LM8UU VS IGUS

Posted by Enlightx

|

LM8UU VS IGUS June 26, 2013 01:25PM |

Registered: 11 years ago Posts: 329 |

|

Re: LM8UU VS IGUS June 26, 2013 03:00PM |

Registered: 11 years ago Posts: 43 |

|

Re: LM8UU VS IGUS June 26, 2013 05:04PM |

Registered: 10 years ago Posts: 22 |

which model have you used for printed linear bearings ?

i've searched the thingiverse and i found several objects ...

for how many months have you used them ? I'm curios if they dont wear out ... or how is their behavior on long term usage ...

thanks,

mihai

492183 Wrote:

-------------------------------------------------------

> I have replaced my LM08UU's with printed PLA

> LM08UU's and they are a lot quieter with the same

> performance. Only cost a couple of cents in

> materials. Might be worth looking into in stead of

> igus bushings.

i've searched the thingiverse and i found several objects ...

for how many months have you used them ? I'm curios if they dont wear out ... or how is their behavior on long term usage ...

thanks,

mihai

492183 Wrote:

-------------------------------------------------------

> I have replaced my LM08UU's with printed PLA

> LM08UU's and they are a lot quieter with the same

> performance. Only cost a couple of cents in

> materials. Might be worth looking into in stead of

> igus bushings.

|

Re: LM8UU VS IGUS June 26, 2013 07:56PM |

Registered: 11 years ago Posts: 186 |

Would you say printed PLA can last for hundreds of hours of printing? I am about to rebuild my Printrbot tonight with some, and hope they last.

BTW, IGUS has a genuine 3D model on their website. I am printing some now, but not sure they will fit yet. I will know in a few hours.

I have already printed these in 8mm and 10mm and they seem good:

[www.thingiverse.com]

[www.matter-replicator.com]

BTW, IGUS has a genuine 3D model on their website. I am printing some now, but not sure they will fit yet. I will know in a few hours.

I have already printed these in 8mm and 10mm and they seem good:

[www.thingiverse.com]

[www.matter-replicator.com]

|

Re: LM8UU VS IGUS June 27, 2013 08:33AM |

Registered: 12 years ago Posts: 253 |

I used printed PLA bushings on a Prusa for almost a year. I made mine square on the ID so there was only 4 places of contact with the rod and used them on the X carriage. Worked fine but it did have a little more drag than it needed to have. The ones linked to on Thingiverse look great. Biggest issue with printing bushings is you better have your machine calibrated spot on and cant have any backlash.

|

Re: LM8UU VS IGUS June 27, 2013 09:44AM |

Registered: 11 years ago Posts: 43 |

The model I used is this one: [www.thingiverse.com]. Right now I am about 50 hours in and am not noticing any type of degradation. After printing the bushing internal diameter was too small for my rods. When warming the bushings to 60c (glass transition temperature) with warm water and sliding the rod in the bushing the bushing ID will exactly be the same as the rod OD.

|

Re: LM8UU VS IGUS June 27, 2013 09:47AM |

Registered: 11 years ago Posts: 186 |

I printed the IGUS models and it was not snug enough. The ones that I linked to did fit well.

[www.matter-replicator.com]

[www.matter-replicator.com]

|

Re: LM8UU VS IGUS June 28, 2013 06:17AM |

Admin Registered: 11 years ago Posts: 3,096 |

I am curious to hear more stories about these PLA bushings. I have also seen someone experiment with Nylon (Think it was Taulman 618/645?).

I have so far only printed with ABS, but am willing to try and make a switch to PLA some day. Also still planning my 2nd printer built, the idea is to rig that printer to run completely for PLA parts and keep my current printer for ABS.

I have so far only printed with ABS, but am willing to try and make a switch to PLA some day. Also still planning my 2nd printer built, the idea is to rig that printer to run completely for PLA parts and keep my current printer for ABS.

|

Re: LM8UU VS IGUS June 29, 2013 01:55AM |

Registered: 11 years ago Posts: 1,592 |

I made some of these [www.thingiverse.com]

Been using them on my Z axis for about 2 months without issue. I will soon be trying them on Y too (not sure yet about X). When they were printed, they were slightly tight (like previous poster mentioned with his) but did what Triffid Hunter suggested and just ran them down some spare 8mm shaft - they were free in seconds for a perfect fit.

_______________________________________

Waitaki 3D Printer

Been using them on my Z axis for about 2 months without issue. I will soon be trying them on Y too (not sure yet about X). When they were printed, they were slightly tight (like previous poster mentioned with his) but did what Triffid Hunter suggested and just ran them down some spare 8mm shaft - they were free in seconds for a perfect fit.

_______________________________________

Waitaki 3D Printer

|

Re: LM8UU VS IGUS June 29, 2013 05:31AM |

Registered: 11 years ago Posts: 43 |

Ohmarinus Wrote:

-------------------------------------------------------

> I am curious to hear more stories about these PLA

> bushings. I have also seen someone experiment with

> Nylon (Think it was Taulman 618/645?).

