perimeter separating

Posted by arjena

|

perimeter separating September 07, 2013 07:48AM |

Registered: 10 years ago Posts: 13 |

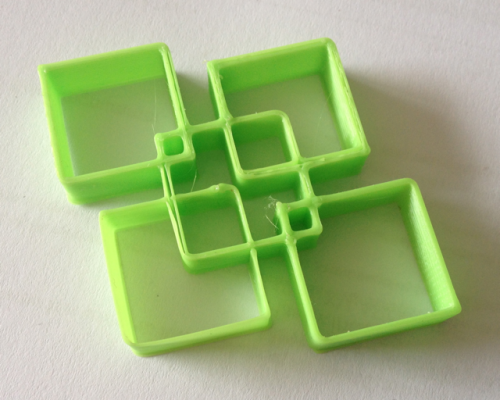

I have been experimenting with cookie cutters, trying to find the ideal balance between wall thickness and strength.

So I made a test object (in Rhino) consisting of 5 intersecting thin-walled objects (very much like the .5mm thin wall calibration object). These objects vary in wall thickness from .4mm (my nozzle size) to 1.2 mm. I set slicer to 100% infill, layer height .25mm. For good measure I also set solid infil every layer. I'm printing PLA at 205C with a E3D hot-end, when I go lower the layers don't stick together well enough.

The .4mm thick wall measures .5mm after print and is build from one perimeter. the .6 is .8, also one perimeter. The .8mm is 1 mm, still one perimeter.

The problem begins with the 1 mm thick wall. This is build from two perimeters, but these do not seem to be connected. When I check my gcode at gcode.ws it shows infill between the two walls, and while printing the head goes over the area three times, but there is a gap between the two. I can easily put my fingernail inbetween the two perimeters and when I try to bend the object the two wall parts come apart.

I figured maybe my nozzle is less than .4 mm causing the perimeters to turn out narrower than they should be, so I created new gcode with the nozzle width set to .35. Now the .8mm wall is build from two perimeters, still not connected...

My extruder is calibrated, extruding 50 mm. of filament results in 50mm plus or minus .1 mm. so I don't think that can cause this problem.

Any ideas?

So I made a test object (in Rhino) consisting of 5 intersecting thin-walled objects (very much like the .5mm thin wall calibration object). These objects vary in wall thickness from .4mm (my nozzle size) to 1.2 mm. I set slicer to 100% infill, layer height .25mm. For good measure I also set solid infil every layer. I'm printing PLA at 205C with a E3D hot-end, when I go lower the layers don't stick together well enough.

The .4mm thick wall measures .5mm after print and is build from one perimeter. the .6 is .8, also one perimeter. The .8mm is 1 mm, still one perimeter.

The problem begins with the 1 mm thick wall. This is build from two perimeters, but these do not seem to be connected. When I check my gcode at gcode.ws it shows infill between the two walls, and while printing the head goes over the area three times, but there is a gap between the two. I can easily put my fingernail inbetween the two perimeters and when I try to bend the object the two wall parts come apart.

I figured maybe my nozzle is less than .4 mm causing the perimeters to turn out narrower than they should be, so I created new gcode with the nozzle width set to .35. Now the .8mm wall is build from two perimeters, still not connected...

My extruder is calibrated, extruding 50 mm. of filament results in 50mm plus or minus .1 mm. so I don't think that can cause this problem.

Any ideas?

|

Re: perimeter separating September 08, 2013 09:02AM |

Registered: 10 years ago Posts: 13 |

|

Re: perimeter separating September 08, 2013 10:57AM |

Registered: 16 years ago Posts: 824 |

|

Re: perimeter separating September 08, 2013 09:59PM |

Registered: 13 years ago Posts: 486 |

what you are seeing is backlash. because those walls are approached from a different direction, the lash in your system leaves a gap between them. I suggest you attempt to adjust your mechanics (tighten belts etc). you are using machined pulleys? if not, do. and if all else fails compensate for lash in your slicing.

|

Re: perimeter separating October 01, 2013 06:39AM |

Registered: 10 years ago Posts: 13 |

|

Re: perimeter separating October 01, 2013 08:52AM |

Registered: 11 years ago Posts: 305 |

Replace `2d_shape` with your cookie cutter shape. I could be set with `import`, but afaik it just works on .dxf(well for 2d) Dont know how to convert .png etc to .dxf decently, inkscape? (no SAAS allowed for me, and i kindah just want it via commandline)

maybe i should try use ImplicitCAD, but as haskell this time. (Openscad making its own language might well have been a bad idea. Well, it being c-like and not java helps with popularity, and i dont know what options they really had.)

maybe i should try use ImplicitCAD, but as haskell this time. (Openscad making its own language might well have been a bad idea. Well, it being c-like and not java helps with popularity, and i dont know what options they really had.)

h=10;

w=40; h=40;

t = 1;

bt = 4;

bh=2;

module 2d_shape()

{ square([w,h],center=true);

}

module shape_to_wall(t=t,h=h)

{

linear_extrude(height=h) difference()

{ minkowski(){ 2d_shape(); circle(t); }

2d_shape();

}

}

module shape_cookie_cutter(t=t,bt=bt)

{ union()

{ shape_to_wall(t,h);

shape_to_wall(bt,bh);

}

}

shape_cookie_cutter();

Would kindah be handy to be able to pass a module as an argument here  maybe i should try use ImplicitCAD, but as haskell this time. (Openscad making its own language might well have been a bad idea. Well, it being c-like and not java helps with popularity, and i dont know what options they really had.)

maybe i should try use ImplicitCAD, but as haskell this time. (Openscad making its own language might well have been a bad idea. Well, it being c-like and not java helps with popularity, and i dont know what options they really had.)

|

Re: perimeter separating October 02, 2013 02:08PM |

Registered: 10 years ago Posts: 2 |

What ended up being the solution to your issue? I'm currently facing the same issue where my perimeters aren't properly fusing together and the parts are printing out ever so slightly larger than they should be when measured with a micrometer. I ran out of ideas and google led me to this thread.

|

Re: perimeter separating October 02, 2013 02:35PM |

Registered: 11 years ago Posts: 305 |

Lowering the various extrusion widths (In particular `--solid-infill-extrusion-width`, `--first-layer-extrusion-width`) can help. Basically it makes more thinner lines, so it might more quickly put a bit of solid infill in between.

> When I check my gcode at gcode.ws it shows infill between the two walls, and while printing the head goes over the area three times, but there is a gap between the two.

This seems a bit strange to me though, you'd say with backlash you would see evidence of some print moves between the layers? It could be a plain move(non-extruding move) gcode, in particular if `--avoid-crossing-perimeters` was enabled.(In which case it is more likely to follow the profile)

(attachment is in case people dont feel like using openscad just to see what i posted)

> When I check my gcode at gcode.ws it shows infill between the two walls, and while printing the head goes over the area three times, but there is a gap between the two.

This seems a bit strange to me though, you'd say with backlash you would see evidence of some print moves between the layers? It could be a plain move(non-extruding move) gcode, in particular if `--avoid-crossing-perimeters` was enabled.(In which case it is more likely to follow the profile)

(attachment is in case people dont feel like using openscad just to see what i posted)

|

Re: perimeter separating October 03, 2013 08:26AM |

Registered: 10 years ago Posts: 2 |

Sorry, only registered users may post in this forum.