Prusa Nozzle Released

Posted by akhlut

|

Anonymous User

Re: Prusa Nozzle Released May 17, 2013 09:07PM |

|

Re: Prusa Nozzle Released May 17, 2013 09:22PM |

Admin Registered: 15 years ago Posts: 1,470 |

ohioplastics Wrote:

-------------------------------------------------------

> Why pay $100 when you can pay $25?

> [i.ebayimg.com]

> m-filament-reprap-makerbot-3d-printer-ultimaker-/0

> 0/s/MjUyWDIzNw==/z/ackAAMXQh5JRltJl/$T2eC16R,!w0E9

> szNYg28BRltJk49Qg~~60_3.JPG

> Ebay

Because that hot end most likely does not work with PLA. I bet that hot end transfers a ton of heat up the barrel considering it is using an m6 stainless rod with a 2mm (most likely, since it is for 1.75mm filament) hole. That leaves a lot of material to conduct heat. Plus the barrel is super short, meaning more heat will be conducted into the extruder. Looks aren't everything, but that one looks like crap.

-------------------------------------------------------

> Why pay $100 when you can pay $25?

> [i.ebayimg.com]

> m-filament-reprap-makerbot-3d-printer-ultimaker-/0

> 0/s/MjUyWDIzNw==/z/ackAAMXQh5JRltJl/$T2eC16R,!w0E9

> szNYg28BRltJk49Qg~~60_3.JPG

> Ebay

Because that hot end most likely does not work with PLA. I bet that hot end transfers a ton of heat up the barrel considering it is using an m6 stainless rod with a 2mm (most likely, since it is for 1.75mm filament) hole. That leaves a lot of material to conduct heat. Plus the barrel is super short, meaning more heat will be conducted into the extruder. Looks aren't everything, but that one looks like crap.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Anonymous User

Re: Prusa Nozzle Released May 17, 2013 09:37PM |

I agree, making 3d printing affordable is everything. 3d printers have been overpriced for a long time. It's time somebody took a page out of the Chinese play book and built something economically feasible for the masses. And it extrudes PLA just fine.Quote

newperfection

Looks aren't everything...

|

Re: Prusa Nozzle Released May 17, 2013 10:02PM |

Registered: 11 years ago Posts: 661 |

ohioplastics Wrote:

-------------------------------------------------------

> Why pay $100 when you can pay $25?

Jo is a known quantity that has actively supported the community by releasing his designs. I would have sent the hundred anyway but this way I get a hot end out of the deal. Yours is an interesting, minimalist design. But without seeing it used more or the capability it's still not a difficult choice for me. I know his will work and I know he'll support it. I'm not saying you won't, but I'm not familiar with your work. You seem to be selling on price and I think that's fine for many, particularly in the DIY movement but when one looks at the broader market I wouldn't so easily discount the aesthetic appeal of a product.

Yours is an interesting, minimalist design. But without seeing it used more or the capability it's still not a difficult choice for me. I know his will work and I know he'll support it. I'm not saying you won't, but I'm not familiar with your work. You seem to be selling on price and I think that's fine for many, particularly in the DIY movement but when one looks at the broader market I wouldn't so easily discount the aesthetic appeal of a product.

I'd be interested in seeing what's been printed with that head.

-------------------------------------------------------

> Why pay $100 when you can pay $25?

Jo is a known quantity that has actively supported the community by releasing his designs. I would have sent the hundred anyway but this way I get a hot end out of the deal.

Yours is an interesting, minimalist design. But without seeing it used more or the capability it's still not a difficult choice for me. I know his will work and I know he'll support it. I'm not saying you won't, but I'm not familiar with your work. You seem to be selling on price and I think that's fine for many, particularly in the DIY movement but when one looks at the broader market I wouldn't so easily discount the aesthetic appeal of a product.

Yours is an interesting, minimalist design. But without seeing it used more or the capability it's still not a difficult choice for me. I know his will work and I know he'll support it. I'm not saying you won't, but I'm not familiar with your work. You seem to be selling on price and I think that's fine for many, particularly in the DIY movement but when one looks at the broader market I wouldn't so easily discount the aesthetic appeal of a product. I'd be interested in seeing what's been printed with that head.

|

Re: Prusa Nozzle Released May 18, 2013 07:25AM |

Registered: 11 years ago Posts: 1,592 |

|

Re: Prusa Nozzle Released May 18, 2013 09:38AM |

Registered: 12 years ago Posts: 809 |

So, after 8 hours I wake up to this:

[i.imgur.com]

Well, still printing. Which is a huge plus. I'll share all the changes I've done to get here so you don't have to read the whole thread (but you probably should anyway).

