3D cement printer

Posted by AndreyR

|

Re: 3D cement printer January 09, 2014 10:07PM |

Registered: 10 years ago Posts: 64 |

This project is so cool. I'm from MN also and I don't envy you not having a well heated workspace this week. Where are you located?

If you are doing your pump design in solidworks/CAD program would you consider posting them? I'd love to help out and maybe have some ideas as I've worked with forming concrete to very fine tolerances in the past.

If you are doing your pump design in solidworks/CAD program would you consider posting them? I'd love to help out and maybe have some ideas as I've worked with forming concrete to very fine tolerances in the past.

|

Re: 3D cement printer January 21, 2014 07:30PM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: 3D cement printer January 22, 2014 10:51AM |

Registered: 15 years ago Posts: 84 |

Also because of a story about 3D printing a house (which is using more normal materials) I came across [www.contourcrafting.org] . This is the South Californian team mentioned earlier, the one with the TED X talk [tedxtalks.ted.com] / [www.youtube.com] and and it's true most of the videos of the printer in action seem to be more or less the same thing of unknown printing date e.g. [www.youtube.com] but they do have a few photos [www.contourcrafting.org] and powerpoint [www.contourcrafting.org] and animations [www.contourcrafting.org] and stuff.

But if you want to get a better idea of where they're at, you'd probably need to look more closely at their publications [scholar.google.co.nz] as that's where it'll be being university reseachers. Of course even that will likely be at least a year or two behind what they're doing at the moment, maybe even more so since I think they're quite interested in commercialising i.e. patenting their work where they can.

Note however I think most of their work isn't really with cement per se, but a cement derived ceramic material (and other stuff). They add fibres and stuff for strengthening as they want to print habitable structures with it [www.bkhoshnevis.com] although I think they're also adding rods or mesh and stuff now.

But if you want to get a better idea of where they're at, you'd probably need to look more closely at their publications [scholar.google.co.nz] as that's where it'll be being university reseachers. Of course even that will likely be at least a year or two behind what they're doing at the moment, maybe even more so since I think they're quite interested in commercialising i.e. patenting their work where they can.

Note however I think most of their work isn't really with cement per se, but a cement derived ceramic material (and other stuff). They add fibres and stuff for strengthening as they want to print habitable structures with it [www.bkhoshnevis.com] although I think they're also adding rods or mesh and stuff now.

|

Re: 3D cement printer March 30, 2014 03:48PM |

Registered: 10 years ago Posts: 55 |

|

Re: 3D cement printer March 30, 2014 04:16PM |

Registered: 10 years ago Posts: 34 |

This looks incredible, you have made amazing progress. Are you planning to scale it up so you can print an entire house without repositioning the printer? And will you keep this nozzle size or are you planning to enlarge that as well? I am currently building my first 3D-printer, but that looks like child's play compared to this!

|

Re: 3D cement printer March 30, 2014 07:28PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: 3D cement printer March 30, 2014 08:24PM |

Registered: 11 years ago Posts: 334 |

Looks amazing, I can't wait to play with one. When can I get you to bring it to Chicago

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: 3D cement printer March 30, 2014 10:12PM |

Registered: 10 years ago Posts: 466 |

|

Re: 3D cement printer April 02, 2014 10:21PM |

Registered: 10 years ago Posts: 1,381 |

I think you have a better surface finish than this company.

10 completely 3D printed houses appear in Shanghai, built under a day

WinSun expects 3D printing will save construction companies up to 50% on the cost.

WinSun hopes their 3D printer and technology could offer "affordable and dignified housing" for the impoverished.

[www.3ders.org]

10 completely 3D printed houses appear in Shanghai, built under a day

WinSun expects 3D printing will save construction companies up to 50% on the cost.

WinSun hopes their 3D printer and technology could offer "affordable and dignified housing" for the impoverished.

