Is there any alternative to Teflon?

Posted by Simba

|

Re: Is there any alternative to Teflon? November 01, 2013 07:23AM |

Registered: 12 years ago Posts: 124 |

How about glass?

It is very easy to get hold of a 6mm OD 3mm ID borosilicate glass tube.

Should have a smooth bore, very low conduction, happy with high temps and cheap (5 for a fiver on ebay).

I was thinking that I would mount a combined nozzle/heater block on the end with just 3mm or so between the end of the glass tube and the tip. Probably using an arrangement of stainless studs or similar to control the position of the tip and trap the glass tube like the teflon in an old design J-head.

Anyone tried glass in the past?

George

It is very easy to get hold of a 6mm OD 3mm ID borosilicate glass tube.

Should have a smooth bore, very low conduction, happy with high temps and cheap (5 for a fiver on ebay).

I was thinking that I would mount a combined nozzle/heater block on the end with just 3mm or so between the end of the glass tube and the tip. Probably using an arrangement of stainless studs or similar to control the position of the tip and trap the glass tube like the teflon in an old design J-head.

Anyone tried glass in the past?

George

|

Re: Is there any alternative to Teflon? November 01, 2013 07:34AM |

Admin Registered: 13 years ago Posts: 7,001 |

|

Re: Is there any alternative to Teflon? November 01, 2013 08:45AM |

Registered: 11 years ago Posts: 374 |

Quote

I don't know why there is such a fixation on stainless steel, other than it conducts heat kind of poorly...

Because it conducts heat very poorly and is therefore a good material to use for the thermal break. And in order to reduce part count people combine the thermal break with other parts of the hotend, such as the upper barrel.

Injection molding equipment is a poor comparison because it does not have the same requirement as a printer hotend as far as needing a very sharp, short thermal transition between hot-enough-to-melt and cold. They typically have several heating zones that are controlled independently along the length of the barrel and heat the plastic up more gradually.

|

Re: Is there any alternative to Teflon? November 01, 2013 09:03AM |

Registered: 12 years ago Posts: 1,450 |

@Beekeper

The cost of stainless steel is not a significant factor as the amount used in a hot end is very small, mine use a bar 6mm diameter by 50mm long. The thermal conductivity of stainless steel at 16 W/(m.K) is one third of steel at 43 W/(m.K) This allows a short region between the incoming filament softening against the wall and the actual melted plastic. While other steels could be used to advantage, there would still be quite a large loss of heat up the tube to the heatsink/watercooler. I think that most hotends either use hard tubular stainless steel of the type designed for hypodernic needles, or free machining stainless steels such as 303. The polishing is an item of some concern, but there has been a bit of talk on these forums of methods such as electropolishing - note that polishing is of little importance outside of the area mentioned above, the thermal break.

Mike

The cost of stainless steel is not a significant factor as the amount used in a hot end is very small, mine use a bar 6mm diameter by 50mm long. The thermal conductivity of stainless steel at 16 W/(m.K) is one third of steel at 43 W/(m.K) This allows a short region between the incoming filament softening against the wall and the actual melted plastic. While other steels could be used to advantage, there would still be quite a large loss of heat up the tube to the heatsink/watercooler. I think that most hotends either use hard tubular stainless steel of the type designed for hypodernic needles, or free machining stainless steels such as 303. The polishing is an item of some concern, but there has been a bit of talk on these forums of methods such as electropolishing - note that polishing is of little importance outside of the area mentioned above, the thermal break.

Mike

|

Re: Is there any alternative to Teflon? November 01, 2013 09:17AM |

Registered: 12 years ago Posts: 1,450 |

@gsport

Two thoughts from things that I have seen done in the past:

To put a small calibrated orifice in the end of the glass tube, put a bit of copper wire of a known size in the tube, heat and shrink with an oxy acetylene torch, break/cut to length and use acid to disolve the copper. The trick is to flux the wire with a coating of borax to form a crude version of a "Houskeeper seal"

To make a heater: Coat the outside of the tube with borax and wrap nichrome wire around it. Heat up wire and sprinkle with crushed soda glass, alowing to build up to a thickish layer. Don't allow the soda glass layer to fully fuse, more like sintered or "pate de verre". If it is fully fused the difference in the coefficient of expansion will crack the borosilicate tube.