Firmware changes:

I went and dialed back my E axis

#define DEFAULT_MAX_FEEDRATE {500, 500, 50, 60}

#define DEFAULT_MAX_ACCELERATION {9000,9000,10,3000}

#define DEFAULT_RETRACT_ACCELERATION 1000

#define DEFAULT_EJERK 1

Hardware changes:

1.) I insulated the heater block with ceramic tape and that has made a significant difference in the amount of heat radiated.

2.) I pushed the heater block as far down the nozzle as it would go, as you can see here. [i.imgur.com]

3.) Most importantly I turned my heated chamber off. This is kindof a bummer as you can see some warping at the corners of the print I'm running right now.

Slicing changes:

I use slic3r, but the changes should be easy enough to implement in other programs.

1.) I'm running the hotend at 270C for New Image Plastics Natural ABS. Whatever you do I would highly recommend a good flow test at max speed for a given series of temps before you print anything.

2.) Currently I'm using 0.4mm of retraction, which looks pretty good.

3.) Retraction speed is 7mm/s

That's really it.

I didn't change the mounting plate position because I'm afraid of a large gap between the groovemount extruder and the hotend. Maybe I'll print out a new extruder specifically designed for this hotend.

I'll keep you posted.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

[i.imgur.com]

Well, still printing. Which is a huge plus. I'll share all the changes I've done to get here so you don't have to read the whole thread (but you probably should anyway).

Firmware changes:

I went and dialed back my E axis

#define DEFAULT_MAX_FEEDRATE {500, 500, 50, 60}

#define DEFAULT_MAX_ACCELERATION {9000,9000,10,3000}

#define DEFAULT_RETRACT_ACCELERATION 1000

#define DEFAULT_EJERK 1

Hardware changes:

1.) I insulated the heater block with ceramic tape and that has made a significant difference in the amount of heat radiated.

2.) I pushed the heater block as far down the nozzle as it would go, as you can see here. [i.imgur.com]

3.) Most importantly I turned my heated chamber off. This is kindof a bummer as you can see some warping at the corners of the print I'm running right now.

Slicing changes:

I use slic3r, but the changes should be easy enough to implement in other programs.

1.) I'm running the hotend at 270C for New Image Plastics Natural ABS. Whatever you do I would highly recommend a good flow test at max speed for a given series of temps before you print anything.

2.) Currently I'm using 0.4mm of retraction, which looks pretty good.

3.) Retraction speed is 7mm/s

That's really it.

I didn't change the mounting plate position because I'm afraid of a large gap between the groovemount extruder and the hotend. Maybe I'll print out a new extruder specifically designed for this hotend.

I'll keep you posted.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Prusa Nozzle Released May 18, 2013 10:38AM |

Registered: 11 years ago Posts: 273 |

Hi,

quite interresting that you really need 270 for ABS. With my Hotend, (reprapfab V3 All Metal) I can start extruding at 220, and end up printing at 226 at high speeds. How hot can the prusa nozzle go ? When will the Thermo element die ? Also that you had to turn off the chamber looks like you need more cooling on the cold end... I am quite unsure if the all SS way will allow really freedom on temperatures used....

Also the non exchangeable orifice is a drawback from my point of view. Has anyone not only experience with the prusa one, but also the E3d and maybe Magma ? I don't think anyone has tested all those nice al metal hotends ?

quite interresting that you really need 270 for ABS. With my Hotend, (reprapfab V3 All Metal) I can start extruding at 220, and end up printing at 226 at high speeds. How hot can the prusa nozzle go ? When will the Thermo element die ? Also that you had to turn off the chamber looks like you need more cooling on the cold end... I am quite unsure if the all SS way will allow really freedom on temperatures used....

Also the non exchangeable orifice is a drawback from my point of view. Has anyone not only experience with the prusa one, but also the E3d and maybe Magma ? I don't think anyone has tested all those nice al metal hotends ?

|

Re: Prusa Nozzle Released May 18, 2013 11:18AM |

Registered: 13 years ago Posts: 7,616 |

ohioplastics Wrote:

-------------------------------------------------------

> Why pay $100 when you can pay $25?

> ... Ebay

By all means, remove these glass fibers!

Technically, an insulation of the heater block is a clear advantage over those hotends without one, but ...

