Prusa Nozzle Released

Posted by akhlut

|

Re: Prusa Nozzle Released June 07, 2013 01:36AM |

vegasloki Wrote:

-------------------------------------------------------

> elgambitero Wrote:

> --------------------------------------------------

> -----

> > Anyway, it gets solved with a good cooling

> system.

> > When I get my prusanozzle, I'm planning to make

> a

> > carriage with the prusanozzle(s) raised and

> inside

> > a cooled case, so the cool air impacts directly

> on

> > the tubing. (Also, the fan will be needed to

> > prevent the carriage from melting).

>

>

> Even with two fans it won't cool PLA enough on the

> test i2 so that it can print reliably over time.

That's a very valuable testimony. I was pretending to make the coolers be very close to the tubing, but seems like it will be no easy task.

May it go with 4 coolers? (2 at the entrance, 2 at the exit of the case)

-------------------------------------------------------

> elgambitero Wrote:

> --------------------------------------------------

> -----

> > Anyway, it gets solved with a good cooling

> system.

> > When I get my prusanozzle, I'm planning to make

> a

> > carriage with the prusanozzle(s) raised and

> inside

> > a cooled case, so the cool air impacts directly

> on

> > the tubing. (Also, the fan will be needed to

> > prevent the carriage from melting).

>

>

> Even with two fans it won't cool PLA enough on the

> test i2 so that it can print reliably over time.

That's a very valuable testimony. I was pretending to make the coolers be very close to the tubing, but seems like it will be no easy task.

May it go with 4 coolers? (2 at the entrance, 2 at the exit of the case)

|

Re: Prusa Nozzle Released June 07, 2013 02:29AM |

Registered: 11 years ago Posts: 514 |

|

Re: Prusa Nozzle Released June 07, 2013 08:13AM |

Registered: 11 years ago Posts: 374 |

elgambitero Wrote:

> I was pretending to make the coolers be very close to the tubing,

> but seems like it will be no easy task.

As reference to solve your point: In my design, I've used a aluminum heatsink. I've put the core stainless steel bar into a heatsink, and then, if is needed you could add a fan. See [reprap.org].

> I was pretending to make the coolers be very close to the tubing,

> but seems like it will be no easy task.

As reference to solve your point: In my design, I've used a aluminum heatsink. I've put the core stainless steel bar into a heatsink, and then, if is needed you could add a fan. See [reprap.org].

|

Re: Prusa Nozzle Released June 07, 2013 08:18AM |

Registered: 11 years ago Posts: 41 |

|

Re: Prusa Nozzle Released June 07, 2013 08:59AM |

Registered: 12 years ago Posts: 809 |

I'm actually working on a different solution. I've got a couple of peltier elements and I'm making a filament chiller. Basically, it's a miniature fridge that the filament passes into and then out of through an attached tube. The tube then passes into the heated chamber and finally meets the top of the extruder. I've got a massive air pump from an old pond attached, so there should be plenty of air to cool and insulate the filament from the heat. Who knows, maybe I'll make a cowling the fits over the entire extruder.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Prusa Nozzle Released June 07, 2013 01:42PM |

jameghino Wrote:

-------------------------------------------------------

> As reference to solve your point: In my design,

> I've used a aluminum heatsink. I've put the core

> stainless steel bar into a heatsink, and then, if

> is needed you could add a fan. See

> [reprap.org].

Looks nice! The fan is as close to the tubing as I imagined for my carriage. How does it work with PLA?

-------------------------------------------------------

> As reference to solve your point: In my design,

> I've used a aluminum heatsink. I've put the core

> stainless steel bar into a heatsink, and then, if

> is needed you could add a fan. See

> [reprap.org].

Looks nice! The fan is as close to the tubing as I imagined for my carriage. How does it work with PLA?

|

Re: Prusa Nozzle Released June 07, 2013 09:21PM |

Registered: 12 years ago Posts: 177 |

JollyGrimReaper

I have my own little CNC lathe, Boxford 250 - but it's just used for prototyping/development/customising hotends for certain peoples needs. We then outsource to a UK based CNC shop for manufacture of all the production units.

