Working Electric Motor Printed

Posted by Gene Hacker

|

Working Electric Motor Printed September 28, 2013 06:43PM |

Registered: 16 years ago Posts: 174 |

The details are scant, but it appears this electrical motor was printed by stopping the print mid-way to wrap wires and embedding magnets into the print.

It should not be hard to replicate this with a reprap.

It should not be hard to replicate this with a reprap.

|

Re: Working Electric Motor Printed September 28, 2013 11:18PM |

Admin Registered: 13 years ago Posts: 730 |

Cool! It is hard to see what is going on, but to me it looks like they are adding bearings, magnets, and wire.

This work is from the Keck Center, the same group that is working on metal FDM

(see Fused Deposition Modeling of Metals by Jorge Mireles, et. al. ).

The Keck Center website shows several objects that look like they have embedded metal traces in them, so I wonder if this motor actually has 3D printed coils? The description of the video makes it sound like there is a paper that goes along with it. Does anyone have info on the paper?

I can't pass up this opportunity to link these other 3D printed motor projects that I'm aware of

Homemade 3D printed stepper motor

Printable electric motor

Electric Motor

Electric Motor 2

This work is from the Keck Center, the same group that is working on metal FDM

(see Fused Deposition Modeling of Metals by Jorge Mireles, et. al. ).

The Keck Center website shows several objects that look like they have embedded metal traces in them, so I wonder if this motor actually has 3D printed coils? The description of the video makes it sound like there is a paper that goes along with it. Does anyone have info on the paper?

I can't pass up this opportunity to link these other 3D printed motor projects that I'm aware of

Homemade 3D printed stepper motor

Printable electric motor

Electric Motor

Electric Motor 2

|

Re: Working Electric Motor Printed September 29, 2013 02:56AM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Working Electric Motor Printed September 29, 2013 03:49AM |

Registered: 16 years ago Posts: 174 |

@MattMoses looks like it was presented at the 2013 Solid Freeform Fabrication Symposium as: "3D Printing of Electro Mechanical Systems" by Efrain Aguilera, Jorge Ramos, David Espalin, Elaine Maestas, Fernando Cedillos, Dan Muse, Eric MacDonald, and Ryan Wicker.

Unfortunately, conference proceedings haven't been posted online yet. They will probably be posted here pretty soon.

It also looks like they were wrapping the wires on. It looks like the objects with metal traces were made with their Stereolithography/nScrypt Direct Print process. IE, they clean out a SL print in build, put electrical components into holes, and use a special extruder to put UV cure silver paste in channels for traces.

It doesn't look like they mounted their special silver paste extruder on the machine in the video, so I doubt they were

'printing' the coils. They also say in the video description that they don't use conductive ink.

Edited 1 time(s). Last edit at 09/29/2013 03:51AM by Gene Hacker.

Unfortunately, conference proceedings haven't been posted online yet. They will probably be posted here pretty soon.

It also looks like they were wrapping the wires on. It looks like the objects with metal traces were made with their Stereolithography/nScrypt Direct Print process. IE, they clean out a SL print in build, put electrical components into holes, and use a special extruder to put UV cure silver paste in channels for traces.

It doesn't look like they mounted their special silver paste extruder on the machine in the video, so I doubt they were

'printing' the coils. They also say in the video description that they don't use conductive ink.

Edited 1 time(s). Last edit at 09/29/2013 03:51AM by Gene Hacker.

|

Re: Working Electric Motor Printed September 29, 2013 08:10AM |

Registered: 10 years ago Posts: 219 |

Very cool! Thanks for sharing the information. Has to be seen how such a construction performs in real applications, but looks like a promising concept to me.

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

|

Re: Working Electric Motor Printed September 30, 2013 07:52AM |

Registered: 10 years ago Posts: 94 |

Hey Guys,

I was thinking about this the other day as one of the first things to print once I build a printer , but if your using neodymium magnet couldn't they get attracted to something on the print head?

the nozzles are all brass aren't they ? what about the E3D all metal head surely that would cause some problems with larger magnets ?

Jeremy

also found this 3d printed stepper motor here. That would aid the reprap cause !

Matt -- How embarrassing somehow didn't see your links , so much potential though

Edited 2 time(s). Last edit at 09/30/2013 09:01AM by Jerms.a320.

I was thinking about this the other day as one of the first things to print once I build a printer , but if your using neodymium magnet couldn't they get attracted to something on the print head?

the nozzles are all brass aren't they ? what about the E3D all metal head surely that would cause some problems with larger magnets ?

Jeremy

also found this 3d printed stepper motor here. That would aid the reprap cause !