... have you seen how people talk about Prusa's hotend? "Shiny", "Looks good!", "Clean design!", "Epic!". In this thread it took some 20 posts until somebody started to talk about technical advantages. You see the difference between his and your hotend?

BTW., where's the drawing of yours?

-------------------------------------------------------

> Why pay $100 when you can pay $25?

> ... Ebay

By all means, remove these glass fibers!

Technically, an insulation of the heater block is a clear advantage over those hotends without one, but ...

... have you seen how people talk about Prusa's hotend? "Shiny", "Looks good!", "Clean design!", "Epic!". In this thread it took some 20 posts until somebody started to talk about technical advantages. You see the difference between his and your hotend?

BTW., where's the drawing of yours?

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Anonymous User

Re: Prusa Nozzle Released May 18, 2013 11:33AM |

It's a mk7 hot end. They're on thingiverse. [www.thingiverse.com] It's just not as pretty as theirs.Quote

traumflug

where's the drawing of yours?

|

Re: Prusa Nozzle Released May 19, 2013 02:16PM |

Registered: 10 years ago Posts: 180 |

"That's not at all what he said. ... The point, which you've missed in your responses is that for some the time and effort to build a hot end like this (or even an entire printer) isn't worth it."

No, this is exactly what he said:

"i gotta ask though why on earth would you try and make it? why not just buy one"

There are several reasons one might want to build this. To make. We are makers. To learn. We won't stop that as long as we breathe. To improve. Nothing is perfect. And for some it might be cheaper to spend the time than the money.

If people just go and buy, that would be the end of the revolution because there would be no more evolution.

I do understand that there are people who don't have the time or tools to make a hotend. But that's not what happened. Someone was asking for the plans because he wanted to make one. And was asked why on earth would he want to do that.

On the other hand, it sounds a bit fishy for someone to say this, with a link to a store in his sig where, guess what, he sells metal hotends. There's a fine line between fighting the machine and being the machine.

No, this is exactly what he said:

"i gotta ask though why on earth would you try and make it? why not just buy one"

There are several reasons one might want to build this. To make. We are makers. To learn. We won't stop that as long as we breathe. To improve. Nothing is perfect. And for some it might be cheaper to spend the time than the money.

If people just go and buy, that would be the end of the revolution because there would be no more evolution.

I do understand that there are people who don't have the time or tools to make a hotend. But that's not what happened. Someone was asking for the plans because he wanted to make one. And was asked why on earth would he want to do that.

On the other hand, it sounds a bit fishy for someone to say this, with a link to a store in his sig where, guess what, he sells metal hotends. There's a fine line between fighting the machine and being the machine.

|

Re: Prusa Nozzle Released May 19, 2013 07:52PM |

Admin Registered: 11 years ago Posts: 1,063 |

lajos Wrote:

-------------------------------------------------------

> "That's not at all what he said. ... The point,

> which you've missed in your responses is that for

> some the time and effort to build a hot end like

> this (or even an entire printer) isn't worth it."

>

> No, this is exactly what he said:

>

> "i gotta ask though why on earth would you try and

> make it? why not just buy one"

>

> There are several reasons one might want to build

> this. To make. We are makers. To learn. We won't

> stop that as long as we breathe. To improve.

> Nothing is perfect. And for some it might be

> cheaper to spend the time than the money.

>

> If people just go and buy, that would be the end

> of the revolution because there would be no more

> evolution.

>

> I do understand that there are people who don't

> have the time or tools to make a hotend. But

> that's not what happened. Someone was asking for

> the plans because he wanted to make one. And was

> asked why on earth would he want to do that.

>

> On the other hand, it sounds a bit fishy for

> someone to say this, with a link to a store in his

> sig where, guess what, he sells metal hotends.

> There's a fine line between fighting the machine

> and being the machine.

fishy? ...

some would say yes some would say no, my reasons for why relate more to declaring my position and on anything i say so people know the source and reason of any bias, my descision to put it there was actually triggered from my experience on the up! forums where what was happening was that people were asking questions about the up! before buying one (including me) and all the distrubutors/resellers would pounch on the thread declaring what a wonderful printer it is and there wasn't much of a clue about any commercial bias, as far as i know it still happens today, and it's not until you have one of those printers that you discover the truth behind it and the source of all the good reviews,

i would be more concerned about the hidden agendas of those who don't actively declare their interests in such a way

the interesting part to this whole thread is what Traumflug said,

i asked the question initially out of interest in what drives people to attempt it given that it's the type of job a lot of machine shops would refuse to do,

somthing to bear in mind when buying an opensource product directly from the developer is that you are not nessarily lining pockets but also contributing to the development cost of the product in the first place, and funding further development

here's another question directed at anyone with a cnc capable lathe/mill and (and the copy shops , you know who you are)

if you took and drawings and made one (prusanozzle for example) would you put your tooling to use producing one off and small batches of prototypes to help hotend developers who otherwise have to go to cnc machine shops and meet hefty and expensive MOQ's to get their prototyping done? and do it at material + wear and tear cost?