Vegasloki

We the gap between the heatsink and the hotside is only a touch over 2mm in the E3Dv4, with the thermal gradient this means that in practice the area where filament is in the "twilight zone" of not solid, not liquid, but a sticky rubbery consistency is around 1mm.

Maddox

The parts are now all with the affected guys, hopefully hear back from them soon!

Totally agree about maintaining consistent condition around temperatures and location of various temperature zones. With these long prusa nozzles the length of the melt zone will actually move around quite a lot, it also seems you can move the position of the heater block, which could also affect things. I suppose this might be good for high speed printing but I'm not sure what it's going to be like from a precision or oozing perspective. I do intuitively like the whole "one piece" thing though.

3ntrlab

I really want to get a hold of some PEEK filament to print. Can't even get the chinese extrusion companies to make me some unless I order tonnes of it. I think I might buy some stratasys Ultem (Which is a similar polymer to peek) which should come in filament form. Anyone know what diameter stratasys machines filament is?

Possible way of getting prusa nozzles working?

I know it's a bit kludgy, but if you are having issues with a prusa nozzle you could stick a few self adhesive heatsinks to it along with a fan, I bet that would stabilise and confine temps enough to get it printing. RAM heatsinks might be a good size to stick to the hexagonal flats on the prusa nozzle?

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

I have my own little CNC lathe, Boxford 250 - but it's just used for prototyping/development/customising hotends for certain peoples needs. We then outsource to a UK based CNC shop for manufacture of all the production units.

Vegasloki

We the gap between the heatsink and the hotside is only a touch over 2mm in the E3Dv4, with the thermal gradient this means that in practice the area where filament is in the "twilight zone" of not solid, not liquid, but a sticky rubbery consistency is around 1mm.

Maddox

The parts are now all with the affected guys, hopefully hear back from them soon!

Totally agree about maintaining consistent condition around temperatures and location of various temperature zones. With these long prusa nozzles the length of the melt zone will actually move around quite a lot, it also seems you can move the position of the heater block, which could also affect things. I suppose this might be good for high speed printing but I'm not sure what it's going to be like from a precision or oozing perspective. I do intuitively like the whole "one piece" thing though.

3ntrlab

I really want to get a hold of some PEEK filament to print. Can't even get the chinese extrusion companies to make me some unless I order tonnes of it. I think I might buy some stratasys Ultem (Which is a similar polymer to peek) which should come in filament form. Anyone know what diameter stratasys machines filament is?

Possible way of getting prusa nozzles working?

I know it's a bit kludgy, but if you are having issues with a prusa nozzle you could stick a few self adhesive heatsinks to it along with a fan, I bet that would stabilise and confine temps enough to get it printing. RAM heatsinks might be a good size to stick to the hexagonal flats on the prusa nozzle?

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

|

Re: Prusa Nozzle Released June 08, 2013 08:35AM |

Registered: 11 years ago Posts: 490 |

@SanjayM: Some guys I know have brought two Stratasys cartridges to our workshop (in order to disassemble them  ). Just measured the filament size to vary between 1.71 and 1.75mm, so you are in luck. The filament may be from an older machine, though, as the manufacturing date of the cartridge is December 2011. Hope they didn't change anything about the filament itself.

). Just measured the filament size to vary between 1.71 and 1.75mm, so you are in luck. The filament may be from an older machine, though, as the manufacturing date of the cartridge is December 2011. Hope they didn't change anything about the filament itself.

). Just measured the filament size to vary between 1.71 and 1.75mm, so you are in luck. The filament may be from an older machine, though, as the manufacturing date of the cartridge is December 2011. Hope they didn't change anything about the filament itself.

). Just measured the filament size to vary between 1.71 and 1.75mm, so you are in luck. The filament may be from an older machine, though, as the manufacturing date of the cartridge is December 2011. Hope they didn't change anything about the filament itself.

|

Re: Prusa Nozzle Released June 08, 2013 09:09AM |

Registered: 11 years ago Posts: 67 |

That Stratasys Ultem is a Sabic resin, and I might try to get my hands on some to extrude into filament myself. I heard some pretty crazy numbers about the machine when they print the Ultem though, something like extruding at 300 C and they have the heated chamber above 100 C IIRC.