Matt -- How embarrassing somehow didn't see your links , so much potential though

Edited 2 time(s). Last edit at 09/30/2013 09:01AM by Jerms.a320.

|

Re: Working Electric Motor Printed September 30, 2013 11:29AM |

Admin Registered: 13 years ago Posts: 730 |

|

Re: Working Electric Motor Printed September 30, 2013 12:59PM |

Registered: 11 years ago Posts: 482 |

I've always thought 3D printers would become more EPIC with the creation of two materials: Conductive and magnetically attracted. Allowing us to make, say, a $2 electric screw driver. While a 3D printed motor will not be as powerful as a neo-dynium based motor with copper, necessarily, it would be cheap as hell and have a high power/weight ratio, and can be easily geared (like a cheap DC motor). That's one reason why I made iron-filled plastic for 3D printers. They were demo'd at the maker faire and are almost ready for sale, if anyone can think of how to integrate this with a conductive system like copper wires, I'm happy to send samples for this purpose!

|

Re: Working Electric Motor Printed September 30, 2013 02:00PM |

Admin Registered: 12 years ago Posts: 2,569 |

Jeez, iron filled plastic filament ? What is the size/concentration of the iron particles embedded in the plastic ?

I wonder how fast it will erode/enlarge the nozzles...

Actually this news deserves its own topic to get discussed, did you make one anywhere already ?

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

I wonder how fast it will erode/enlarge the nozzles...

Actually this news deserves its own topic to get discussed, did you make one anywhere already ?

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Working Electric Motor Printed September 30, 2013 03:28PM |

Registered: 11 years ago Posts: 482 |

DeuxVis Wrote:

-------------------------------------------------------

> Jeez, iron filled plastic filament ? What is the

> size/concentration of the iron particles embedded

> in the plastic ?

>

> I wonder how fast it will erode/enlarge the

> nozzles...

>

> Actually this news deserves its own topic to get

> discussed, did you make one anywhere already ?

Yes.

The first batch *partially* clogged the nozzles 3 times (across 5 KG total used). We stuck a pin into the tip (0.35 mm Afinia nozzle) and that solved the problem. We didn't expect this (mesh size was 325) so this time we asked for an overkill safety measure where the iron producer, plastic compounded, and filament extruder all have filters in place to make sure it won't happen again. There are a ton of really neat properties too, you can see some of them in our brochure. [printm3d.com] However, I'm not opening it for sale to the public until I am very comfortable with the material properties. The titanium is closer to release (having a density near 60% heavier than ABS makes for really, really nice feeling when you hold these prints in your hand)

If a normal nozzle degrades at a certain rate (say, 1000 KG of ABS = 0.02 mm nozzle widening = failure) then this iron filled material could shorten the lifetime of the nozzle a significant fraction, but it is very unlikely that your printer would live to see this much material extruded. In any case it would be a few $$ to replace. I haven't replaced mine yet after 5KG which is quite a lot of printing, and switching back and fourth to ABS has not shown any quality difference. Plus, it is iron oxide which I think is quite a bit less hard or abrasive than iron itself.

Edited 1 time(s). Last edit at 09/30/2013 03:31PM by Simba.

-------------------------------------------------------

> Jeez, iron filled plastic filament ? What is the

> size/concentration of the iron particles embedded

> in the plastic ?

>

> I wonder how fast it will erode/enlarge the

> nozzles...

>

> Actually this news deserves its own topic to get

> discussed, did you make one anywhere already ?

Yes.

The first batch *partially* clogged the nozzles 3 times (across 5 KG total used). We stuck a pin into the tip (0.35 mm Afinia nozzle) and that solved the problem. We didn't expect this (mesh size was 325) so this time we asked for an overkill safety measure where the iron producer, plastic compounded, and filament extruder all have filters in place to make sure it won't happen again. There are a ton of really neat properties too, you can see some of them in our brochure. [printm3d.com] However, I'm not opening it for sale to the public until I am very comfortable with the material properties. The titanium is closer to release (having a density near 60% heavier than ABS makes for really, really nice feeling when you hold these prints in your hand)

If a normal nozzle degrades at a certain rate (say, 1000 KG of ABS = 0.02 mm nozzle widening = failure) then this iron filled material could shorten the lifetime of the nozzle a significant fraction, but it is very unlikely that your printer would live to see this much material extruded. In any case it would be a few $$ to replace. I haven't replaced mine yet after 5KG which is quite a lot of printing, and switching back and fourth to ABS has not shown any quality difference. Plus, it is iron oxide which I think is quite a bit less hard or abrasive than iron itself.