>

> I have so far only printed with ABS, but am

> willing to try and make a switch to PLA some day.

> Also still planning my 2nd printer built, the idea

> is to rig that printer to run completely for PLA

> parts and keep my current printer for ABS.

Actually got some Taulman 645 in this week and am definitely planning on printing the bushings in nylon as well. Will post any results in this thread. Might be a while though since I need to find some Garolite as print surface first.

-------------------------------------------------------

> I am curious to hear more stories about these PLA

> bushings. I have also seen someone experiment with

> Nylon (Think it was Taulman 618/645?).

>

> I have so far only printed with ABS, but am

> willing to try and make a switch to PLA some day.

> Also still planning my 2nd printer built, the idea

> is to rig that printer to run completely for PLA

> parts and keep my current printer for ABS.

Actually got some Taulman 645 in this week and am definitely planning on printing the bushings in nylon as well. Will post any results in this thread. Might be a while though since I need to find some Garolite as print surface first.

|

Re: LM8UU VS IGUS July 10, 2013 06:38PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi, did you already try out your Nylon printing tests?

I have contacted IGUS again, they have a reseller in the Netherlands who is charging over 6 euros per bushing. You understand I am NOT going to pay 6 euros per linear bearing to that company.

Meanwhile I have also found a company that can sell me similar bushings for around 1.44 euros a piece, all I have to do is design some kind of holder that goes around the bushing because the bushing has a very thin wall.

On the web I see all kind of IGUS Drylin bushings being sold for much less, like on some places you can get 4 pieces for just 5 euro's, only problem is that they are not the 8mm ID and 15mm OD I am looking for.

Today I have sent a new order, if the price is right this time, I'll get those. I have added a note that the prices were outrageous and felt like they were completely random.

I have contacted IGUS again, they have a reseller in the Netherlands who is charging over 6 euros per bushing. You understand I am NOT going to pay 6 euros per linear bearing to that company.

Meanwhile I have also found a company that can sell me similar bushings for around 1.44 euros a piece, all I have to do is design some kind of holder that goes around the bushing because the bushing has a very thin wall.

On the web I see all kind of IGUS Drylin bushings being sold for much less, like on some places you can get 4 pieces for just 5 euro's, only problem is that they are not the 8mm ID and 15mm OD I am looking for.

Today I have sent a new order, if the price is right this time, I'll get those. I have added a note that the prices were outrageous and felt like they were completely random.

|

Re: LM8UU VS IGUS July 10, 2013 11:16PM |

Registered: 12 years ago Posts: 411 |

The Igus bushings that are the same size and shape as linear bearings are said to be quote good (never used them myself), but they are extremely expensive. In the past, I have both used and sold the much cheaper (< $1 apiece) press-fit Igus bushings with great success, but you need to choose the right ones; some do not last for very long. The ones I used in the past tended to wear out after about 8 months. I'm about to start using their more long-lasting cousins and I'm hopeful they live up to the longevity claims, because I really like how smooth and quiet and cheap the press-fit Igus bushings are.

Edited 1 time(s). Last edit at 07/11/2013 02:25AM by Pointedstick.

Edited 1 time(s). Last edit at 07/11/2013 02:25AM by Pointedstick.

|

Re: LM8UU VS IGUS July 11, 2013 12:26AM |

Registered: 11 years ago Posts: 661 |

The IGUS bearings are ultra high performance and have a price to match. They are designed for high end, high demand precision applications. For the amount it would cost to outfit a Reprap with them it's not cost effective. They do have a line of bushings that are more competitive in pricing. Something like a Dry Lin bearing can't be compared to low cost bushings or linear bearings. Thomason also has a precision LM8UU but it's also quite expensive compared to the low end bushings and import bearings.

|

Re: LM8UU VS IGUS July 11, 2013 05:04AM |

Admin Registered: 11 years ago Posts: 3,096 |

I have found a company that produces a type of bushing for me in a custom length, that is free of maintenance and lasts very long.

All I get from IGUS is not very useful quotes so I'm done with that company. Also, the questions I ask in the comments that I sent in with the order are completely skipped, twice.

If the bearings are any good from the other company, I might start selling them here, if anyone is interested. I also have matching STL's that work with these bearings instead of LM8UU's.

vegasloki, I am aware of the quality of the bearings, and I know it comes with a price, but if another company offers me something equal or better for 1/5th of the price that I even have direct contact with, I don't know...

All I get from IGUS is not very useful quotes so I'm done with that company. Also, the questions I ask in the comments that I sent in with the order are completely skipped, twice.

If the bearings are any good from the other company, I might start selling them here, if anyone is interested. I also have matching STL's that work with these bearings instead of LM8UU's.

vegasloki, I am aware of the quality of the bearings, and I know it comes with a price, but if another company offers me something equal or better for 1/5th of the price that I even have direct contact with, I don't know...

|

Re: LM8UU VS IGUS July 11, 2013 05:51AM |

Registered: 11 years ago Posts: 490 |

I have dealt with Igus before, too. If you have a project as a student, they are really one of the best companies to work with. You can get free samples and information pretty easily. The only thing you have to do is to send them your concept with some photographs so that they can put it onto their site.