Edited 1 time(s). Last edit at 06/08/2013 09:10AM by maddox.

Edited 1 time(s). Last edit at 06/08/2013 09:10AM by maddox.

|

Re: Prusa Nozzle Released June 08, 2013 11:17AM |

Registered: 11 years ago Posts: 67 |

akhlut Wrote:

-------------------------------------------------------

> I'm actually working on a different solution.

> I've got a couple of peltier elements and I'm

> making a filament chiller. Basically, it's a

> miniature fridge that the filament passes into and

> then out of through an attached tube. The tube

> then passes into the heated chamber and finally

> meets the top of the extruder. I've got a massive

> air pump from an old pond attached, so there

> should be plenty of air to cool and insulate the

> filament from the heat. Who knows, maybe I'll

> make a cowling the fits over the entire extruder.

I'm looking into using peltier elements for a different application, where are you getting your hardware from?

-------------------------------------------------------

> I'm actually working on a different solution.

> I've got a couple of peltier elements and I'm

> making a filament chiller. Basically, it's a

> miniature fridge that the filament passes into and

> then out of through an attached tube. The tube

> then passes into the heated chamber and finally

> meets the top of the extruder. I've got a massive

> air pump from an old pond attached, so there

> should be plenty of air to cool and insulate the

> filament from the heat. Who knows, maybe I'll

> make a cowling the fits over the entire extruder.

I'm looking into using peltier elements for a different application, where are you getting your hardware from?

|

Re: Prusa Nozzle Released June 08, 2013 11:24AM |

Registered: 12 years ago Posts: 809 |

|

Re: Prusa Nozzle Released June 08, 2013 10:52PM |

Registered: 11 years ago Posts: 374 |

elgambitero Wrote:

-------------------------------------------------------

> jameghino Wrote:

> --------------------------------------------------

> -----

>

> > As reference to solve your point: In my design,

> > I've used a aluminum heatsink. I've put the

> core

> > stainless steel bar into a heatsink, and then,

> if

> > is needed you could add a fan. See

> > [reprap.org].

>

>

> Looks nice! The fan is as close to the tubing as I

> imagined for my carriage. How does it work with

> PLA?

I'm testing it, but some PLA filament jam has been appeared. I'm need some advise to polish the stainless steel 2mm hole because I think this is the big problem

-------------------------------------------------------

> jameghino Wrote:

> --------------------------------------------------

> -----

>

> > As reference to solve your point: In my design,

> > I've used a aluminum heatsink. I've put the

> core

> > stainless steel bar into a heatsink, and then,

> if

> > is needed you could add a fan. See

> > [reprap.org].

>

>

> Looks nice! The fan is as close to the tubing as I

> imagined for my carriage. How does it work with

> PLA?

I'm testing it, but some PLA filament jam has been appeared. I'm need some advise to polish the stainless steel 2mm hole because I think this is the big problem

|

Re: Prusa Nozzle Released June 09, 2013 04:16AM |

Registered: 12 years ago Posts: 1,236 |

|

Re: Prusa Nozzle Released June 09, 2013 04:28AM |

Registered: 12 years ago Posts: 972 |

I have just done my first few hours of testing with 0.4mm prusanozzle and white ABS. Any temp below 270C did not work for me. At 290-300C I get a good plastic flow with no smoke. But every restart seems to be tricky. I mean that once I end one part, let everything cool down and repeat the cycle, I may or may not get extrusion again. If not, it is because the extruder ate the filament (maybe I should wait longer since the desired temp is reached [to make sure the filament is hot enough]).

It seems the learning curve here is steeper that with other nozzles.

Things I love is that nozzle comes pre-wired, with Dupont socket for thermistor wires and with a silent fan included.

Speed-wise it seems to be doing well up to 80mm/s, but I would like to hear from other users about that (please note this is just a first impression).

It seems the learning curve here is steeper that with other nozzles.

Things I love is that nozzle comes pre-wired, with Dupont socket for thermistor wires and with a silent fan included.