Mike

Two thoughts from things that I have seen done in the past:

To put a small calibrated orifice in the end of the glass tube, put a bit of copper wire of a known size in the tube, heat and shrink with an oxy acetylene torch, break/cut to length and use acid to disolve the copper. The trick is to flux the wire with a coating of borax to form a crude version of a "Houskeeper seal"

To make a heater: Coat the outside of the tube with borax and wrap nichrome wire around it. Heat up wire and sprinkle with crushed soda glass, alowing to build up to a thickish layer. Don't allow the soda glass layer to fully fuse, more like sintered or "pate de verre". If it is fully fused the difference in the coefficient of expansion will crack the borosilicate tube.

Mike

|

Re: Is there any alternative to Teflon? November 01, 2013 09:30AM |

Registered: 12 years ago Posts: 124 |

Thanks Dust that is interesting. I was searching for people who might have used it as a thermal break rather than including the nozzle so didn't find that.

I am pretty sure I can build it very easily, my only concern is how the plastic will slide in it. There will obviously be a section that is at heated bed kind of temperature which is obviously likely to stick if given the chance, which will depend on how much plastic is in contact with it.

The thermal conductivity of this glass is 1.14W/m°C vs 14-16W/m°C for stainless. So hopefully the "danger-zone" will be short.

George

Edited 1 time(s). Last edit at 11/01/2013 11:39AM by gsport.

I am pretty sure I can build it very easily, my only concern is how the plastic will slide in it. There will obviously be a section that is at heated bed kind of temperature which is obviously likely to stick if given the chance, which will depend on how much plastic is in contact with it.

The thermal conductivity of this glass is 1.14W/m°C vs 14-16W/m°C for stainless. So hopefully the "danger-zone" will be short.

George

Edited 1 time(s). Last edit at 11/01/2013 11:39AM by gsport.

|

Re: Is there any alternative to Teflon? November 01, 2013 03:16PM |

Registered: 12 years ago Posts: 124 |

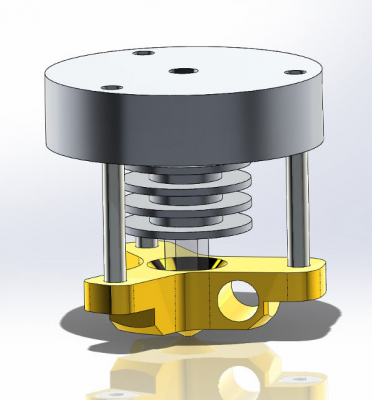

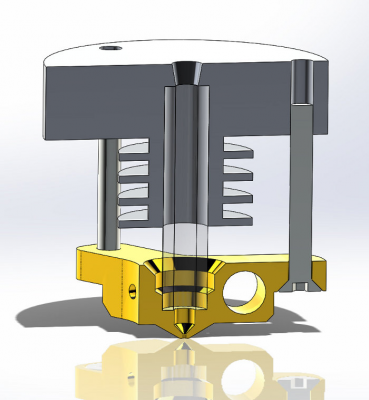

This is the sort of thing I had in mind.

Bit of machining on the brass tip and aluminium upper but glass tube just needs ends grinding flat.

Stainless M2 - M3 screws (this is modeled with M3 as much cheaper, and uses 2mm hex key like other parts) keep the tube clamped to the aluminium top. There is the possibility that the glass will become loose as the bolts expand, but this shouldn't be insurmountable.

My hope is that the filament would remain solid almost all the way through the glass and just melt in the last few mm of brass at the bottom. There is only a couple of mm of the cylindrical outer wall of the glass in contact with the brass and the end face. Small air gap above should minimise heat transfer to the glass there.

Not sure if the aluminium heatsink would really be necessary. but having it there means I can add a fan if it looks like it needs it.

Anyone have any good reasons why this wont work before I waste too much time making it?