This way, I got some Igus W series linear rail, but it turned out to be too heavy and not precise enough for my tastes. Someone I know did work with them for a little bit longer and got about 1.5m of drylin W rail and other samples.

That being said, I am all for printing your own bushings. We are getting further from the original goal of self-replicating machines if we always look for specialty solutions. Not that this is inherently wrong, but I myself would like to see this project goal being reached some time.

With a little bit of material research and the right hot end, the filament available right now turns out to be well suited for DIY bushings.

Have a look at this document: (sorry it's in German, but pages 4-7 show the relevant info like wear and friction).

So if we transfer this to our print stock, the taulman and PET filament we already have available seems to be ideally suited for this kind of application. In fact, I once did an experiment with taulman 618 as linear bushing material on aluminium. Results were pretty positive for the plastic, less so for the aluminium.

Of course, having an all-metal hot end will come in handy especially with PET.

I can imagine printed bushings being adjustable and removable without disassembling the axis via screws. Entirely new carriage designs not bound to the limitations and shapes of pre-existing bearings might appear.

This way, I got some Igus W series linear rail, but it turned out to be too heavy and not precise enough for my tastes. Someone I know did work with them for a little bit longer and got about 1.5m of drylin W rail and other samples.

That being said, I am all for printing your own bushings. We are getting further from the original goal of self-replicating machines if we always look for specialty solutions. Not that this is inherently wrong, but I myself would like to see this project goal being reached some time.

With a little bit of material research and the right hot end, the filament available right now turns out to be well suited for DIY bushings.

Have a look at this document: (sorry it's in German, but pages 4-7 show the relevant info like wear and friction).

So if we transfer this to our print stock, the taulman and PET filament we already have available seems to be ideally suited for this kind of application. In fact, I once did an experiment with taulman 618 as linear bushing material on aluminium. Results were pretty positive for the plastic, less so for the aluminium.

Of course, having an all-metal hot end will come in handy especially with PET.

I can imagine printed bushings being adjustable and removable without disassembling the axis via screws. Entirely new carriage designs not bound to the limitations and shapes of pre-existing bearings might appear.

|

Re: LM8UU VS IGUS July 11, 2013 07:02AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi uGen, I am aware of these bushings, I have also been following the other topic in which talk takes place about self-printed bushings, and even some tests with PLA!

However, the vitamins I have ordered and by budget don't allow me to buy either IGUS bushing, nor another hotend and all the other things needed with it to print the other types of material.

So for me, getting incredibly good bushings that only cost around 1,40 euros per piece, it's a great solution for now.

I must admit that I am also for having a machine that can print itself for the biggest part, but for me, reprap means not purely printed, but printed + vitamins. And, since I have already printed out all parts for my machine, I'll first finish the design I'm currently on before changing things again

When the 2nd machine is ready, I can start working on the first one. I have a Reprap Air 2 now, but will most likely be turned into a Prusa i3 or something similar. The Air lacks stability. I have glued, drilled, screwed, squared everything a thousand times, but still the 6mm acrylic has a slight flex in it that I cannot get rid of. There is two solutions, which is or another frame, or another extruder system (think Bowden).

The plan is to incorporate everything that I learn from building my MendelMax, back into the new version of the Reprap Air 2, since the Air 2 was bought as a very shitty kit, I haven't learned what I wanted to learn from it, and after the MendelMax my knowledge will be so much richer..

However, the vitamins I have ordered and by budget don't allow me to buy either IGUS bushing, nor another hotend and all the other things needed with it to print the other types of material.

So for me, getting incredibly good bushings that only cost around 1,40 euros per piece, it's a great solution for now.

I must admit that I am also for having a machine that can print itself for the biggest part, but for me, reprap means not purely printed, but printed + vitamins. And, since I have already printed out all parts for my machine, I'll first finish the design I'm currently on before changing things again

When the 2nd machine is ready, I can start working on the first one. I have a Reprap Air 2 now, but will most likely be turned into a Prusa i3 or something similar. The Air lacks stability. I have glued, drilled, screwed, squared everything a thousand times, but still the 6mm acrylic has a slight flex in it that I cannot get rid of. There is two solutions, which is or another frame, or another extruder system (think Bowden).

The plan is to incorporate everything that I learn from building my MendelMax, back into the new version of the Reprap Air 2, since the Air 2 was bought as a very shitty kit, I haven't learned what I wanted to learn from it, and after the MendelMax my knowledge will be so much richer..

|

Re: LM8UU VS IGUS July 12, 2013 10:52AM |

Registered: 11 years ago Posts: 490 |

Hi Marinus,

yeah, that's true. The specialty filament is still a little bit expensive and even though the E3D hot end is priced lower than some traditional ones, these things don't come cheap.

Have you considered sintered bronze bushings? They should be relatively cheap, too and are supposed to last quite a long time with the right amount of lubrication. If you have a Conrad electronics store or scale model/RC car shop near you, chances are that you can even get them without ordering.

