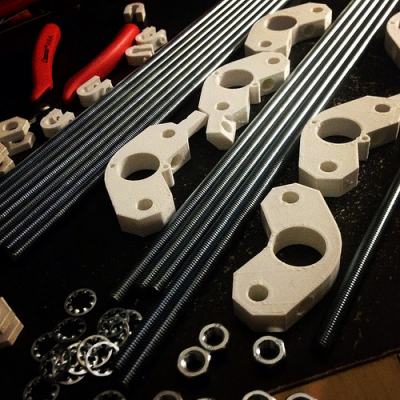

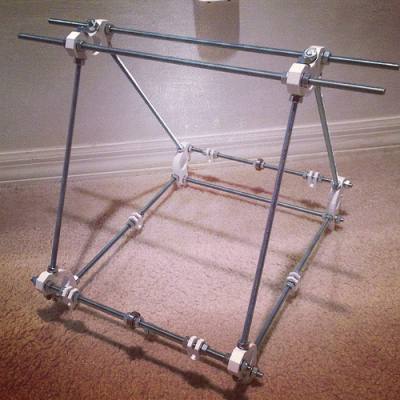

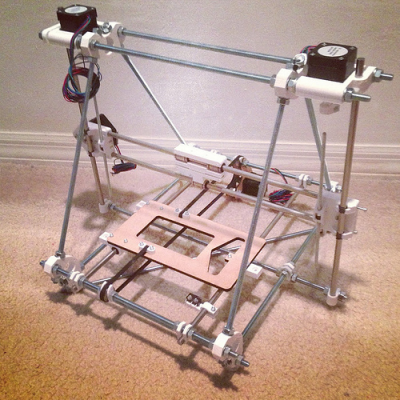

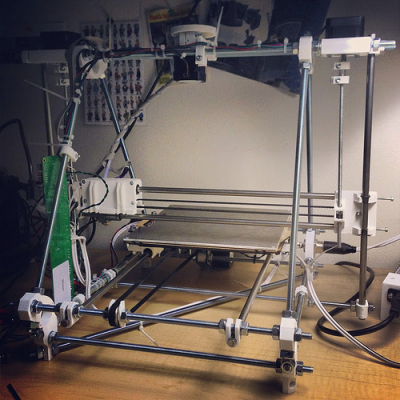

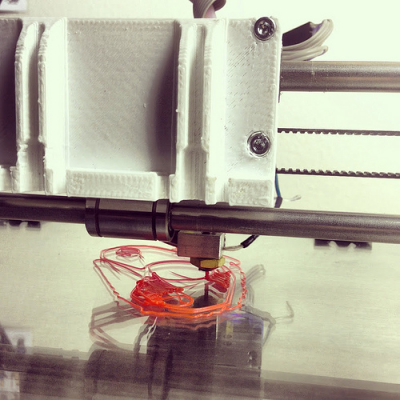

Super excited. Just got my Reprappro tricolor Mendel up (only single color built thus far, other two hot ends and extrusion gears will be built soon...) and working after a ~2 week build (a few hours each night after work) and ran my first prints this afternoon. I was surprised that the only thing I got wrong out of the whole build process was the polarity of the LED on the heated bed (I couldn't find indications on the circuitboard to indicate orientation). After wiring it all up this morning, everything worked perfectly apart from the hot end which I disassembled and reassembled which fixed whatever filament feed problem I was having.