George

Bit of machining on the brass tip and aluminium upper but glass tube just needs ends grinding flat.

Stainless M2 - M3 screws (this is modeled with M3 as much cheaper, and uses 2mm hex key like other parts) keep the tube clamped to the aluminium top. There is the possibility that the glass will become loose as the bolts expand, but this shouldn't be insurmountable.

My hope is that the filament would remain solid almost all the way through the glass and just melt in the last few mm of brass at the bottom. There is only a couple of mm of the cylindrical outer wall of the glass in contact with the brass and the end face. Small air gap above should minimise heat transfer to the glass there.

Not sure if the aluminium heatsink would really be necessary. but having it there means I can add a fan if it looks like it needs it.

Anyone have any good reasons why this wont work before I waste too much time making it?

George

|

Re: Is there any alternative to Teflon? November 01, 2013 04:22PM |

Registered: 11 years ago Posts: 246 |

Hey George,

Your design is very interesting and I encourage you to experiment with it!

However, before you get your hopes up, I would like to mention that you may have problems with the plastic sticking to the inside of the glass tube. As we know, PLA sticks very well to heated glass (many people print PLA directly onto heated glass), so I imagine that you would get frequent jams printing with PLA. The same goes for ABS but the problem will be less significant as ABS does not stick to glass nearly as well as PLA.

Anyway, it would definitely be worth testing if you have the time

Eric

Your design is very interesting and I encourage you to experiment with it!

However, before you get your hopes up, I would like to mention that you may have problems with the plastic sticking to the inside of the glass tube. As we know, PLA sticks very well to heated glass (many people print PLA directly onto heated glass), so I imagine that you would get frequent jams printing with PLA. The same goes for ABS but the problem will be less significant as ABS does not stick to glass nearly as well as PLA.

Anyway, it would definitely be worth testing if you have the time

Eric

|

Re: Is there any alternative to Teflon? November 01, 2013 04:29PM |

Registered: 12 years ago Posts: 124 |

^^^

This is my worry...

The one huge benefit is that you would be able to see some of what was going on, and perhaps even take temperature readings of the filament itself in the tube!

Already ordered the glass tubes and should have some 1.5" brass and aluminium somewhere.

George

Edited 1 time(s). Last edit at 11/01/2013 04:29PM by gsport.

This is my worry...

The one huge benefit is that you would be able to see some of what was going on, and perhaps even take temperature readings of the filament itself in the tube!

Already ordered the glass tubes and should have some 1.5" brass and aluminium somewhere.

George

Edited 1 time(s). Last edit at 11/01/2013 04:29PM by gsport.

|

Re: Is there any alternative to Teflon? November 01, 2013 04:35PM |

Registered: 11 years ago Posts: 246 |

|

Re: Is there any alternative to Teflon? November 01, 2013 05:57PM |

Registered: 12 years ago Posts: 1,450 |

Really good looking hotend. The PLA/ABS adhesion problem may or may not exist as the area of contact where the plastic is both hot enough to adhere and cool enough to be fairly rigid is likely to be quite small.

Have you thought about seepage of plastic through the joint between the hot end and the borosilicate tube?

Mike

Have you thought about seepage of plastic through the joint between the hot end and the borosilicate tube?

Mike

|

Re: Is there any alternative to Teflon? November 01, 2013 07:44PM |

Registered: 12 years ago Posts: 124 |

^^^^ That was my hope. The conductivity is so low and hopefully the filament in the section that corresponds to that temperature is still fairly stiff so only touches on a small tangent.

Yes, the seepage at the joint from glass to brass is a worry. Hopefully I can grind the end of the glass tube to be nice and flat like a bottle stopper, but getting a good surface on the brass may not be so easy. I could maybe make a small aluminium gasket to go in the gap and conform to the brass. However even if I get a good seal, If the stainless screws expand significantly then it could open right up.

The glass is less conductive and has a much lower coefficient of thermal expansion (3.3 vs 17). So the stainless will get hotter and therefore do more expanding AND will expand more.