About the flexing acrylic of the Prusa Air: My machine also wobbled a bit, but after I put it into a box with braces to fix the printer in place, the slightly unstable frame doesn't cause problems anymore. That being achieved with a rather cheap and lazy solution. The second advantage is that the box also helps to contain warmth and ABS fumes. If I understand your situation correctly, your printer is in your living room? I am using the box as a desk for my computer and can't smell anything although I am not actively filtering the air from the printer, so you might want give it a try.

yeah, that's true. The specialty filament is still a little bit expensive and even though the E3D hot end is priced lower than some traditional ones, these things don't come cheap.

Have you considered sintered bronze bushings? They should be relatively cheap, too and are supposed to last quite a long time with the right amount of lubrication. If you have a Conrad electronics store or scale model/RC car shop near you, chances are that you can even get them without ordering.

About the flexing acrylic of the Prusa Air: My machine also wobbled a bit, but after I put it into a box with braces to fix the printer in place, the slightly unstable frame doesn't cause problems anymore. That being achieved with a rather cheap and lazy solution. The second advantage is that the box also helps to contain warmth and ABS fumes. If I understand your situation correctly, your printer is in your living room? I am using the box as a desk for my computer and can't smell anything although I am not actively filtering the air from the printer, so you might want give it a try.

|

Re: LM8UU VS IGUS July 12, 2013 11:33AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi uGen, I will post some pictures of my machine, and of the bushings I've ordered now. Indeed I've scored some sintered bronze bushings, BUT, they have a very nice coating of PTFE that gives them almost no resistance.

To add, I have found myself some very affordable chromed rods, this means that I don't have to lubricate anything and the rods will probably never wear

I'll keep you posted.

To add, I have found myself some very affordable chromed rods, this means that I don't have to lubricate anything and the rods will probably never wear

I'll keep you posted.

|

Re: LM8UU VS IGUS July 12, 2013 03:25PM |

Admin Registered: 11 years ago Posts: 3,096 |

Ok, so the linear bearings were both around 50 and 70 cents.

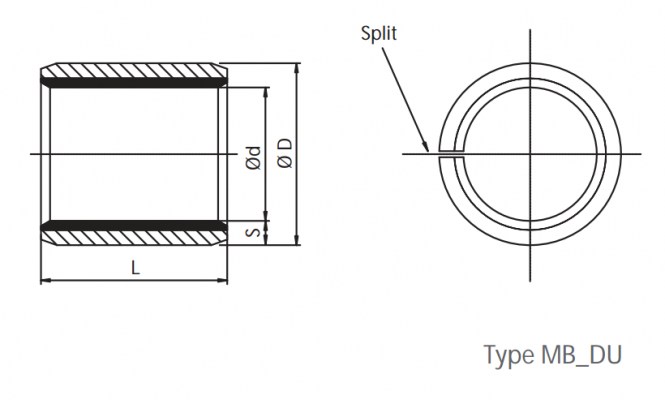

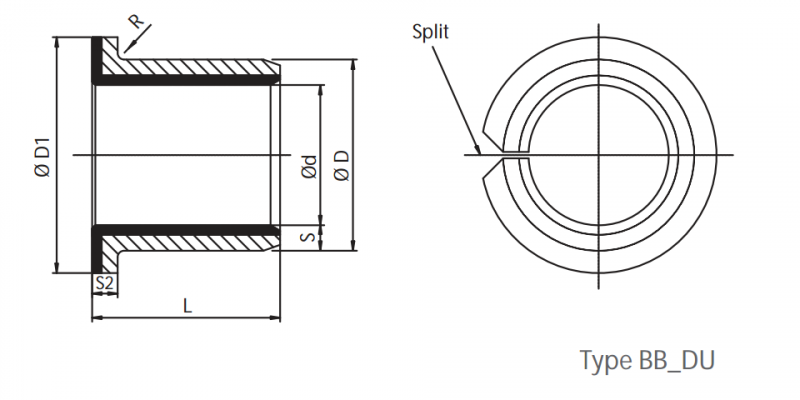

These are the models I've bought:

The one with the edge was the more expensive one.

Both linear bushing/bearings are lined with a layer of Pb-PTFE for smooth, oilless operation.

From the inside to the outside of the material the layers consist of Steel, Sintered bronze and then a lining of Pb-PTFE

The DU-type bearing I bought, has the following recommendations in certain uses:

Dry - Outstanding

Oiled - Good

Greased - Average

Water - Average

Process Liquid - Average

Straight Bushing:

Bushing with an Edge:

I am REALLLLY interested in how this works out, I bought Chromed rods, they were cheaper per rod, than one IGUS bushing.

My vendor is: www.thn.nl

These are the models I've bought:

The one with the edge was the more expensive one.

Both linear bushing/bearings are lined with a layer of Pb-PTFE for smooth, oilless operation.

