Cheap, Low Vitamin Count Single Rail Linear Guide

Posted by uGen

|

Cheap, Low Vitamin Count Single Rail Linear Guide May 08, 2013 08:54AM |

Registered: 11 years ago Posts: 490 |

Some of you might remember my experiments with UHMW-PE bushings, trying to create an easy DIY solution, but there was still one problem: they are not printable and still require smooth rods.

Well, that was before I got my hands on the Taulman 618 filament. While researching different materials for plastic bushings, it became apparent that Polyamide is also a viable material since it is wear resistant and slippery. However, what makes it interesting in addition to availability as filament is that it requires a rougher surface than UHMW-PE for it to exhibit ideal characteristics. This in turn means that we can use guides of lower quality.

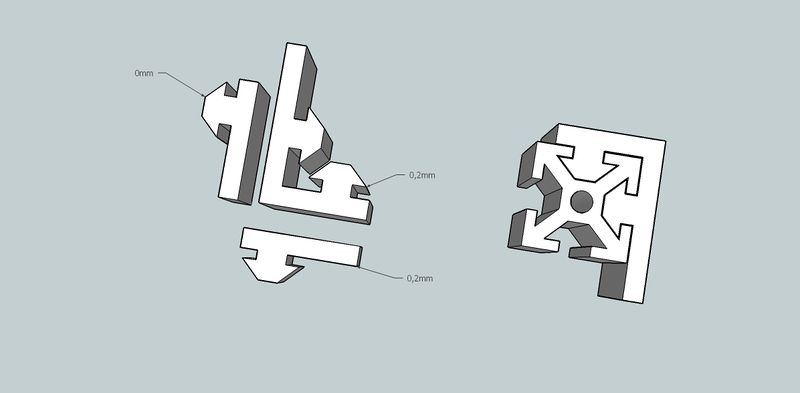

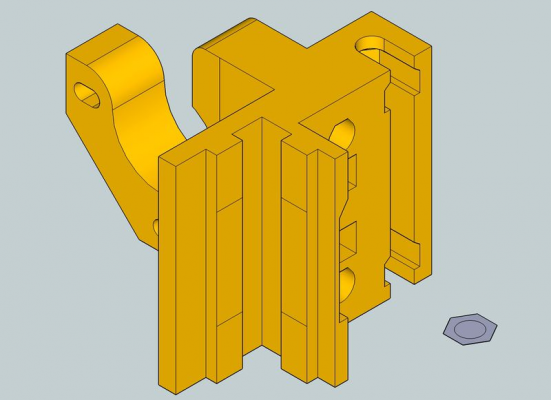

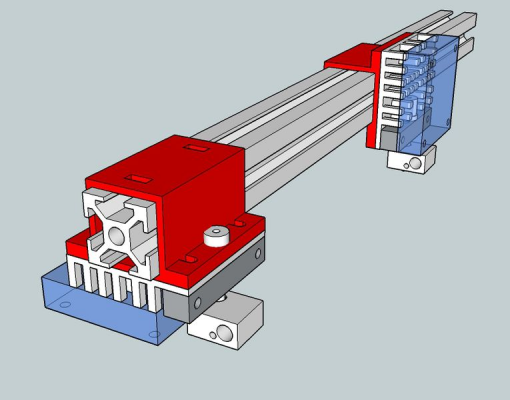

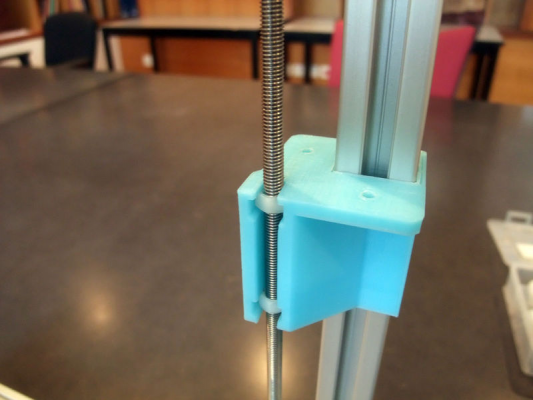

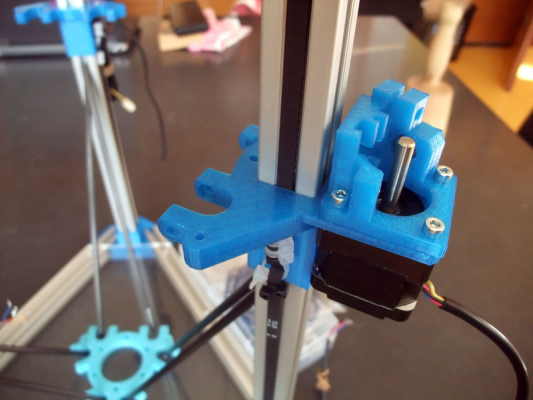

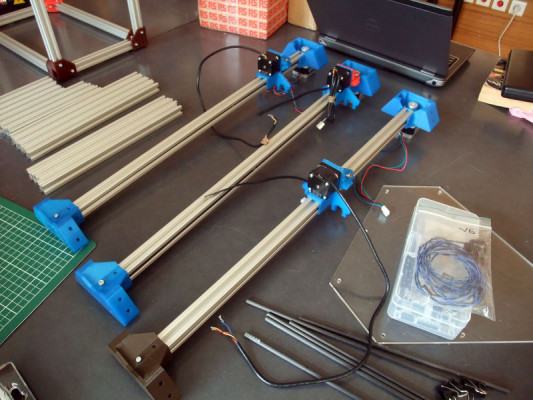

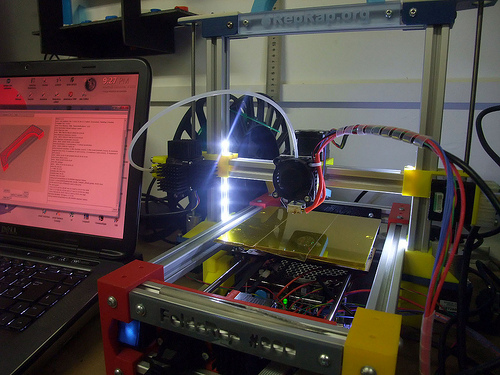

Another consideration was that one guide with a rectangular cross section would in theory be enough to provide constraint to the bearing while being much more stiff than two 8mm rods. For this experiment I settled on 23.5mm square profiles I have lying around, but any other aluminium profile will do.

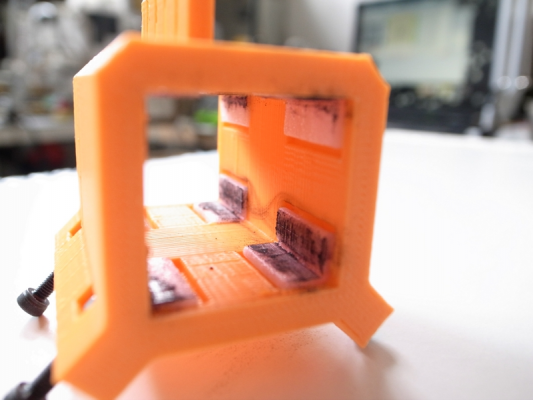

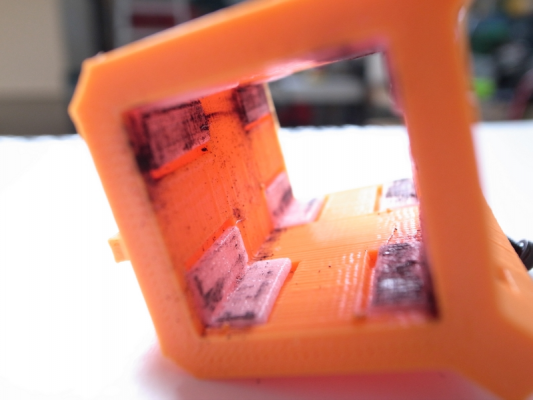

Some preliminary photos:

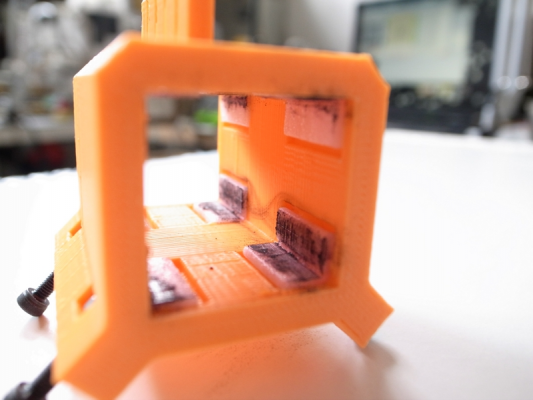

The insides of the carriage shown are not up to date. An updated version allows for the pads (which also stick out more than here) to be adjusted.

Since zip-ties are also made of PA, one could theoretically use them as glide surfaces; you would need a second row of them for the carriage not to pitch and yaw, but hey, they are cheap and this is a simple solution!

As I am writing this post, the test set-up is performing runs in order to test wear, but one thing I can already say: the friction between PA and aluminium seems to be less than that of UHMW-PE on stainless steel or ground Cf53 steel.

I hope that in the future, we might simplify our machines even further, making them lighter and getting closer to the original goal of RepRap.

By the way: Do you prefer the imgur albums or long posts with single images?

Well, that was before I got my hands on the Taulman 618 filament. While researching different materials for plastic bushings, it became apparent that Polyamide is also a viable material since it is wear resistant and slippery. However, what makes it interesting in addition to availability as filament is that it requires a rougher surface than UHMW-PE for it to exhibit ideal characteristics. This in turn means that we can use guides of lower quality.

Another consideration was that one guide with a rectangular cross section would in theory be enough to provide constraint to the bearing while being much more stiff than two 8mm rods. For this experiment I settled on 23.5mm square profiles I have lying around, but any other aluminium profile will do.