Edited 1 time(s). Last edit at 09/30/2013 03:31PM by Simba.

|

Re: Working Electric Motor Printed September 30, 2013 03:45PM |

Admin Registered: 13 years ago Posts: 730 |

Simba, have you tried making, say, an electromagnet using your iron filament as the core? I've tried using iron-filled epoxy for actuator tests and it didn't work very well... Results here.

Also, while you're making new filament materials, how about piezoelectric PVDF? Automatically poled during printing?

Also, while you're making new filament materials, how about piezoelectric PVDF? Automatically poled during printing?

|

Re: Working Electric Motor Printed September 30, 2013 03:50PM |

Registered: 11 years ago Posts: 482 |

MattMoses Wrote:

-------------------------------------------------------

> Simba, have you tried making, say, an

> electromagnet using your iron filament as the

> core? I've tried using iron-filled epoxy for

> actuator tests and it didn't work very well...

> Results

> here.

>

> Also, while you're making new filament materials,

> how about piezoelectric PVDF?

> [url=http://forums.reprap.org/read.php?2,207096,20

> 7402#msg-207402]Automatically poled during

> printing[/url]?

Do you think the magnetic field could align the iron when it is molten, such that it becomes a permenant magnet ?? I don't know if the "domains" of iron particles work this way on such a large scale (not atoms, but ~20 micron particles)? How cool if it works. That's exactly the kind of thing I hope people will try if I contribute by pumping out new materials.

Can you tell me more about this piezoelectric properties you want? What is this good for? As a general rule we avoid fluro or halogenated anything. Fluoro + Delrin, or PVC + delrin = explosion. A we really, really want delrin, so we planned this out early on, otherwise it would sent a mixed signal to the user that combining these materials are safe. How about a non fluorinated TPE?

-------------------------------------------------------

> Simba, have you tried making, say, an

> electromagnet using your iron filament as the

> core? I've tried using iron-filled epoxy for

> actuator tests and it didn't work very well...

> Results

> here.

>

> Also, while you're making new filament materials,

> how about piezoelectric PVDF?

> [url=http://forums.reprap.org/read.php?2,207096,20

> 7402#msg-207402]Automatically poled during

> printing[/url]?

Do you think the magnetic field could align the iron when it is molten, such that it becomes a permenant magnet ?? I don't know if the "domains" of iron particles work this way on such a large scale (not atoms, but ~20 micron particles)? How cool if it works. That's exactly the kind of thing I hope people will try if I contribute by pumping out new materials.

Can you tell me more about this piezoelectric properties you want? What is this good for? As a general rule we avoid fluro or halogenated anything. Fluoro + Delrin, or PVC + delrin = explosion. A we really, really want delrin, so we planned this out early on, otherwise it would sent a mixed signal to the user that combining these materials are safe. How about a non fluorinated TPE?

|

Re: Working Electric Motor Printed September 30, 2013 10:12PM |

Admin Registered: 13 years ago Posts: 730 |

Quote

Simba

Can you tell me more about this piezoelectric properties you want? What is this good for?

Quote

Nicholas Seward

Why should we care? We could use this polymer to make stepper-less RepRaps and do all sorts of other neat tricks.

Here is a short list of actuators that can use this.

[*] Traveling-wave Motor

[*] Inchworm Motor (Linear motion)

[*] Rectangular Four-Quadrant Motor

[*] Ratcheting Piezo Motor

[*] etc.

There are details in this thread and this thread, but basically PVDF is:

1) used to make piezoelectric actuators

2) printable (probably)

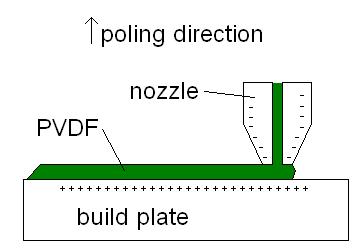

This picture shows a concept for 3D printing a thin sheet of poled PVDF:

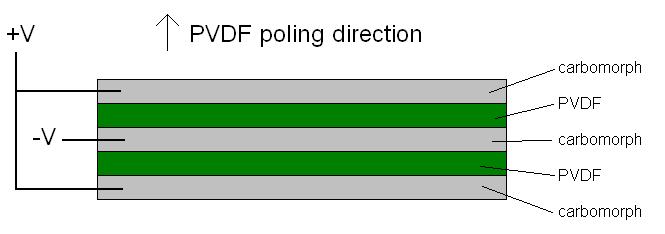

This picture shows a concept for making a 3D printed piezoelectric bimorph actuator with a dual extruder (one for PVDF and one for carbomorph):