From the inside to the outside of the material the layers consist of Steel, Sintered bronze and then a lining of Pb-PTFE

The DU-type bearing I bought, has the following recommendations in certain uses:

Dry - Outstanding

Oiled - Good

Greased - Average

Water - Average

Process Liquid - Average

Straight Bushing:

Bushing with an Edge:

I am REALLLLY interested in how this works out, I bought Chromed rods, they were cheaper per rod, than one IGUS bushing.

My vendor is: www.thn.nl

|

Re: LM8UU VS IGUS July 14, 2013 10:56AM |

Registered: 11 years ago Posts: 490 |

Interesting, PTFE alone has rather bad wear (but excellent friction) characteristics, but apparently by adding fillers, it is hard-wearing enough to be used in all kinds of different polymer bearings.

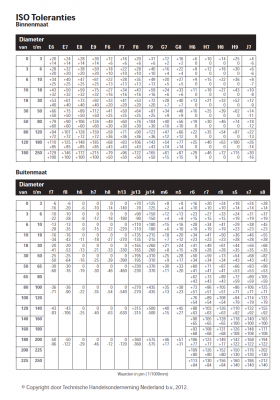

Normally, the kind of bushings you bought (and pretty much all of Igus' inexpensive products) are supposed to be fit into bores complying to a certain tolerance in order to reach their designed inner diameter, no? Maybe I am a little bit too paranoid about tolerances, but shouldn't that lead to problems like loose fit or too tight fit etc. if you press them into any bore? Didn't the manufacturer specify that in datasheets cause I can't find this info on their site?

Normally, the kind of bushings you bought (and pretty much all of Igus' inexpensive products) are supposed to be fit into bores complying to a certain tolerance in order to reach their designed inner diameter, no? Maybe I am a little bit too paranoid about tolerances, but shouldn't that lead to problems like loose fit or too tight fit etc. if you press them into any bore? Didn't the manufacturer specify that in datasheets cause I can't find this info on their site?

|

Re: LM8UU VS IGUS July 14, 2013 12:42PM |

Admin Registered: 11 years ago Posts: 3,096 |

Yes it's in their datasheet, I am not familiar with tolerances and just decided to experiment, but I can look it up for you and share the information if you want.

I thought to just start printing parts and see if it fits and adjust according to the tolerances

uGen Wrote:

-------------------------------------------------------

> Interesting, PTFE alone has rather bad wear (but

> excellent friction) characteristics, but

> apparently by adding fillers, it is hard-wearing

> enough to be used in all kinds of different

> polymer bearings.

> Normally, the kind of bushings you bought (and

> pretty much all of Igus' inexpensive products) are

> supposed to be fit into bores complying to a

> certain tolerance in order to reach their designed

> inner diameter, no? Maybe I am a little bit too

> paranoid about tolerances, but shouldn't that lead

> to problems like loose fit or too tight fit etc.

> if you press them into any bore? Didn't the

> manufacturer specify that in datasheets cause I

> can't find this info on their site?

I thought to just start printing parts and see if it fits and adjust according to the tolerances

uGen Wrote:

-------------------------------------------------------

> Interesting, PTFE alone has rather bad wear (but

> excellent friction) characteristics, but

> apparently by adding fillers, it is hard-wearing

> enough to be used in all kinds of different

> polymer bearings.

> Normally, the kind of bushings you bought (and

> pretty much all of Igus' inexpensive products) are

> supposed to be fit into bores complying to a

> certain tolerance in order to reach their designed

> inner diameter, no? Maybe I am a little bit too

> paranoid about tolerances, but shouldn't that lead

> to problems like loose fit or too tight fit etc.

> if you press them into any bore? Didn't the

> manufacturer specify that in datasheets cause I

> can't find this info on their site?

|

Re: LM8UU VS IGUS July 14, 2013 06:09PM |

Registered: 11 years ago Posts: 490 |

Thank you, but I don't use this kind of bearings. Just asked out of interest.

Well, let's hope that the inherent flexibility of the plastic makes this work even if the bore doesn't comply to any tolerance class.

I have several PDF files with ISO tolerance specifications, though, if you are interested.

Well, let's hope that the inherent flexibility of the plastic makes this work even if the bore doesn't comply to any tolerance class.

I have several PDF files with ISO tolerance specifications, though, if you are interested.

|

Re: LM8UU VS IGUS July 14, 2013 06:45PM |

Admin Registered: 11 years ago Posts: 3,096 |

To be honest, I am totally new to tolerances. I come from a creative background and not a technical one. So just trying out new things here

It's the first time I had contact with a technical company to order special parts.

The part about tolerance is here, I hope you understand a bit of Dutch:

Edited 1 time(s). Last edit at 07/14/2013 06:45PM by Ohmarinus.

It's the first time I had contact with a technical company to order special parts.

The part about tolerance is here, I hope you understand a bit of Dutch:

Edited 1 time(s). Last edit at 07/14/2013 06:45PM by Ohmarinus.

|

Re: LM8UU VS IGUS July 15, 2013 06:16AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi uGen, received my bearings and rods today. And I know what you mean with tolerance now too

Maybe I kinda overdid the smooth rod part, the chromed rods are beautiful and will probably outlive me, so good investment, but the bearings indeed have a little play.