[www.3ders.org]

|

Re: 3D cement printer April 03, 2014 10:07PM |

Registered: 10 years ago Posts: 16 |

|

Re: 3D cement printer April 07, 2014 07:22PM |

Registered: 10 years ago Posts: 55 |

The first part of the experiment was a success. At this time, I have reached the phase where the 3D printer can print straight, even layers and be configured to print different shapes. The next step is to build a small castle that will be used as a children’s playhouse. This project will allow me to test printing walls other than straight walls. I need to test the printer’s ability to build leaning walls without collapsing. The first configuration of the castle will be more of a playground, which will help me learn more about cement printer possibilities and what angles can be constructed with what speeds of the printer, etc. This will allow me to build a more contemporary configuration in the future.

I’m still having the same issue with the slicing. The most common slicer software doesn’t work. For now, I am writing the g-code used for my projects manually. This is okay for simple rectangular-shape models. However, I need to get some type of customized slicer software to address future needs. If anybody is willing to help, it would be much appreciated. In short, I am looking for a simple slicer program without any complicated additional settings like mesh etc.

A2

I think you have a better surface finish than this company.------------------------- I got the same poor quality surface finish a year ago, but I am a perfectionist so it would be shame for me to have so ugly finish. I have much better result now.

10 completely 3D printed houses appear in Shanghai, built under a day------few questions: insulation? size? if it's printed within a day, how many days they will take to get ready/dry for transportation to the site ? what kind of truck will be able to move, load, unload? e.t.c.

My opinion is that it's a wrong concept to "print and then move"

When will the ravenous wolves get access to some DIY kits or instructions?----- The website is in progress, coming soon. I didn't think about a DIY kit. Sounds like a good idea.

Edited 2 time(s). Last edit at 04/07/2014 08:01PM by AndreyR.

I’m still having the same issue with the slicing. The most common slicer software doesn’t work. For now, I am writing the g-code used for my projects manually. This is okay for simple rectangular-shape models. However, I need to get some type of customized slicer software to address future needs. If anybody is willing to help, it would be much appreciated. In short, I am looking for a simple slicer program without any complicated additional settings like mesh etc.

A2

I think you have a better surface finish than this company.------------------------- I got the same poor quality surface finish a year ago, but I am a perfectionist so it would be shame for me to have so ugly finish. I have much better result now.

10 completely 3D printed houses appear in Shanghai, built under a day------few questions: insulation? size? if it's printed within a day, how many days they will take to get ready/dry for transportation to the site ? what kind of truck will be able to move, load, unload? e.t.c.

My opinion is that it's a wrong concept to "print and then move"

When will the ravenous wolves get access to some DIY kits or instructions?----- The website is in progress, coming soon. I didn't think about a DIY kit. Sounds like a good idea.

Edited 2 time(s). Last edit at 04/07/2014 08:01PM by AndreyR.

|

Re: 3D cement printer April 07, 2014 08:18PM |

Registered: 11 years ago Posts: 334 |

What slicers have you tried so far?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: 3D cement printer April 07, 2014 09:39PM |

Registered: 10 years ago Posts: 1,381 |

If you modeled a solid object, then shelled the walls (hollow), then sliced it would it work.

Is the limitation the inability to draw the walls to the thickness that you want, or is it because you're unable to turn off infill.

Or is there something about plastic filament slicer software that is incompatible with cement extrusion slicing requirements.

I modeled the walls of this home as a solid, then I shelled the walls with a 30 mm thickness, would this slice.

3D House Printer. Pre Test.

[www.youtube.com]

Edited 2 time(s). Last edit at 04/07/2014 09:39PM by A2.

Is the limitation the inability to draw the walls to the thickness that you want, or is it because you're unable to turn off infill.

Or is there something about plastic filament slicer software that is incompatible with cement extrusion slicing requirements.

I modeled the walls of this home as a solid, then I shelled the walls with a 30 mm thickness, would this slice.

3D House Printer. Pre Test.

[www.youtube.com]

Edited 2 time(s). Last edit at 04/07/2014 09:39PM by A2.

|

Re: 3D cement printer April 07, 2014 11:38PM |

Registered: 10 years ago Posts: 55 |

What slicers have you tried so far? ----sli3er

Is the limitation the inability to draw the walls to the thickness that you want------------------yes. problem is how to print a wall in one path. the thickness of the wall is about thickness of the filament. i have 20 mm nozzle diameter and 25 mm thickness of the wall ( you can see it on the video)

Or is there something about plastic filament slicer software that is incompatible with cement extrusion slicing requirements.-------------difficult to set up and calibrate 20 mm nozzle diameter. very very difficult to set up speed/ diameter. it works like automaticaly: if i change diameter it will change the speed and something more. I have spent 2 weeks to play with sli3er settings and gave up

also the path has to be like predicted and too many filament " connections" looks bad

Edited 2 time(s). Last edit at 04/09/2014 11:32PM by AndreyR.