However, even assuming that the glass pretty much doesn't move, and the bolt sees a 200 degree gradient over 20mm (In reality I think that it would taper off a lot quicker than this, but for the sake of the worst case scenario) so an average of 100degrees gives an expansion of 100 x 17x10^-6 or 0.17% which should be much much less than the included strain.

George

Yes, the seepage at the joint from glass to brass is a worry. Hopefully I can grind the end of the glass tube to be nice and flat like a bottle stopper, but getting a good surface on the brass may not be so easy. I could maybe make a small aluminium gasket to go in the gap and conform to the brass. However even if I get a good seal, If the stainless screws expand significantly then it could open right up.

The glass is less conductive and has a much lower coefficient of thermal expansion (3.3 vs 17). So the stainless will get hotter and therefore do more expanding AND will expand more.

However, even assuming that the glass pretty much doesn't move, and the bolt sees a 200 degree gradient over 20mm (In reality I think that it would taper off a lot quicker than this, but for the sake of the worst case scenario) so an average of 100degrees gives an expansion of 100 x 17x10^-6 or 0.17% which should be much much less than the included strain.

George

|

Re: Is there any alternative to Teflon? November 01, 2013 09:18PM |

Registered: 11 years ago Posts: 334 |

|

Re: Is there any alternative to Teflon? November 01, 2013 09:55PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Is there any alternative to Teflon? November 01, 2013 09:56PM |

Registered: 10 years ago Posts: 1,381 |

Consider running the bolts through the upper manifold and secure with a nut.

Locate a compression spring (washer spring, cup spring) under the nut to help maintain a constant contact force.

Springs can be stacked to increase compression force.

Maybe brass wool could be used as a compression seal, expansion compensation at the top.

To help prevent leakage (if it's an issue): If you're able to grind a taper on the end of the glass tube,

and a matching pocket (maybe off by 1/2 degree), it might afford an improved seal near the hot end.

This would also give you a face seal, free of metal contact.

How much clearance are you going to have between the glass and the aluminum heat exchanger?

If it's not 1:1, the aluminum might be only for show? If it's a press fit, might the glass tube break?

Locate a compression spring (washer spring, cup spring) under the nut to help maintain a constant contact force.

Springs can be stacked to increase compression force.

Maybe brass wool could be used as a compression seal, expansion compensation at the top.

To help prevent leakage (if it's an issue): If you're able to grind a taper on the end of the glass tube,

and a matching pocket (maybe off by 1/2 degree), it might afford an improved seal near the hot end.

This would also give you a face seal, free of metal contact.

How much clearance are you going to have between the glass and the aluminum heat exchanger?

If it's not 1:1, the aluminum might be only for show? If it's a press fit, might the glass tube break?

|

Re: Is there any alternative to Teflon? November 01, 2013 10:30PM |

Registered: 12 years ago Posts: 124 |

I found the glass tubes on ebay without much hunting

ebay glass tubes

I was going to wait and see what the tolerance on the tubes comes out like and then either have the aluminium heatsink clamp around the glass tube, or more likely just have the smallest clearance I can manage and fill the gap with a thermally conductive glue or aluminium foil or something.. Now I think about it more, I may just try it without the heatsink at all first.

George

ebay glass tubes

I was going to wait and see what the tolerance on the tubes comes out like and then either have the aluminium heatsink clamp around the glass tube, or more likely just have the smallest clearance I can manage and fill the gap with a thermally conductive glue or aluminium foil or something.. Now I think about it more, I may just try it without the heatsink at all first.

George

|

Re: Is there any alternative to Teflon? November 01, 2013 10:35PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Is there any alternative to Teflon? November 01, 2013 11:08PM |

Registered: 13 years ago Posts: 1,918 |

What puzzles me: As PLA sticks well to the hot glass on the heated bed then why do you expect it to not stick at the hot glass tube?

Detlef

Detlef

| Excalibur Hotend |

reprapzone.blogspot.de |

|

Re: Is there any alternative to Teflon? November 02, 2013 11:01AM |

Registered: 11 years ago Posts: 253 |

As you mention, why include the heatsink on the top surface/block.