Now I can do two things, just use the bushings or still go for LM8UU, I first want to give the bushings a chance, because they do slide beautifully, it's incredible how little resistance they offer when I slide them along the rod.

I have managed to print the tightest possible holder for the bushings so the tolerances are down to a minimum, and with two bushings on each side of the thing I want to clip onto the rods, they might just work perfectly.. or fail altogether Anyway, the tolerance of the bushing is in the region of maybe 0.001mm of play, so you feel there is a small wiggle possible, but it's so incredibly small that I probably won't notice it in my prints, hell, probably won't even notice it in the corners of prints.

Anyway, the tolerance of the bushing is in the region of maybe 0.001mm of play, so you feel there is a small wiggle possible, but it's so incredibly small that I probably won't notice it in my prints, hell, probably won't even notice it in the corners of prints.

Today my frame will also arrive, so I will wait and see. When the build is ready to testprint, I will post here if it works

Maybe I kinda overdid the smooth rod part, the chromed rods are beautiful and will probably outlive me, so good investment, but the bearings indeed have a little play.

Now I can do two things, just use the bushings or still go for LM8UU, I first want to give the bushings a chance, because they do slide beautifully, it's incredible how little resistance they offer when I slide them along the rod.

I have managed to print the tightest possible holder for the bushings so the tolerances are down to a minimum, and with two bushings on each side of the thing I want to clip onto the rods, they might just work perfectly.. or fail altogether

Anyway, the tolerance of the bushing is in the region of maybe 0.001mm of play, so you feel there is a small wiggle possible, but it's so incredibly small that I probably won't notice it in my prints, hell, probably won't even notice it in the corners of prints.

Anyway, the tolerance of the bushing is in the region of maybe 0.001mm of play, so you feel there is a small wiggle possible, but it's so incredibly small that I probably won't notice it in my prints, hell, probably won't even notice it in the corners of prints.Today my frame will also arrive, so I will wait and see. When the build is ready to testprint, I will post here if it works

|

Re: LM8UU VS IGUS July 18, 2013 05:07PM |

Registered: 11 years ago Posts: 490 |

Hi Marinus,

my DIY bearings also wiggle a tiny little bit, but that seems to be OK. Theoretically, an adjustable clamping mechanism might solve tolerance issues - a screw that compresses the holder could do the trick. That way, even wear compensation may be possible by just tightening the screw a little bit more.

I would also go with chromed stainless hardened shafts the next time if I used LM8UU bearings. The Cf53 hardened rods on my printer will rust (they already do after a few months, to be exact, but I didn't oil them) while plain stainless shafts will get grooves from the bearings over time. So you chose the option with the greatest flexibility in my opinion.

my DIY bearings also wiggle a tiny little bit, but that seems to be OK. Theoretically, an adjustable clamping mechanism might solve tolerance issues - a screw that compresses the holder could do the trick. That way, even wear compensation may be possible by just tightening the screw a little bit more.

I would also go with chromed stainless hardened shafts the next time if I used LM8UU bearings. The Cf53 hardened rods on my printer will rust (they already do after a few months, to be exact, but I didn't oil them) while plain stainless shafts will get grooves from the bearings over time. So you chose the option with the greatest flexibility in my opinion.

|

Re: LM8UU VS IGUS July 18, 2013 06:07PM |

Admin Registered: 11 years ago Posts: 3,096 |

Good you say that about the rods

That was my intention too, to put a bit of money in the project but at least make it worth it. I have reasoned, if I ever build a new printer, I will migrate the rods and replace then with normal ones in the older machine.

Meanwhile I am having little trouble with finishing my printed parts for the X-carriage and Prusa i3 hotend holder. It is going to be a Bowden system, just because I want to try something fancy.

Currently in the process of designing my own bushing-holders for the Y-carriage, they should be self-aligning, so it is a challenge

Is there a place where I can see your printer?

uGen Wrote:

-------------------------------------------------------

> Hi Marinus,

>

> my DIY bearings also wiggle a tiny little bit, but

> that seems to be OK. Theoretically, an adjustable

> clamping mechanism might solve tolerance issues -

> a screw that compresses the holder could do the

> trick. That way, even wear compensation may be

> possible by just tightening the screw a little bit

> more.

>

> I would also go with chromed stainless hardened

> shafts the next time if I used LM8UU bearings. The

> Cf53 hardened rods on my printer will rust (they

> already do after a few months, to be exact, but I

> didn't oil them) while plain stainless shafts will

> get grooves from the bearings over time. So you

> chose the option with the greatest flexibility in

> my opinion.

That was my intention too, to put a bit of money in the project but at least make it worth it. I have reasoned, if I ever build a new printer, I will migrate the rods and replace then with normal ones in the older machine.

Meanwhile I am having little trouble with finishing my printed parts for the X-carriage and Prusa i3 hotend holder. It is going to be a Bowden system, just because I want to try something fancy.

