Prusa Nozzle MKII

Posted by thej

|

Re: Prusa Nozzle MKII December 30, 2013 02:42AM |

Registered: 11 years ago Posts: 544 |

|

Re: Prusa Nozzle MKII December 30, 2013 04:03AM |

Registered: 11 years ago Posts: 173 |

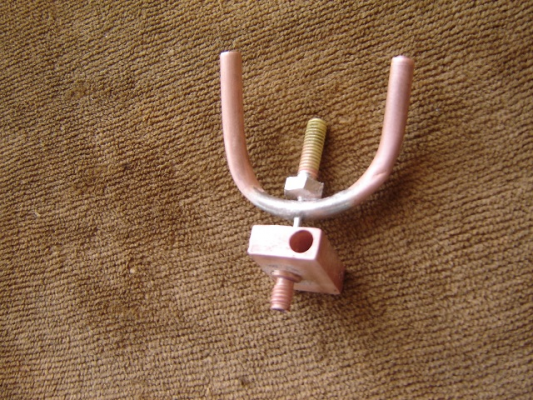

I am currently using a water cooled copper hotend with a brass tip. After reading about the concerns about corrosion of the copper I wondered if one can electroplate the hotend to stop corrosion. What do you think will be the best to coat it with - silver and zinc comes to mind - silver may be the better one for thermal conductivity. Is it chemically possible?

Edited 1 time(s). Last edit at 12/30/2013 04:48AM by Xabbax.

Edited 1 time(s). Last edit at 12/30/2013 04:48AM by Xabbax.

|

Re: Prusa Nozzle MKII December 30, 2013 07:06AM |

Registered: 11 years ago Posts: 544 |

|

Re: Prusa Nozzle MKII December 30, 2013 08:26AM |

Registered: 11 years ago Posts: 173 |

Quote

aduy

have you noticed any corrosion yet?

On the outside yes. The colour turned to a more dark copper but the outside corrosion should not be a problem. The threaded part is protected by a high temperature copper compound (http://www.spanjaard.biz/index.php?option=com_virtuemart&view=productdetails&virtuemart_product_id=833&virtuemart_category_id=1) so no worries there. Corrosion in the inside of the melting chamber tube may lead to an increase in diameter . How much of a problem this can create - Unknown. Will have to wait and see what the effect will be in the months ahead.

|

Re: Prusa Nozzle MKII December 30, 2013 10:06AM |

Registered: 12 years ago Posts: 177 |

We use brass because it provides a good balance of thermal conductivity, resistance to the stresses of printing (where aluminium does not fare well), it also machines to a good surface finish which is important for laying down a clean bead of filament instead of sticking to it and dragging it along the built platform. The inherent low surface energy of brass helps here too, as well as helping screw up to the stainless tube and form a seal. Finally it is also easily machined to produce fine/small diameter nozzle sizes, whereas copper is an absolute pig to drill.

|

Re: Prusa Nozzle MKII January 19, 2014 01:10PM |

Registered: 10 years ago Posts: 12 |

|

Re: Prusa Nozzle MKII January 24, 2014 07:18PM |

Registered: 10 years ago Posts: 16 |

I have been experimenting with the SS nozzles. It can be pretty tricky to print PLA, specially 1.75mm without jamming. I am not familiar with every design out there [opinion] but I have my doubts that the PICO will do very well printing 1.75mm PLA. [/opinion] I will agree with Eric and question the heat signature on the thermal simulation. I am excited to find out how well it does and wish them the best.