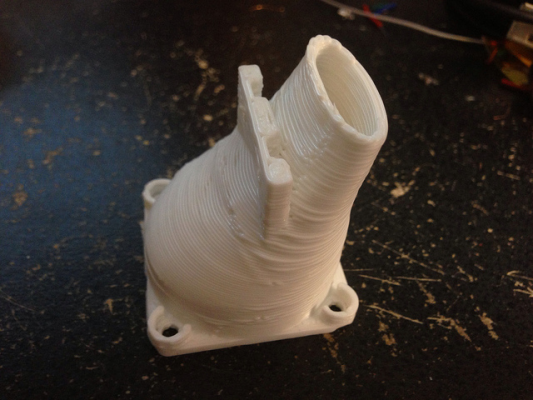

First print was the frame vertex recommended by the build guide and that came out pretty well apart from my extruder gear needing to be tightened because it wasn't feeding properly towards the end of the print. Looks like now I need to dial-in z-axis height a bit and see what else I can optimize. I've done all testing with the pronterface software, but I've seen folks talking about using other software to drive their printers and would be curious to know what everyone recommends.

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

I've got a video of the first print here too:

http://www.flickr.com/photos/kabong/8664190432/in/set-72157633284730332/

\m/ o.O \m/

First print was the frame vertex recommended by the build guide and that came out pretty well apart from my extruder gear needing to be tightened because it wasn't feeding properly towards the end of the print. Looks like now I need to dial-in z-axis height a bit and see what else I can optimize. I've done all testing with the pronterface software, but I've seen folks talking about using other software to drive their printers and would be curious to know what everyone recommends.

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

Reprappro tricolor Mendel build by Senior Kabong, on Flickr

I've got a video of the first print here too:

http://www.flickr.com/photos/kabong/8664190432/in/set-72157633284730332/

\m/ o.O \m/

|

Re: Reprappro tricolor mendel build! April 21, 2013 06:43AM |

Registered: 11 years ago Posts: 130 |

Interesting stuff (nice rock music in the background on the video!)

Would really love to see tri-colour results!

Do you know if it's possible with multiple colours to completely (or at least mostly) 'flush' one colour (say on the corner of the bed), should you want particular sections to be only one colour, rather than a funky gradient?

Would really love to see tri-colour results!

Do you know if it's possible with multiple colours to completely (or at least mostly) 'flush' one colour (say on the corner of the bed), should you want particular sections to be only one colour, rather than a funky gradient?

|

Re: Reprappro tricolor mendel build! April 21, 2013 07:47AM |

Registered: 11 years ago Posts: 203 |

Marcosscriven when printing multi colours it uses multiple heads and builds up a sacrificial box to purge the heads in.

PierreB when building the heated beds I use a 9v pp3 battery to test it this shows if you have the led the right way as the reprappro instructions aren't as clear on this step as they could be, nice build btw.

Ben

PierreB when building the heated beds I use a 9v pp3 battery to test it this shows if you have the led the right way as the reprappro instructions aren't as clear on this step as they could be, nice build btw.

Ben

|

Re: Reprappro tricolor mendel build! April 22, 2013 01:30PM |

Registered: 11 years ago Posts: 70 |

I've been using pronterface for the last few months but only for 1 extruder. I also have a reprappro mendel but it's mono colour.

I gave repetier host a go but switched back to pronterface because that's what I was more familar with. I started to use slic3r to slice then I put it in to pronterface to print.

the new version of slic3r can handle multiple extruders. I find it easier to use than skeinforge.

skeinforge is supposedly better than slic3r for precision. however I haven't compared them properly so I can't really comment.

good luck with your printing!

Edited 1 time(s). Last edit at 04/22/2013 08:30PM by keithCl.

I gave repetier host a go but switched back to pronterface because that's what I was more familar with. I started to use slic3r to slice then I put it in to pronterface to print.

the new version of slic3r can handle multiple extruders. I find it easier to use than skeinforge.

skeinforge is supposedly better than slic3r for precision. however I haven't compared them properly so I can't really comment.

good luck with your printing!

Edited 1 time(s). Last edit at 04/22/2013 08:30PM by keithCl.

|

Re: Reprappro tricolor mendel build! April 23, 2013 09:41AM |

Registered: 11 years ago Posts: 65 |

Hi,

I have just completed my RepRapPro Mendel MONO color (the legacy... two moths ago... version) with the two metal bar horizontal on the X-axe. I did not purchase either the additional two extruders and control boards (I decided to be able to make it run perfectly with ONE, before thinking any more difficult task, since this is my first entry in the reprap world )

)

I am now in the calibrate phase.