-------------------------------------------------------

> "That's not at all what he said. ... The point,

> which you've missed in your responses is that for

> some the time and effort to build a hot end like

> this (or even an entire printer) isn't worth it."

>

> No, this is exactly what he said:

>

> "i gotta ask though why on earth would you try and

> make it? why not just buy one"

>

> There are several reasons one might want to build

> this. To make. We are makers. To learn. We won't

> stop that as long as we breathe. To improve.

> Nothing is perfect. And for some it might be

> cheaper to spend the time than the money.

>

> If people just go and buy, that would be the end

> of the revolution because there would be no more

> evolution.

>

> I do understand that there are people who don't

> have the time or tools to make a hotend. But

> that's not what happened. Someone was asking for

> the plans because he wanted to make one. And was

> asked why on earth would he want to do that.

>

> On the other hand, it sounds a bit fishy for

> someone to say this, with a link to a store in his

> sig where, guess what, he sells metal hotends.

> There's a fine line between fighting the machine

> and being the machine.

fishy? ...

some would say yes some would say no, my reasons for why relate more to declaring my position and on anything i say so people know the source and reason of any bias, my descision to put it there was actually triggered from my experience on the up! forums where what was happening was that people were asking questions about the up! before buying one (including me) and all the distrubutors/resellers would pounch on the thread declaring what a wonderful printer it is and there wasn't much of a clue about any commercial bias, as far as i know it still happens today, and it's not until you have one of those printers that you discover the truth behind it and the source of all the good reviews,

i would be more concerned about the hidden agendas of those who don't actively declare their interests in such a way

the interesting part to this whole thread is what Traumflug said,

i asked the question initially out of interest in what drives people to attempt it given that it's the type of job a lot of machine shops would refuse to do,

somthing to bear in mind when buying an opensource product directly from the developer is that you are not nessarily lining pockets but also contributing to the development cost of the product in the first place, and funding further development

here's another question directed at anyone with a cnc capable lathe/mill and (and the copy shops , you know who you are)

if you took and drawings and made one (prusanozzle for example) would you put your tooling to use producing one off and small batches of prototypes to help hotend developers who otherwise have to go to cnc machine shops and meet hefty and expensive MOQ's to get their prototyping done? and do it at material + wear and tear cost?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Prusa Nozzle Released May 19, 2013 11:17PM |

Registered: 11 years ago Posts: 661 |

lajos Wrote:

-------------------------------------------------------

> No, this is exactly what he said:

>

> "i gotta ask though why on earth would you try and

> make it? why not just buy one"

You were asked why you wanted to make one. Fair enough. You responded by saying..

At no point did he suggest you buy a Replicator 2 or even suggest you not build your own hot end. Your response was sensationalistic and exaggerated and had nothing to do with what is being discussed. I think a mature response would be list the reasons you would prefer to make one. Which you did, only after responding in an argumentative and defensive manner as if it were a personal affront to you and your integrity was being challenged.

Any one that has been following the Reprap movement knows all well that JGR has been instrumental in the development of that hot end. It's common knowledge in the community. He certainly needs no defense from a layperson such as I but his contributions are a known quantity and the work in my opinion is of a high caliber. It's commendable that you'd like to keep the movement innovating. Perhaps you could post some your work, particularly on a precision bore with a Dremel and a hardware store drill through 50 mm of stainless steel.

Back to the thread topic, Reprap Discount is backordered on Jo's ends according to what they sent **after** I checked out... Though I don't mind waiting I am looking forward to using all metal hot ends. If it's going to be more than a week I'll likely get a Trinity as well while I'm waiting for the Prusa Nozzle to ship.

-------------------------------------------------------

> No, this is exactly what he said:

>

> "i gotta ask though why on earth would you try and

> make it? why not just buy one"

You were asked why you wanted to make one. Fair enough. You responded by saying..

Quote

lajos

So what you're saying, is stop what I'm doing and just run buy a Replicator2?