Some preliminary photos:

The insides of the carriage shown are not up to date. An updated version allows for the pads (which also stick out more than here) to be adjusted.

Since zip-ties are also made of PA, one could theoretically use them as glide surfaces; you would need a second row of them for the carriage not to pitch and yaw, but hey, they are cheap and this is a simple solution!

As I am writing this post, the test set-up is performing runs in order to test wear, but one thing I can already say: the friction between PA and aluminium seems to be less than that of UHMW-PE on stainless steel or ground Cf53 steel.

I hope that in the future, we might simplify our machines even further, making them lighter and getting closer to the original goal of RepRap.

By the way: Do you prefer the imgur albums or long posts with single images?

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 08, 2013 09:56AM |

Registered: 12 years ago Posts: 809 |

I really like this. Getting away from rods in a cheap, reliable way is a good thing. Please keep us up to date on your progress!

Oh, and imgur albums are infinitely better.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Oh, and imgur albums are infinitely better.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 08, 2013 11:17AM |

Registered: 11 years ago Posts: 490 |

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 08, 2013 04:12PM |

Registered: 11 years ago Posts: 490 |

Ah, I think I should mention this: the Bukobot by Deezmaker uses UHMW-PE pads on aluminium extrusion similar to my test set-up.

If the surface is smooth and of a high quality, one can also use PET (although I have not been able to find it in filament form yet, there are several bottle recycling, filament making projects going on) since it has similar characteristics to UHMW-PE, else POM (also known as Acetal or Delrin) is also an alternative to PA, but requires a proper ventilation and air purification system.

If the surface is smooth and of a high quality, one can also use PET (although I have not been able to find it in filament form yet, there are several bottle recycling, filament making projects going on) since it has similar characteristics to UHMW-PE, else POM (also known as Acetal or Delrin) is also an alternative to PA, but requires a proper ventilation and air purification system.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 08, 2013 06:00PM |

Registered: 12 years ago Posts: 177 |

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 08, 2013 06:26PM |

Registered: 13 years ago Posts: 301 |

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 09, 2013 04:50AM |

Registered: 13 years ago Posts: 615 |

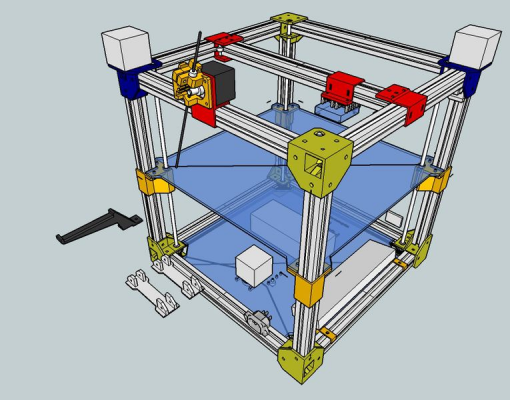

On the same simplification goal, on the FoldaRap the Z are bare PLA on 20x20 extrusion, and it works fine  (pla/alu seems to have a good wear factor indeed).

(pla/alu seems to have a good wear factor indeed).

I tried also for the Y but with less success for the moment

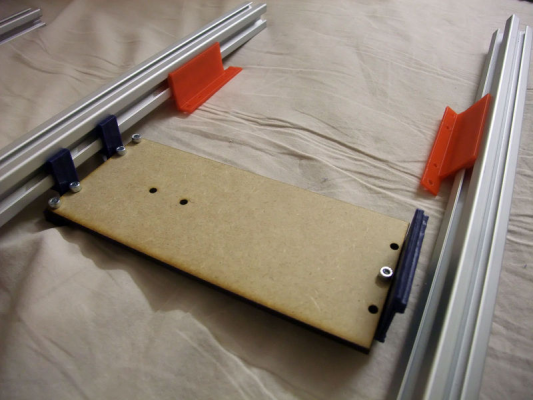

I also tried UHMWPE for the Mondrian, but they had too much play (not many but still) and ended back to a square PLA carriage profile (for all axis this times) :

You just need to slightly file the inner faces of the carriage until it slide, then you are good for a long time... that can make such simple architectures that I don't know why they are trying produce special extrusion profiles to use wheels when you can just use standard 20x20.

Even for a delta

And after having read this post I will have to try the same with 618 nylon to compare

about // liberapay // flickr // wiki // thingiverse - github

(pla/alu seems to have a good wear factor indeed).

(pla/alu seems to have a good wear factor indeed).I tried also for the Y but with less success for the moment

I also tried UHMWPE for the Mondrian, but they had too much play (not many but still) and ended back to a square PLA carriage profile (for all axis this times) :

You just need to slightly file the inner faces of the carriage until it slide, then you are good for a long time... that can make such simple architectures that I don't know why they are trying produce special extrusion profiles to use wheels when you can just use standard 20x20.

Even for a delta

And after having read this post I will have to try the same with 618 nylon to compare

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 09, 2013 09:53AM |

Registered: 11 years ago Posts: 490 |

@SanjayM: after uploading, there is an "Embed" button somewhere at the bottom of the gallery. Just click that and directly copy the link in the pop-up window to the post.