Speed-wise it seems to be doing well up to 80mm/s, but I would like to hear from other users about that (please note this is just a first impression).

|

elgambitero

Re: Prusa Nozzle Released June 09, 2013 05:02AM |

bobc Wrote:

-------------------------------------------------------

> I must admit, I am puzzled why people are trying

> to print PLA with this nozzle. It's like buying a

> Ferrari then using it to pick up the weekly

> shopping.

>

> It's advantages are not related to printing with

> PLA. If you already have a nozzle good for PLA,

> why would you change it?

Because we want a nozzle to print in everything. I use a lot of materials, I don't want to change the nozzle every time i change materials

-------------------------------------------------------

> I must admit, I am puzzled why people are trying

> to print PLA with this nozzle. It's like buying a

> Ferrari then using it to pick up the weekly

> shopping.

>

> It's advantages are not related to printing with

> PLA. If you already have a nozzle good for PLA,

> why would you change it?

Because we want a nozzle to print in everything. I use a lot of materials, I don't want to change the nozzle every time i change materials

|

Re: Prusa Nozzle Released June 09, 2013 08:50AM |

Registered: 11 years ago Posts: 118 |

bobc Wrote:

-------------------------------------------------------

> I must admit, I am puzzled why people are trying

> to print PLA with this nozzle. It's like buying a

> Ferrari then using it to pick up the weekly

> shopping.

>

> It's advantages are not related to printing with

> PLA. If you already have a nozzle good for PLA,

> why would you change it?

Printing ABS is easy, printing PLA is the real challange.

If this is not possible why should i pay 70$?

-------------------------------------------------------

> I must admit, I am puzzled why people are trying

> to print PLA with this nozzle. It's like buying a

> Ferrari then using it to pick up the weekly

> shopping.

>

> It's advantages are not related to printing with

> PLA. If you already have a nozzle good for PLA,

> why would you change it?

Printing ABS is easy, printing PLA is the real challange.

If this is not possible why should i pay 70$?

|

Re: Prusa Nozzle Released June 09, 2013 01:04PM |

Registered: 11 years ago Posts: 374 |

|

elgambitero

Re: Prusa Nozzle Released June 09, 2013 03:10PM |

misan Wrote:

-------------------------------------------------------

> I have just done my first few hours of testing

> with 0.4mm prusanozzle and white ABS. Any temp

> below 270C did not work for me. At 290-300C I get

> a good plastic flow with no smoke. But every

> restart seems to be tricky. I mean that once I end

> one part, let everything cool down and repeat the

> cycle, I may or may not get extrusion again. If

> not, it is because the extruder ate the filament

> (maybe I should wait longer since the desired temp

> is reached ).

>

> It seems the learning curve here is steeper that

> with other nozzles.

>

> Things I love is that nozzle comes pre-wired, with

> Dupont socket for thermistor wires and with a

> silent fan included.

>

> Speed-wise it seems to be doing well up to 80mm/s,

> but I would like to hear from other users about

> that (please note this is just a first

> impression).

I can only imagine, but could it be that the temperature lasts too long to reach the center of the tube, so when you get the cartridge to 240 ºC, the interior may be at 190º C yet?

Maybe some waiting or some initial overheating may solve the problem.

I'm thinking of something like: "preheating at 280ºC for 10 minutes an then print at 240ºC".

Also, I have a question: ¿Do you have the cartridge at the very tip of the nozzle, or a bit higher?

-------------------------------------------------------

> I have just done my first few hours of testing

> with 0.4mm prusanozzle and white ABS. Any temp

> below 270C did not work for me. At 290-300C I get

> a good plastic flow with no smoke. But every

> restart seems to be tricky. I mean that once I end

> one part, let everything cool down and repeat the

> cycle, I may or may not get extrusion again. If

> not, it is because the extruder ate the filament

> (maybe I should wait longer since the desired temp

> is reached ).

>

> It seems the learning curve here is steeper that

> with other nozzles.

>

> Things I love is that nozzle comes pre-wired, with

> Dupont socket for thermistor wires and with a

> silent fan included.