At no point did he suggest you buy a Replicator 2 or even suggest you not build your own hot end. Your response was sensationalistic and exaggerated and had nothing to do with what is being discussed. I think a mature response would be list the reasons you would prefer to make one. Which you did, only after responding in an argumentative and defensive manner as if it were a personal affront to you and your integrity was being challenged.

Any one that has been following the Reprap movement knows all well that JGR has been instrumental in the development of that hot end. It's common knowledge in the community. He certainly needs no defense from a layperson such as I but his contributions are a known quantity and the work in my opinion is of a high caliber. It's commendable that you'd like to keep the movement innovating. Perhaps you could post some your work, particularly on a precision bore with a Dremel and a hardware store drill through 50 mm of stainless steel.

Back to the thread topic, Reprap Discount is backordered on Jo's ends according to what they sent **after** I checked out... Though I don't mind waiting I am looking forward to using all metal hot ends. If it's going to be more than a week I'll likely get a Trinity as well while I'm waiting for the Prusa Nozzle to ship.

|

Re: Prusa Nozzle Released May 20, 2013 03:22PM |

Registered: 14 years ago Posts: 38 |

vegasloki Wrote:

> Back to the thread topic, Reprap Discount is

> backordered on Jo's ends according to what they

> sent **after** I checked out... Though I don't

> mind waiting I am looking forward to using all

> metal hot ends. If it's going to be more than a

> week I'll likely get a Trinity as well while I'm

> waiting for the Prusa Nozzle to ship.

All the nozzles they had on backorder should be on the way :-)

> Back to the thread topic, Reprap Discount is

> backordered on Jo's ends according to what they

> sent **after** I checked out... Though I don't

> mind waiting I am looking forward to using all

> metal hot ends. If it's going to be more than a

> week I'll likely get a Trinity as well while I'm

> waiting for the Prusa Nozzle to ship.

All the nozzles they had on backorder should be on the way :-)

|

Re: Prusa Nozzle Released May 20, 2013 08:36PM |

Registered: 11 years ago Posts: 661 |

Thanks Jo. I got something this morning from them and it had been dispatched to FedEx. It was only a couple of days, I wonder if the backorder email auto responder was left over from the pre order period. Regardless, I'll have it in a couple of days.

Edit: Just got it. It's a well crafted piece. Simple but well made and seemingly robust.

Edited 1 time(s). Last edit at 05/22/2013 02:50PM by vegasloki.

Edit: Just got it. It's a well crafted piece. Simple but well made and seemingly robust.

Edited 1 time(s). Last edit at 05/22/2013 02:50PM by vegasloki.

|

Re: Prusa Nozzle Released May 25, 2013 08:06PM |

Registered: 11 years ago Posts: 41 |

i had the same problem w/ reprapdiscount!!! i ordered 2 of the .4 nozzles after i saw jo's post that reprapdiscount bought 50. i went to their website where they said they had available nozzles and ordered 2. i got an email 2 days later saying they were on back order. then i proceeded to raise a little fuss and ask questions. i then went on ebay and found reprapdiscount auctioning off 3 seperate nozzles 2 days apart!! so if they didnt have nozzles why where they auctioning them on ebay? worst part was the auctioned nozzles werent even getting up to their retail price. i guess i raised enough of a fuss to catch someones attention, they overnighted them from hong kong. i got serial number 15 and 18!?!? when they had already told me they sold their original batch of 50!?!?!

|

Re: Prusa Nozzle Released May 26, 2013 02:27PM |

Registered: 11 years ago Posts: 661 |

I doubt they are shipped in order of serial numbers. They're likely pulled from a box of stock and shipped as needed.

I haven't yet installed mine. Both of my extruders are the older, non symmetrical mounting hole style. The feed hole in the extruder isn't equidistant between the mounting plate holes. The mounts for my J heads are slotted on the mounting holes allowing a bit of latitude. I didn't want to modify either the extruder or the nozzle mount. I've got and extruder coming that has a hole pattern that will fit the new nozzle.

I haven't yet installed mine. Both of my extruders are the older, non symmetrical mounting hole style. The feed hole in the extruder isn't equidistant between the mounting plate holes. The mounts for my J heads are slotted on the mounting holes allowing a bit of latitude. I didn't want to modify either the extruder or the nozzle mount. I've got and extruder coming that has a hole pattern that will fit the new nozzle.

|

Re: Prusa Nozzle Released May 27, 2013 07:13PM |

Registered: 11 years ago Posts: 41 |

|

Re: Prusa Nozzle Released May 28, 2013 10:06AM |

Registered: 12 years ago Posts: 809 |

Not really. :/

Jo suggested a fan on the hobbed bolt, which I am going to try. I've also got an alternate solution to keeping the filament and hobbed bolt cool in the works.