Glass is a really poor conductor, so what's the purpose of the heatsink on the top?

If those 3 bolts holding it together are stainless, then the upper block will be cool to the touch.

You're intuition matches mine up there.

My $0.02:

finishing the glass ends to perpendicular, sealing them, and crushing the assembly for leak free operation needs your attention.

Silicone can help down in the hotend joint, making sure you give it time to fully dry.

I'd make the melt zone longer, because you'll run your short brass section out of hot plastic, even at a modest print speed.

I personally shoot for 10mm+ of melt zone, which is not long versus a Jhead or any of the sideways mounted cartridge heater styles.

make sure your tube ID is close to the filament OD, or you will get a backflow of plastic rolling up the tube, jamming it.

I'd shoot for a 0.15mm-0.25mm max air gap.

Finally, the brass part you have is nice, but there's a lot of scrap and machine setups.

If you have a production intent, be proactive and consider things like that.

Insulating by wrapping ceramic cloth will also be fun, but not mandatory.

Glass is a really poor conductor, so what's the purpose of the heatsink on the top?

If those 3 bolts holding it together are stainless, then the upper block will be cool to the touch.

You're intuition matches mine up there.

My $0.02:

finishing the glass ends to perpendicular, sealing them, and crushing the assembly for leak free operation needs your attention.

Silicone can help down in the hotend joint, making sure you give it time to fully dry.

I'd make the melt zone longer, because you'll run your short brass section out of hot plastic, even at a modest print speed.

I personally shoot for 10mm+ of melt zone, which is not long versus a Jhead or any of the sideways mounted cartridge heater styles.

make sure your tube ID is close to the filament OD, or you will get a backflow of plastic rolling up the tube, jamming it.

I'd shoot for a 0.15mm-0.25mm max air gap.

Finally, the brass part you have is nice, but there's a lot of scrap and machine setups.

If you have a production intent, be proactive and consider things like that.

Insulating by wrapping ceramic cloth will also be fun, but not mandatory.

|

Re: Is there any alternative to Teflon? November 02, 2013 11:11AM |

Registered: 12 years ago Posts: 124 |

^^^

Thanks Davew_tx, that is all good food for thought, I will definitely look at extending the melt zone length.

This was not meant to be a model to build from, just something quick to get the idea across on here, I was going to turn the important parts and then just drill-press, saw and file the rest. I may make the brass part smaller with a ridge and then fix the bolts through a stainless washer to hold it up.

My air gap is going to be dependent on the glass tube. My current PLA is 2.8mm and the glass tubes I have ordered are listed as 3mm. They may turn out to be undersize in which case I will have to think again, or they may be OK.

Theodlief. This is my worry too. I dont think that feed will be a problem because with a heated bed we introduce molten plastic to a relatively cooler surface, whereas here I will be pushing cold plastic at a warmer glass surface and hopefully just a small area. What I do worry about it on retraction, it will be pulling hot possibly molten material up into a cooler glass zone and may stick then, so I will initially be very careful about the amount of retract. At least being glass if this is the problem I will be able to see it happen..

Thanks Davew_tx, that is all good food for thought, I will definitely look at extending the melt zone length.

This was not meant to be a model to build from, just something quick to get the idea across on here, I was going to turn the important parts and then just drill-press, saw and file the rest. I may make the brass part smaller with a ridge and then fix the bolts through a stainless washer to hold it up.

My air gap is going to be dependent on the glass tube. My current PLA is 2.8mm and the glass tubes I have ordered are listed as 3mm. They may turn out to be undersize in which case I will have to think again, or they may be OK.

Theodlief. This is my worry too. I dont think that feed will be a problem because with a heated bed we introduce molten plastic to a relatively cooler surface, whereas here I will be pushing cold plastic at a warmer glass surface and hopefully just a small area. What I do worry about it on retraction, it will be pulling hot possibly molten material up into a cooler glass zone and may stick then, so I will initially be very careful about the amount of retract. At least being glass if this is the problem I will be able to see it happen..

|

Re: Is there any alternative to Teflon? November 02, 2013 12:49PM |

Registered: 10 years ago Posts: 1,381 |

Ideas:

For ease of manufacturing just use two bolts, and use anti-seize on the thread.