Is the limitation the inability to draw the walls to the thickness that you want------------------yes. problem is how to print a wall in one path. the thickness of the wall is about thickness of the filament. i have 20 mm nozzle diameter and 25 mm thickness of the wall ( you can see it on the video)

Or is there something about plastic filament slicer software that is incompatible with cement extrusion slicing requirements.-------------difficult to set up and calibrate 20 mm nozzle diameter. very very difficult to set up speed/ diameter. it works like automaticaly: if i change diameter it will change the speed and something more. I have spent 2 weeks to play with sli3er settings and gave up

also the path has to be like predicted and too many filament " connections" looks bad

Edited 2 time(s). Last edit at 04/09/2014 11:32PM by AndreyR.

|

Re: 3D cement printer April 09, 2014 01:24AM |

Registered: 10 years ago Posts: 1,381 |

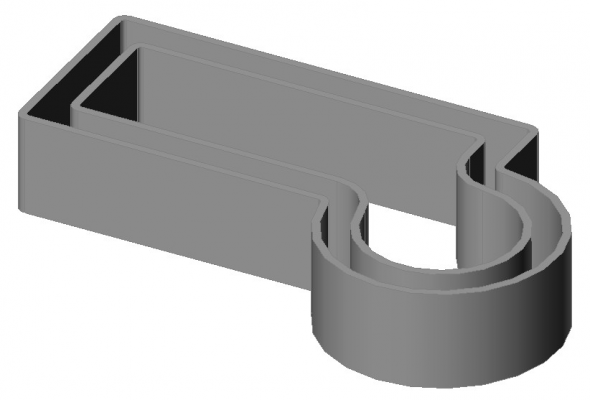

I designed a wall with 25 mm thickness, and with tangent non-intersecting surfaces.

Would this solve your slicing issues.

Or would you prefer 20 mm wall thickness for slicing.

Edited 1 time(s). Last edit at 04/09/2014 01:24AM by A2.

Would this solve your slicing issues.

Or would you prefer 20 mm wall thickness for slicing.

Edited 1 time(s). Last edit at 04/09/2014 01:24AM by A2.

|

Re: 3D cement printer April 09, 2014 06:30AM |

Registered: 11 years ago Posts: 364 |

|

Re: 3D cement printer April 09, 2014 08:19AM |

Registered: 10 years ago Posts: 55 |

|

Re: 3D cement printer April 09, 2014 11:55AM |

Registered: 11 years ago Posts: 334 |

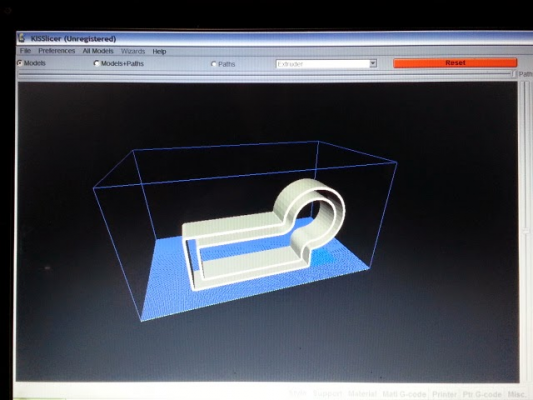

You should try playing with KISSlicer. That being said I think A2 is right about having to model the wall as shelled solid object.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: 3D cement printer April 09, 2014 02:01PM |

Registered: 10 years ago Posts: 1,381 |

O.D. 1000 mm, x 1000 mm tall, added a small door with trim, but it's not designed for printing (just for illustration).

What is the layer thickness, and the radius of the bulge, on some surfaces I can replicate that as well.

Interesting to think about path termination, e.g. where a door, wall or window would intersect.