From what I see, you had my same problems: bed led doesn't turn on and a slide problem to the hot-end.

In addition I had a problem with the wheel of the extruder: due to the filament channel too tight (I did not checked it during the build) after tightening the screws of the extruder, the power of the motor was discharged on the wheel, that tried to rotate, but having the bolt and filament blocked, broken its hexagonal hole-mount that keeps the hexa-bolt at his place, so that it become almost rounded, so that the wheel started to rotate loose.

That's is a conceptual weak, since mechanically it could be better. However I had to fix it with metal sheet, recreating the hexagonal shape to block the bolt.

I have printed some sample tests. I can see the quality are more or less the same.

IN MY CASE:

- There are large irregular layers. I printed the perimeter_wt and of course they didn't fit one inside the other (why ?)

- In addition I saw that there are some random layers shifted one or half millimetre (any idea why ? )

- This object was the best, but the angles come out not squares, but little rounded.

- After printing the large square alignment box, measuring it, I discovered that the square is not really square, so I will have to check the X/Y alignment to be 90 degree.

- PLA solidifies slowly, and on printing the squared tower, after 1 cm hight it starts to become a semi-melted cylinder...

- Have you the same symptoms (sliding layers) ?

Best Regards

Edited 1 time(s). Last edit at 04/23/2013 11:18AM by antimix.

I have just completed my RepRapPro Mendel MONO color (the legacy... two moths ago... version) with the two metal bar horizontal on the X-axe. I did not purchase either the additional two extruders and control boards (I decided to be able to make it run perfectly with ONE, before thinking any more difficult task, since this is my first entry in the reprap world

)

)I am now in the calibrate phase.

From what I see, you had my same problems: bed led doesn't turn on and a slide problem to the hot-end.

In addition I had a problem with the wheel of the extruder: due to the filament channel too tight (I did not checked it during the build) after tightening the screws of the extruder, the power of the motor was discharged on the wheel, that tried to rotate, but having the bolt and filament blocked, broken its hexagonal hole-mount that keeps the hexa-bolt at his place, so that it become almost rounded, so that the wheel started to rotate loose.

That's is a conceptual weak, since mechanically it could be better. However I had to fix it with metal sheet, recreating the hexagonal shape to block the bolt.

I have printed some sample tests. I can see the quality are more or less the same.

IN MY CASE:

- There are large irregular layers. I printed the perimeter_wt and of course they didn't fit one inside the other (why ?)

- In addition I saw that there are some random layers shifted one or half millimetre (any idea why ? )

- This object was the best, but the angles come out not squares, but little rounded.

- After printing the large square alignment box, measuring it, I discovered that the square is not really square, so I will have to check the X/Y alignment to be 90 degree.

- PLA solidifies slowly, and on printing the squared tower, after 1 cm hight it starts to become a semi-melted cylinder...

- Have you the same symptoms (sliding layers) ?

Best Regards

Edited 1 time(s). Last edit at 04/23/2013 11:18AM by antimix.

|

Re: Reprappro tricolor mendel build! April 25, 2013 12:35AM |

Registered: 11 years ago Posts: 32 |

antimix Wrote:

-------------------------------------------------------

> From what I see, you had my same problems: bed led

> doesn't turn on and a slide problem to the

> hot-end.

> In addition I had a problem with the wheel of the

> extruder: due to the filament channel too tight (I

> did not checked it during the build) after

> tightening the screws of the extruder, the power

> of the motor was discharged on the wheel, that

> tried to rotate, but having the bolt and filament

> blocked, broken its hexagonal hole-mount that

> keeps the hexa-bolt at his place, so that it

> become almost rounded, so that the wheel started

> to rotate loose.

