Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618

Posted by NjEmt527

|

Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 August 08, 2013 06:25AM |

Registered: 10 years ago Posts: 31 |

So I am posting this because because I found information scattered around the internet and it was a pain to figured out what was where. Hopefully, next person that googles it will find this post:

I bought my Rep-Rap Prusa I2 used. It came with a small amount of PLA and almost a full roll of Taulman Nylon 618, both 3mm. It came with a plexiglass bed installed and a heated bed (not installed) and a Budaschnozzle. I had read up on Nylon 618, and about how it did not need any extra fans or heated bed. I downloaded slicer 3 and pronterface (eventually stopped using and just used an sd card) and tried printing a some items. Ended up with warping so bad parts were unusable and low quality. So I scoured the web, and found bits and pieces of information on it in this forum and that forum. After trying a bunch of things (I'll spare you the boring details and cursing) I have found the right mix of things that work for me. I have now ran about 12 prints using the setup below with great quality and very little if any warping. Even with solid parts .Hopefully they will help others out too. I will post pics when I get around to cleaning up the parts.

My advice:

#1 Dry the Nylon. Mine came in a plastic casing, So I took it off and zip tied it into a spool. 4 hours @ 200 degree F in my oven.

#2. Dry it again.

#3 When you finally think it is dry, dry it again. On the specs of nylon, it can absorb a ton of moisture. It cause a ton of problems when extruding it. Warping included.

#4 Set your extruder at 230 degrees C and adjust from there. I have mine set currently at 238 C and great great adhesion. My nozzle has teflon liner as far as I know, and I dont want to burn the Teflon (nasty bad skull and cross bones fumes). If you dont have teflon in yours, people push it as high as 248 degrees C.

#5. Use a glass heated bed and no tape. I tired different Garolite, mdf, plexiglass, and wood. The last three with and w/o blue tape. I set mine to 38 degrees C, sometimes a bit more when the room is really cold. All I wanted to do was soften the shock of the hot Nylon on a cold bed.

#5 Elmer's washable glue stick. I coat my glass while the bed is warming up with it. This is one of two very important steps to get it to stick to the glass and prevent warping. And yes, the kinds that starts purple and turns clear is just fine. I currently use it.

#6 Print a Brim. A MUST to keep it from warping. It is an option in the current version of SLic3r. I started big with this one and have been working my way down. On very small parts like your extruder motor gear, use about 7mm brim and go bigger. On most of my parts, they get at least a 10mm brim.

#7 Be ladylike and wear a skirt. I have found nylon takes a long time to get flowing well through your nozzle. I normally use a 1 layer skirt of 5 loops and I set the distance (this is important) to whatever the size of my brim is. So if I'm using a 7mm brim, set the distance from object in the skirt menu to 7mm.

#8. If your one of those people that like to push there machines as fast as they can, slow your roll. Much better results. All my speeds are less than slic3r defaults.

#9 And finally, pick up something to pry your part up with. I use a metal putty knife. Once you parts cool, start at the brim and work your way around slowly.

# 10. Wash and enjoy your new Nylon print. There will be some glue on the bottom of it but since it is washes off with plain water, it comes off easily.

If anyone else has any tips or sees something I missed, just post and let me know. Hope this helps.

-Clark

I bought my Rep-Rap Prusa I2 used. It came with a small amount of PLA and almost a full roll of Taulman Nylon 618, both 3mm. It came with a plexiglass bed installed and a heated bed (not installed) and a Budaschnozzle. I had read up on Nylon 618, and about how it did not need any extra fans or heated bed. I downloaded slicer 3 and pronterface (eventually stopped using and just used an sd card) and tried printing a some items. Ended up with warping so bad parts were unusable and low quality. So I scoured the web, and found bits and pieces of information on it in this forum and that forum. After trying a bunch of things (I'll spare you the boring details and cursing) I have found the right mix of things that work for me. I have now ran about 12 prints using the setup below with great quality and very little if any warping. Even with solid parts .Hopefully they will help others out too. I will post pics when I get around to cleaning up the parts.

My advice:

#1 Dry the Nylon. Mine came in a plastic casing, So I took it off and zip tied it into a spool. 4 hours @ 200 degree F in my oven.

#2. Dry it again.

#3 When you finally think it is dry, dry it again. On the specs of nylon, it can absorb a ton of moisture. It cause a ton of problems when extruding it. Warping included.

#4 Set your extruder at 230 degrees C and adjust from there. I have mine set currently at 238 C and great great adhesion. My nozzle has teflon liner as far as I know, and I dont want to burn the Teflon (nasty bad skull and cross bones fumes). If you dont have teflon in yours, people push it as high as 248 degrees C.