Retract is about 1mm at this point. Still playing/refining.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Jo suggested a fan on the hobbed bolt, which I am going to try. I've also got an alternate solution to keeping the filament and hobbed bolt cool in the works.

Retract is about 1mm at this point. Still playing/refining.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Prusa Nozzle Released May 28, 2013 10:34AM |

Registered: 11 years ago Posts: 41 |

still refining also, im getting fairly good small prints at 270C w/ 7mm/s retraction speed and .5 length. i have a fan pointed at the extruder stepper which i moved a little to also cool the hobbed bolt, i think the filament strips were due to extruding at to low a temp. this nozzle definitely doesn't like fast retractions as someone stated earlier. on another note in this thread, i work at a huge machine shop with enough material and machines capable of making this nozzle, but i chose to buy it because of all the R&D that went into it. i like the fact that the nozzle is backed by a person/ company, if you make one and have problems with it, you are the only one that can really help you.

|

Re: Prusa Nozzle Released May 28, 2013 02:21PM |

Registered: 11 years ago Posts: 205 |

I finally got it working nicely and reliably with PLA. But I need a very fast big retract (3 mm @ 20mm/s ), or I get strippings of filament and jams at about the 1 hour mark despite the 2 fans on the hotend.

235°C and very leaky.

Still need works, but the print quality is really very good.

235°C and very leaky.

Still need works, but the print quality is really very good.

|

Re: Prusa Nozzle Released May 28, 2013 07:01PM |

Registered: 11 years ago Posts: 41 |

so yesterday i was getting good .5 mm thin wall boxes. today i cant even get it too extrude consistently. ive tried up to 180C, ive tried all kinds of tightness and looseness on the extruder. im starting to think its the filament, i noticed air bubbles inside of it. im thinking the hobbed bolt hits an air bubble and collapses the filament then eats into it. im waiting on new ABS from Lulzbot. im also going to try upping the retract length and speed to those settings and see if that helps....

|

Re: Prusa Nozzle Released May 29, 2013 01:56AM |

Registered: 11 years ago Posts: 661 |

I was able to run a couple of prints today. Until it jammed. I used the included fan. I appreciate all the pointers in this thread so I didn't have to reinvent the wheel.

What I was able to print turned out fine. I did the tweaks to the firmware and temp settings from the thread. Mounting while not difficult does not offer flexibility for legacy type extruders particularly J Head mounts. The depth of the J Head mount inside the extruder is enough so that filament can not be loaded. There is too great a distance between the nozzle and where the material exits the extruder. I noticed this when I first got it and hoped there wouldn't be an issue. It is. I had to unscrew the nozzle from the mounting plate to load the filament. This can be easily retrofitted for those with J Head sized counter bores in the extruder bottom (which I would guess is a pretty substantial amount). A printed ABS plug could be used as a stop gap measure until one gets an extruder designed to work better with this hot end. You just need something to guide the 10mm or so between the two.

The ease at which it jammed is a concern. With the mounting incompatibility in the previous post and the work around to even load material jamming after a few prints has soured me to the part a little bit. The jamming I could expect as part of the tuning but not being able to mount it to a legacy extruder (and by legacy I mean older than a few months...) and have to remove the nozzle from the mounting plate is a design issue. All metal hot ends are still in development and I understand that but not being able to mount and feed it with minimal effort is something I think that needs to be addressed if the part is to be used as a retro fit for older systems. At least at this point we can get the info out there so people will know that they might not be able to mount (the asymmetrical hole issue) or that the bore for the J Head isn't optimal and at least a new extruder can be considered. That's the easiest, just replace that part of the extruder with something more compatible. And not too much more money than that ABS plug I mentioned.

The good...

Top quality workmanship and materials. Good attention to detail in the manufacturing. The small profile of the nozzle end is great as it has no ends to catch the print like on my J Heads. The extrusion consistency is good. The wiring connections are nice and robust and the heater and thermistor appear to be excellent quality. When it was printing it printed very well.

Dave

What I was able to print turned out fine. I did the tweaks to the firmware and temp settings from the thread. Mounting while not difficult does not offer flexibility for legacy type extruders particularly J Head mounts. The depth of the J Head mount inside the extruder is enough so that filament can not be loaded. There is too great a distance between the nozzle and where the material exits the extruder. I noticed this when I first got it and hoped there wouldn't be an issue. It is. I had to unscrew the nozzle from the mounting plate to load the filament. This can be easily retrofitted for those with J Head sized counter bores in the extruder bottom (which I would guess is a pretty substantial amount). A printed ABS plug could be used as a stop gap measure until one gets an extruder designed to work better with this hot end. You just need something to guide the 10mm or so between the two.