Taulman 645 vs 618: I couldn't find conclusive data on wear characteristics of both. While 645 seems to be generally stronger, one would have to consider coefficient of friction, tribological partner, surface roughness and probably a lot more to determine definitely which of both is better suited as bushing material. But when I get my hands on some 645, I can do some comparisons.

@billyzelsnack: Thanks, it only occurred to me after thinking of printing the PA glide pads. Zip ties even provide preload due to the curvature and tension. They are more finicky to implement, though, because it is hard to estimate how much they will bend around tight corners.

@Emmanuel: How long did the PLA bearings last in the Y axis? And did they slop significantly after some time due to wear? I am worried that they might wear too fast, but there is no detailed information about wear characteristics of PLA yet.

That is why I opted for the modular design where I can exchange and adjust tension to compensate for wear.

I have made rather good experiences with UHMW-PE on Cf53. My printer runs on this, lubrication-free, for about 2 months or so already without a problem. Are your UHMW-PE pads from 80/20?

Taulman 645 vs 618: I couldn't find conclusive data on wear characteristics of both. While 645 seems to be generally stronger, one would have to consider coefficient of friction, tribological partner, surface roughness and probably a lot more to determine definitely which of both is better suited as bushing material. But when I get my hands on some 645, I can do some comparisons.

@billyzelsnack: Thanks, it only occurred to me after thinking of printing the PA glide pads. Zip ties even provide preload due to the curvature and tension. They are more finicky to implement, though, because it is hard to estimate how much they will bend around tight corners.

@Emmanuel: How long did the PLA bearings last in the Y axis? And did they slop significantly after some time due to wear? I am worried that they might wear too fast, but there is no detailed information about wear characteristics of PLA yet.

That is why I opted for the modular design where I can exchange and adjust tension to compensate for wear.

I have made rather good experiences with UHMW-PE on Cf53. My printer runs on this, lubrication-free, for about 2 months or so already without a problem. Are your UHMW-PE pads from 80/20?

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 09, 2013 01:16PM |

Registered: 13 years ago Posts: 615 |

I've only real experience on the Z for the moment, where the parts are ok after almost one year.

On XY we could compare maybe to the time when they used PLA bushings on the Prusa, but I tend to think they wear less on aluminium.

A wear compensation mechanism is the right mechanichal answer, I'm just betting we can go without but I may be wrong, we will see, my other prototypes are not printing yet, I'm still optimistic about these kind of carriages

And yes I have plenty pads from 80/20 !

about // liberapay // flickr // wiki // thingiverse - github

On XY we could compare maybe to the time when they used PLA bushings on the Prusa, but I tend to think they wear less on aluminium.

A wear compensation mechanism is the right mechanichal answer, I'm just betting we can go without but I may be wrong, we will see, my other prototypes are not printing yet, I'm still optimistic about these kind of carriages

And yes I have plenty pads from 80/20 !

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 09, 2013 03:35PM |

Registered: 11 years ago Posts: 490 |

Ah, I see. Have read that others also had problems with lacking precision of the 80/20 pads.

About the PLA bushings on the Prusa: that was a little bit before my time with RepRap, but if my information is correct, they lasted 10 hours of print time only? That would be quite too often for my liking. Compared to how long I have been running UHMW-PE, which performs similarly to PA, PLA seems to be a choice of availability rather than optimized performance.

And still, PET performs even better (in theory at least), allowing for high bushing temperatures, having extremely low wear, less humidity absorption and friction than PA, better stability than UHMW-PE etc.

I would SO love to get my hands on this in filament form, but apparently, no one is selling that. Well, at least we know a good source for raw material and filament extruders are also soon to be more common.

Without wear compensation, you might get away with it as long as the bearing is long enough? But I can imagine adding some compensation mechanism into a monolithic design wouldn't be too difficult.

About the PLA bushings on the Prusa: that was a little bit before my time with RepRap, but if my information is correct, they lasted 10 hours of print time only? That would be quite too often for my liking. Compared to how long I have been running UHMW-PE, which performs similarly to PA, PLA seems to be a choice of availability rather than optimized performance.

And still, PET performs even better (in theory at least), allowing for high bushing temperatures, having extremely low wear, less humidity absorption and friction than PA, better stability than UHMW-PE etc.

I would SO love to get my hands on this in filament form, but apparently, no one is selling that. Well, at least we know a good source for raw material and filament extruders are also soon to be more common.

Without wear compensation, you might get away with it as long as the bearing is long enough? But I can imagine adding some compensation mechanism into a monolithic design wouldn't be too difficult.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 13, 2013 10:20AM |

Registered: 11 years ago Posts: 490 |

A little update: today, the motor suddenly started to lose steps and the carriage seized multiple times.

After loosening the adjustment screws, I could continue the test runs.

What struck me as odd is that I did not tighten the screws before this happened. Since PA has a low thermal expansion compared to UHMW-PE, I don't think an overheating of the pads is an issue or else my tests with UHMW-PE wouldn't have been successful in the first place.