#5. Use a glass heated bed and no tape. I tired different Garolite, mdf, plexiglass, and wood. The last three with and w/o blue tape. I set mine to 38 degrees C, sometimes a bit more when the room is really cold. All I wanted to do was soften the shock of the hot Nylon on a cold bed.

#5 Elmer's washable glue stick. I coat my glass while the bed is warming up with it. This is one of two very important steps to get it to stick to the glass and prevent warping. And yes, the kinds that starts purple and turns clear is just fine. I currently use it.

#6 Print a Brim. A MUST to keep it from warping. It is an option in the current version of SLic3r. I started big with this one and have been working my way down. On very small parts like your extruder motor gear, use about 7mm brim and go bigger. On most of my parts, they get at least a 10mm brim.

#7 Be ladylike and wear a skirt. I have found nylon takes a long time to get flowing well through your nozzle. I normally use a 1 layer skirt of 5 loops and I set the distance (this is important) to whatever the size of my brim is. So if I'm using a 7mm brim, set the distance from object in the skirt menu to 7mm.

#8. If your one of those people that like to push there machines as fast as they can, slow your roll. Much better results. All my speeds are less than slic3r defaults.

#9 And finally, pick up something to pry your part up with. I use a metal putty knife. Once you parts cool, start at the brim and work your way around slowly.

# 10. Wash and enjoy your new Nylon print. There will be some glue on the bottom of it but since it is washes off with plain water, it comes off easily.

If anyone else has any tips or sees something I missed, just post and let me know. Hope this helps.

-Clark

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 August 08, 2013 07:43AM |

Admin Registered: 12 years ago Posts: 2,569 |

Thanks for your information. I have been experimenting with nylon too (trimmer line) and warping is still a big problem.

I noticed it warp less than ABS (regarding deformation dimensions) but with what feels like a greater force.

I'll give a test try at drying in an owen. Is there a reason for choosing that specific temperature ?

Regarding the glue, we don't have elmer's around here. Does this looks similar ?

Additional question : did I read it right, you print directly on glue-coated heated glass, only at 38°C warm ?

Edited 1 time(s). Last edit at 08/08/2013 09:41AM by DeuxVis.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

I noticed it warp less than ABS (regarding deformation dimensions) but with what feels like a greater force.

I'll give a test try at drying in an owen. Is there a reason for choosing that specific temperature ?

Regarding the glue, we don't have elmer's around here. Does this looks similar ?

Additional question : did I read it right, you print directly on glue-coated heated glass, only at 38°C warm ?

Edited 1 time(s). Last edit at 08/08/2013 09:41AM by DeuxVis.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 August 08, 2013 09:39AM |

Registered: 10 years ago Posts: 474 |

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 August 08, 2013 03:21PM |

Registered: 10 years ago Posts: 31 |

DeuxVis,

As far as warping, I have yet to print ABS. But nylon warps with a bit of for and a lot of curve if it is moist, a 50mm hexagon ended up looking like a 1/2 ball on the bottom before drying it.

I used the temp of 200 F because I felt comfortable leaving the oven at that while I was sleeping. Threw the nylon in when I got home from work and went to bed with the timer set.

Any washable glue stick may work, some better than others. But those look similar to the ones Im using. So give it a try

Yes, I am coating my glass with the glue stick an printing directly on it. You may have to adjust your nozzle height.

Cnc Dick,

I am not sure if I ran across his blog in my searches. Would you post a link?

As far as warping, I have yet to print ABS. But nylon warps with a bit of for and a lot of curve if it is moist, a 50mm hexagon ended up looking like a 1/2 ball on the bottom before drying it.

I used the temp of 200 F because I felt comfortable leaving the oven at that while I was sleeping. Threw the nylon in when I got home from work and went to bed with the timer set.

Any washable glue stick may work, some better than others. But those look similar to the ones Im using. So give it a try

Yes, I am coating my glass with the glue stick an printing directly on it. You may have to adjust your nozzle height.

Cnc Dick,

I am not sure if I ran across his blog in my searches. Would you post a link?

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 August 08, 2013 04:12PM |

Registered: 11 years ago Posts: 77 |

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 November 23, 2013 11:46PM |

Registered: 11 years ago Posts: 160 |

I've tried the method in the OP with no luck at all. I've tried many things, with no luck. I have not yet tried garolite, but I decided to give a piece of luan a try. Luan can be bought in any hardware store, it's cheap too. At this point, I've only printed 3 pieces on it, so the jury is still out. I am also using the elmers glue, as it stopped some of the fibers from being pulled up when I lifted the work. I am heating the bed to 38C, but not even sure that's necessary yet. One thing I noticed is that luan is not very flat, so be mindful of that when leveling the bed. I am using a 10mm brimm.