The ease at which it jammed is a concern. With the mounting incompatibility in the previous post and the work around to even load material jamming after a few prints has soured me to the part a little bit. The jamming I could expect as part of the tuning but not being able to mount it to a legacy extruder (and by legacy I mean older than a few months...) and have to remove the nozzle from the mounting plate is a design issue. All metal hot ends are still in development and I understand that but not being able to mount and feed it with minimal effort is something I think that needs to be addressed if the part is to be used as a retro fit for older systems. At least at this point we can get the info out there so people will know that they might not be able to mount (the asymmetrical hole issue) or that the bore for the J Head isn't optimal and at least a new extruder can be considered. That's the easiest, just replace that part of the extruder with something more compatible. And not too much more money than that ABS plug I mentioned.

The good...

Top quality workmanship and materials. Good attention to detail in the manufacturing. The small profile of the nozzle end is great as it has no ends to catch the print like on my J Heads. The extrusion consistency is good. The wiring connections are nice and robust and the heater and thermistor appear to be excellent quality. When it was printing it printed very well.

Dave

|

Re: Prusa Nozzle Released May 29, 2013 05:20AM |

Registered: 11 years ago Posts: 118 |

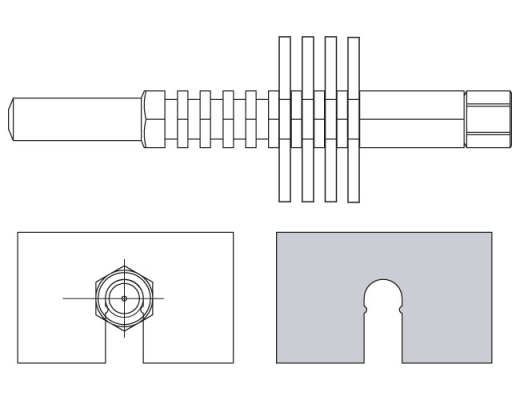

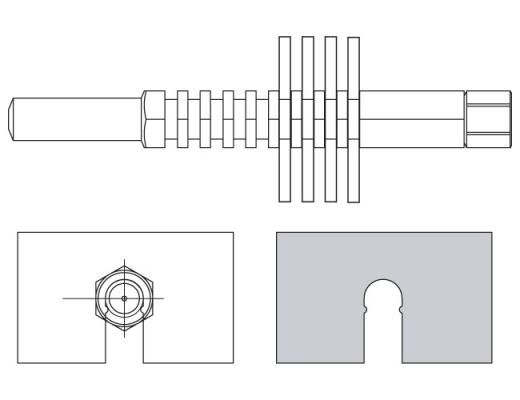

ive read a lot about this hotend,

but some of the problems sound like they have trouble

getting the heat away.

i thought about Fins, which could be easily produced and clamped like that:

with thermal grease and a 20-25mm fan it should be a very effective cooler...

also i was curious if there will be a 1.75mm version of it...

ps: it would be nice if Prusa would add usable 3D Files,

this drawing just sucks.

Edited 3 time(s). Last edit at 05/29/2013 07:55AM by mrc.

but some of the problems sound like they have trouble

getting the heat away.

i thought about Fins, which could be easily produced and clamped like that:

with thermal grease and a 20-25mm fan it should be a very effective cooler...

also i was curious if there will be a 1.75mm version of it...

ps: it would be nice if Prusa would add usable 3D Files,

this drawing just sucks.

Edited 3 time(s). Last edit at 05/29/2013 07:55AM by mrc.

|

Re: Prusa Nozzle Released May 29, 2013 05:35AM |

Admin Registered: 11 years ago Posts: 1,063 |

you'll find the thermal barrier is very effective and there's probably very little heat getting to the top, it's the pla that conducting heat upwards,

mrc Wrote:

-------------------------------------------------------

> ive read a lot about this hotend,

> but some of the problems sound like they have

> trouble

> getting the heat away.

>

> i thought about Fins, which could be easily

> produced and clamped like that:

>

> [forums.reprap.org]

> ename=prusacooler.jpg

> with thermal grease and a 20-25mm fan it should be

> a very effective cooler...

>

> also i was curious if there will be a 1.75mm

> version of it...