However, PA expands with moisture absorption, so increased air humidity compared to the other days might have been a problem.

Another explanation is that something became loose and got caught in the carriage and me dabbling with it to fix the problem knocked it into the right place again.

If the first assumption proves true, it would be a pain to use PA since you would have to adjust tension according to the weather. An alternative material could be PET then, but it is more difficult to get your hands on some 3mm PET plastic welding rod and it requires an all-metal hot end because of the higher melting point.

Other than that, the PA bearing seems to be quite suitable for a printed linear guide system. But let's wait some days until I have finished the test runs before jumping to conclusions.

After loosening the adjustment screws, I could continue the test runs.

What struck me as odd is that I did not tighten the screws before this happened. Since PA has a low thermal expansion compared to UHMW-PE, I don't think an overheating of the pads is an issue or else my tests with UHMW-PE wouldn't have been successful in the first place.

However, PA expands with moisture absorption, so increased air humidity compared to the other days might have been a problem.

Another explanation is that something became loose and got caught in the carriage and me dabbling with it to fix the problem knocked it into the right place again.

If the first assumption proves true, it would be a pain to use PA since you would have to adjust tension according to the weather. An alternative material could be PET then, but it is more difficult to get your hands on some 3mm PET plastic welding rod and it requires an all-metal hot end because of the higher melting point.

Other than that, the PA bearing seems to be quite suitable for a printed linear guide system. But let's wait some days until I have finished the test runs before jumping to conclusions.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 14, 2013 06:37PM |

Registered: 13 years ago Posts: 632 |

In addition to the zip tie idea (which I love BTW), PET is available in sheet form by cutting soda bottles apart, HDPE is used for milk bottles and five gallon buckets. Crosslinked HDPE is sold in tubing form as PEX pipe for plumbing. Seems like it wouldn't be too hard to use standard ABS parts with one of these as the bearing pad. That way you don't need to deal with trying to print with suboptimal materials but you get the bennefits.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 15, 2013 05:57AM |

Registered: 11 years ago Posts: 490 |

You are right, PET is easily available. And sort of like with the zip ties, it didn't occur to me. Thanks for the idea!

HDPE is in my opinion not really worth it as bearing material as vitamin since its bigger, meaner brother UHMW-PE is quite common and easily outperforms HDPE. My printer is equipped with UHMW-PE bushings by the way.

However, seeing how the early developers overcame a lot of difficulties and bringing us to where we are now, I would like to get PET extrusion working because after all, RepRap is about self-replication. So if I was to cop out because PA and PET are already available in usable forms, it wouldn't feel right for me. As a stopgap solution, though, zip ties (for those who can't get their hands on Taulman filament) and cut-up bottles may be excellent bang-for-the-buck and simplicity / efficiency wise.

HDPE is in my opinion not really worth it as bearing material as vitamin since its bigger, meaner brother UHMW-PE is quite common and easily outperforms HDPE. My printer is equipped with UHMW-PE bushings by the way.

However, seeing how the early developers overcame a lot of difficulties and bringing us to where we are now, I would like to get PET extrusion working because after all, RepRap is about self-replication. So if I was to cop out because PA and PET are already available in usable forms, it wouldn't feel right for me. As a stopgap solution, though, zip ties (for those who can't get their hands on Taulman filament) and cut-up bottles may be excellent bang-for-the-buck and simplicity / efficiency wise.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 15, 2013 06:54PM |

Registered: 11 years ago Posts: 82 |

I was so happy after I switch from my bench top CNC machine (which uses dovetail rails and large stepper motors to get decent speed). I could only get up to 20mm/s without loosing steps. I imagine these printed sleeves can have quite large friction and can be a nightmare to print at the correct dimension?

Thanks

Thanks

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 16, 2013 05:38PM |

Registered: 12 years ago Posts: 313 |

plastic2print.com recently introduced some new filaments, PET was one of these and I bought a small roll of it. My first test print contained a lot of bubbles from the absorbed moisture (PET is apparently very moisture-sensitive) and unfortunately, when drying the filament after this, I accidentally overheated it and the whole roll melted together. (Oh, bugger.) Now, for some reason, this plastic seems to have disappeared from plastic2print.com's website. I have no idea if or when it's coming back.

orbi-tech.de also has a new selection of stuff under "3D Filaments", and this includes Nylon. I have a roll of that in the mail. It will be interesting to see how it compares with Taulman 618. Orbi-tech advertises their Nylon as "extremely rigid and hard", whereas the 618 is extremely flexible.

orbi-tech.de also has a new selection of stuff under "3D Filaments", and this includes Nylon. I have a roll of that in the mail. It will be interesting to see how it compares with Taulman 618. Orbi-tech advertises their Nylon as "extremely rigid and hard", whereas the 618 is extremely flexible.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 16, 2013 06:46PM |

Registered: 11 years ago Posts: 490 |

@ThanhTran: It really depends on the materials used and also on the drivetrain.

I assume you have a leadscrew in your CNC mill, which exhibits more friction than timing belts and also covers less distance per revolution of the stepper motor. The steppers will lose torque above certain RPM's. So that was probably one of the limiting factors.