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 November 25, 2013 01:16PM |

Registered: 10 years ago Posts: 7 |

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 November 26, 2013 10:13PM |

Registered: 11 years ago Posts: 160 |

A little update as I mess around with this 618. I got my garolite from mcmaster carr, and after 5 prints it is sticking beautiful. No heat on the bed, no mess, no glue, no cleanup. I hope it stays this way, very easy to use. I was having trouble with the laminations to stick together at the suggested temps. I think my thermister is off or something, I had to keep raising the temps to get bondage. I am at 270 now, and the prints are so tuff they piratically broke my pliers testing them.

Check it out:

[www.youtube.com]

Check it out:

[www.youtube.com]

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 January 19, 2014 10:00AM |

Registered: 11 years ago Posts: 69 |

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 January 19, 2014 03:22PM |

Registered: 11 years ago Posts: 246 |

OP's method works perfectly

I actually have been using Elmer's glue stick on heated glass for printing ABS and PC for a long time and it works great. No warping!

It works for Nylon as well, but I needed a brim to combat the increased warping. BTW, I use a bed temp of about 50C which is just at the glass transition temp of Nylon 618, though I could probably drop the bed temp another 10C without problems.

Eric

I actually have been using Elmer's glue stick on heated glass for printing ABS and PC for a long time and it works great. No warping!

It works for Nylon as well, but I needed a brim to combat the increased warping. BTW, I use a bed temp of about 50C which is just at the glass transition temp of Nylon 618, though I could probably drop the bed temp another 10C without problems.

Eric

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 January 20, 2014 03:38AM |

Registered: 11 years ago Posts: 160 |

Quote

bytemedwb

Which garolite variant did you purchase?

Garolite LE. My piece from mcmaster was not flat. I purchased the 1/4" piece. I think if I were to buy the Garolite again I would get a thin piece and laminate it to something flat.

Next in line is a piece of 1/4 nylon I got from mcmaster carr. My theory with that is there is a temp you can print were the layers stick very well but when pressure is applied the layers split. For me it is around 245. So I plan on printing that first layer at a temp that allows that to happen. The rest of the layers will be printed for maximum adhesion.

Another side note on the warping issues. No matter how well your piece sticks to the build platform, on some pieces you will still get a warp once you pull it off. The pieces I am trying to make are having that problem. The solution is to print with a larger nozzle of a heated bed and print faster to minimize cooling between top and bottom layers. However that will only go so far and if you are trying to make precision pieces like me there may be no solution at all. Soooo, I ordered some 645 which is supposed to have less warpage because it is stiffer and shrinks less when cooling, and taulman has sent me some 910 to beta test, which should be even better. I will be posting my results.

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 February 16, 2014 08:12PM |

Registered: 11 years ago Posts: 19 |

I'm using 1/16" Garolite LE or CE (LE or sanded CE is best) bonded to aluminum Mic-6 bed plate using water soluble wood glue. The thicker Garolite is often badly warped from the manufacturer--too warped to machine and use without the Mic-6 plate. The Garolite can be renewed, when necessary (not very often) by soaking the plate in a bucket of water. The 1/16" sheets are flexible and bond to provide a reasonably flat surface, which can be further leveled by sanding on a large plate of thick glass (inherently flat). For the best adhesion, a glue stick can be applied to the Garolite and blotted with a terry cloth before it dries to provide a little texture to the glue surface, improving its performance. A wet sponge works well to redistribute the glue between print runs. I have not found heat to be useful with nylon.

|

Re: Printing with Nylon 618 Sucess! A post for anyone having issues printing with Nylon 618 March 19, 2014 05:28PM |