When properly engineered it could be very strong and material efficient.

Edited 1 time(s). Last edit at 04/09/2014 02:03PM by A2.

|

Re: 3D cement printer April 09, 2014 08:09PM |

Registered: 10 years ago Posts: 1,381 |

Castle: 20 mm single wall thickness.

I don't imagine you are going to print the roof, but I added one to see what it would look like.

Edited 1 time(s). Last edit at 04/09/2014 08:10PM by A2.

I don't imagine you are going to print the roof, but I added one to see what it would look like.

Edited 1 time(s). Last edit at 04/09/2014 08:10PM by A2.

|

Re: 3D cement printer April 09, 2014 11:29PM |

Registered: 10 years ago Posts: 55 |

oh man, you surprised me about the castle!

I'd like to start with a round-barn-house. Can you help with a stl file? I will definitely experiment with KISSlicer, as jzatopa advised. I guess I need a stl, right?

The thickness of the walls is 20 mm, and can you make the trim/door to be very simple? The thickness of the layers is 5mm, but i think it should be settings on KISSlicer.

By the way, i remember your idea about a Dutch hot tub. I'm just waiting for a warm weather to start.

I'd like to start with a round-barn-house. Can you help with a stl file? I will definitely experiment with KISSlicer, as jzatopa advised. I guess I need a stl, right?

The thickness of the walls is 20 mm, and can you make the trim/door to be very simple? The thickness of the layers is 5mm, but i think it should be settings on KISSlicer.

By the way, i remember your idea about a Dutch hot tub. I'm just waiting for a warm weather to start.

|

Re: 3D cement printer April 10, 2014 01:37AM |

Registered: 10 years ago Posts: 1,381 |

A round barn house sounds cool, provide a sketch with dimensions, and provide you with a .stl file.

The design can evolve, so no need to get it correct on the first round.

Doors, windows, overhangs: if you can pause the print to insert a wood former then you can print it as modeled.

If not, then you need a way to cut out sections.

Describe what a simple trim/door looks like, and I'll draw it.

Extrudate:

layer width: 20 mm.

layer height: 5 mm.

I plan to design the height of the walls based on the layer thickness.

A cement Dutch tub will be very cool to see printed too.

The design can evolve, so no need to get it correct on the first round.

Doors, windows, overhangs: if you can pause the print to insert a wood former then you can print it as modeled.

If not, then you need a way to cut out sections.

Describe what a simple trim/door looks like, and I'll draw it.

Extrudate:

layer width: 20 mm.

layer height: 5 mm.

I plan to design the height of the walls based on the layer thickness.

A cement Dutch tub will be very cool to see printed too.

|

Re: 3D cement printer April 11, 2014 12:47PM |

Registered: 10 years ago Posts: 3 |

I just found this thread, this is awesome, you seem way ahead of almost everyone else except in scale, and i know you'll get there. I can't wait til you get a website going, this will be awesome, talk about a huge revolution to the construction industry.

Please keep us appraised, and thanks for sharing your great work

Regards,

Scire

Please keep us appraised, and thanks for sharing your great work

Regards,

Scire

|

Re: 3D cement printer April 12, 2014 10:42PM |

Registered: 10 years ago Posts: 55 |

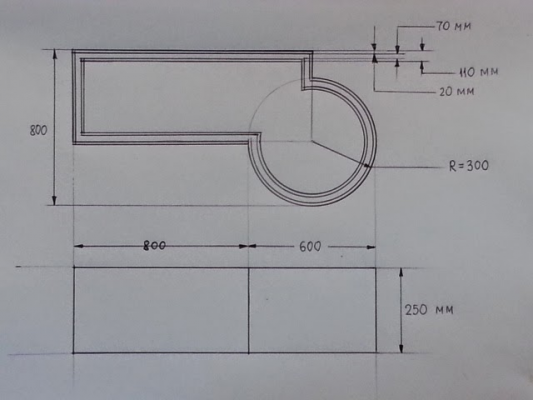

A2- I think we need to start from this simple shape. Then if we are lucky and Kisslicer works okay, we can make a more complex model.