> That's is a conceptual weak, since mechanically it

> could be better. However I had to fix it with

> metal sheet, recreating the hexagonal shape to

> block the bolt.

>

> I have printed some sample tests. I can see the

> quality are more or less the same.

>

> IN MY CASE:

>

> - There are large irregular layers. I printed the

> perimeter_wt and of course they didn't fit one

> inside the other (why ?)

> - In addition I saw that there are some random

> layers shifted one or half millimetre (any idea

> why ? )

> - This object was the best, but the angles come

> out not squares, but little rounded.

> - After printing the large square alignment box,

> measuring it, I discovered that the square is not

> really square, so I will have to check the X/Y

> alignment to be 90 degree.

> - PLA solidifies slowly, and on printing the

> squared tower, after 1 cm hight it starts to

> become a semi-melted cylinder...

>

> - Have you the same symptoms (sliding layers) ?

>

> Best Regards

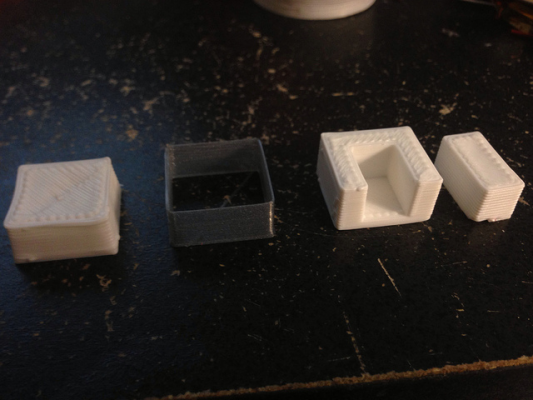

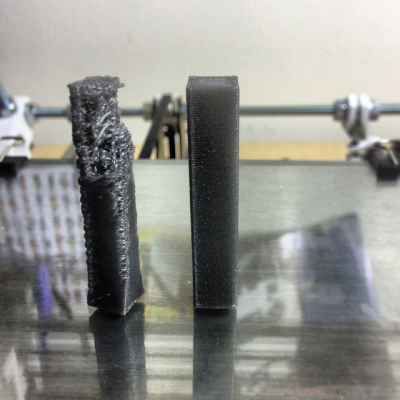

My biggest problem right now seems to be what I can only describe as z-axis binding/drift over time. I printed many of the same calibration parts that you did and all of my x and y measurements are spot on and my z are usually good as well. The problem I have is that over time it seems to start dragging the nozzle through the part as it prints. This is visible here where I was testing repetier-host and slic3r (left) vs pronterface (right):

Untitled by Senior Kabong, on Flickr

The pronterface print was looking great until it got to the top of the legs, then it promptly started dragging the nozzle through the body.

Here are a few things I've been able to print successfully:

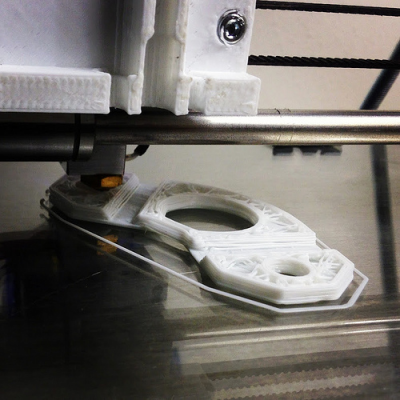

Calibration parts

Untitled by Senior Kabong, on Flickr

x-axis endstop

Untitled by Senior Kabong, on Flickr

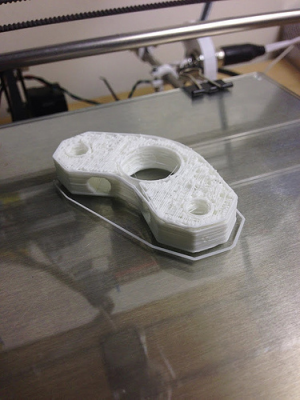

frame vertex (bottom was first print, extruder gear wasn't tightened, fixed it on print above)