Registered: 10 years ago Posts: 39 |

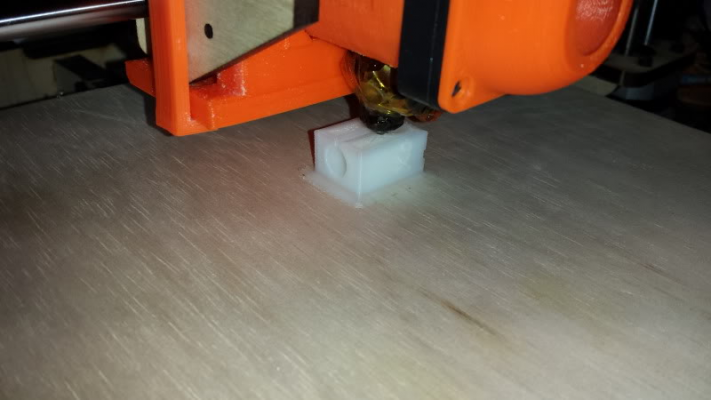

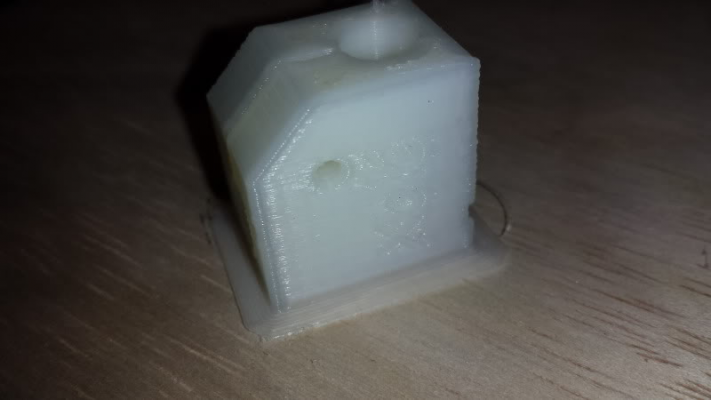

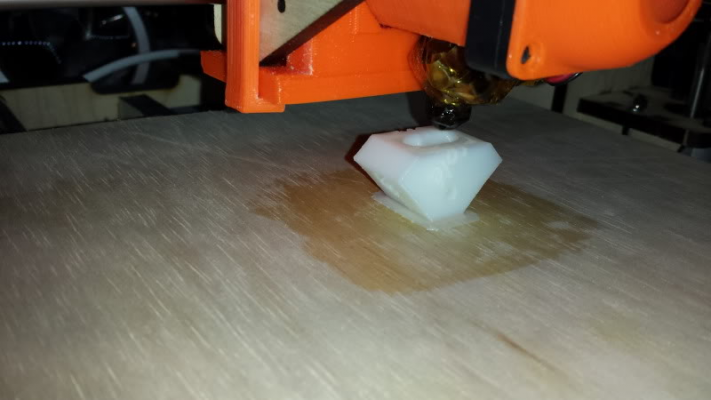

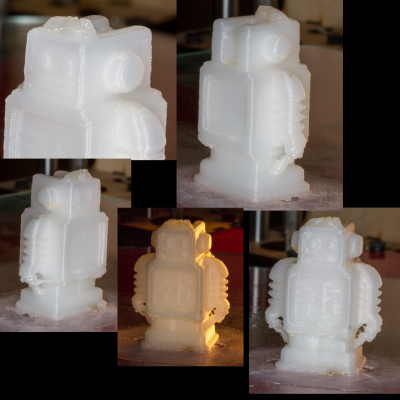

NjEmt527 (Clark), I just made my first Nylon print with my Makerfarm Prusa i3 8" and followed your directions to the letter. It worked perfectly. There are a few tweaks I need to make of course but for a first print I'm thrilled. It was not difficult to remove the part either. I printed 6 skirts and did find that it does take a bit longer for the filament to settle down and get consistent. Here's a few shots. It's always difficult to shoot white filament but as you can see it's completely satisfactory as a first print. Thanks for the post and guidance.

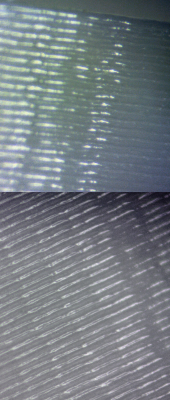

Edit: I just added a x45 microscopic shot of my 2nd print and the layer height was set to 0.10. It printed really, really well. Here's how the layers look. It's always difficult to photograph translucent white objects but I think you can see that they laid down pretty nicely. When I bought my printer last year there was some chat about experiments with nylon and they weren't too encouraging. I have to say, I'm pretty excited about it. I did get a tiny little bit of warping so I think it's time to build a cabinet so I can control drafts and the print envelope a bit better.

Edited 1 time(s). Last edit at 03/19/2014 10:52PM by RobH2.

Prusa i3 8" (Makerfarm) / Dual Hexagon 0.4 extruder

Edit: I just added a x45 microscopic shot of my 2nd print and the layer height was set to 0.10. It printed really, really well. Here's how the layers look. It's always difficult to photograph translucent white objects but I think you can see that they laid down pretty nicely. When I bought my printer last year there was some chat about experiments with nylon and they weren't too encouraging. I have to say, I'm pretty excited about it. I did get a tiny little bit of warping so I think it's time to build a cabinet so I can control drafts and the print envelope a bit better.

Edited 1 time(s). Last edit at 03/19/2014 10:52PM by RobH2.

Prusa i3 8" (Makerfarm) / Dual Hexagon 0.4 extruder

Sorry, only registered users may post in this forum.