Scire- Thank you, much appreciated. Please join, we are always open to new ideas and new members. A lot has been done, but even more is ahead.

Edited 2 time(s). Last edit at 04/13/2014 12:04AM by AndreyR.

|

Re: 3D cement printer April 13, 2014 02:15AM |

Registered: 10 years ago Posts: 1,381 |

I radiused the corners to help reduce over extrusion in the corners, and to improve the strength.

If you want the square corners back, I'll modify it.

If the attached.stl file doesn't work, or work well, let me know as I have a couple of different ways to save/convert to a .stl.

Edited 3 time(s). Last edit at 04/13/2014 03:36AM by A2.

If you want the square corners back, I'll modify it.

If the attached.stl file doesn't work, or work well, let me know as I have a couple of different ways to save/convert to a .stl.

Edited 3 time(s). Last edit at 04/13/2014 03:36AM by A2.

|

Re: 3D cement printer April 13, 2014 09:33AM |

Registered: 10 years ago Posts: 55 |

looks like wrong direction... is there any possible way to rotate?

|

Re: 3D cement printer April 13, 2014 09:47AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: 3D cement printer April 14, 2014 08:41AM |

Registered: 10 years ago Posts: 55 |

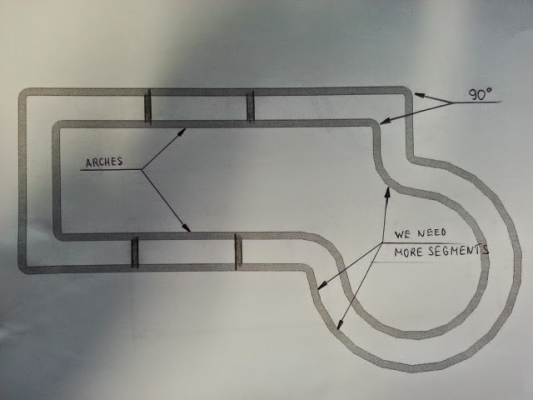

I spent about twelve hours trying to get Slicer/Kisslicer to work today, and have finally gotten good results. Everything looks very promising, and it appears that we’re on the right track. I'm going to print this model, but before printing, I would like to ask you to make some changes. Firstly, we need to increase number of

the segments about 3- 5 times. Secondly, it looks like you made a small radius on the corners. For a big, massive printer, this is an additional source of shaking, it's better to have simple, 90-degree corners. Finally, I would like to try putting in a couple arches to test the ability to print them.

Edited 1 time(s). Last edit at 04/14/2014 08:46AM by AndreyR.

Edited 1 time(s). Last edit at 04/14/2014 08:46AM by AndreyR.

|

Re: 3D cement printer April 14, 2014 09:49AM |

Registered: 10 years ago Posts: 1,381 |

Ok, I'll add the 90 degree corners back, and I'll add two arches.

How much space do you want between the top of the arch and the top of the wall?

To be clear, segments are ribs between two adjacent walls?

Do you have a rule for me to use to space the segments around the circle, or just make it look good?

I see the wall height has doubled to 500 mm, is that correct?

How much space do you want between the top of the arch and the top of the wall?

To be clear, segments are ribs between two adjacent walls?

Do you have a rule for me to use to space the segments around the circle, or just make it look good?

I see the wall height has doubled to 500 mm, is that correct?

|

Re: 3D cement printer April 14, 2014 07:46PM |

Registered: 10 years ago Posts: 55 |

Ok, I'll add the 90 degree corners back, and I'll add two arches.----------------------------only small corners, that inner-circle-wall looks great

How much space do you want between the top of the arch and the top of the wall?------ about 80mm

To be clear, segments are ribs between two adjacent walls?-----------no, between walls going to be just concrete or insulation. I mean segments are short line that move point to point to make a circle

I see the wall height has doubled to 500 mm, is that correct?---------yes

How much space do you want between the top of the arch and the top of the wall?------ about 80mm

To be clear, segments are ribs between two adjacent walls?-----------no, between walls going to be just concrete or insulation. I mean segments are short line that move point to point to make a circle

I see the wall height has doubled to 500 mm, is that correct?---------yes

Sorry, only registered users may post in this forum.