Untitled by Senior Kabong, on Flickr

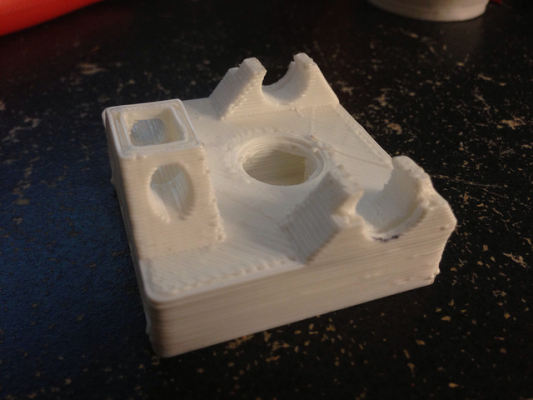

mount for cooling fan (hoping this might help with PLA cooling?)

Untitled by Senior Kabong, on Flickr

To try and address the z-axis binding issue, I took each smooth rod out of the x-axis one at a time, popped out the grey collars/inserts and sanded down the inside to give more clearance for the collars/inserts to slide on the smooth rods. That doesn't seem to have fixed my issue, so I'm still testing things...

-------------------------------------------------------

> From what I see, you had my same problems: bed led

> doesn't turn on and a slide problem to the

> hot-end.

> In addition I had a problem with the wheel of the

> extruder: due to the filament channel too tight (I

> did not checked it during the build) after

> tightening the screws of the extruder, the power

> of the motor was discharged on the wheel, that

> tried to rotate, but having the bolt and filament

> blocked, broken its hexagonal hole-mount that

> keeps the hexa-bolt at his place, so that it

> become almost rounded, so that the wheel started

> to rotate loose.

> That's is a conceptual weak, since mechanically it

> could be better. However I had to fix it with

> metal sheet, recreating the hexagonal shape to

> block the bolt.

>

> I have printed some sample tests. I can see the

> quality are more or less the same.

>

> IN MY CASE:

>

> - There are large irregular layers. I printed the

> perimeter_wt and of course they didn't fit one

> inside the other (why ?)

> - In addition I saw that there are some random

> layers shifted one or half millimetre (any idea

> why ? )

> - This object was the best, but the angles come

> out not squares, but little rounded.

> - After printing the large square alignment box,

> measuring it, I discovered that the square is not

> really square, so I will have to check the X/Y

> alignment to be 90 degree.

> - PLA solidifies slowly, and on printing the

> squared tower, after 1 cm hight it starts to

> become a semi-melted cylinder...

>

> - Have you the same symptoms (sliding layers) ?

>

> Best Regards

My biggest problem right now seems to be what I can only describe as z-axis binding/drift over time. I printed many of the same calibration parts that you did and all of my x and y measurements are spot on and my z are usually good as well. The problem I have is that over time it seems to start dragging the nozzle through the part as it prints. This is visible here where I was testing repetier-host and slic3r (left) vs pronterface (right):

Untitled by Senior Kabong, on Flickr

The pronterface print was looking great until it got to the top of the legs, then it promptly started dragging the nozzle through the body.

Here are a few things I've been able to print successfully:

Calibration parts

Untitled by Senior Kabong, on Flickr

x-axis endstop

Untitled by Senior Kabong, on Flickr

frame vertex (bottom was first print, extruder gear wasn't tightened, fixed it on print above)

Untitled by Senior Kabong, on Flickr

mount for cooling fan (hoping this might help with PLA cooling?)

Untitled by Senior Kabong, on Flickr

To try and address the z-axis binding issue, I took each smooth rod out of the x-axis one at a time, popped out the grey collars/inserts and sanded down the inside to give more clearance for the collars/inserts to slide on the smooth rods. That doesn't seem to have fixed my issue, so I'm still testing things...

|

Re: Reprappro tricolor mendel build! April 25, 2013 12:40AM |

Admin Registered: 15 years ago Posts: 1,470 |

Looks like you are spitting out too much plastic. Have you verified your E steps?