>

> Speed-wise it seems to be doing well up to 80mm/s,

> but I would like to hear from other users about

> that (please note this is just a first

> impression).

I can only imagine, but could it be that the temperature lasts too long to reach the center of the tube, so when you get the cartridge to 240 ºC, the interior may be at 190º C yet?

Maybe some waiting or some initial overheating may solve the problem.

I'm thinking of something like: "preheating at 280ºC for 10 minutes an then print at 240ºC".

Also, I have a question: ¿Do you have the cartridge at the very tip of the nozzle, or a bit higher?

|

Re: Prusa Nozzle Released June 09, 2013 03:23PM |

Registered: 12 years ago Posts: 972 |

Quote

I can only imagine, but could it be that the temperature lasts too long to reach the center of the tube, so when you get the cartridge to 240 ºC, the interior may be at 190º C yet?

Maybe some waiting or some initial overheating may solve the problem.

I'm thinking of something like: "preheating at 280ºC for 10 minutes an then print at 240ºC".

Also, I have a question: ¿Do you have the cartridge at the very tip of the nozzle, or a bit higher?

My tests show that waiting one extra minute will help the filament to reach extruding temperature.

But I cannot reduce the set temperature below 270C if I want extrusion to keep on working.

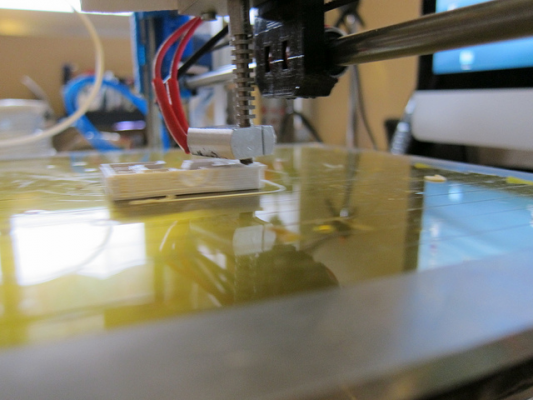

I have the cartridge almost at the top of the way. It can be seen here:

|

Re: Prusa Nozzle Released June 10, 2013 02:44AM |

Registered: 11 years ago Posts: 248 |

|

Re: Prusa Nozzle Released June 10, 2013 02:48AM |

Registered: 12 years ago Posts: 972 |

I guess this and the corresponding scad in the same repo may help you: [github.com]

You can see the picture of the inside too: [twitter.com]

You can see the picture of the inside too: [twitter.com]

|

Re: Prusa Nozzle Released June 10, 2013 03:00AM |

Registered: 11 years ago Posts: 544 |

|

Re: Prusa Nozzle Released June 10, 2013 06:23AM |

Registered: 11 years ago Posts: 661 |

elgambitero Wrote:

-------------------------------------------------------

> Because we want a nozzle to print in everything. I

> use a lot of materials, I don't want to change the

> nozzle every time i change materials

As materials get more esoteric and require higher temps it may not be possible to use a single nozzle, at least with current technology. It's the same thing with machine tools, one set of tooling isn't appropriate for all materials or applications. A mechanism to quickly change the nozzle I think is a more appropriate technology than trying to print all material and temp ranges with a single tool. The current limitation of nozzles only working with a single size filament is also a good reason to have quick change tooling. For the i2 or horizontal mount extruders there have been quick change extruders but I think taking it a step further and keeping the extruder but changing the hot end could be beneficial for users that print more than one material or diameter with a single printer.

-------------------------------------------------------

> Because we want a nozzle to print in everything. I

> use a lot of materials, I don't want to change the

> nozzle every time i change materials

As materials get more esoteric and require higher temps it may not be possible to use a single nozzle, at least with current technology. It's the same thing with machine tools, one set of tooling isn't appropriate for all materials or applications. A mechanism to quickly change the nozzle I think is a more appropriate technology than trying to print all material and temp ranges with a single tool. The current limitation of nozzles only working with a single size filament is also a good reason to have quick change tooling. For the i2 or horizontal mount extruders there have been quick change extruders but I think taking it a step further and keeping the extruder but changing the hot end could be beneficial for users that print more than one material or diameter with a single printer.

|

Re: Prusa Nozzle Released June 10, 2013 06:31AM |

Registered: 11 years ago Posts: 661 |

woo Wrote:

-------------------------------------------------------

> still no drawings of nozzle...and its claimed to

> be open source?