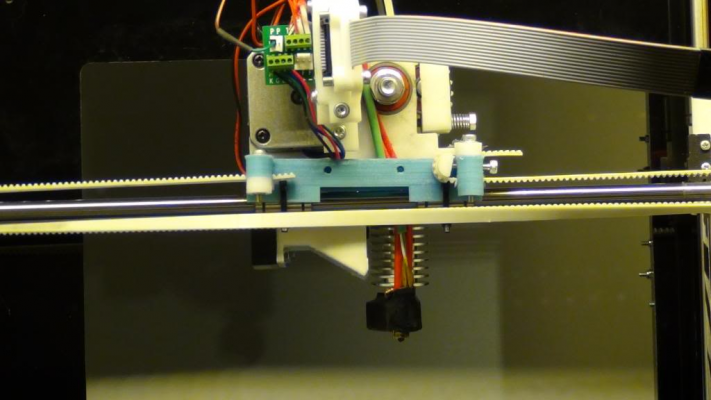

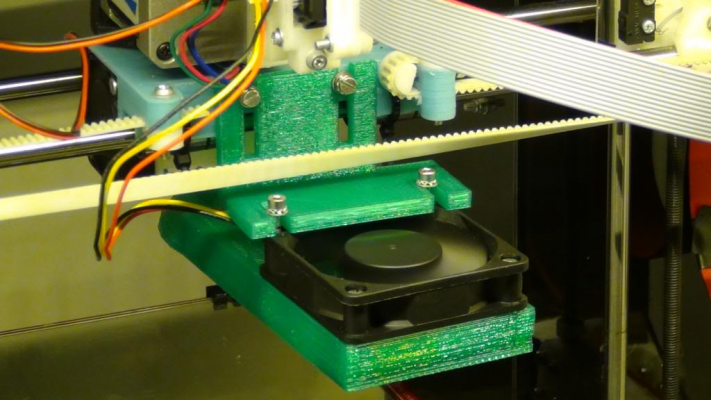

Looks like a fan is required for every single design out there to cool the all metal heat-sink and people are reporting having to aim the fan in a particular location (upper side of the heat-sink to cool it down). I bet it can be very frustrating.

I find that once the filament is inserted the heat signature changes quite a bit in the SS. I can get a heat sink and heat break tuned just right for one condition, but once the filament is inserted after 2 or 3 minutes things change quite a bit and it warms up pretty quick in the upper end of the heat-sink. I have done some FLIR images comparing the conditions and it was very interesting to compare the before and after filament conditions.

Like mentioned before the all metal design seems to be a pretty cool idea for the non PLA materials and the way to go. I use a Buda for all the PLA and it is great.

Cheers!

Looks like a fan is required for every single design out there to cool the all metal heat-sink and people are reporting having to aim the fan in a particular location (upper side of the heat-sink to cool it down). I bet it can be very frustrating.

I find that once the filament is inserted the heat signature changes quite a bit in the SS. I can get a heat sink and heat break tuned just right for one condition, but once the filament is inserted after 2 or 3 minutes things change quite a bit and it warms up pretty quick in the upper end of the heat-sink. I have done some FLIR images comparing the conditions and it was very interesting to compare the before and after filament conditions.

Like mentioned before the all metal design seems to be a pretty cool idea for the non PLA materials and the way to go. I use a Buda for all the PLA and it is great.

Cheers!

|

Re: Prusa Nozzle MKII March 16, 2014 12:12PM |

Registered: 10 years ago Posts: 1 |

|

Re: Prusa Nozzle MKII March 16, 2014 01:35PM |

Registered: 10 years ago Posts: 439 |

Perhaps something similar to my E3D setup which prints PLA fine could work. The hotend is insulated somewhat with E-Z fuse tape.

A ducted fan on the fins:

[www.thingiverse.com]

and another ducted fan for print cooling:

[www.thingiverse.com]

Edited 5 time(s). Last edit at 03/16/2014 01:41PM by Ralph.Hilton.

A ducted fan on the fins:

[www.thingiverse.com]

and another ducted fan for print cooling:

[www.thingiverse.com]

Edited 5 time(s). Last edit at 03/16/2014 01:41PM by Ralph.Hilton.

|

Re: Prusa Nozzle MKII March 16, 2014 01:55PM |

Registered: 10 years ago Posts: 439 |

Silver plating of a decent quality uses cyanide :-(Quote

Xabbax

What do you think will be the best to coat it with - silver and zinc comes to mind - silver may be the better one for thermal conductivity. Is it chemically possible?

Tin would be safer: [transistor-man.com]

Or perhaps a high temperature tin/silver/copper solder ?

|

Re: Prusa Nozzle MKII March 16, 2014 02:41PM |

Registered: 10 years ago Posts: 18 |

For PCB work, I sometimes use this for silver plating:

[www.cool-amp.com]

Takes a good amount of work rubbing it in, and doesn't create a *thick* layer… but I've been pretty happy with the results.

[www.cool-amp.com]

Takes a good amount of work rubbing it in, and doesn't create a *thick* layer… but I've been pretty happy with the results.

Sorry, only registered users may post in this forum.