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Reprappro tricolor mendel build! April 25, 2013 03:28AM |

Registered: 11 years ago Posts: 67 |

I was looking for some high quality example prints from the RRP mendel before I bought mine, and I was a little surprised that I almost couldn't find any super high quality showoff prints (like you can find in abundance for Ultimaker, tantillus etc). I'm in the process of assembling my RRP mendel, and I hope I'm able to eventually get it calibrated super tightly, and that there aren't major flaws with the printer. These posts are kind of discouraging.

|

Re: Reprappro tricolor mendel build! April 25, 2013 07:54AM |

Registered: 11 years ago Posts: 172 |

|

Re: Reprappro tricolor mendel build! April 25, 2013 08:57AM |

Registered: 11 years ago Posts: 32 |

NewPerfection Wrote:

-------------------------------------------------------

> Looks like you are spitting out too much plastic.

> Have you verified your E steps?

I believe so? I performed the 'tuning your printer' steps described here: [reprappro.com]

It wasn't off by much, it was putting out 102mm of filament instead of 100mm, but I think I have that dialed in now. That said, almost all of the parts in pictures I posted were printed before I did that. The only stuff I've printed since were the Makerbot robots, the thin wall calibration cube and the calibration part that has the part that fits inside of it.

-------------------------------------------------------

> Looks like you are spitting out too much plastic.

> Have you verified your E steps?

I believe so? I performed the 'tuning your printer' steps described here: [reprappro.com]

It wasn't off by much, it was putting out 102mm of filament instead of 100mm, but I think I have that dialed in now. That said, almost all of the parts in pictures I posted were printed before I did that. The only stuff I've printed since were the Makerbot robots, the thin wall calibration cube and the calibration part that has the part that fits inside of it.

|

Re: Reprappro tricolor mendel build! April 25, 2013 03:43PM |

Registered: 11 years ago Posts: 67 |

ajayre Wrote:

-------------------------------------------------------

> I have one. The only flaw I can see is the

> incredibly annoying and tedious bed leveling

> system with three screws. I understand

> over-constraining, etc. but it's a big pain for

> me. I'm tired of doing it and redoing it. Apart

> from that it works well.

>

> Andy

How is 3 points defining a plane over-constraining?

-------------------------------------------------------

> I have one. The only flaw I can see is the

> incredibly annoying and tedious bed leveling

> system with three screws. I understand

> over-constraining, etc. but it's a big pain for

> me. I'm tired of doing it and redoing it. Apart

> from that it works well.

>

> Andy

How is 3 points defining a plane over-constraining?

|

Re: Reprappro tricolor mendel build! April 25, 2013 03:54PM |

Registered: 11 years ago Posts: 172 |

|

Re: Reprappro tricolor mendel build! April 25, 2013 08:15PM |

Registered: 11 years ago Posts: 32 |

Good news, I'm pretty sure that I found my problem: heat.