>

> ps: it would be nice if Pursa would add usable 3D

> Files,

> this drawing just sucks.

mrc Wrote:

-------------------------------------------------------

> ive read a lot about this hotend,

> but some of the problems sound like they have

> trouble

> getting the heat away.

>

> i thought about Fins, which could be easily

> produced and clamped like that:

>

> [forums.reprap.org]

> ename=prusacooler.jpg

> with thermal grease and a 20-25mm fan it should be

> a very effective cooler...

>

> also i was curious if there will be a 1.75mm

> version of it...

>

> ps: it would be nice if Pursa would add usable 3D

> Files,

> this drawing just sucks.

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Prusa Nozzle Released May 29, 2013 05:45AM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Prusa Nozzle Released May 29, 2013 05:51AM |

Admin Registered: 11 years ago Posts: 1,063 |

nophead Wrote:

-------------------------------------------------------

> PLA is two orders of magnitude less conductive

> than stainless steel.

yes very true however the fan blowing air across it wicking every little bit of heat off it mitigates that, the pla on the inside is doesn't have that luxury

-------------------------------------------------------

> PLA is two orders of magnitude less conductive

> than stainless steel.

yes very true however the fan blowing air across it wicking every little bit of heat off it mitigates that, the pla on the inside is doesn't have that luxury

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Prusa Nozzle Released May 29, 2013 06:12AM |

Admin Registered: 17 years ago Posts: 7,879 |

But with a shorter PEEK / PTFE J-Head I can extrude PLA without a fan (although that is a bit marginal since it got shortened from MK4 to Mk5).

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Prusa Nozzle Released May 29, 2013 06:32AM |

Admin Registered: 11 years ago Posts: 1,063 |

nophead Wrote:

-------------------------------------------------------

> But with a shorter PEEK / PTFE J-Head I can

> extrude PLA without a fan (although that is a bit

> marginal since it got shortened from MK4 to Mk5).

but that jhead has a ptfe liner inside it, the extrusion force in a jhead/ptfe lined hotend isn't a linear melt-length/pushing -resistance

-------------------------------------------------------

> But with a shorter PEEK / PTFE J-Head I can

> extrude PLA without a fan (although that is a bit

> marginal since it got shortened from MK4 to Mk5).

but that jhead has a ptfe liner inside it, the extrusion force in a jhead/ptfe lined hotend isn't a linear melt-length/pushing -resistance

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Prusa Nozzle Released May 29, 2013 06:36AM |

Registered: 12 years ago Posts: 972 |

|

Re: Prusa Nozzle Released May 29, 2013 10:04AM |

Registered: 11 years ago Posts: 41 |

i still cant get it to consistently extrude in manual control, even pushing the filament hard by hand into it(helping it), it always strips the filament. ive completely disassembled the extruder and cleaned it. ive tried very loose to very tight on the extruder spring also. ive tried temps from 250-290. ive triple checked the alignment of the extruder to the nozzle also.

Backtracking-

when i first got the new nozzle i did about 4 test hollow pyramids and got the stringers and blobbage under control. i felt good about it so my 5th print was a full print, i printed the x idler end for my i3 gantry at 250C. after 1 hour 45 it came out extremely well!! i cooled the whole machine down as a reward for the long successful print. next i tried to print an extruder gear and it stripped filament so i let it cool. now that i think of it, the nozzle hasn't performed right since this initial jam. ive been manually extruding at 270C since the initial jam also( up 20C from my initial successful long print's temp).

i agree with vegasloki, the easy tendency of jamming bothers me. filament feels very rough inside of the shaft. on a good note i also agree that when it was printing it printed well!! im going back to the budaschnozzle briefly to make sure its not the extruder and im waiting for new ABS.

Backtracking-

when i first got the new nozzle i did about 4 test hollow pyramids and got the stringers and blobbage under control. i felt good about it so my 5th print was a full print, i printed the x idler end for my i3 gantry at 250C. after 1 hour 45 it came out extremely well!! i cooled the whole machine down as a reward for the long successful print. next i tried to print an extruder gear and it stripped filament so i let it cool. now that i think of it, the nozzle hasn't performed right since this initial jam. ive been manually extruding at 270C since the initial jam also( up 20C from my initial successful long print's temp).

i agree with vegasloki, the easy tendency of jamming bothers me. filament feels very rough inside of the shaft. on a good note i also agree that when it was printing it printed well!! im going back to the budaschnozzle briefly to make sure its not the extruder and im waiting for new ABS.

Sorry, only registered users may post in this forum.