I don't understand what you mean by "Fluoro + Delrin = explosion". For example, Delrin AF appears to be an off-the-shelf blend of Delrin with PTFE fibers.

|

Re: Working Electric Motor Printed October 01, 2013 01:08AM |

Registered: 11 years ago Posts: 482 |

Just a basic knowledge in the field > more aimed at other things than PTFE (i extrude delrin on PTFE)

[www.americanoandp.com]:

Decomposition of halogenated polymers and phenolic

resins may also be accelerated when they are in contact

with TPE at processing temperatures. Thoroughly purge

processing equipment with polyolefin polymers, including

polypropylene, when using the same equipment to process

TPE and acetal resins, halogenated polymers and phenolic

resins. Do not mix TPE, acetal resins, halogenated polymers or phenolic resins at elevated temperatures. Smoke,

carbon mon-oxide and possibly hydrocarbons may evolve

when processing temperatures exceed 500 F, or when the

material is ignited.

[www.americanoandp.com]:

Decomposition of halogenated polymers and phenolic

resins may also be accelerated when they are in contact

with TPE at processing temperatures. Thoroughly purge

processing equipment with polyolefin polymers, including

polypropylene, when using the same equipment to process

TPE and acetal resins, halogenated polymers and phenolic

resins. Do not mix TPE, acetal resins, halogenated polymers or phenolic resins at elevated temperatures. Smoke,

carbon mon-oxide and possibly hydrocarbons may evolve

when processing temperatures exceed 500 F, or when the

material is ignited.

|

Re: Working Electric Motor Printed October 01, 2013 02:47AM |

Registered: 11 years ago Posts: 248 |

|

Re: Working Electric Motor Printed October 02, 2013 10:49PM |

Admin Registered: 13 years ago Posts: 730 |

Add another one to the list! Solenoid Engine

|

Re: Working Electric Motor Printed November 05, 2013 01:15PM |

Registered: 16 years ago Posts: 174 |

The 2013 Solid Freeform Fabrication Symposium proceedings have been published, so we have details of how UTEP printed a motor.

Apparently, they also have a nice method of embedding copper wires into prints by pressing heated copper wire into the print.

Apparently, they also have a nice method of embedding copper wires into prints by pressing heated copper wire into the print.

|

Re: Working Electric Motor Printed November 10, 2013 03:36AM |

Registered: 12 years ago Posts: 80 |

Cool projects, a motor is a fairly mature device and requires the maintenance of decent tolerances to operate efficiently. It should be cheaper to purchase standard motors (stepper/brush/brushless) for quite a while . However I expect that certain niche uses for actuators that are not available in consumer products will become a good application for printed motors. I'm following this with anticipation.

Simba: Some of the highly developed magnetic particles were those developed for the magnetic tape (and eventually magnetic disk) industry. It might even be possible to use a solvent to separate the particles from a few video cassettes worth of tape to test the various properties. They may not be the most powerful products for permanent magnetisation but they are able to be magnetised predictably and may be suitable for some alternate applications that need a 'harder' magnetic material.

Gene: You can have a look at a couple of other ideas for wire printing on the wiki page Fibre Core [reprap.org]

Kalle

--

Lahti, Finland

The only stable form of government is Open Source Government. - Kalle Pihlajasaari 2013

Quote

Simba

Do you think the magnetic field could align the iron when it is molten, such that it becomes a permenant magnet ?? I don't know if the "domains" of iron particles work this way on such a large scale (not atoms, but ~20 micron particles)? How cool if it works. That's exactly the kind of thing I hope people will try if I contribute by pumping out new materials.

Quote

Simba

Plus, it is iron oxide which I think is quite a bit less hard or abrasive than iron itself

Simba: Some of the highly developed magnetic particles were those developed for the magnetic tape (and eventually magnetic disk) industry. It might even be possible to use a solvent to separate the particles from a few video cassettes worth of tape to test the various properties. They may not be the most powerful products for permanent magnetisation but they are able to be magnetised predictably and may be suitable for some alternate applications that need a 'harder' magnetic material.

Quote

Gene Hacker

The 2013 Solid Freeform Fabrication Symposium proceedings have been published, so we have details of how UTEP printed a motor.

Apparently, they also have a nice method of embedding copper wires into prints by pressing heated copper wire into the print.

Gene: You can have a look at a couple of other ideas for wire printing on the wiki page Fibre Core [reprap.org]

Kalle

--

Lahti, Finland

The only stable form of government is Open Source Government. - Kalle Pihlajasaari 2013

Sorry, only registered users may post in this forum.