Prusa has rudimentary drawings and has publicly provided enough info for someone to make one if they wish. He has stated he's not good enough at drawing to do a proper drawing. If anyone is miffed there are no comprehensive drawings and are versed in CAD, offer to make him a set of drawings.

As said above, this sort of fabrication can't be done by most. Those that have the ability, expertise and access to the equipment could build one with everything that has been made public. Many of those people though have their own designs.

-------------------------------------------------------

> still no drawings of nozzle...and its claimed to

> be open source?

Prusa has rudimentary drawings and has publicly provided enough info for someone to make one if they wish. He has stated he's not good enough at drawing to do a proper drawing. If anyone is miffed there are no comprehensive drawings and are versed in CAD, offer to make him a set of drawings.

As said above, this sort of fabrication can't be done by most. Those that have the ability, expertise and access to the equipment could build one with everything that has been made public. Many of those people though have their own designs.

|

Re: Prusa Nozzle Released June 10, 2013 07:52AM |

Registered: 11 years ago Posts: 248 |

I didnt search cad on github, just checked prusanozzle page,thank you.

i will try to make one once i finish my first repstrap.

vegasloki:

in this case we have 2 things:

i quote you:

ability, expertise and access to the equipment. for example i have acess to lathe(manual) and my best mate works in other company on cnc lathe, so lets say thats not a problem.

other thing is knowledge about nozzles, wich often requires learning from mistakes,a lot of reading and learning. these guys have made a lot of nozzles to get it work right.

so , in my case not enough knowledge, time, or will to sit hours and learn how stuff works, because i have few another projects wich i am working on

i will try to make one once i finish my first repstrap.

vegasloki:

in this case we have 2 things:

i quote you:

ability, expertise and access to the equipment. for example i have acess to lathe(manual) and my best mate works in other company on cnc lathe, so lets say thats not a problem.

other thing is knowledge about nozzles, wich often requires learning from mistakes,a lot of reading and learning. these guys have made a lot of nozzles to get it work right.

so , in my case not enough knowledge, time, or will to sit hours and learn how stuff works, because i have few another projects wich i am working on

|

Re: Prusa Nozzle Released June 12, 2013 02:39AM |

Registered: 10 years ago Posts: 28 |

|

Re: Prusa Nozzle Released June 12, 2013 02:53AM |

Registered: 11 years ago Posts: 544 |

|

Re: Prusa Nozzle Released June 12, 2013 02:59AM |

Registered: 12 years ago Posts: 972 |

PLA expands with the heat, this feature makes PLA more tricky. PFTE tubing function is to ease filament motion down the tube. PLA will stick to PFTE if too hot.

Inner tube lapping does a similar job than PFTE (or so I think).

Many extruders require a cooling fan to get consistent results with PLA, this one too.

Inner tube lapping does a similar job than PFTE (or so I think).

Many extruders require a cooling fan to get consistent results with PLA, this one too.

|

Re: Prusa Nozzle Released June 12, 2013 02:25PM |

Registered: 11 years ago Posts: 661 |

The cooling issues also have to do with the carriage design and where the nozzle is mounted. On an i2 with the nozzle under the extruder but within the carriage there is a heat trap. Moving the nozzle below the carriage yields a noticeable improvement in results with PLA. PLA can be printed but at this point I would suggest to one using primarily PLA that there are better solutions. OTOH, if one is printing a mix of materials or primarily materials that require hotter melting points this part is suitable and appropriate. I intend to try it once more with PLA on an i3 I'm just commissioning to see what difference the carriage mounting assembly has compared to the i2. Using the X carriage on the i3 appears to me to be designed in such a way there is no possibility of a heat pocket making it easier to consistently cool.

|

Re: Prusa Nozzle Released June 13, 2013 01:36AM |

Registered: 11 years ago Posts: 334 |

Sorry, only registered users may post in this forum.