SS contacting aluminum will corrode, the anti-seize will help slow it down.

For experimentation purposes, begin as davew_tx suggested with 10 mm deep hole in the copper hot end.

I would only use a glass face seal, don't embedded the glass tube into the hot end (only use a face seal/contact).

With the glass out side of the heat zone, you might not have a leakage issue, just depends on how high the heat will travel up.

Then incrementally machine away the copper hot end until some thing fails.

Then you will know how deep the bored hole needs to be in the hot end.

I don't think a silicone seal will work, it probably will creep out of location.

I would use a taper connection, or I would lap the glass tube to the surface of the hot end.

If the glass tube is outside of the heat zone, it will just act as a filament guide.

Put the glass tube in your drill press chuck with some abrasive, and grind/lap it until 1:1.

Don't use water for lapping glass, just in case there is a micro crack in the glass, water will try to expand that gap.

I like the idea of a very short melt zone.

This is a good test to determine how short the heating zone can be.

The glass tube hopefully will generate new ideas (providing it doesn't get coated).

For ease of manufacturing just use two bolts, and use anti-seize on the thread.

SS contacting aluminum will corrode, the anti-seize will help slow it down.

For experimentation purposes, begin as davew_tx suggested with 10 mm deep hole in the copper hot end.

I would only use a glass face seal, don't embedded the glass tube into the hot end (only use a face seal/contact).

With the glass out side of the heat zone, you might not have a leakage issue, just depends on how high the heat will travel up.

Then incrementally machine away the copper hot end until some thing fails.

Then you will know how deep the bored hole needs to be in the hot end.

I don't think a silicone seal will work, it probably will creep out of location.

I would use a taper connection, or I would lap the glass tube to the surface of the hot end.

If the glass tube is outside of the heat zone, it will just act as a filament guide.

Put the glass tube in your drill press chuck with some abrasive, and grind/lap it until 1:1.

Don't use water for lapping glass, just in case there is a micro crack in the glass, water will try to expand that gap.

I like the idea of a very short melt zone.

This is a good test to determine how short the heating zone can be.

The glass tube hopefully will generate new ideas (providing it doesn't get coated).

|

Re: Is there any alternative to Teflon? November 02, 2013 03:30PM |

Registered: 12 years ago Posts: 1,450 |

For a seal between the glass tube and the heater block a ring of very soft pure aluminium would work very well if you can keep under pressure. I came across this on old Kratos mass spectrometers where they used very pure very soft gold sealing rings - possibly a bit of overkill here though

Mike

Mike

|

Re: Is there any alternative to Teflon? November 03, 2013 04:11AM |

Registered: 11 years ago Posts: 791 |

If you use a heat insulator like those used for mounting power transistors, between the stainless steel bolts and the brass end, the heat transferred to the stainless bolts will be much less and that will reduce the expansion of the bolts. Mica washers or ceramic washers if you can find them may also be useful.

You could also turn some very small stepped washers that insulate all around the bolts and the head (hat shaped), maybe use some PEEK.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

You could also turn some very small stepped washers that insulate all around the bolts and the head (hat shaped), maybe use some PEEK.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Is there any alternative to Teflon? November 03, 2013 06:36AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

If you use a heat insulator like those used for mounting power transistors

Those are are electrical insulators with good thermal conduction, not thermal insulators.

[www.hydraraptor.blogspot.com]

|

Re: Is there any alternative to Teflon? November 06, 2013 02:18PM |

Registered: 10 years ago Posts: 7 |

Interesting, I was thinking in make a Thermal Brake with glass and you already have 1/2 way in.

I think if the glass it's over 120 °C pla will not stick (I've made some proof of concept with sheets of glass) it's not definitive, but I hope to try soon with a proper tube.