The other is that you usually have to tighten the dovetail guides a little bit in order to eliminate play. But for 3D printers, a little bit play is ok, so we can use systems with lower friction due to tension. Of course, ball bearings will have even lower friction, but comparing cheap LM8UU's to plastic bushings, the difference is not that much anymore.

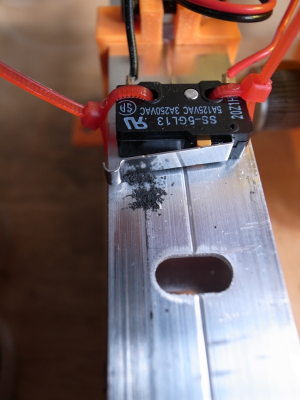

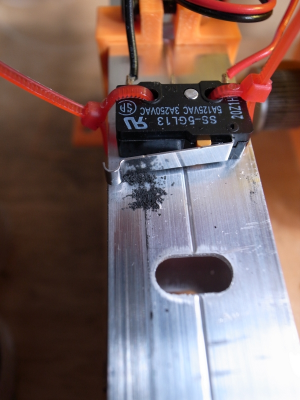

Materials used for the bearings are very important in order to make this work correctly. For example, I am using an unanodized aluminium profile for these tests and can already see how the PA pads more or less polished and shaved a minuscule amount off the surface, resulting in fine, black powder residue. Steel or anodized aluminium as rail is preferable. Then, the plastic with the lowest friction is PTFE, but wear characteristics are subpar. So the next good candidates would be PA, POM (both are good on mediocre surfaces with little blemishes, so good for us), PET and UHMW-PE (both of these are better on smoother surfaces, but still work well with less ideal ones). All of these exhibit low friction and high resistance to wear. Of these, currently only PA (Taulman 618) is reliably extrudable among RepRap operators, but I hope to get PET working some time because it is harder than PA and can stand higher temperatures.

You are right that printed plastic parts are never as accurate as machined or injection-moulded ones. That is one of the reasons I made the carriage 100% adjustable. Even if dimensions are a little bit off, you can usually adjust errors out.

I hope my rather long-winded post answered your questions.

@ttsalo: That's strange, PET is supposed to be less moisture absorbing than PA. Saw the material selection of plastic2print on the Wiki and was filled with hope only to find that they don't seem to have it in their shop anymore. Well, no other way than to contact some vendors without online shops. Maybe when experiments are successful and more people have all-metal hot ends, PET can become a stock RepRap material. That would be great.

The Orbi-Tech Nylon sounds interesting. Guess PA is one of the most varied plastics out there (proteins by the way are technically also polyamides, heh).

I assume you have a leadscrew in your CNC mill, which exhibits more friction than timing belts and also covers less distance per revolution of the stepper motor. The steppers will lose torque above certain RPM's. So that was probably one of the limiting factors.

The other is that you usually have to tighten the dovetail guides a little bit in order to eliminate play. But for 3D printers, a little bit play is ok, so we can use systems with lower friction due to tension. Of course, ball bearings will have even lower friction, but comparing cheap LM8UU's to plastic bushings, the difference is not that much anymore.

Materials used for the bearings are very important in order to make this work correctly. For example, I am using an unanodized aluminium profile for these tests and can already see how the PA pads more or less polished and shaved a minuscule amount off the surface, resulting in fine, black powder residue. Steel or anodized aluminium as rail is preferable. Then, the plastic with the lowest friction is PTFE, but wear characteristics are subpar. So the next good candidates would be PA, POM (both are good on mediocre surfaces with little blemishes, so good for us), PET and UHMW-PE (both of these are better on smoother surfaces, but still work well with less ideal ones). All of these exhibit low friction and high resistance to wear. Of these, currently only PA (Taulman 618) is reliably extrudable among RepRap operators, but I hope to get PET working some time because it is harder than PA and can stand higher temperatures.

You are right that printed plastic parts are never as accurate as machined or injection-moulded ones. That is one of the reasons I made the carriage 100% adjustable. Even if dimensions are a little bit off, you can usually adjust errors out.

I hope my rather long-winded post answered your questions.

@ttsalo: That's strange, PET is supposed to be less moisture absorbing than PA. Saw the material selection of plastic2print on the Wiki and was filled with hope only to find that they don't seem to have it in their shop anymore. Well, no other way than to contact some vendors without online shops. Maybe when experiments are successful and more people have all-metal hot ends, PET can become a stock RepRap material. That would be great.

The Orbi-Tech Nylon sounds interesting. Guess PA is one of the most varied plastics out there (proteins by the way are technically also polyamides, heh).

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 17, 2013 08:16AM |

Registered: 12 years ago Posts: 313 |

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 22, 2013 08:12AM |

Registered: 11 years ago Posts: 490 |

Ugh, imgur is acting up on me. So I'll just post results in the traditional form.