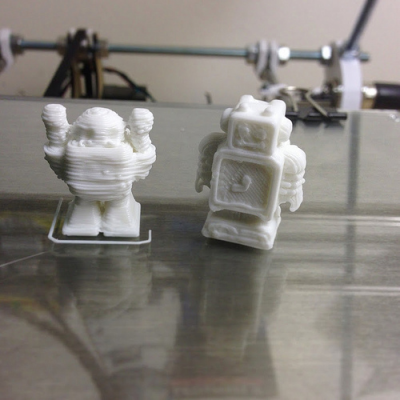

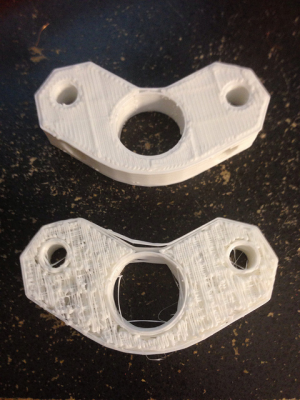

I always notice that my prints are warm (or hot) to the touch when I take them off the bed, while prints that I would take off the makerbot replicator 2 at work would be cool to the touch immediately when printing was completed. I also remembered reading posts about how active cooling could increase the quality of small parts, so I hauled a big fan in front of my Mendel and did a test of cooling on vs. cooling off (.25 layer height, 205 degree hot end, 60 degree bed). The results are pretty obvious:

Untitled by Senior Kabong, on Flickr

The part on the right printed perfectly at 50mm and is of a quality that I'm quite happy with!

I'm kind of surprised that active cooling isn't standard equipment, or at least that there isn't some size 40 font part of the build instructions that mention this. Next step isto install a 40mm fan (http://www.thingiverse.com/thing:75078) and see how that goes.

Assuming this print quality holds up, which I'm hopeful that it will, my last thing to figure out is how to manage spools. I'm currently planning to build one of these: [www.thingiverse.com]. I'm quite open to suggestions if anyone has a more elegant solution.

edit: Finally able to print a decent quality robot, victory!

Untitled by Senior Kabong, on Flickr

Edited 2 time(s). Last edit at 04/25/2013 09:22PM by PierreB.

I always notice that my prints are warm (or hot) to the touch when I take them off the bed, while prints that I would take off the makerbot replicator 2 at work would be cool to the touch immediately when printing was completed. I also remembered reading posts about how active cooling could increase the quality of small parts, so I hauled a big fan in front of my Mendel and did a test of cooling on vs. cooling off (.25 layer height, 205 degree hot end, 60 degree bed). The results are pretty obvious:

Untitled by Senior Kabong, on Flickr

The part on the right printed perfectly at 50mm and is of a quality that I'm quite happy with!

I'm kind of surprised that active cooling isn't standard equipment, or at least that there isn't some size 40 font part of the build instructions that mention this. Next step isto install a 40mm fan (http://www.thingiverse.com/thing:75078) and see how that goes.

Assuming this print quality holds up, which I'm hopeful that it will, my last thing to figure out is how to manage spools. I'm currently planning to build one of these: [www.thingiverse.com]. I'm quite open to suggestions if anyone has a more elegant solution.

edit: Finally able to print a decent quality robot, victory!

Untitled by Senior Kabong, on Flickr

Edited 2 time(s). Last edit at 04/25/2013 09:22PM by PierreB.

|

Re: Reprappro tricolor mendel build! April 25, 2013 09:51PM |

Registered: 11 years ago Posts: 72 |

Great robot print! That's a pretty incredible improvement.

I'm going to echo NewPerfection, here, but it's worth it. The fills on your calibration parts look like there's way too much plastic. The tutorials page on the Tantillus site has a good bit on tuning flow, if you scroll to the bottom (I can't link it - Reprap forums thinks it's a spam link for some reason... But just google "Tantillus Tutorials"). If I were you, I'd bookmark that page for later. At high layer heights and lower infill, a high flow rate doesn't really matter, but at .1 or 100% infill parts, having a perfect flow rate is a lifesaver.

I'm going to echo NewPerfection, here, but it's worth it. The fills on your calibration parts look like there's way too much plastic. The tutorials page on the Tantillus site has a good bit on tuning flow, if you scroll to the bottom (I can't link it - Reprap forums thinks it's a spam link for some reason... But just google "Tantillus Tutorials"). If I were you, I'd bookmark that page for later. At high layer heights and lower infill, a high flow rate doesn't really matter, but at .1 or 100% infill parts, having a perfect flow rate is a lifesaver.

|

Re: Reprappro tricolor mendel build! April 26, 2013 04:54AM |

Registered: 11 years ago Posts: 203 |

Sorry, only registered users may post in this forum.