On the gap clearance thing, I think if you have reached X temperature the expansion will stabilize, therefore you can just use springs on a system similar to que filament feeder on repraps to keep everything tight all the time, not so hard to do, also I prefer to have the nozzle as a different piece to be able to change diameters.

maybe, if my poor explanation it's not enough (sorry but I'm rusty with my english) I can make a sketch.

I will try to find some tubing and do some prototypes, keep you posted

I think if the glass it's over 120 °C pla will not stick (I've made some proof of concept with sheets of glass) it's not definitive, but I hope to try soon with a proper tube.

On the gap clearance thing, I think if you have reached X temperature the expansion will stabilize, therefore you can just use springs on a system similar to que filament feeder on repraps to keep everything tight all the time, not so hard to do, also I prefer to have the nozzle as a different piece to be able to change diameters.

maybe, if my poor explanation it's not enough (sorry but I'm rusty with my english) I can make a sketch.

I will try to find some tubing and do some prototypes, keep you posted

|

Re: Is there any alternative to Teflon? November 06, 2013 03:32PM |

Registered: 12 years ago Posts: 124 |

I have got my glass now and ground the ends flat which was very easy. Unfortunately is comes in at 3.05 ID which is fine on some of my filament that is 2.85 or so (and very oval) but will be a problem on the 3.02mm filament I have.

I am less worried about the filament sticking to the glass now, because I think that the glass will soon become "dirty" with oils etc out of the filament and then be more like a dirty heated glass bed which is obviously not that sticky!

Will carry on with this glass for now, but I may need to switch to the 3.5 x 5 version later and I am a bit worried about the (relatively) thin wall on that.

I am less worried about the filament sticking to the glass now, because I think that the glass will soon become "dirty" with oils etc out of the filament and then be more like a dirty heated glass bed which is obviously not that sticky!

Will carry on with this glass for now, but I may need to switch to the 3.5 x 5 version later and I am a bit worried about the (relatively) thin wall on that.

|

Re: Is there any alternative to Teflon? November 13, 2013 12:40PM |

Registered: 12 years ago Posts: 1,450 |

Earlier in this thread I said that I was trying Tecapeek/PVX/Graphite loaded PEEK instead of PTFE. Although earlier trials were promising, I must tell you that it is yet another negative result. After about an hour of the first print the nozzle blocked - the ABS was firmly welded to the Tecapeek liner. A shame since in non printing conditions it had seemed free of any sticking and melted ABS or PLA wouldn't stick to hot Tecapeek even after 8 hours of hot soaking

Mike

Mike

|

Re: Is there any alternative to Teflon? November 13, 2013 01:18PM |

Registered: 11 years ago Posts: 205 |

Quote

LoboCNC

Seems like there is a whole world of high temp / low friction coatings:

http://industrialcoatingsworld.com/low-friction-coatings/

It would be interesting to experiment with some of these.

Forget about graphite and/or Mo2S based solution as those are not stable films. About the only 2 solutions that may not be too costly because of the industrial process needed i can think of are :

- CVD or LPCVD, analog to the coating (usually gold) you find on HSS or carbide drill bits. that is affordable but need a non stainless, high nickel base metal I think. The fact that we need to coat the inside of a tube with a regular coat will make it costlier though.

- Anodizing on some porous ceramics compounds. Problem, the only applications i can think of are on rather big diameters, calibrating the blank to 3mm or 1.75mm will be hard. After it is a gazeous process so no problem.

|

Re: Is there any alternative to Teflon? November 13, 2013 03:25PM |

Admin Registered: 11 years ago Posts: 1,063 |

why exactly the push to get away from ptfe?, aside from the temperature limit,what is wrong with having more than one hotend?

we don't have 1 screw driver for 101 different types of screws do we?

we don't have 1 screw driver for 101 different types of screws do we?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Is there any alternative to Teflon? November 13, 2013 05:59PM |

Registered: 12 years ago Posts: 1,450 |

Quote

thejollygrimreaper

why exactly the push to get away from ptfe?, aside from the temperature limit,what is wrong with having more than one hotend?

we don't have 1 screw driver for 101 different types of screws do we?

Because something else may be better. We don't know until we try.

Mike

Sorry, only registered users may post in this forum.