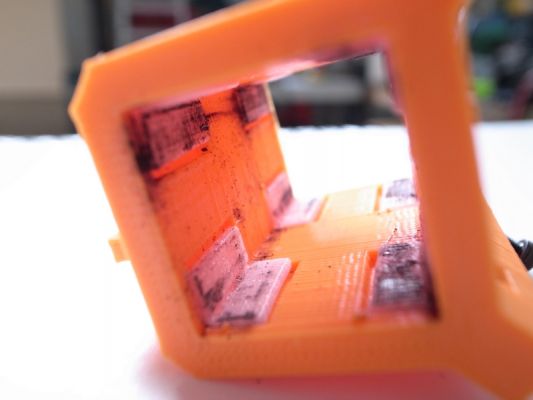

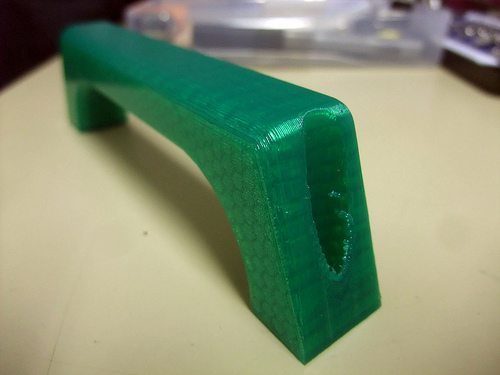

After letting the carriage run about 16km (probably a little bit more, but my computer crashed two times, destroying some log data), I disassembled the test arrangement to inspect the carriage for wear. To say that I was surprised is maybe a little bit understated.

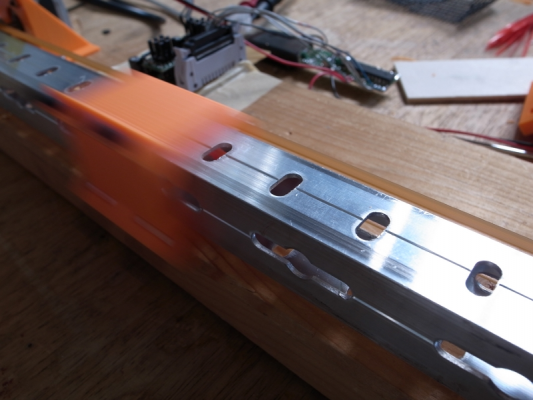

Essentially, the rail wore more than the glide pad, as it seems. Given that the rail used for the tests is unanodized, it was to be expected that it isn't as stable or wear-resistant as e.g. anodized ones or even steel rails, but still, this is quite something.

Here, you can see the shavings from the rail on the taulman 618 pads. The layers are still clearly discernible, which was the second surprise. I thought that with wear, these features would vanish rather quickly, but well, these are pretty good news! Also, uneven pressure on the pads became rather obvious after disassembling the test arrangement. Guess I have to re-design the tension adjustment mechanism a bit for "production" units.

Being aluminium is suffering. I polished the extrusion rather quickly (the second day of the tests, the rail already looked like this) and can even feel the difference with my fingernails.

Good that the glide pads are rather dirt resistant and just wiped the crud away. Recirculating ball bearings like the LM8UU's would have a massive problem with this stuff, I guess - even if they are sealed, some of this very fine grit might find its way in.

Conclusion so far:

I'm SO going to use printed bearings for my next printer. Not only is this a further step in self-manufacture and self-replication, but also the square aluminium rails offer weight and deflection advantages over the smooth rods in addition to only having to use one rail per axis because the profile is twist proof.

Interestingly, Igus came up with something very similar at roughly the same time: Igus adjustable Q series

Their adjustment system is much more sophisticated of course, but the whole thing is built to finer tolerances, uses different materials and so on. Earlier versions were non-adjustable, by the way.

Edited 1 time(s). Last edit at 05/22/2013 08:21AM by uGen.

After letting the carriage run about 16km (probably a little bit more, but my computer crashed two times, destroying some log data), I disassembled the test arrangement to inspect the carriage for wear. To say that I was surprised is maybe a little bit understated.

Essentially, the rail wore more than the glide pad, as it seems. Given that the rail used for the tests is unanodized, it was to be expected that it isn't as stable or wear-resistant as e.g. anodized ones or even steel rails, but still, this is quite something.

Here, you can see the shavings from the rail on the taulman 618 pads. The layers are still clearly discernible, which was the second surprise. I thought that with wear, these features would vanish rather quickly, but well, these are pretty good news! Also, uneven pressure on the pads became rather obvious after disassembling the test arrangement. Guess I have to re-design the tension adjustment mechanism a bit for "production" units.

Being aluminium is suffering. I polished the extrusion rather quickly (the second day of the tests, the rail already looked like this) and can even feel the difference with my fingernails.

Good that the glide pads are rather dirt resistant and just wiped the crud away. Recirculating ball bearings like the LM8UU's would have a massive problem with this stuff, I guess - even if they are sealed, some of this very fine grit might find its way in.

Conclusion so far:

I'm SO going to use printed bearings for my next printer. Not only is this a further step in self-manufacture and self-replication, but also the square aluminium rails offer weight and deflection advantages over the smooth rods in addition to only having to use one rail per axis because the profile is twist proof.