Currently in the process of designing my own bushing-holders for the Y-carriage, they should be self-aligning, so it is a challenge

Is there a place where I can see your printer?

uGen Wrote:

-------------------------------------------------------

> Hi Marinus,

>

> my DIY bearings also wiggle a tiny little bit, but

> that seems to be OK. Theoretically, an adjustable

> clamping mechanism might solve tolerance issues -

> a screw that compresses the holder could do the

> trick. That way, even wear compensation may be

> possible by just tightening the screw a little bit

> more.

>

> I would also go with chromed stainless hardened

> shafts the next time if I used LM8UU bearings. The

> Cf53 hardened rods on my printer will rust (they

> already do after a few months, to be exact, but I

> didn't oil them) while plain stainless shafts will

> get grooves from the bearings over time. So you

> chose the option with the greatest flexibility in

> my opinion.

|

Re: LM8UU VS IGUS July 23, 2013 05:51PM |

Registered: 11 years ago Posts: 490 |

ack, sorry, I was procrastinating this reply forever...

I like nophead's loose bearing system on his Mendel90 for self-alignment. Simple, yet efficient. Is yours of similar design or did you design something completely different?

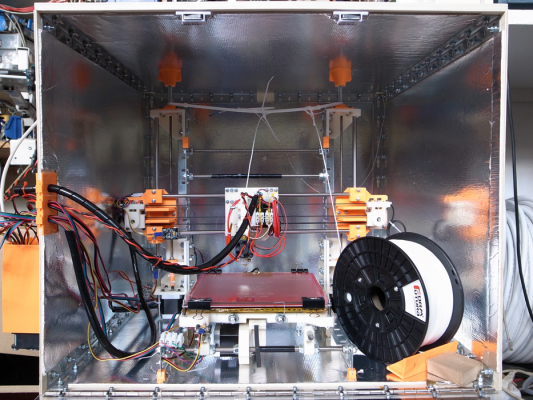

And my printer:

The heat insulating chamber is outfitted with aluminium coated styrofoam that I got in the local hardware store. It is normally being used to insulate the wall behind radiators. Cost is about 2€ / square meter.

To keep the electronic cool, they are situated in the orange box on the left with a fan blowing fresh air through the box from below, adding to the chimney effect of warm air rising and sucking in cooler air from below.

Right now, I am in the process of building a real filament spool holder. This solution here is rather ridiculous and prone to failure.

Finally, to secure the printer against vibrations, I installed the braces that screw against the top of the chamber. Works really well and can be detached quickly.

This is the most recent configuration. I haven't really officially documented it because there are so many design flaws that I feel if I post build plans and people are actually building it, this wouldn't be right. I would prefer documenting my second printer that is in the planning phase, though.

Older images and descriptions can be found here: µGen T/B (alpha)

The biggest changes are improved X ends and the E3D hot end. I also went from M8 to M5 lead screws for Z to combat wobble, but it seems like wobble is caused by the threaded rod sliding around in the nuts, creeping up the threads to the extend the play between both element allows as the M5 ones also exhibit wobble. So the solution would be installing an anti backlash system.

I like nophead's loose bearing system on his Mendel90 for self-alignment. Simple, yet efficient. Is yours of similar design or did you design something completely different?

And my printer:

The heat insulating chamber is outfitted with aluminium coated styrofoam that I got in the local hardware store. It is normally being used to insulate the wall behind radiators. Cost is about 2€ / square meter.

To keep the electronic cool, they are situated in the orange box on the left with a fan blowing fresh air through the box from below, adding to the chimney effect of warm air rising and sucking in cooler air from below.

Right now, I am in the process of building a real filament spool holder. This solution here is rather ridiculous and prone to failure.

Finally, to secure the printer against vibrations, I installed the braces that screw against the top of the chamber. Works really well and can be detached quickly.

This is the most recent configuration. I haven't really officially documented it because there are so many design flaws that I feel if I post build plans and people are actually building it, this wouldn't be right. I would prefer documenting my second printer that is in the planning phase, though.

Older images and descriptions can be found here: µGen T/B (alpha)

The biggest changes are improved X ends and the E3D hot end. I also went from M8 to M5 lead screws for Z to combat wobble, but it seems like wobble is caused by the threaded rod sliding around in the nuts, creeping up the threads to the extend the play between both element allows as the M5 ones also exhibit wobble. So the solution would be installing an anti backlash system.

|

Re: LM8UU VS IGUS January 18, 2015 11:25PM |

Registered: 9 years ago Posts: 12 |

I know this is a bit old, but FWIW, Igus now sell their polymer bushing material as a filament for you to print your own:

[www.igus.com]

I am heading towards the reduction of inertia as the way forward in improving print speed and quality and am using carbon-fibre shafts with Igus polymer bushings and finding it is working really well.

The overall cost above that of a steel shaft/LM8UU roller bearing is about double, but the shipping costs are half (which for me, are significant). This makes it more affordable than the steel/bearing solution.

For those living with easy access to good quality steel and bearing supplies, you probably won't get the same economy.

Edited 1 time(s). Last edit at 01/18/2015 11:29PM by ledaero.