Interestingly, Igus came up with something very similar at roughly the same time: Igus adjustable Q series

Their adjustment system is much more sophisticated of course, but the whole thing is built to finer tolerances, uses different materials and so on. Earlier versions were non-adjustable, by the way.

Edited 1 time(s). Last edit at 05/22/2013 08:21AM by uGen.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 22, 2013 06:06PM |

Registered: 12 years ago Posts: 177 |

Remembering that aluminium oxidises quite readily and is infact always coated in a thin layer of oxide at all times that protects the aluminium below - perhaps what you are experiencing is the brittle oxide layer being removed by the pad, the aluminium below being exposed, oxidising, wearing, oxidising .. etc.

Maybe this cycle could be prevented with some corrosion protection oil.

Maybe this cycle could be prevented with some corrosion protection oil.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 22, 2013 06:22PM |

Registered: 11 years ago Posts: 205 |

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 22, 2013 06:35PM |

Registered: 11 years ago Posts: 490 |

@SanjayM: Yes, since the non-worn parts look brighter and duller than the polished ones, this might be what happened. Still, I found it rather noteworthy that the pads wore less than the aluminium. Although your idea of applying some oil might work, an anodized beam like alj_rprp suggests may work better. The surface is just more wear and corrosion resistant and harder (that is also why T-Slots and Igus linear rails are anodized); overall surface finish is more consistent and better. I only used this particular beam because I had some of it available. And although I quite like the aesthetics of it, I already found more suitable parts in the hardware store.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 22, 2013 07:00PM |

Registered: 11 years ago Posts: 254 |

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 23, 2013 02:23AM |

Admin Registered: 16 years ago Posts: 13,886 |

... in some of my old XY-plotters with gliders the surface of the rail was covered with a thin stripe of PTFE ... have some self-adhesion sheets of PTFE on glass-fabric, that are used as wear-protection on the bottoms of moved technical parts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide May 23, 2013 06:47AM |

Registered: 11 years ago Posts: 490 |

PTFE is a lot less wear-resistant than PA and the other plastics I am considering (PET, [POM, UHMWPE; have to be machined]) in addition to not being printable. Considering that the printers move quite a bit per print, PTFE suddenly sounds much less interesting. However, I can imagine using PTFE-based lubricants to improve overall performance.

@Gerard Choinka: That most likely won't be necessary when using anodized aluminium, but I actually intended to print the pads in a way so that the layers line up with the actual movement, creating small grooves where crud can pass through (like in the Igus bearings). But printing angled glide pads conforming to this configuration meant that I had to print them standing on an edge like a V. Didn't turn out that well so far, unfortunately.

@Gerard Choinka: That most likely won't be necessary when using anodized aluminium, but I actually intended to print the pads in a way so that the layers line up with the actual movement, creating small grooves where crud can pass through (like in the Igus bearings). But printing angled glide pads conforming to this configuration meant that I had to print them standing on an edge like a V. Didn't turn out that well so far, unfortunately.

|

Re: Cheap, Low Vitamin Count Single Rail Linear Guide December 25, 2013 06:20PM |

Registered: 13 years ago Posts: 615 |

A little update on this topic with more experience/time.

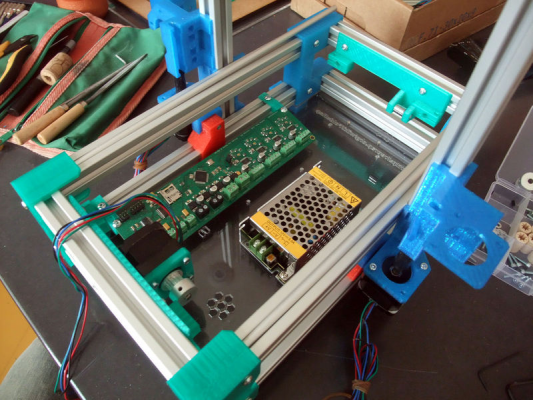

On the second major revision of the FoldaRap, as for the Z-axis before I'm now gliding on an aluminium profile for the X-axis too

(PLA / anodized aluminium)

[youtu.be]

[youtu.be]

[youtu.be]

The printed part needs to be printed at just the right dimension, to avoid having play/backlash, but if done right (or filed to adapt if too tight), the movement can be perfectly smooth

Edited 2 time(s). Last edit at 12/25/2013 06:22PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

On the second major revision of the FoldaRap, as for the Z-axis before I'm now gliding on an aluminium profile for the X-axis too

(PLA / anodized aluminium)

[youtu.be]

[youtu.be]

[youtu.be]

The printed part needs to be printed at just the right dimension, to avoid having play/backlash, but if done right (or filed to adapt if too tight), the movement can be perfectly smooth

Edited 2 time(s). Last edit at 12/25/2013 06:22PM by Emmanuel.

about // liberapay // flickr // wiki // thingiverse - github

Sorry, only registered users may post in this forum.