[www.igus.com]

I am heading towards the reduction of inertia as the way forward in improving print speed and quality and am using carbon-fibre shafts with Igus polymer bushings and finding it is working really well.

The overall cost above that of a steel shaft/LM8UU roller bearing is about double, but the shipping costs are half (which for me, are significant). This makes it more affordable than the steel/bearing solution.

For those living with easy access to good quality steel and bearing supplies, you probably won't get the same economy.

Edited 1 time(s). Last edit at 01/18/2015 11:29PM by ledaero.

|

Re: LM8UU VS IGUS January 19, 2015 01:24PM |

Registered: 9 years ago Posts: 376 |

Quote

Pointedstick

The Igus bushings that are the same size and shape as linear bearings are said to be quote good (never used them myself), but they are extremely expensive. In the past, I have both used and sold the much cheaper (< $1 apiece) press-fit Igus bushings with great success, but you need to choose the right ones; some do not last for very long. The ones I used in the past tended to wear out after about 8 months. I'm about to start using their more long-lasting cousins and I'm hopeful they live up to the longevity claims, because I really like how smooth and quiet and cheap the press-fit Igus bushings are.

Igus 8mm are 1mm wider and 1mm longer. They are really nice though. Very quiet, very smooth.

|

Re: LM8UU VS IGUS January 22, 2015 09:11AM |

Registered: 9 years ago Posts: 1,011 |

Hi all ! Well I guess we all agree that standard LM8UU are rubbish, loosing balls, short lasting, and pretty loose. I tryed several things, like order 4xLM8UU from the serious NSK company. Well, to be totaly honnest, they are ways better. No play, much less operating noise and durable. BUT, they cost about 10 bocks each  So I printed some linear bushings, several types, some from thingiverse, some I designed myself. Honnestly, I could not get enough precision to make them fit perfectly without gap or too much friction. I noticed that after long prints, it can get too warm to stand their dimensions. Tthe noise was ducked through.

So I printed some linear bushings, several types, some from thingiverse, some I designed myself. Honnestly, I could not get enough precision to make them fit perfectly without gap or too much friction. I noticed that after long prints, it can get too warm to stand their dimensions. Tthe noise was ducked through.

Then I made easy PTFE bushings just by drilling a precision hole thru a PTFE block. Several bit diameters was needed because the bit pushes the PTFE away and the hole is slightly tighter than the drill bit. So you want a 8.3mm bit to get perfect 8.1mm holes. No more noise, that was great. BUT, PTFE is not cheap either, and the lasting is not good enough. Within 100 hours, some gap appears, no big deal, but I noticed the M3 hardware also dig a bit into the PTFE.

Meanwhile, I ordered some Igus RJMP-01-08 bearings to replace the X carriage ones and give them a try. The price was about $3.5 each on ebay, not too expensive. I now use the Igus for more than 500 hours, they're still like new. I changed even the NSK ones for Igus, to get the machine quieter. Now the only sound I heard during printing comes from the steppers ! Each time I upgraded an axis with Igus bushings, the print quality was significantly improoved. Less vibrations = better quality. It's realy worth the money. I'm now a huge fan of Igus bushing, and I highly recommand it. I aggree with Omarinus that you don't want to printout anything. Especialy wear parts, even if there's some cost. Guides and bearings, like transmission parts, needs to be as accurate and durable as possible. The FDM technology cannot garantee that today.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

So I printed some linear bushings, several types, some from thingiverse, some I designed myself. Honnestly, I could not get enough precision to make them fit perfectly without gap or too much friction. I noticed that after long prints, it can get too warm to stand their dimensions. Tthe noise was ducked through.

So I printed some linear bushings, several types, some from thingiverse, some I designed myself. Honnestly, I could not get enough precision to make them fit perfectly without gap or too much friction. I noticed that after long prints, it can get too warm to stand their dimensions. Tthe noise was ducked through. Then I made easy PTFE bushings just by drilling a precision hole thru a PTFE block. Several bit diameters was needed because the bit pushes the PTFE away and the hole is slightly tighter than the drill bit. So you want a 8.3mm bit to get perfect 8.1mm holes. No more noise, that was great. BUT, PTFE is not cheap either, and the lasting is not good enough. Within 100 hours, some gap appears, no big deal, but I noticed the M3 hardware also dig a bit into the PTFE.

Meanwhile, I ordered some Igus RJMP-01-08 bearings to replace the X carriage ones and give them a try. The price was about $3.5 each on ebay, not too expensive. I now use the Igus for more than 500 hours, they're still like new. I changed even the NSK ones for Igus, to get the machine quieter. Now the only sound I heard during printing comes from the steppers ! Each time I upgraded an axis with Igus bushings, the print quality was significantly improoved. Less vibrations = better quality. It's realy worth the money. I'm now a huge fan of Igus bushing, and I highly recommand it. I aggree with Omarinus that you don't want to printout anything. Especialy wear parts, even if there's some cost. Guides and bearings, like transmission parts, needs to be as accurate and durable as possible. The FDM technology cannot garantee that today.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Sorry, only registered users may post in this forum.